Three-stage pressure regulating double-coil type magneto-rheological valve

A magnetorheological valve, double coil technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problem of hindering the development of magnetorheological valve industrial application, narrow pressure condition range, inlet and outlet pressure difference Small problems, etc., to achieve the effect of flexible control of magnetic field strength, wide pressure adjustment range, and good control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

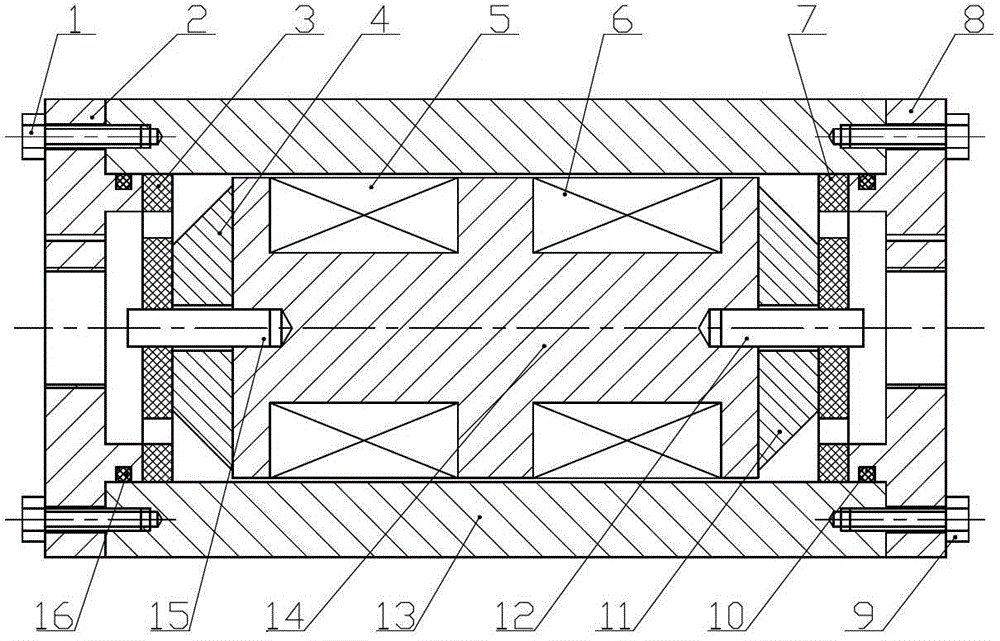

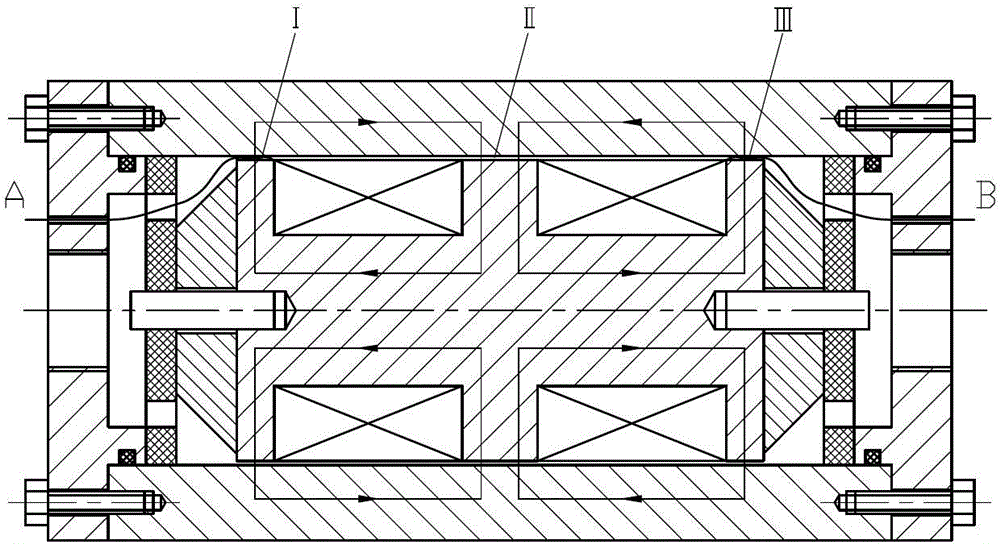

[0013] like figure 1 As shown, the present invention includes: screw I1, left end cover 2, left positioning block 3, left guide block 4, coil I5, coil II6, right positioning block 7, right end cover 8, screw II9, sealing ring II10, right guide block 11 , right positioning pin 12, valve body 13, valve core 14, left positioning pin 15 and sealing ring I16; left end cover 2 and valve body 13 are fixedly connected by screw I1, and the connection between left end cover 2 and valve body 13 is carried out by sealing ring I16 Sealing; the left positioning block 3 is transitionally matched with the valve body 13, and its left end is pressed by the left end cover 2; the left end of the left guide block 4 is close to the left positioning block 3, and its right end is close to the valve core 14; the left positioning block 3, the left guide block 4 and the valve core 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com