Application of soil hardener in wall body building of greenhouse

A technology of soil curing agent and greenhouse, which is applied in the direction of construction, building components, building structures, etc., can solve the problems of resource consumption, energy, unacceptable by farmers, and high cost, so as to reduce project cost, shorten construction period, and save construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

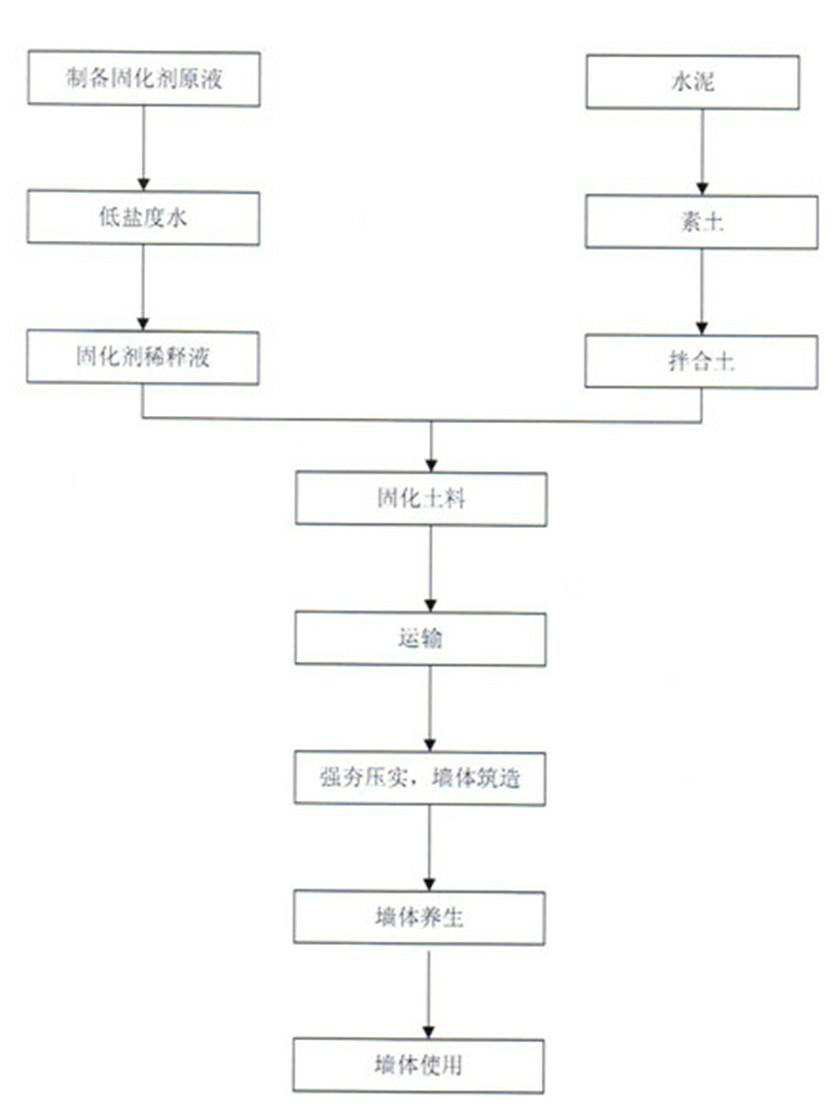

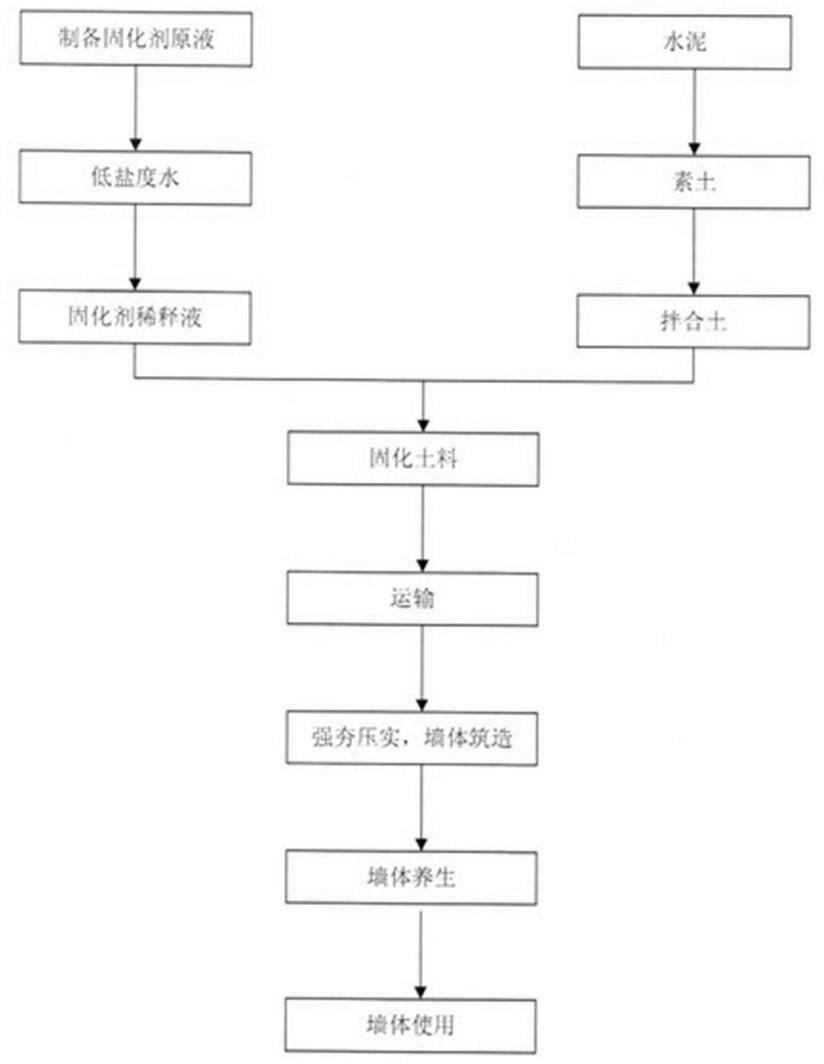

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Application of soil curing agent in greenhouse wall construction

[0031] % by mass percentage, the concrete steps of the application method of the soil curing agent on the greenhouse wall construction are as follows.

[0032] (1) Dissolve 2.5% hydroxypropyl methylcellulose and 5% polyacrylamide in 22.5% water to form an aqueous solution; add 70% water glass, the modulus of water glass is 2.5-3, the density 1.35-1.50 g / cm 3 , the degree of Baume is 38-48, and the stock solution of curing agent is formed by stirring evenly.

[0033] (2) Preparation of curing agent dilution: Add 0.2% of the curing agent stock solution prepared in step (1) into 99.8% low-salinity tap water and mix evenly to form a curing agent dilution.

[0034] (3) Preparation of plain soil: remove weeds, trees, tree root debris and large soil clods in the soil, and control the water content at 15%-18%.

[0035] (4) Preparation of mixed soil: uniformly mix 6%-8% cement into the 94%-92% pla...

Embodiment 2

[0042] Embodiment 2: Application of soil curing agent on greenhouse wall construction

[0043] (1) Dissolve 2.5% hydroxypropyl methylcellulose and 5% polyacrylamide in 22.5% water to form an aqueous solution; add 70% water glass, the modulus of water glass is 2.5-3, the density 1.35-1.50 g / cm 3 , the degree of Baume is 38-48, and the stock solution of curing agent is formed by stirring evenly.

[0044] (2) Preparation of curing agent dilution: Add 0.2% of the curing agent stock solution prepared in step (1) into 99.8% low-salinity tap water and mix evenly to form a curing agent dilution.

[0045] (3) Preparation of plain soil: remove weeds, trees, tree root debris and large soil clods in the soil, and control the water content at 15%.

[0046] (4) Preparation of mixed soil: Evenly mix 6% cement into the 94% plain soil prepared in step (3) to make mixed soil.

[0047] (5) Preparation of solidified soil: Spray the 12% curing agent dilution in step (2) evenly into the 88% mi...

Embodiment 3

[0052] Example 3: Application of soil curing agent in greenhouse wall construction

[0053] (1) Dissolve 2.5% hydroxypropyl methylcellulose and 5% polyacrylamide in 22.5% water to form an aqueous solution; add 70% water glass, the modulus of water glass is 2.5-3, the density 1.35-1.50 g / cm 3 , the degree of Baume is 38-48, and the stock solution of curing agent is formed by stirring evenly.

[0054] (2) Preparation of curing agent dilution: Add 0.2% of the curing agent stock solution prepared in step (1) into 99.8% low-salinity tap water and mix evenly to form a curing agent dilution.

[0055] (3) Preparation of plain soil: remove weeds, trees, tree root debris and large soil clods in the soil, and control the water content at 15%-18%.

[0056] (4) Preparation of mixed soil: uniformly mix 8% cement into 92% plain soil prepared in step (3) to make mixed soil.

[0057] (5) Preparation of solidified soil: Spray the 12% curing agent dilution in step (2) evenly into the 88% mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com