Combined clamp for welding sleeve and reinforcing pin on welding shoe panel

A welding sleeve and combined fixture technology, applied in welding equipment, manufacturing tools, non-electric welding equipment and other directions, can solve the problems of difficult to guarantee processing accuracy, difficult to grasp the welding position, and many processing and manufacturing procedures, and achieve high welding processing accuracy. , The effect of saving manpower and material resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

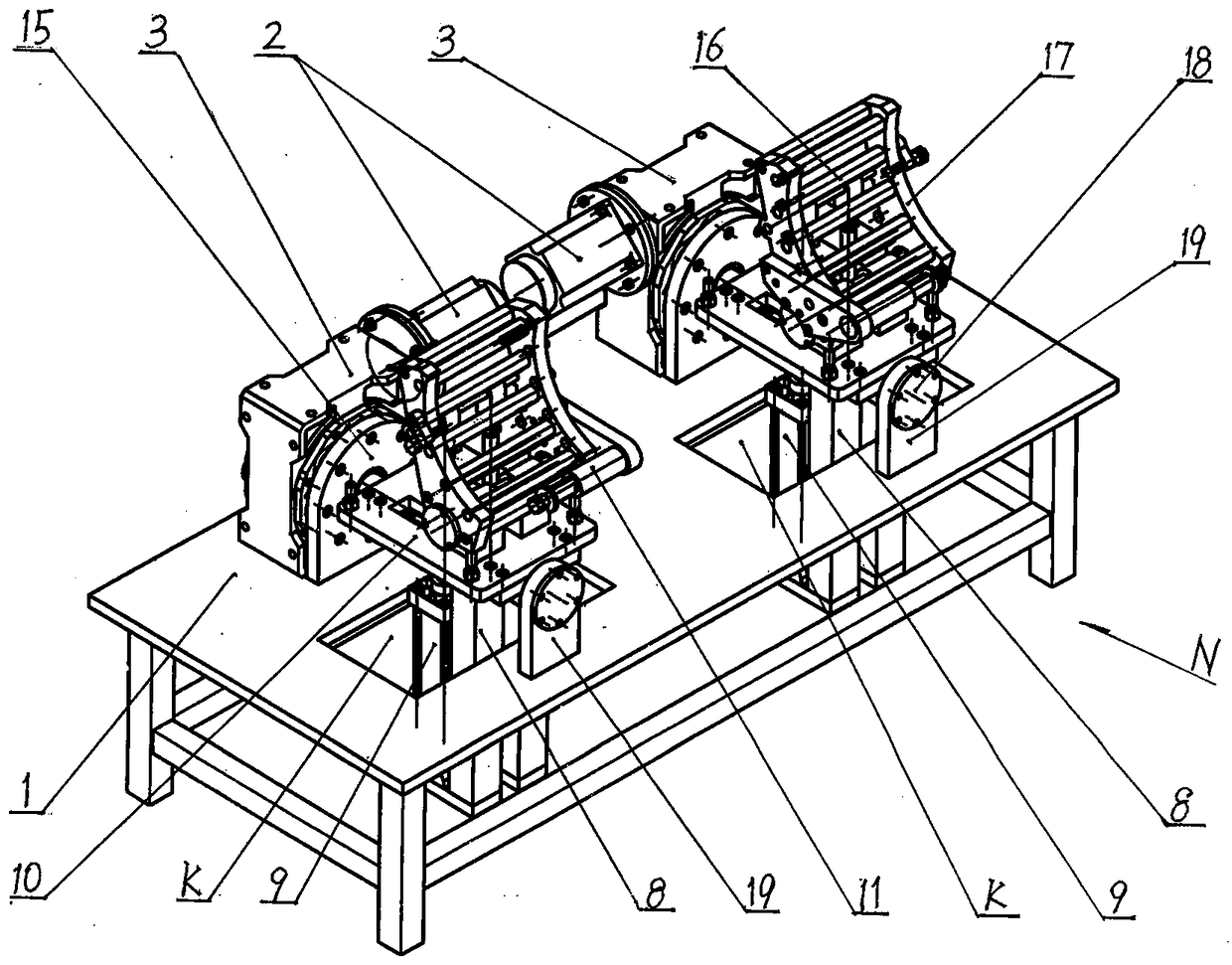

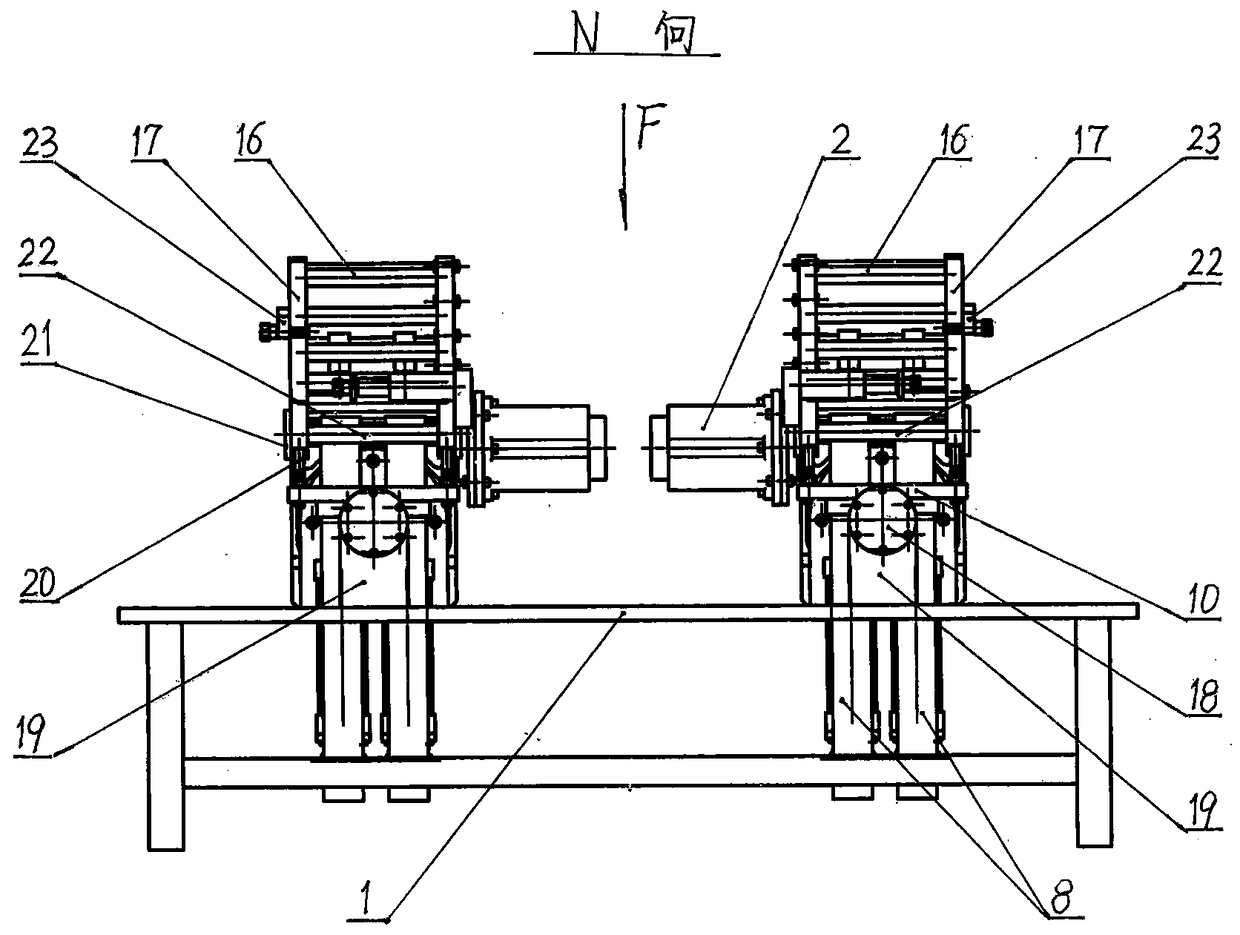

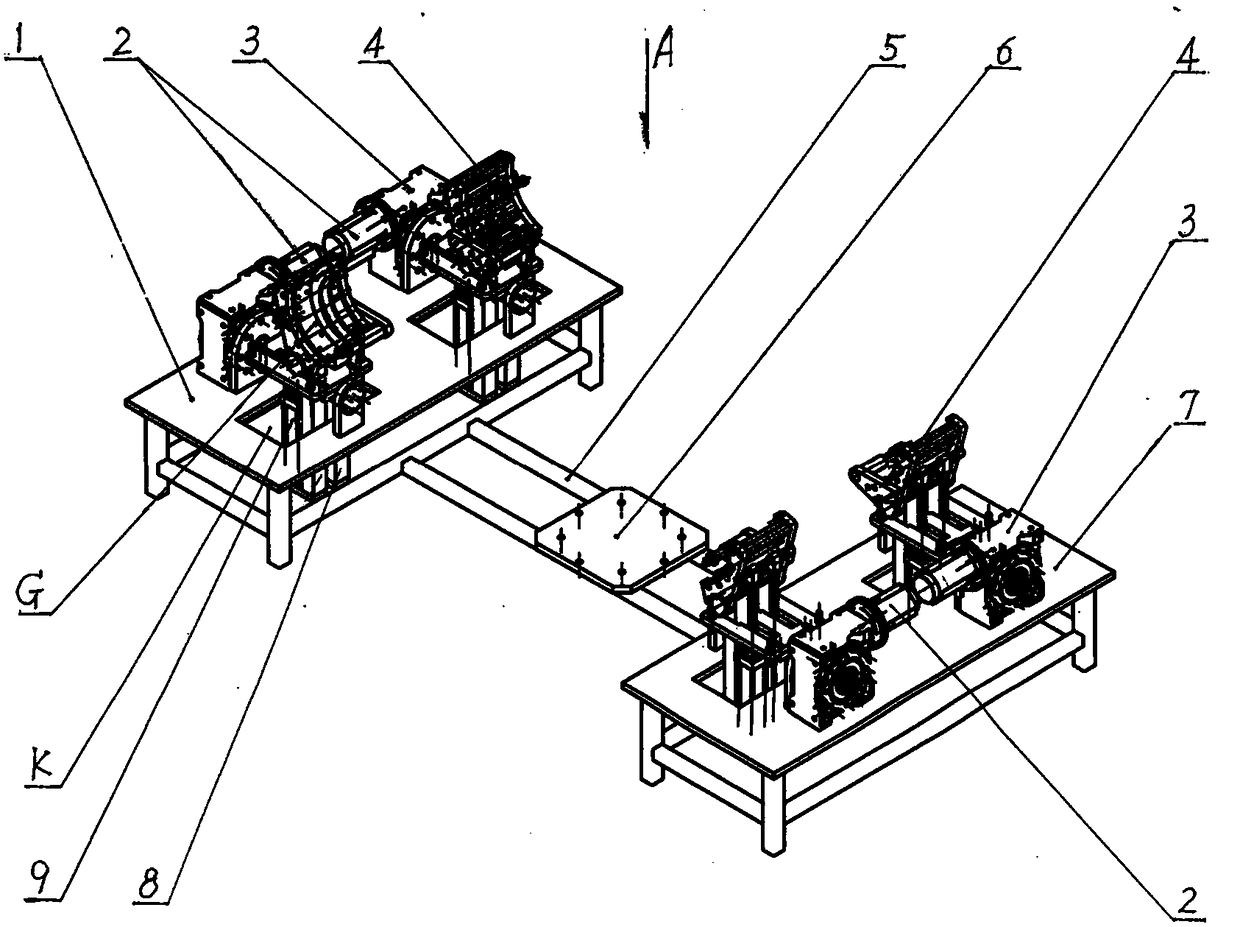

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] refer to figure 1 , figure 2 , image 3 , the present invention is composed of frame, clamp body 4, reducer 3, numerical control motor 2, longitudinal axis 14, horizontal axis 22, cylinder 9, cylinder frame 8, and is matched with welding equipment, controlled by electric control system and pneumatic system , Automatically weld the casing T and the reinforcing pin J to the panel M of the stamping and welding shoe. The frame includes a left frame 1 and a right frame 7, the middle is connected by a beam 5, a welding robot is set on the welding equipment mounting seat 6 in the middle of the beam 5, and two sets of clamps are respectively installed on the left frame 1 and the right frame 7. Seat 10, clamp body 4 is installed on the clamp body mounting base 10, reducer 3 and numerical control motor 2 are horizontally fixed on the left f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com