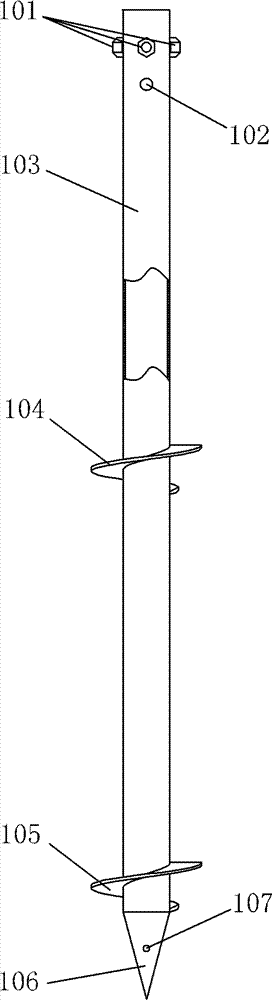

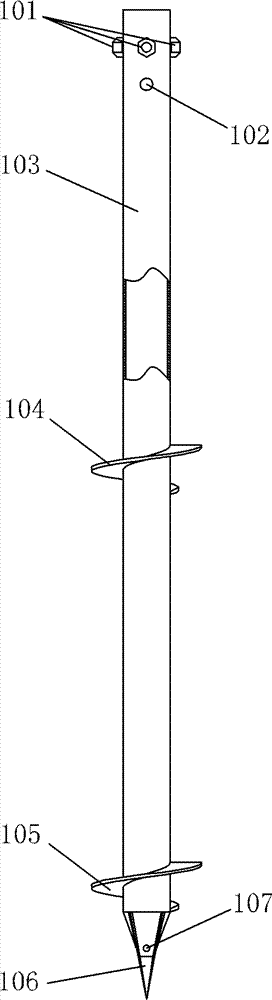

Automatic nut welding equipment for spiral pile production

A spiral ground pile and automatic welding technology, applied in welding equipment, high-frequency current welding equipment, metal processing equipment, etc., can solve the problems of poor product quality consistency, high labor intensity, and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as Figure 5 An automatic production line for spiral ground piles is shown, including pipe cutting equipment 200, automatic punching equipment 300, automatic nut welding equipment 400, tapered part automatic forming equipment 500, automatic Drilling equipment 600, automatic piercing welding equipment 700, the conveying device 800, pipe cutting equipment 200, automatic punching equipment 300, nut automatic welding equipment 400, pointed cone automatic forming equipment 500, automatic drilling equipment 600 and automatic The piercing welding equipment 700 is uniformly controlled by the control device.

[0045] The pipe cutting equipment 200 is an existing technology, for example, a fully automatic pipe cutting machine disclosed with the publication number CN201320636Y. The pipe cutting device 200 cuts long pipes into short pipes of required length.

[0046] The automatic punching equipment 300, such as Figure 6 As shown, eight punching presses 301 arranged side b...

Embodiment 2

[0072] An automatic production line for spiral ground piles differs from Embodiment 1 only in that the tapered portion automatic forming equipment 500 is different. Embodiment 1 adopts upsetting forming, while this embodiment adopts spinning forming, and other equipment is the same as Embodiment 1.

[0073] Such as Figure 24 , Figure 25 The shown automatic forming equipment for the sharp cone part includes eight tapered pipe machines 511 distributed side by side, and a frame G513 is set on the feeding side of the eight tapered pipe machines 511, and eight feeding manipulators are arranged on the frame G513 G514, a feeding device G512 and a discharging device G515; the eight feeding manipulators G514 are set in one-to-one correspondence with the plurality of tapered tube machines 511. The structure and setting of the feeding device G512 are the same as the feeding device A302 in the automatic punching equipment 300 described in Embodiment 1, and the structure and setting of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com