Flavor-improving material

A technology for flavor and food and drink products, applied in the field of imparting aroma and/or flavor to food, and can solve problems such as easy deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (Example 1 imparts the impact of the difference in the addition ratio of the composition of aroma and / or flavor on the sensory evaluation of soups)

[0074]

[0075] As a pretreatment, boil the pork leg meat for 5 minutes to remove the foam. Put 1.6kg of pre-treated pork and 10.1kg of water into a cylindrical deep-bottomed pot and heat to boiling over high heat, then turn to low heat after boiling, and cook for 4 hours. Remove foam at any time during heating and stewing. After 4 hours of simmering, the simmering liquid was filtered through cooking paper to obtain pork broth.

[0076]

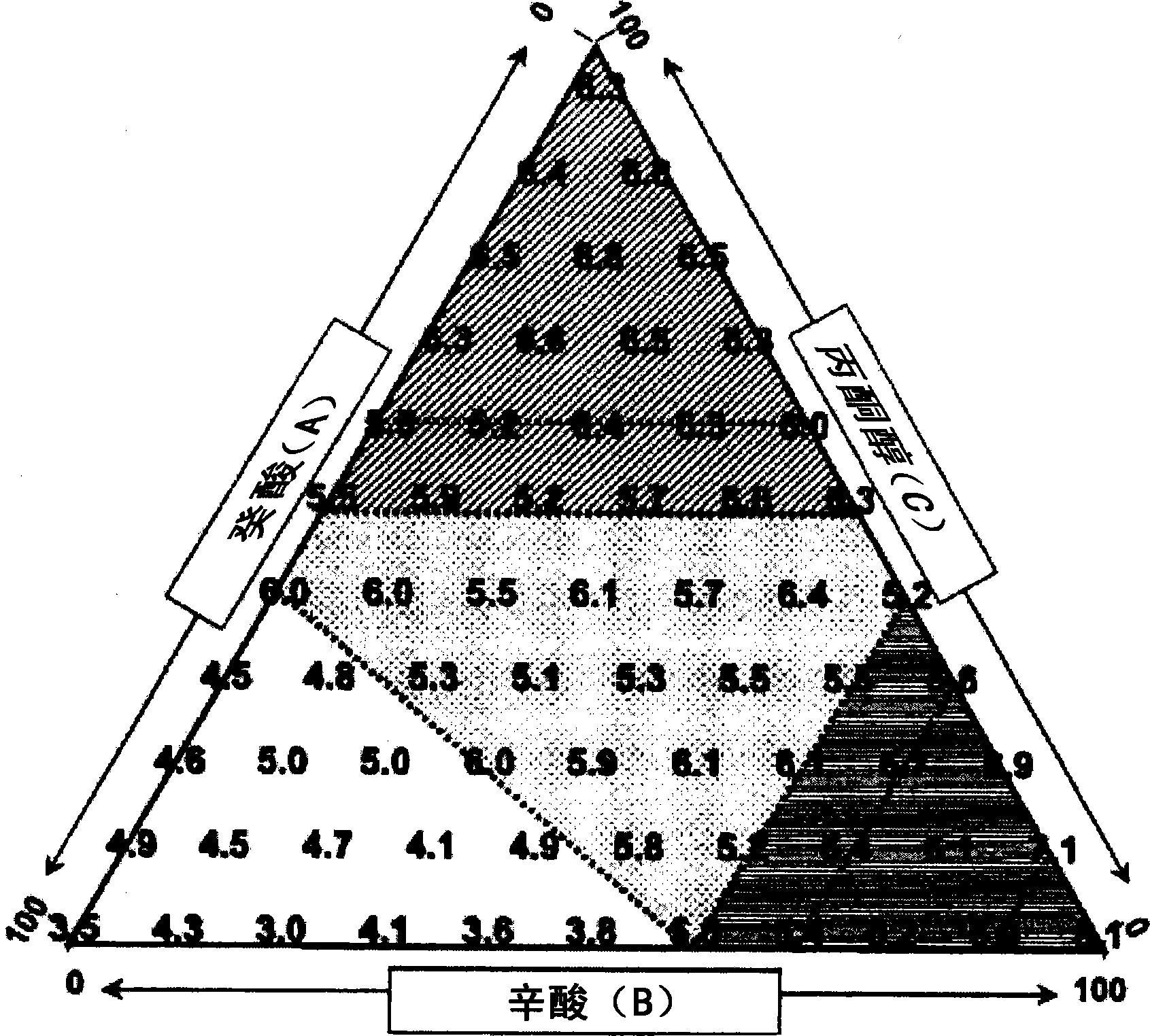

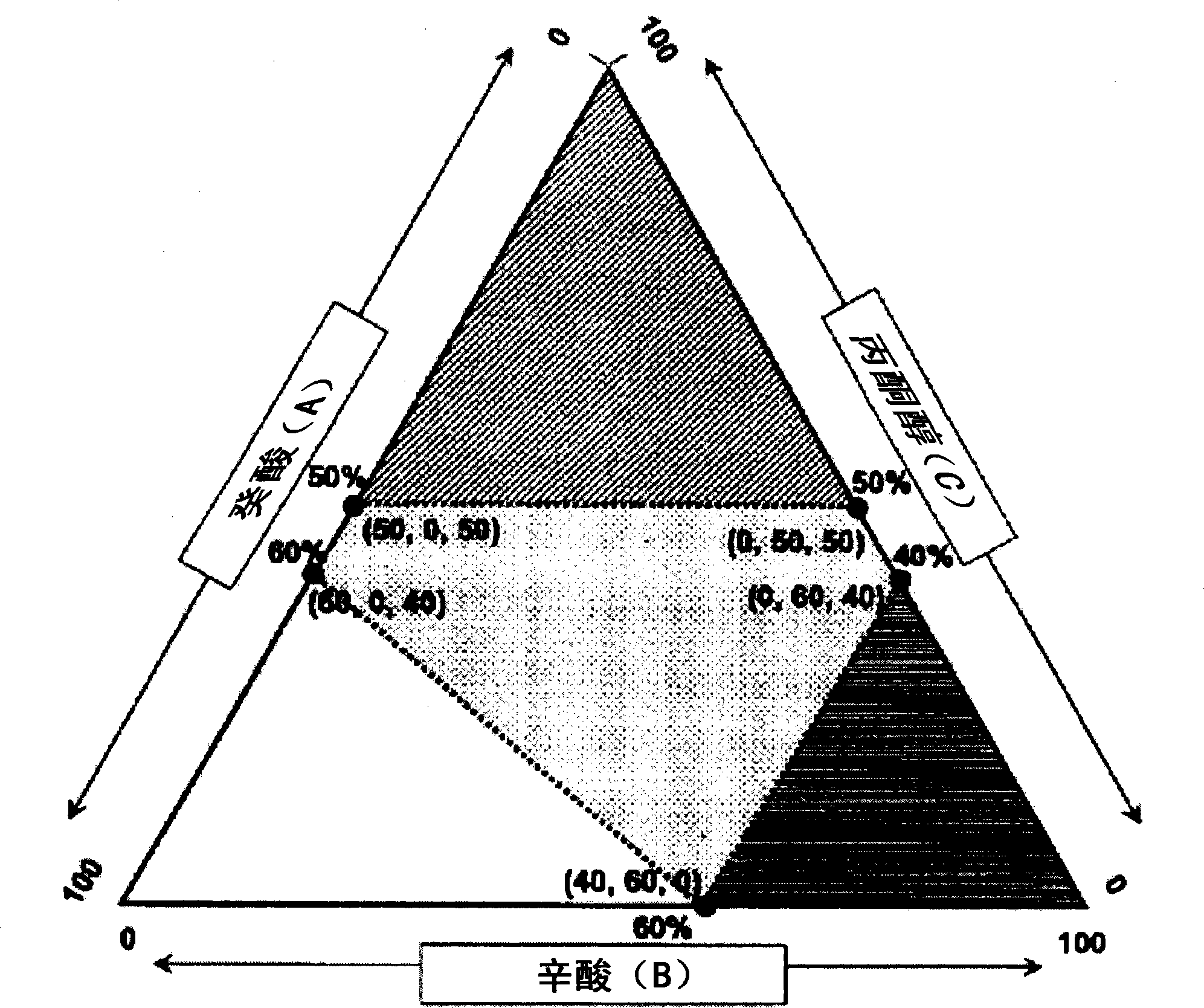

[0077] Three components of capric acid, caprylic acid, and acetol were added to the pork broth prepared in Example 1, and the ratio of each component was changed in units of 10%, so that the total concentration of the three components was 61.05 ppm. The pork broth without adding the three ingredients was used as the control group.

[0078] The sensory evaluation is carried out by 5...

Embodiment 2

[0081] (Embodiment 2 imparts the impact of the difference in concentration of the composition of aroma and / or flavor on the sensory evaluation of soups)

[0082]

[0083] Add capric acid, caprylic acid, and acetol to the pork broth prepared above at a ratio of 10%, 10%, and 80% (recipe 1) or respectively at a ratio of 62.6%, 34.7%, and 2.7% (recipe 2) Capric acid, caprylic acid, and acetol were added, and the total concentrations of the three components were 1ppb, 10ppb, 100ppb, 10ppm, 1000ppm, and 1%. The pork broth without adding the three ingredients was used as the control group.

[0084] The sensory evaluation is carried out by 3 fully trained panelists. For the ideal degree of aroma and / or flavor of the meat broth, 5 points are used for the control group, 10 points are taken as the full score and free comments are used to evaluate. The results are shown in Table 1.

[0085] Table 1

[0086] Sensory evaluation of soups according to differences in added concentrations...

Embodiment 3

[0089] (Example 3 Evaluation of furan ring-containing compound)

[0090]

[0091] The food raw materials were mixed according to the formula in the following Table 2 to make the powder meat-based flavor seasoning. It should be noted that these food raw materials are all commercial products.

[0092] Table 2

[0093]

[0094]

[0095]1.3 g of the meat-based flavor seasonings in Table 2 were dissolved in 98.7 g of soup to prepare a 1.3% meat-based flavor seasoning. Among them, any one of (i) capric acid, (ii) caprylic acid, (iii) acetol, furfural, methyl tetrahydrofuranone, and 2-acetyl-5-methylfuran, respectively, with (i) 8% , (ii) 8%, (iii) 84% (formulation 1), or (i) 31%, (ii) 49%, (iii) 20% (formulation 2), or respectively ( Add i) 80%, (ii) 10%, and (iii) 10% (recipe 3) so that the total concentration of the three components of (i)(ii)(iii) is 61.05ppm. The meat-based flavor seasoning without adding the three ingredients was used as the control group.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com