Axial side gap enlargement device for blade of disc shear

A technique of enlarging devices and discs, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., and can solve the problems of production line shutdown, large economic losses, and affecting the service life of side clearance adjustment devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

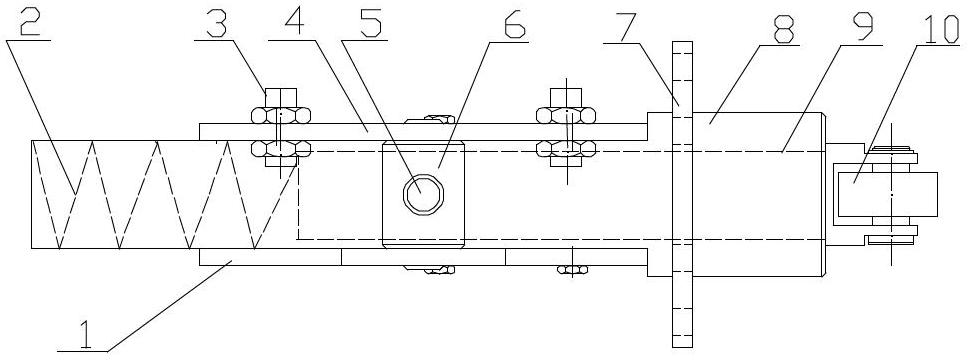

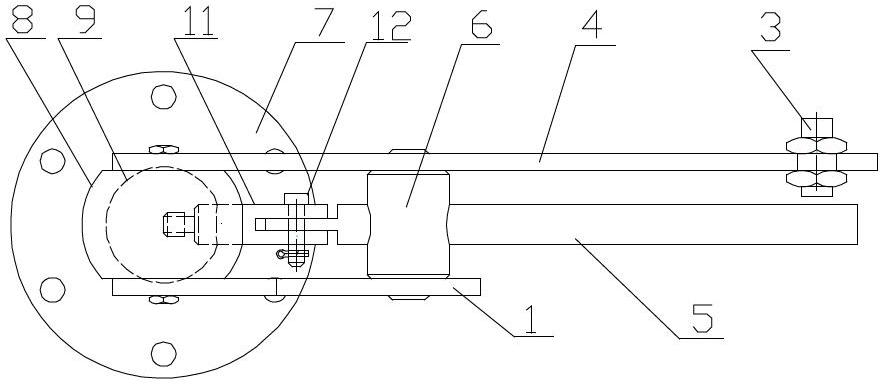

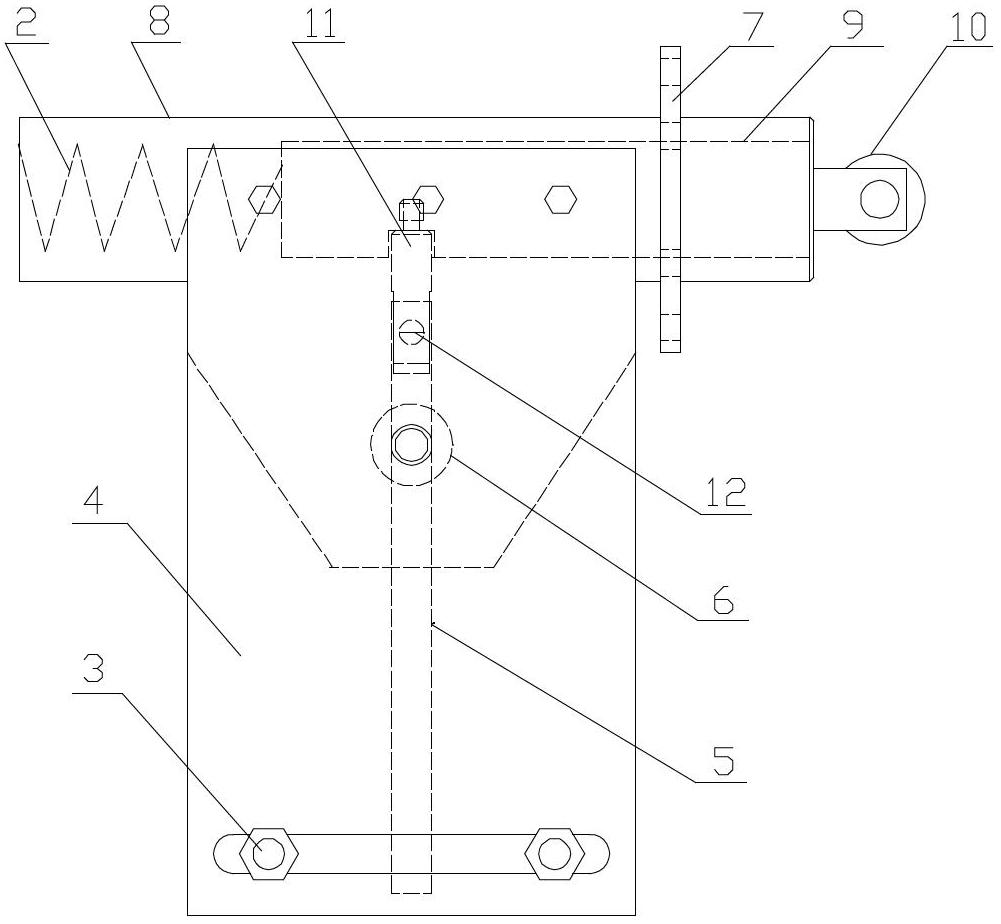

[0015] As can be seen from the accompanying drawings, the disc shear blade axial side clearance enlargement device of the present invention is composed of a lower support plate 1, a spring 2, a travel switch 3, an upper support plate 4, a swing rod 5, a rotating shaft 6, a flange 7, a slide Cover 8, slide bar 9, bearing 10, connecting rod 11, bearing pin 12 are formed.

[0016] Spring 2 is housed in the sliding sleeve 8, and the rear end of the sliding rod 9 is pressed against the spring 2, and the whole shaft is movably installed in the sliding sleeve 8, and can slide along the sliding sleeve 8 inner cavity. The front end of the slide bar 9 has a bearing 10, and the sliding sleeve 8 is connected to the body of the disc shears through the flange 7, so that the front end bearing 10 of the slide bar 9 leans against the shaft of the disc shears under the action of the spring 2. The middle part of slide bar 9 is provided with a connecting rod hole, and connecting rod 11 one ends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com