Clamp system for electrical connection among cell units

An electrical connection, battery cell technology, applied in electrical components, battery pack components, clamping/spring connections, etc., can solve problems such as short service life, shortened battery cell life, and battery pack damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Regarding the type and specification of the battery core, I choose the laminated battery core. Compared with cylindrical cells, laminated cells have lower internal resistance and thus generate less heat during charging and discharging. And it has a high energy / power density. Due to its flat profile and large exposed surface, it facilitates heat exchange.

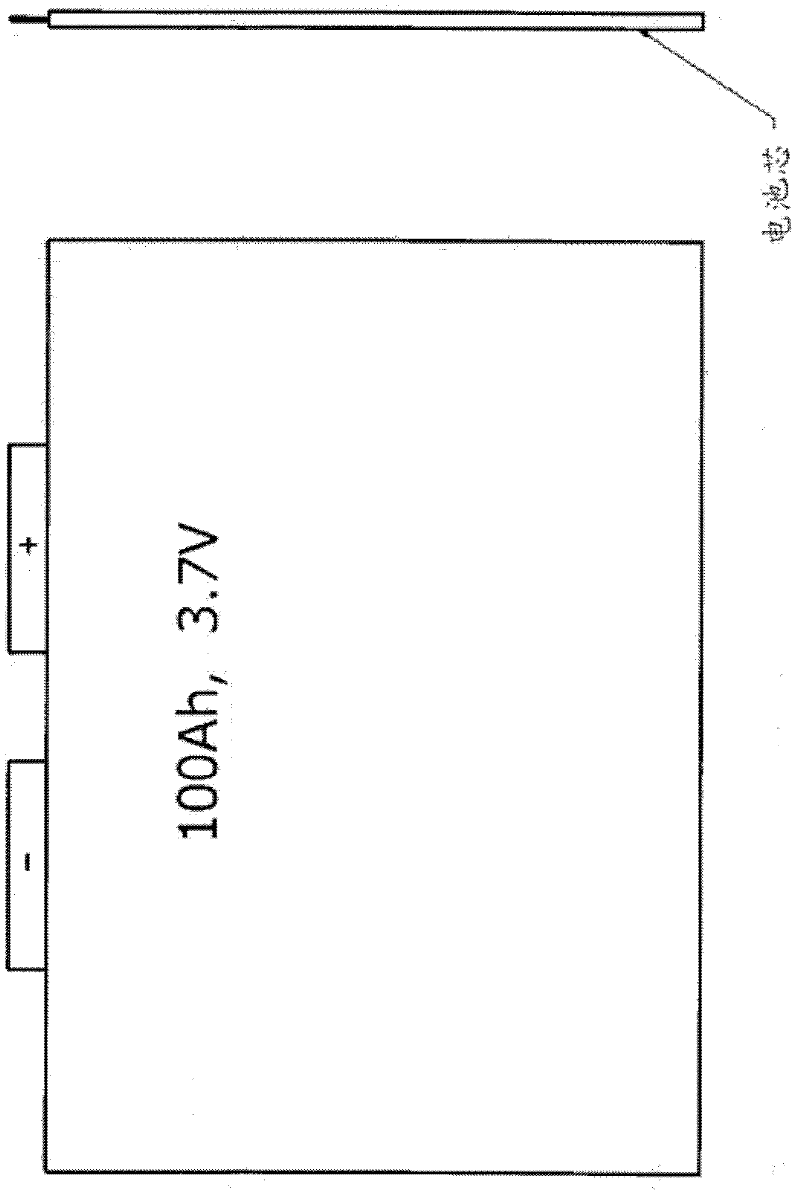

[0057] The battery box I designed has 86 large-scale laminated battery cells (100Ah, 3.7V, such as figure 1 ). The cells are connected by novel clips that provide electrical connections where space is limited, as described below.

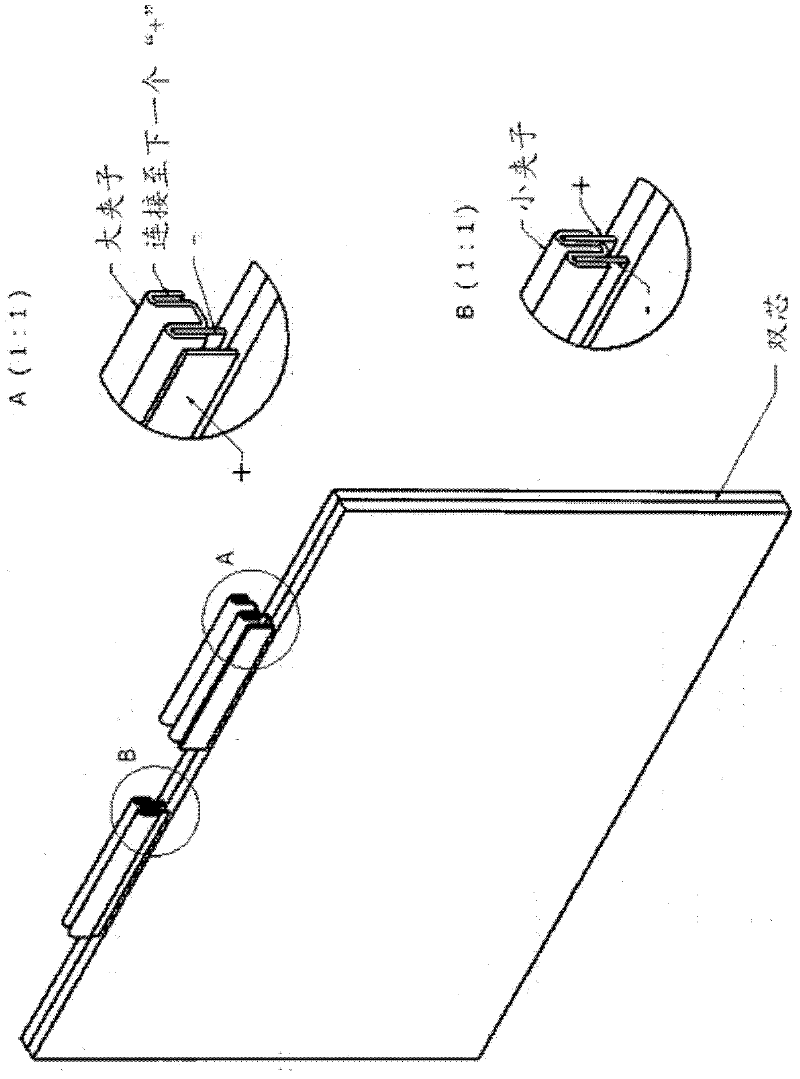

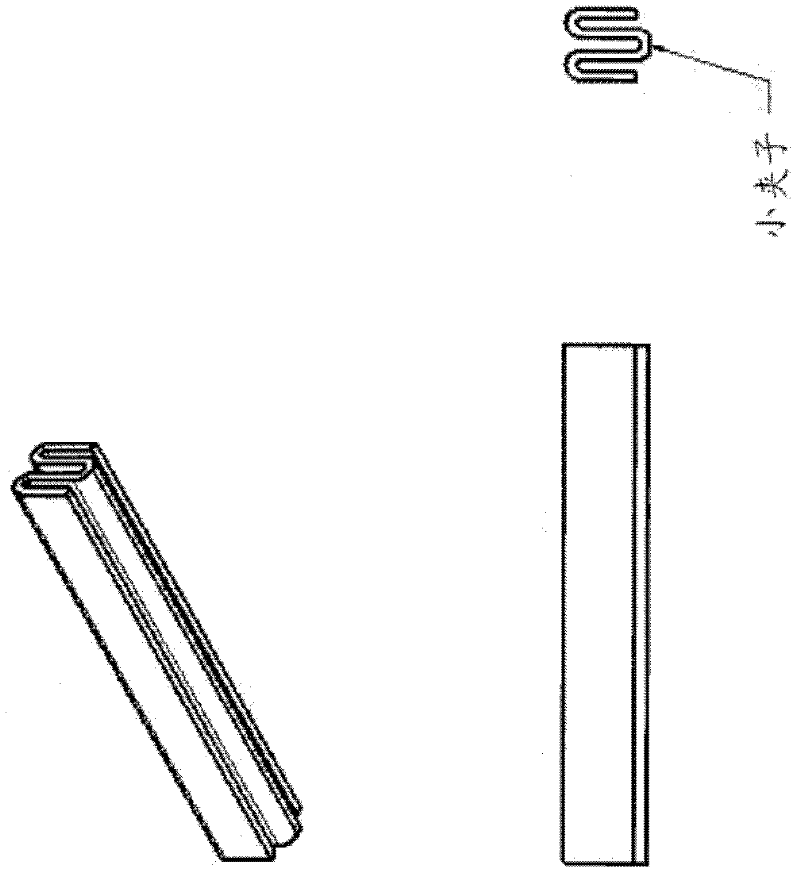

[0058] Two battery cells are connected face to face in series ( figure 2 ), connect the different electrodes of the two battery cells through a small clip ( image 3 ). This will form a two-cell series connection (dual-cell for short). Two sides of the duplex with cooling channel plate ( Figure 18 ) contact for heat exchange.

[0059] The two cores are placed in the same orienta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com