Micro-scale speckle manufacturing method for interface high-temperature deformation measurement

A technology of high temperature deformation and production method, which is applied in the direction of measuring device, optical device, instrument, etc., to achieve the effect of simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the present invention.

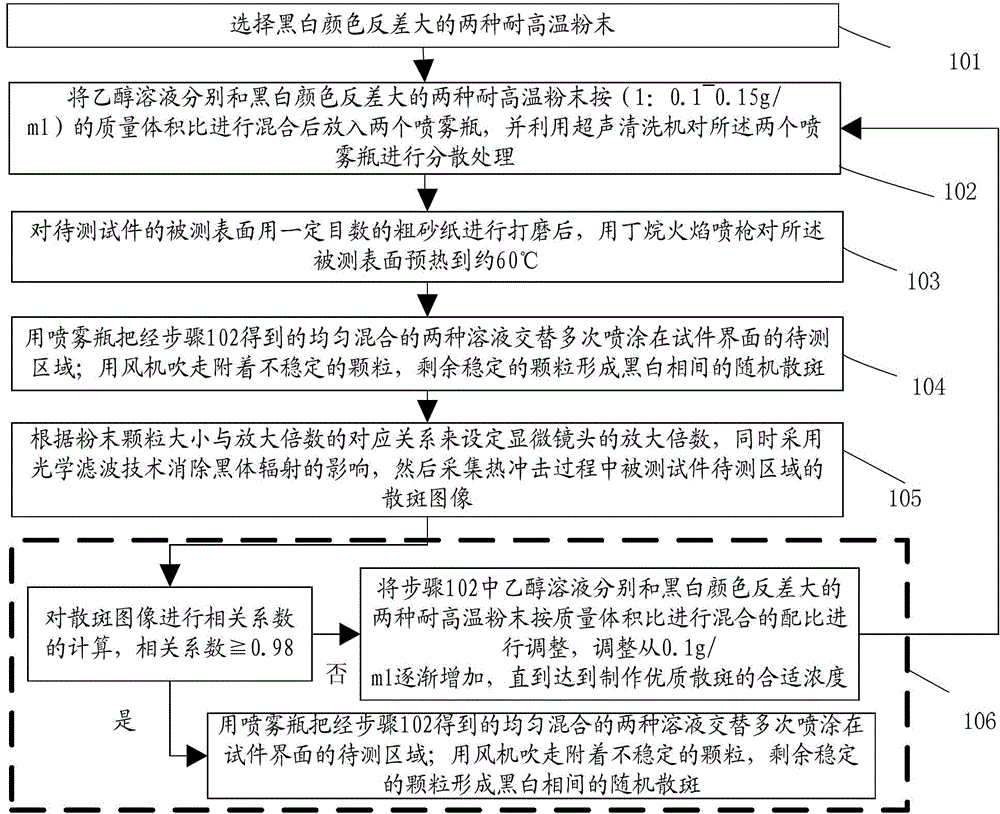

[0033] Such as figure 1 As shown, it is a micro-scale speckle manufacturing method for interface high-temperature deformation measurement described in the embodiment of the present invention. The method includes the following steps:

[0034] In step 101, two high-temperature-resistant micro-nanoparticle powders with high black-and-white color contrast are selected.

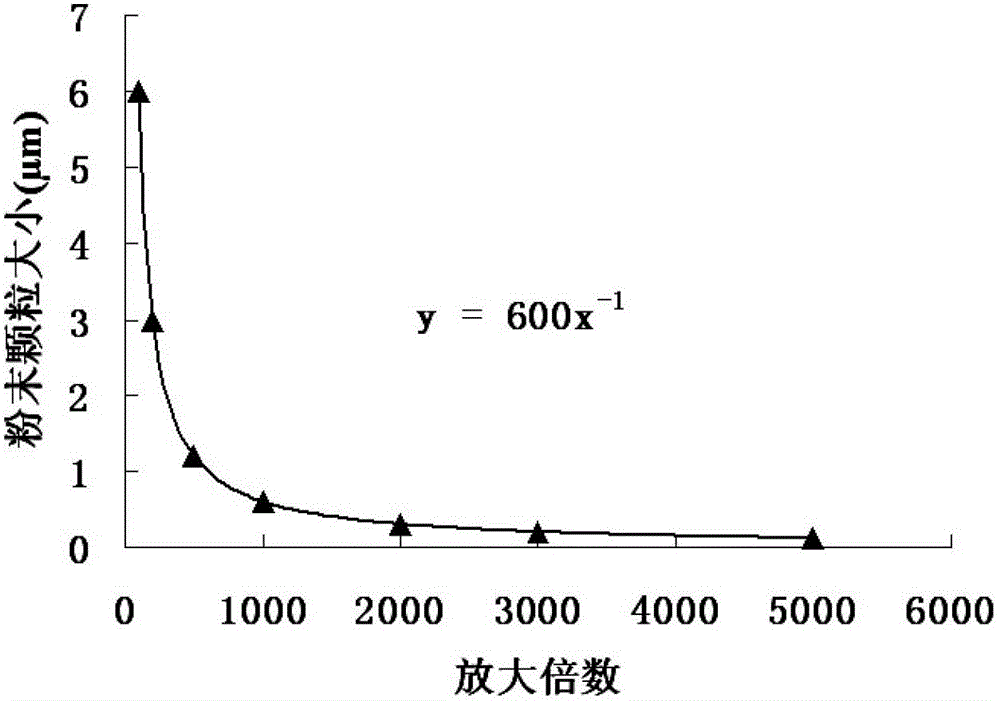

[0035] The further step 101 is specifically: according to the optimal speckle size and the size corresponding to each pixel under the microscope magnification, obtain the corresponding relationship curve between the particle size of the high temperature resistant powder and the magnification, and then according to the observed magnification of the test piece, Using the corresponding relationship curve to select two kinds of micro-nano parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com