Externally controllable built-in lift platform

A lifting platform, controllable technology, applied in the field of lifting platform, can solve the problems of inability to achieve continuous adjustment, affecting efficiency, affecting focusing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

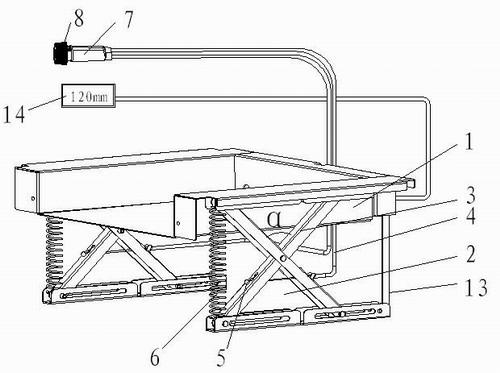

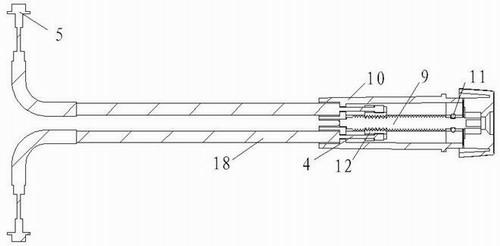

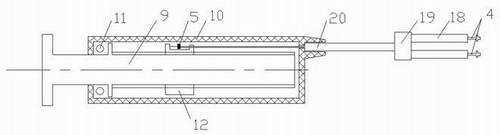

[0013] Such as figure 1 , Figure 4 and Figure 5 As shown, a controllable built-in lifting platform outside the case includes a box body, which is characterized in that: a lifting platform 1 is arranged in the box, and a group of cross-shaped support rods 2 are respectively arranged on the left and right sides of the lifting platform. , the cross-type support rod is composed of two hinged rods 3 through the middle, and one of the cross-type support rods is controlled by the traction end 5 of a traction rope 4 so that the crossing of the cross-type support rod The angle α is reduced to realize the lifting of the lifting platform. The cross-shaped support rod is also provided with a return spring 6 that drives the cross-type support rod to open the cross angle α and resets the leading end of the traction rope. The traction rope passes through the The traction mechanism 7 on the body controls retraction, and the control knob 8 of the traction mechanism is arranged outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com