Bridge deck bonding layer torsional shearing device and detection method thereof

A bonding layer and device pairing technology, applied in the field of testing instruments for evaluating bridge deck performance, can solve the problem of difficulty in realizing bridge deck bonding layer monitoring and unification of indoor and outdoor tests, poor field operability, and large bridge deck damage and other problems, to achieve the effect of comprehensive test results, strong integrity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

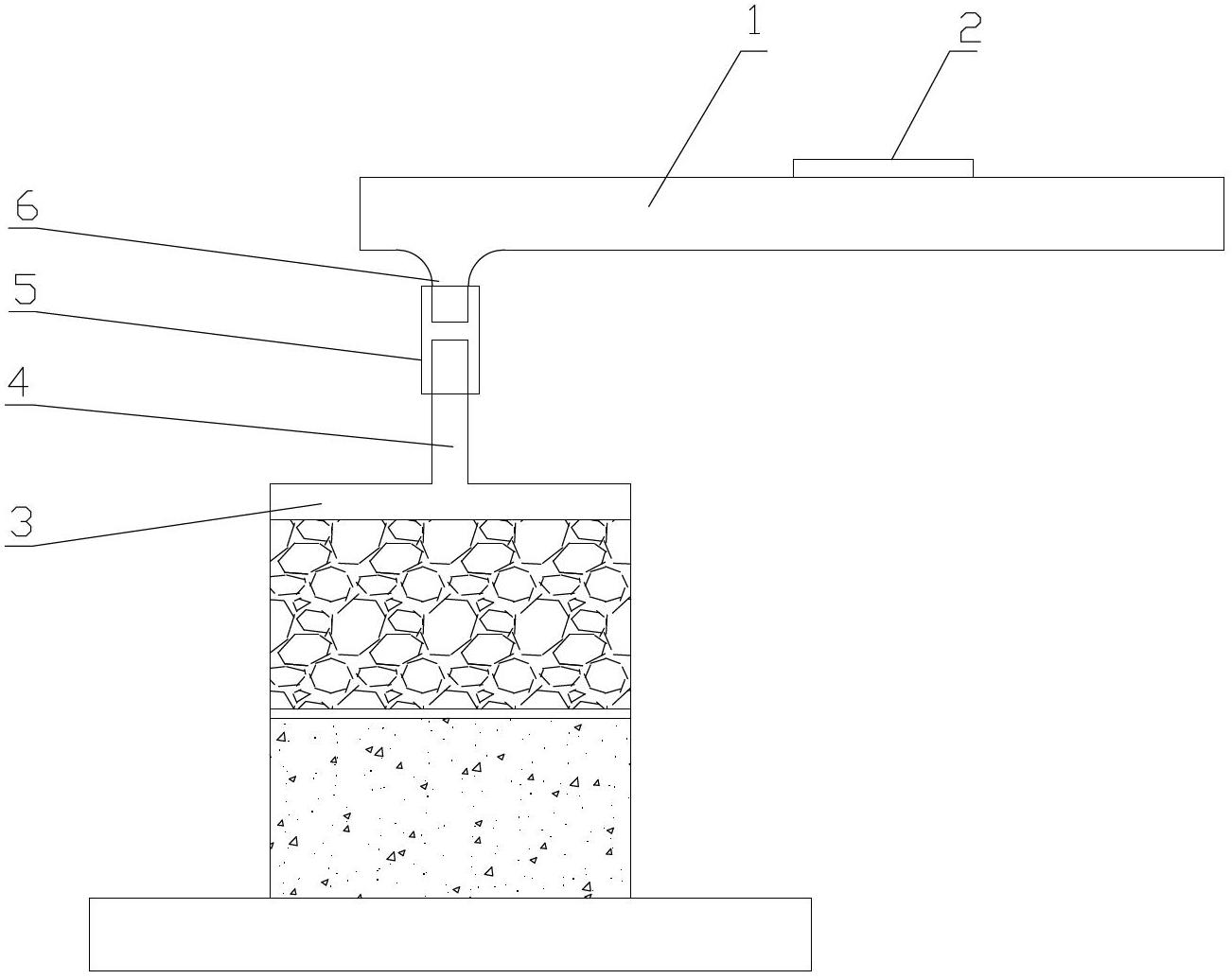

[0027] see figure 1 , The bridge deck bonding layer torsion shear device in this embodiment is composed of a torque wrench 1 , a torque measuring instrument 2 , a torsion shear head 6 , a torsion shear plate 3 , a bolt 4 , and an adapter 5 .

[0028] The above-mentioned torque wrench 1 selects a conventional manual torque wrench 1, and a hexagonal torsion shear head 6 that is perpendicular to the torque wrench 1 is installed at one end of the torque wrench 1, and the torque measuring instrument 2 is installed on the torque wrench 1 and can sense the change of torque, It is displayed in digital form. The lower end of the torsion shear head 6 is connected to the upper end of the hexagonal bolt 4 through the adapter 5, and the other end of the bolt 4 is welded to the center of the torsion shear plate 3. The torsion shear plate 3 is in the shape of a disc, and the bottom surface is flat, which is connected with the torque wrench. The center plane of 1 is parallel, and it is bonde...

Embodiment 2

[0041] In the bridge deck bonding layer torsion shear device of this embodiment, the torsion shear plate 3 is a square structure with a side length of 100 mm, the connecting end of the bolt 4 and the adapter 5 is processed into a square structure, and the lower end of the torsion shear head 6 is connected to the rotating The end connected by the joint 5 is also processed into a square structure. The adapter 5 fastens the torsion shear head 6 and the bolt 4, and the torsion shear disc 3 will not rotate when the torsion shear wrench is rotated. Other components and their connection relationships are the same as those in Embodiment 1.

[0042] The method for testing the shear resistance of the adhesive layer of the test piece using this device is the same as that in Example 1.

Embodiment 3

[0044] In the bridge deck bonding layer torsion shear device of this embodiment, the torsion shear head 6 and the adapter 5 are welded into an integral structure, and the torsion shear plate 3 is a rectangular structure with an area larger than that of the drill core. Other components and their connection relationships and implementation Example 1 is the same.

[0045] The method for testing the shear resistance of the adhesive layer of the test piece using this device is the same as that in Example 1.

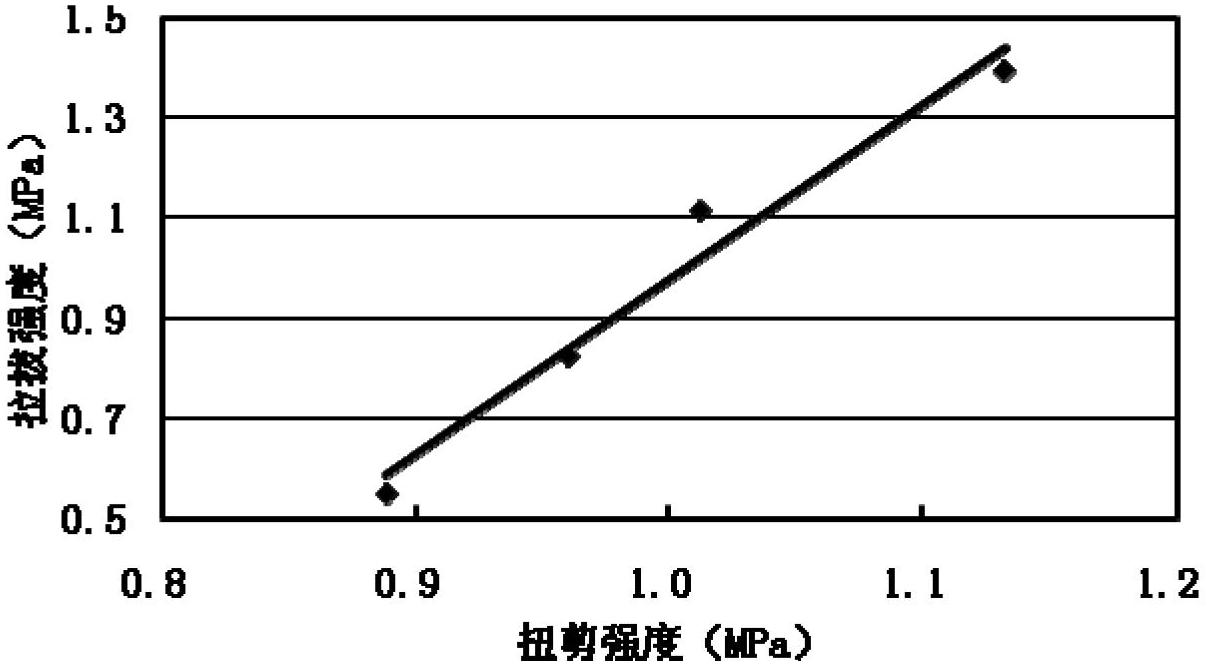

[0046] The technical scheme of the present invention is further verified by the torsion shear instrument and the shear resistance detection method in Example 1 below, and the results are as follows:

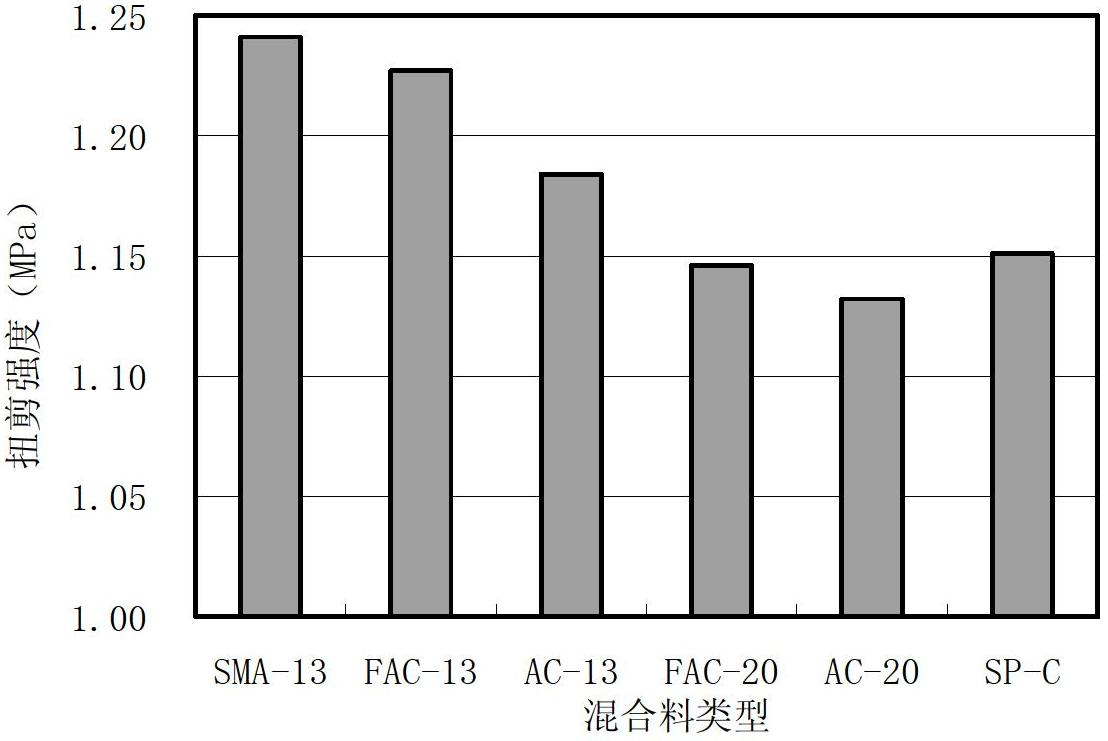

[0047] 1. Detection of different mixture specimens

[0048] Using the detection method in the above-mentioned Example 1, six kinds of mixed material test pieces including SMA-13, FAC-13, AC-13, FAC-20, AC-20 and SP-C were used for torsion shear test. The test data are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com