Energy-saving prying driving method for vehicle

A technology of vehicles and transmission wheels, which is applied in the direction of transmission devices, vehicle parts, portable lifting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

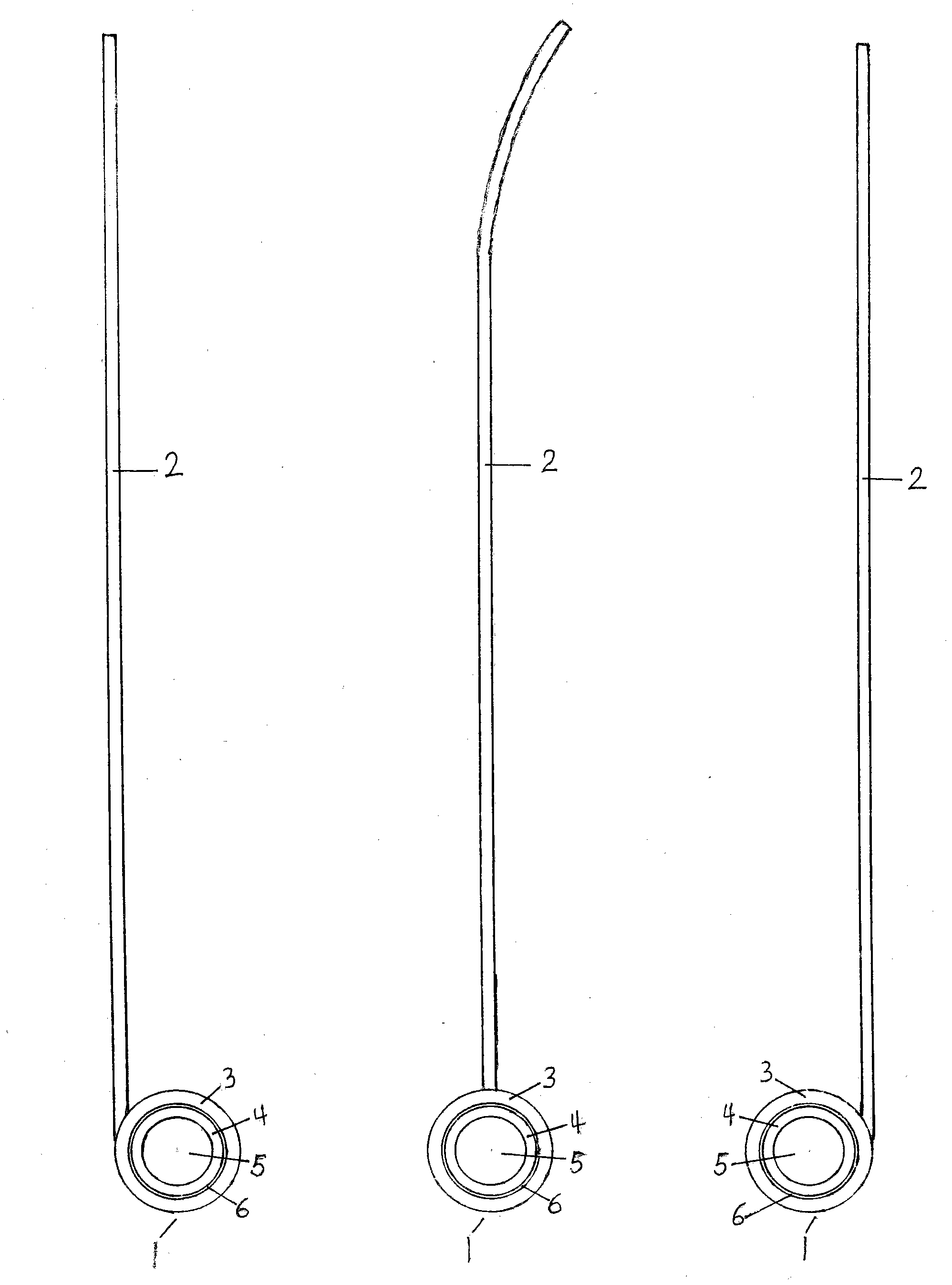

[0043] figure 1 is a schematic diagram of the pry bar drive wheel. In the figure, the internal structures of the three transmission wheels are the same, but the positions of the crowbars are different. 1 in the figure is the drive wheel; 2 is the pry bar fixed on the outer ring of the drive wheel; 3 is the outer ring of the drive wheel; 4 is the inner ring of the drive wheel; 5 is the inner hole of the drive wheel, which is set behind the vehicle Play fixed effect on the transverse axis; 6 is the joint mouth of outer ring and inner ring, and two circles of balls are housed in the inside, also have steel teeth and oblique notch, and the internal structure of bicycle flywheel is basically identical (made in the content of the invention the inside for details). Pull up the pry bar of the drive wheel of the pry bar, the steel teeth inside the drive wheel can be locked, and the pry bar can be pressed down to pry.

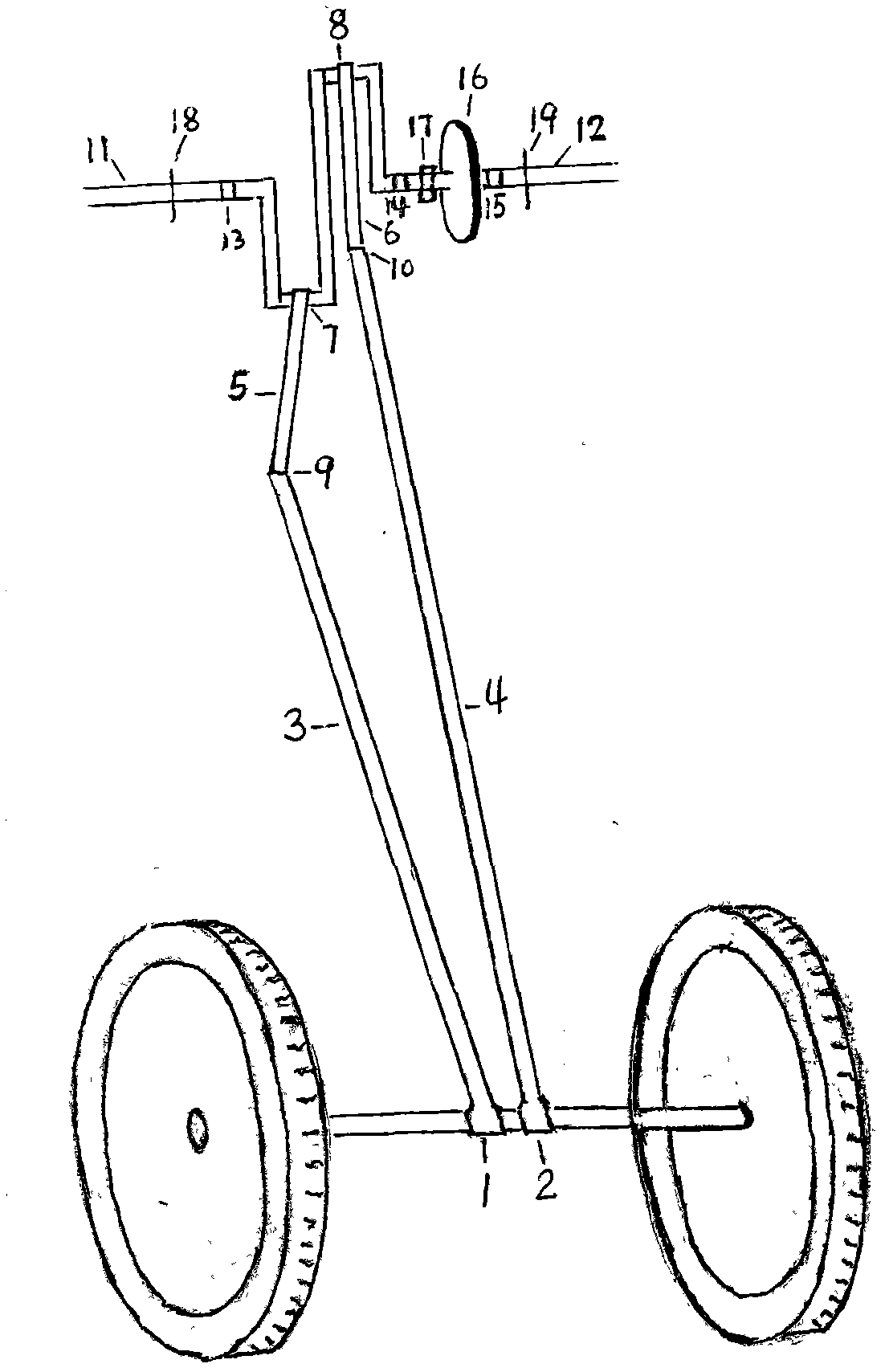

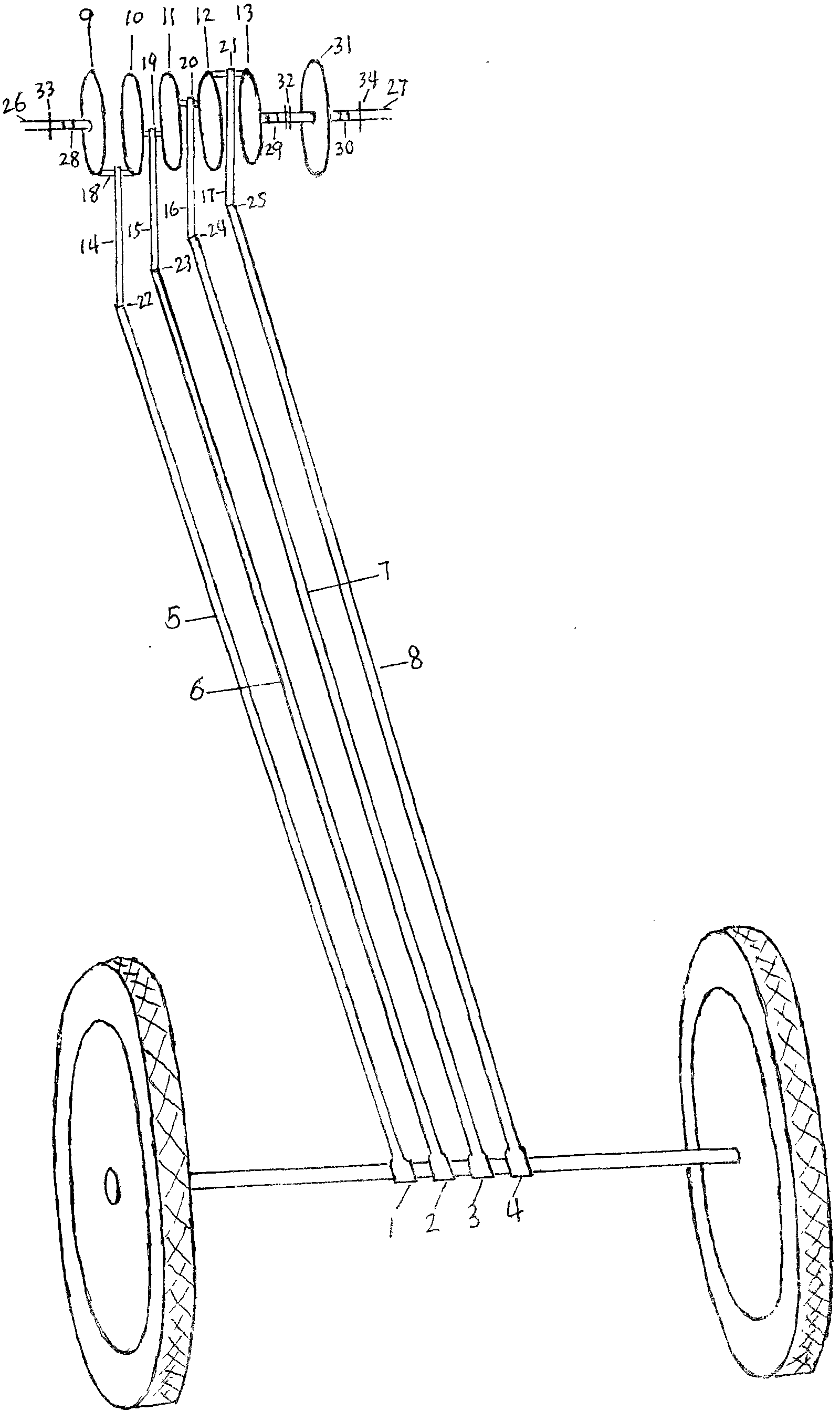

[0044] figure 2 It is a schematic diagram of a crowbar drive w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com