Improved laser annealing device

A technology of laser annealing and equipment, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of affecting the passage of laser beam 30 and increase the cost, and achieve the effect of reducing replacement and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

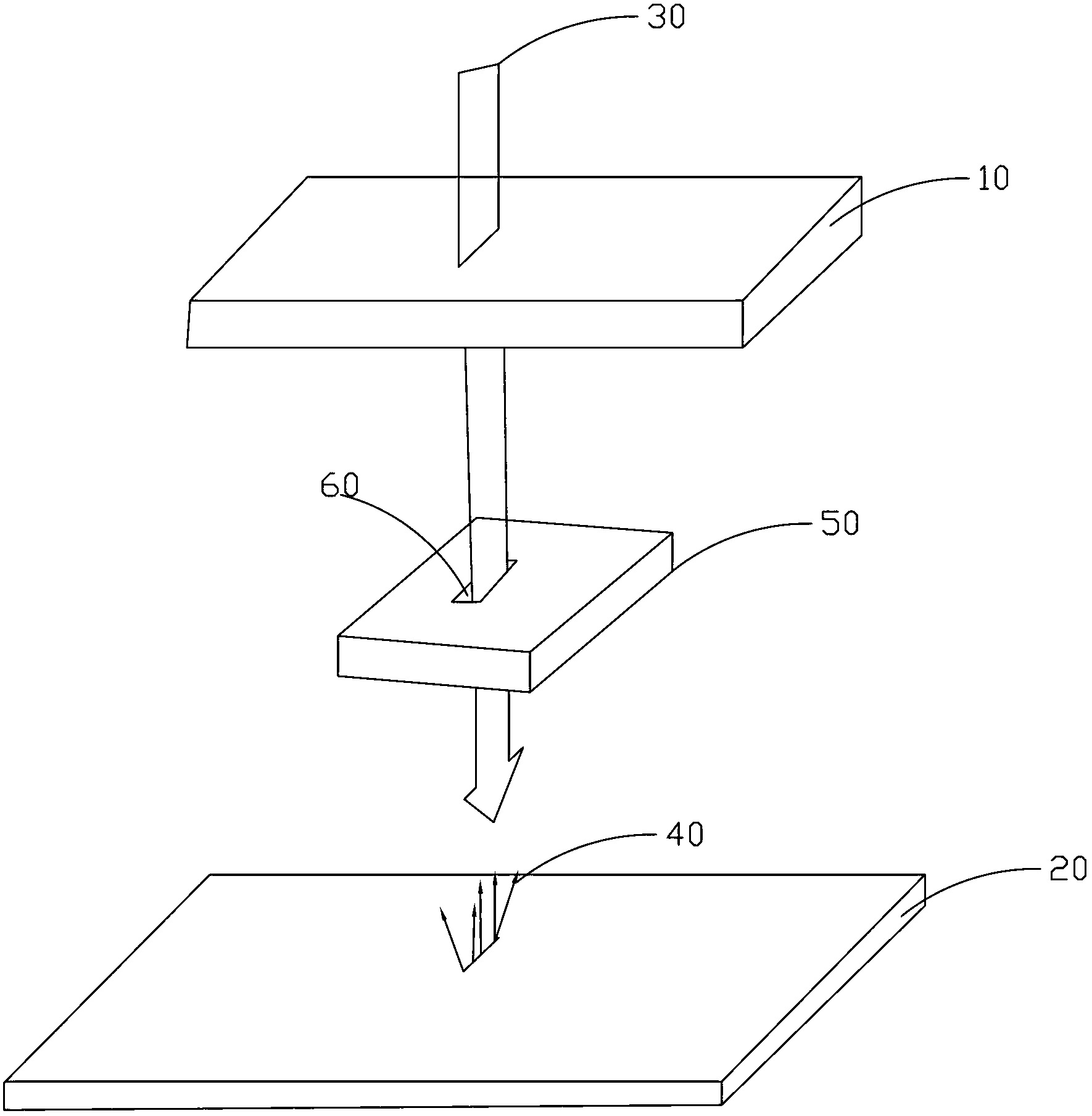

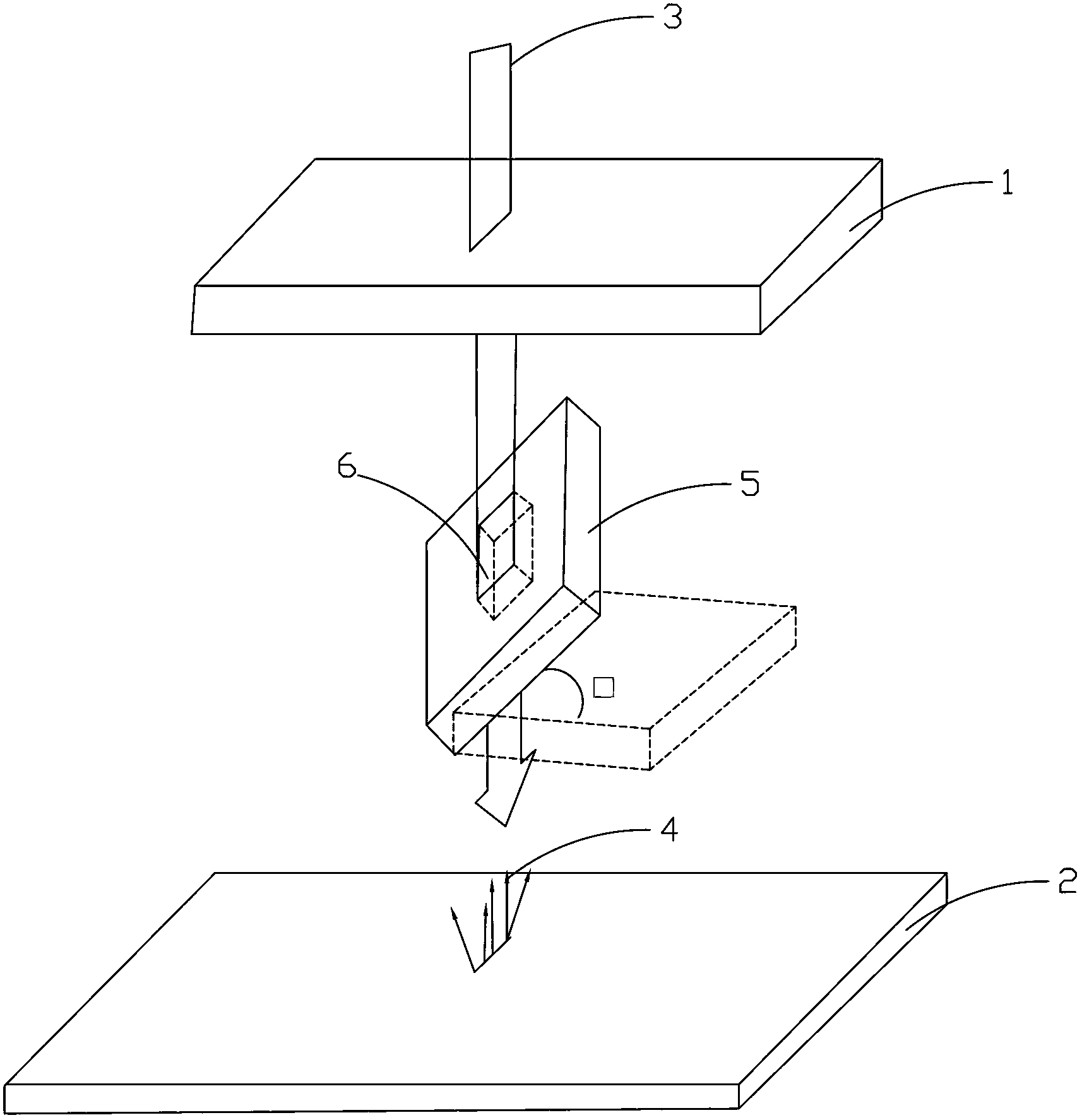

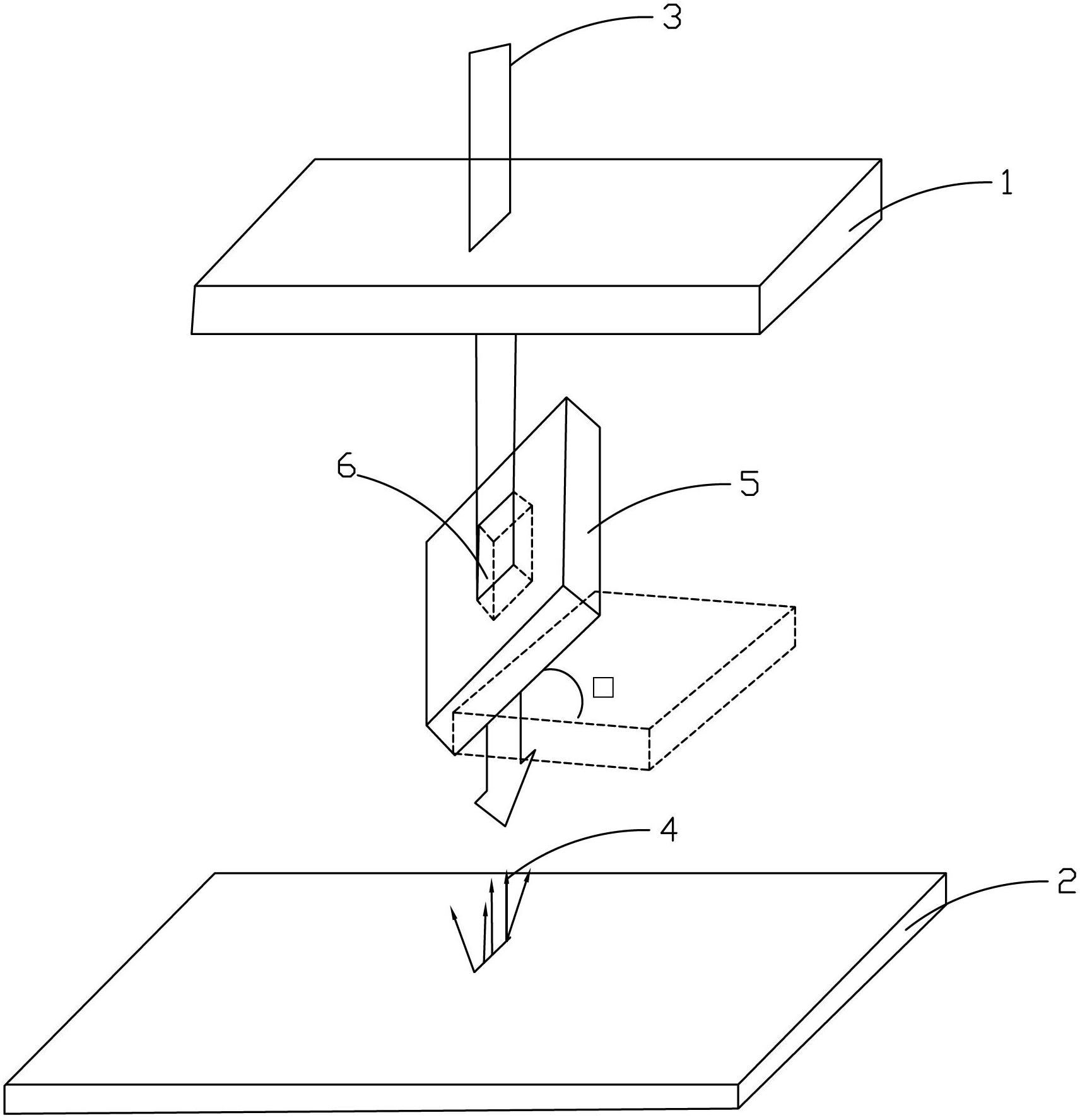

[0022] see figure 2 , which is a structural schematic diagram of a preferred embodiment of the improved laser annealing equipment of the present invention. The improved laser annealing equipment of the present invention comprises a laser beam 3, a casing (not shown), a laser beam output window 1 positioned at the top side of the casing, a substrate 2 positioned at the bottom side of the casing for carrying materials to be annealed, and a A movable protective block 5 between the laser beam output window 1 and the substrate 2, the protective block 5 is inclined with an inclination angle θ with respect to the horizontal direction, and in this preferred embodiment is 45° with the horizontal / vertical direction, On the one hand, it can protect the laser head, and on the other hand, it can reflect the splashed debris4. The protective block 5 is provided with a slit 6 passing through its upper and lower surfaces, and the laser beam 3 passes through the laser beam output window 1 ver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com