A suspension melting furnace nozzle

A suspension smelting furnace and nozzle technology, applied in furnaces, fluidized bed furnaces, furnace components, etc., can solve the problem of uneven mixing of concentrate and oxygen, achieve the effects of improving smelting efficiency, low smoke and dust rate, and improving the ignition position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

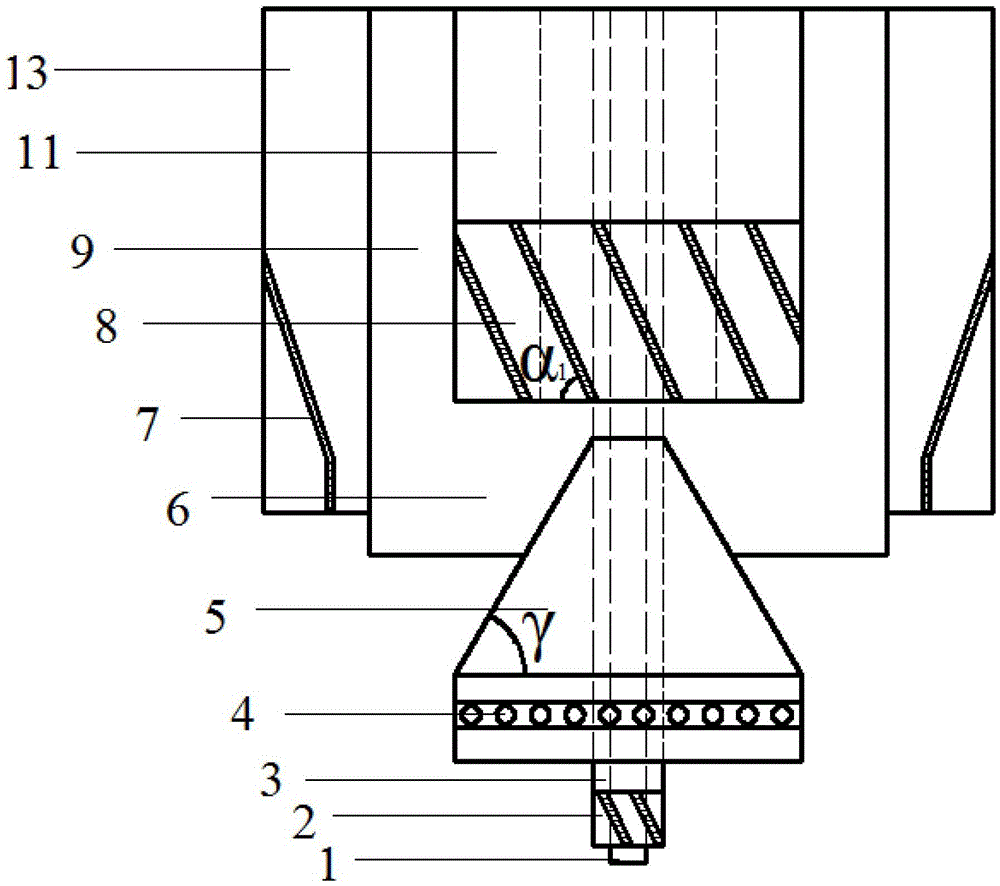

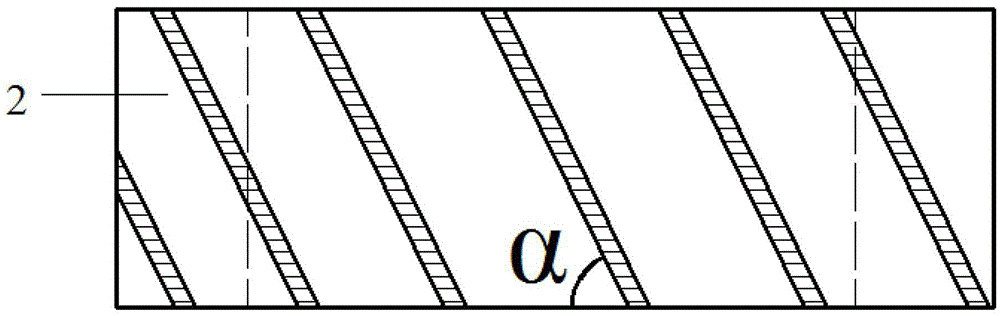

[0029] See figure 1 , A suspension smelting furnace nozzle, including a central natural gas pipe 1, a central oxygen pipe 3, a premixed air ring pipe 11, and a discharge chute 9 that are set in order from the inside and outside; the premixed air ring The length of the pipe 11 is 1 / 3-1 / 2 of the length of the central oxygen pipe 3, and the length of the discharging chute 9 is 1.1-1.6 times the length of the premixed air ring pipe 11; A pre-mixing zone 6 is formed at the lower end of the discharging chute 9 and the pre-mixing air ring pipe 11, so that the rotating air flow and the concentrate particles are uniformly mixed before entering the furnace.

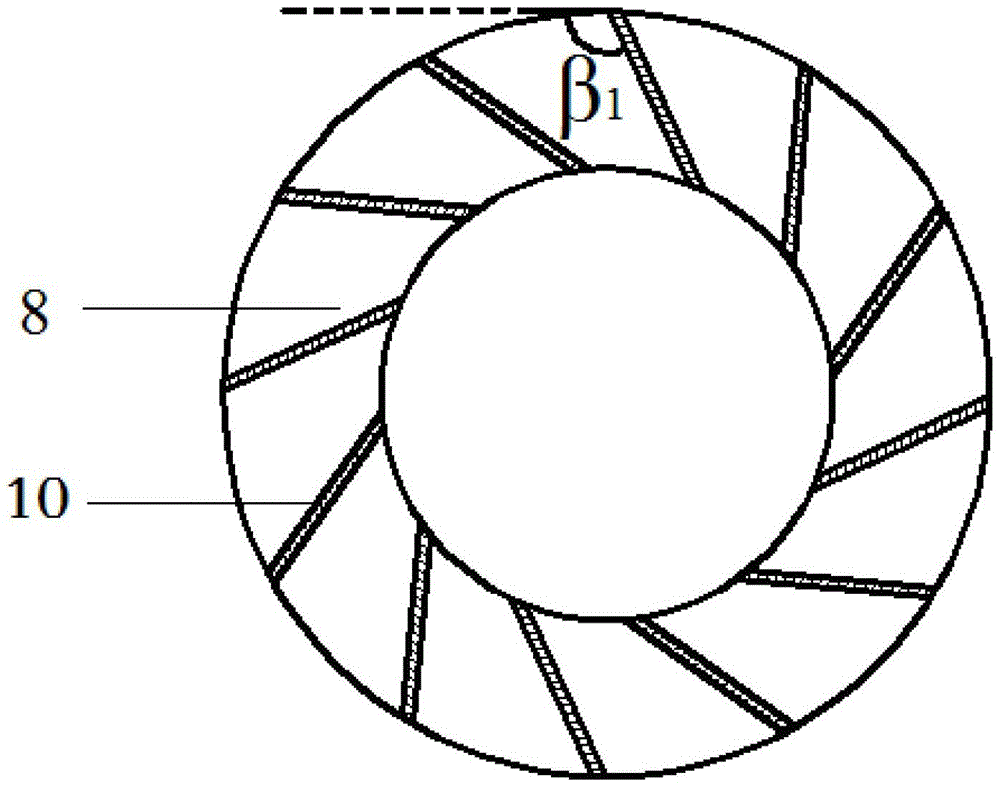

[0030] A premixed air swirling device 8 is provided on the inner side of the lower end of the prem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com