Upright column structure of stacker

A stacker and column technology, applied in the field of column structure, can solve the problems of wasting materials and large column cross-sectional size, and achieve the effects of saving materials, simple structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

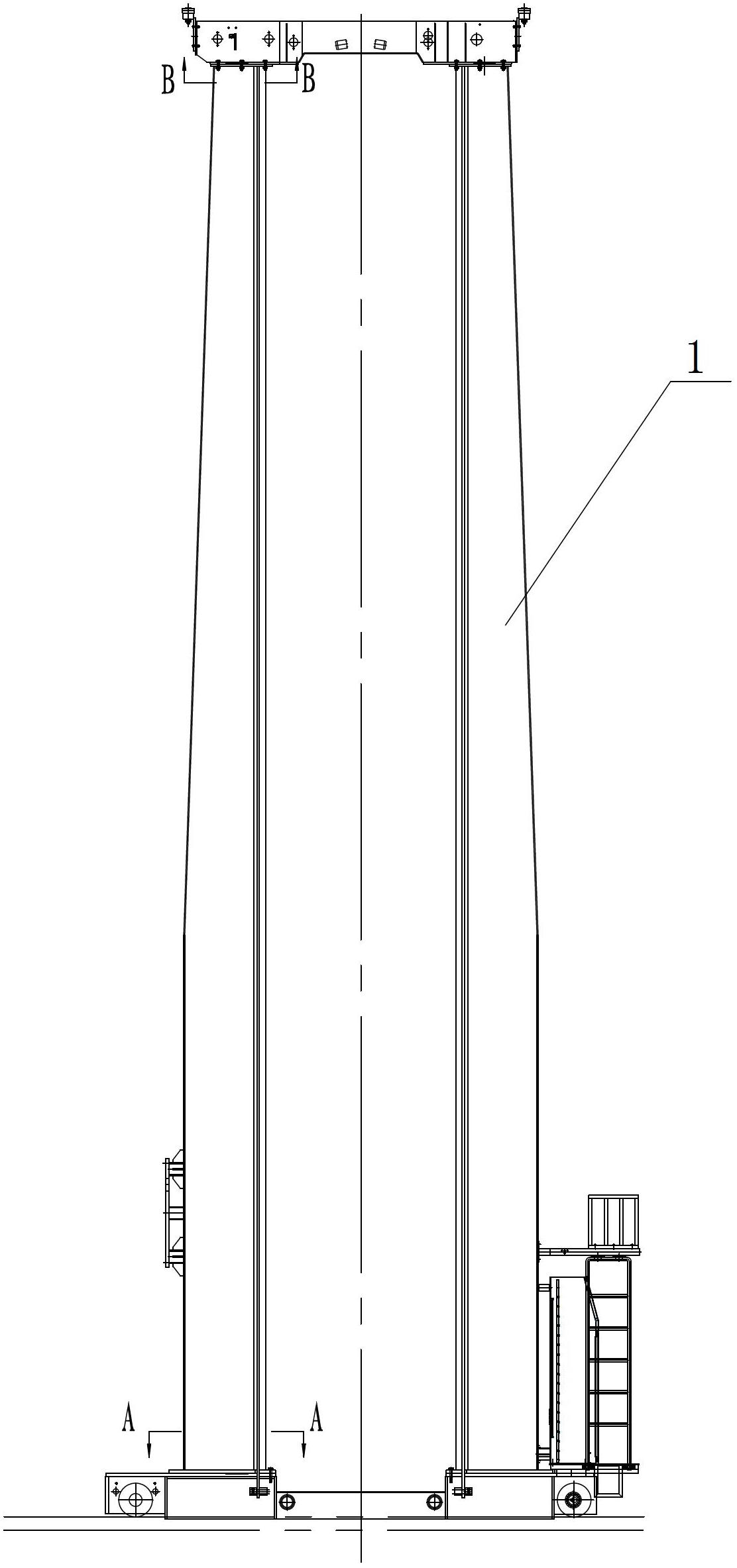

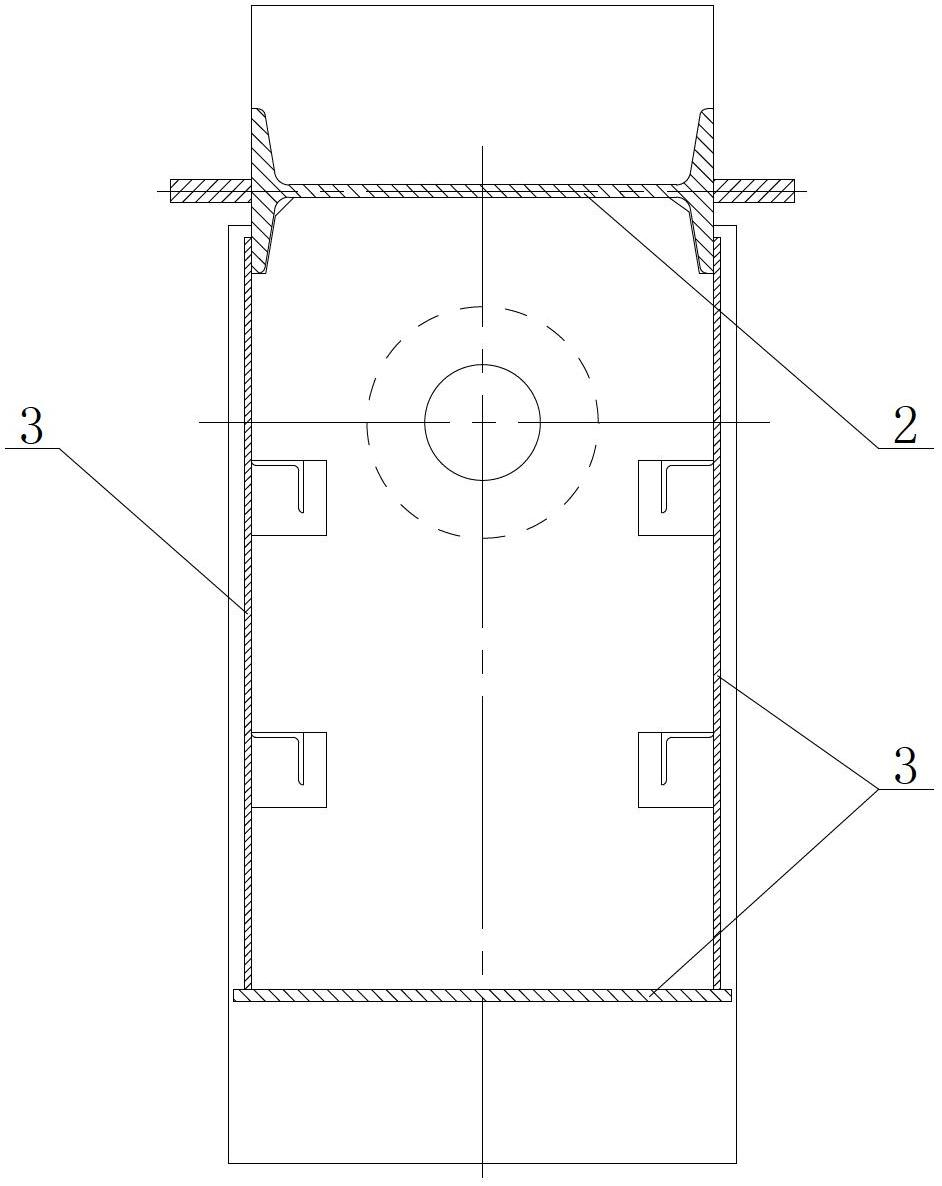

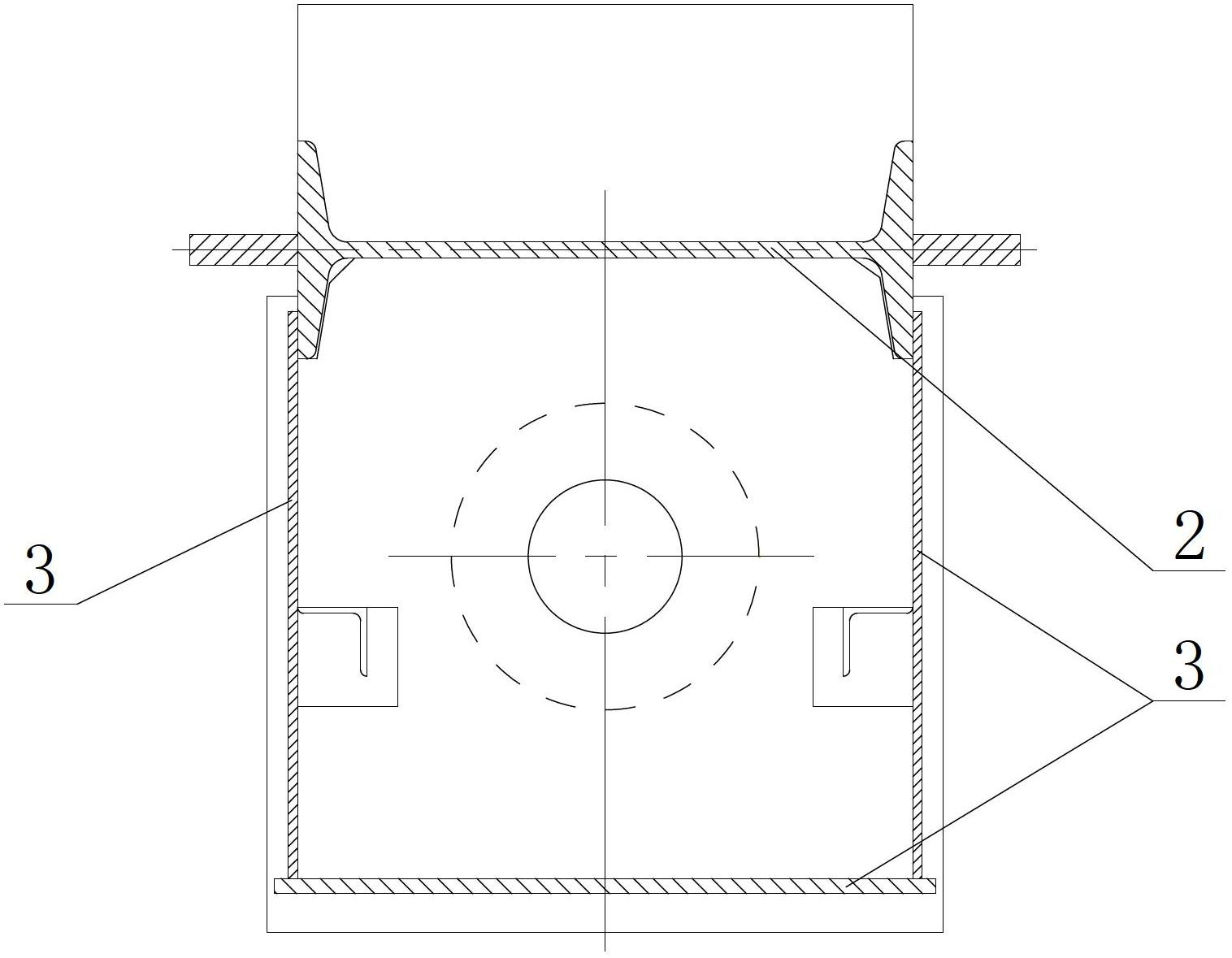

[0015] Please refer to Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of the column structure of the stacker of the present invention; figure 2 yes figure 1 The schematic cross-sectional view of the column structure of the stacker shown at A-A; image 3 yes figure 1 The schematic cross-sectional view of the column structure of the stacker shown at B-B. In this embodiment, a stacker column structure includes a column body 1, the column body 1 is formed by welding an I-shaped steel 2 and a steel plate 3, and its longitudinal section is a trapezoidal structure, and its cross-sectional area is from above increasing successively.

[0016] The cross-sectional area of the column structure of the stacker increases sequentially from top to bottom. While ensuring that the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com