Connection method of double-core coaxial line welding connector

A connection method and connector technology, applied in the field of data lines, to achieve the effect of simple production and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiments.

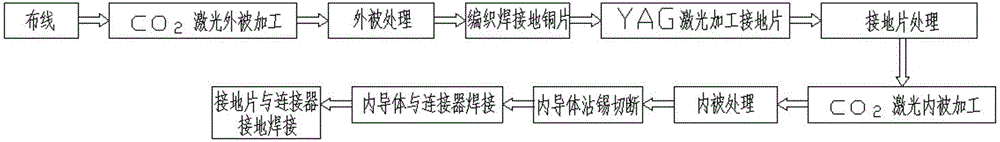

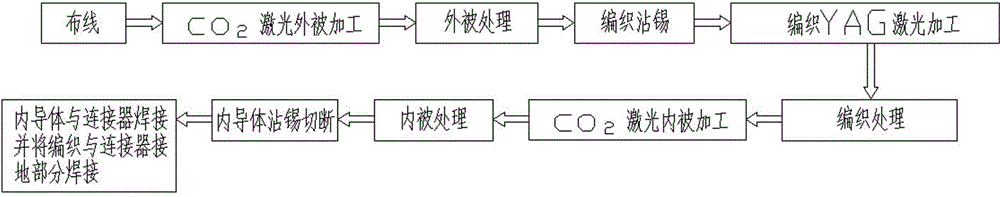

[0019] See figure 2 , A connection method of dual-core coaxial wire welding connector, the process steps are:

[0020] The first step: wiring, use wiring jigs to arrange the coiled wire to the required length and number and cut it;

[0021] The second step: outside processing, using CO 2 The laser machine cuts the outermost layer of the dual axis cut in the first step, and it can be changed according to different sizes of connectors;

[0022] The third step: the outer layer is processed, and the two-axis cut in the second step is used to extract the outer layer of the outer layer to the corresponding size;

[0023] Step 4: Weaving and dip tin, weave and dip the part of the outer cover that was pulled out in the third step;

[0024] Step 5: Weave and process with YAG laser, and process the biaxial line that has been tin-dipped in the fourth step with a metal YAG cutting machine. The size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com