Liquid reservoir

A liquid reservoir and container technology, which is applied in the field of liquid reservoirs, can solve problems such as vibration or high-pressure refrigerant impact, and achieve the effects of saving processing time, simple assembly, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

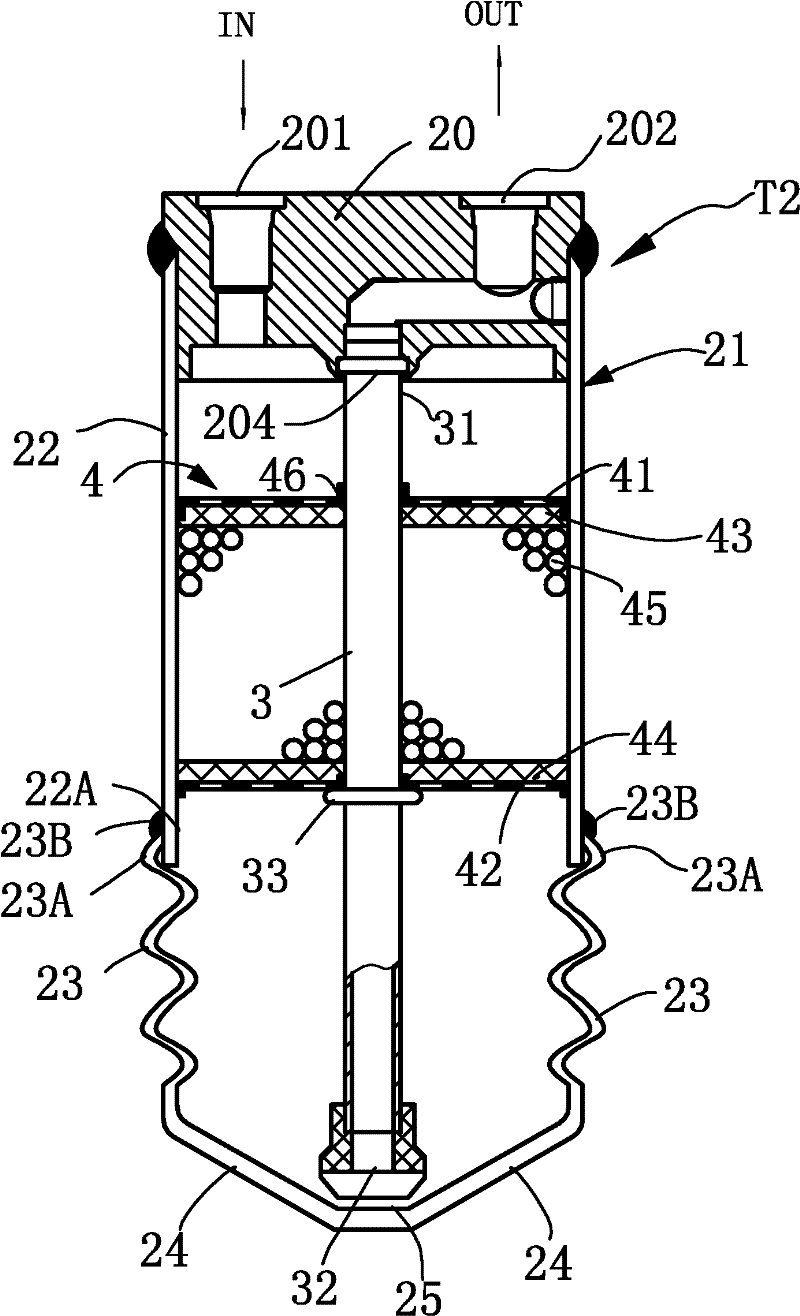

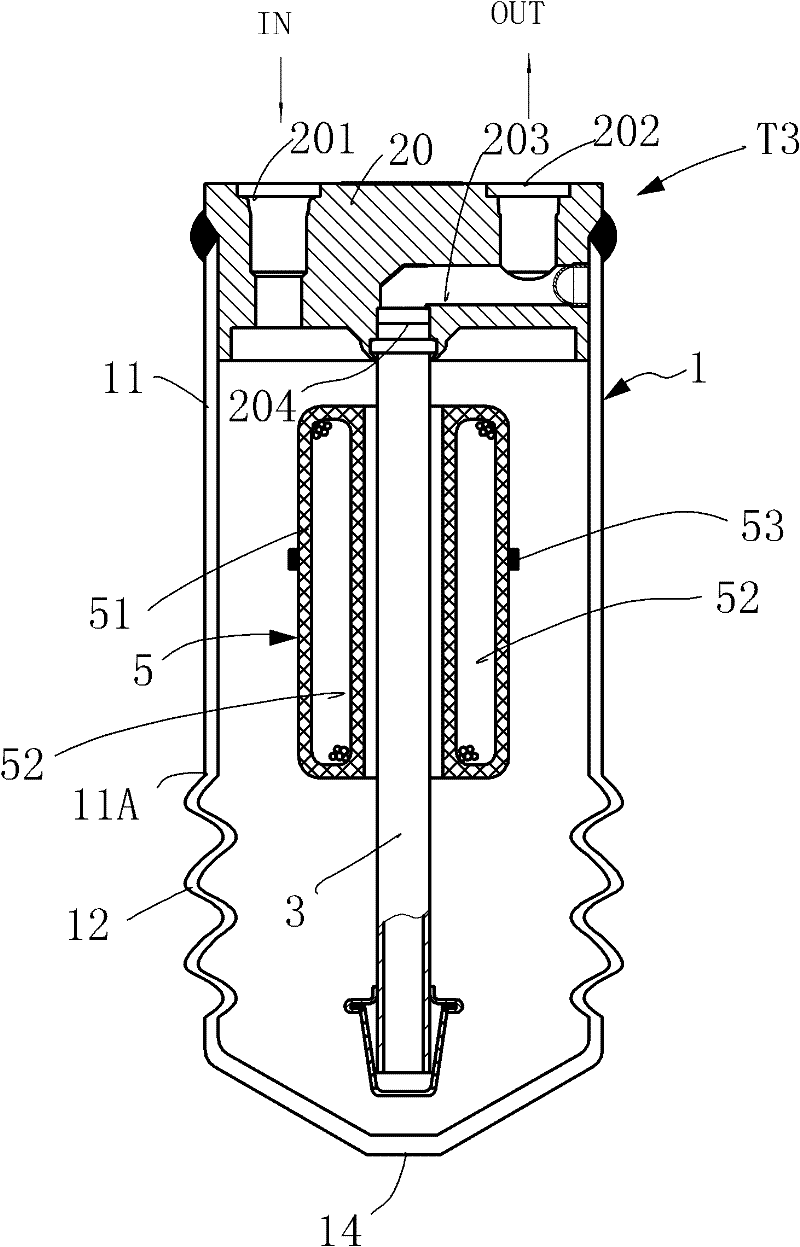

[0027] The following reference Figure 1 to Figure 4 The embodiments of the present invention will be described in detail.

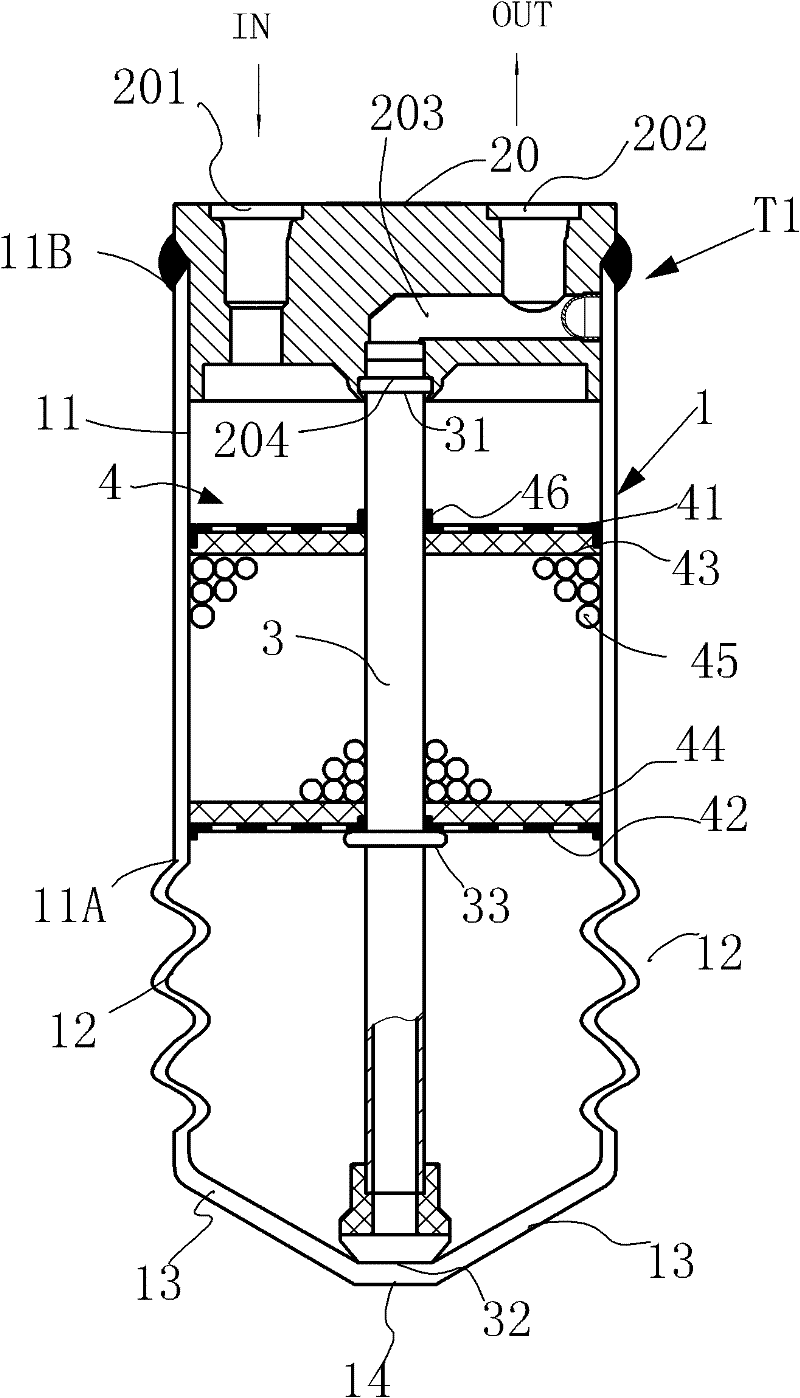

[0028] figure 1 It is a cross-sectional side view of an embodiment of the reservoir T1 of the present invention. The basic structure of the reservoir T1 is the same as that shown in FIG. 5 of Patent Document 1, except that it does not have the supporting member 7 in FIG. 5.

[0029] figure 1 Among them, the container 1 composed of cylindrical parts mainly includes a cylindrical portion 11 constituting the upper half of the container 1 and a corrugated portion forming the side wall of the lower half of the container 1, and the lower corrugated portion 12 It is connected and joined to the lower end opening 11A of the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com