Ring beam support

A technology of ring beams and support seats, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex shape and large space size, and achieve the effect of simple, easy-to-obtain and low-cost materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

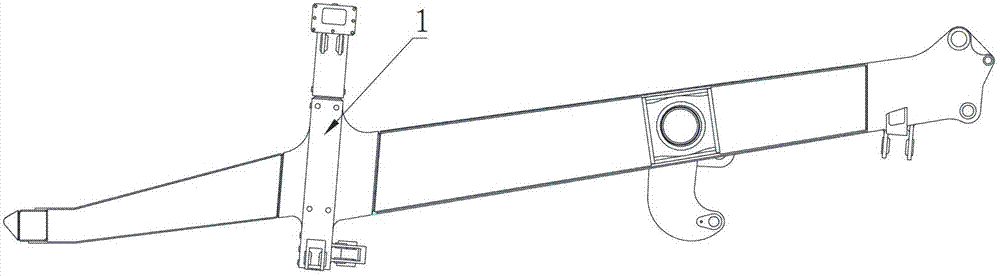

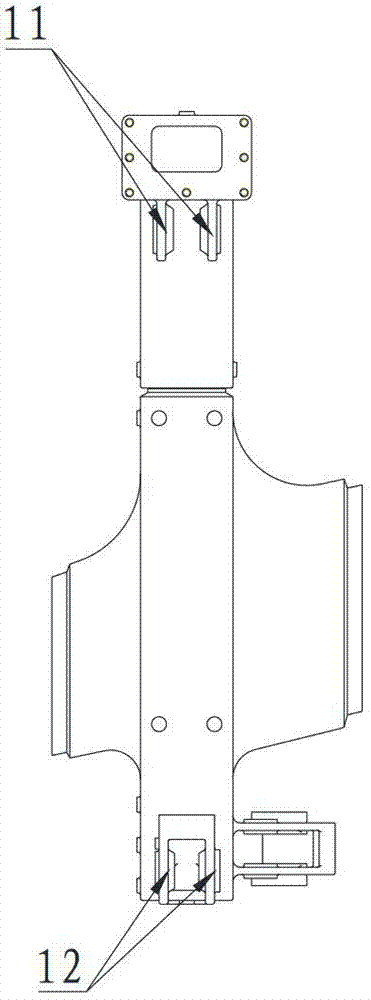

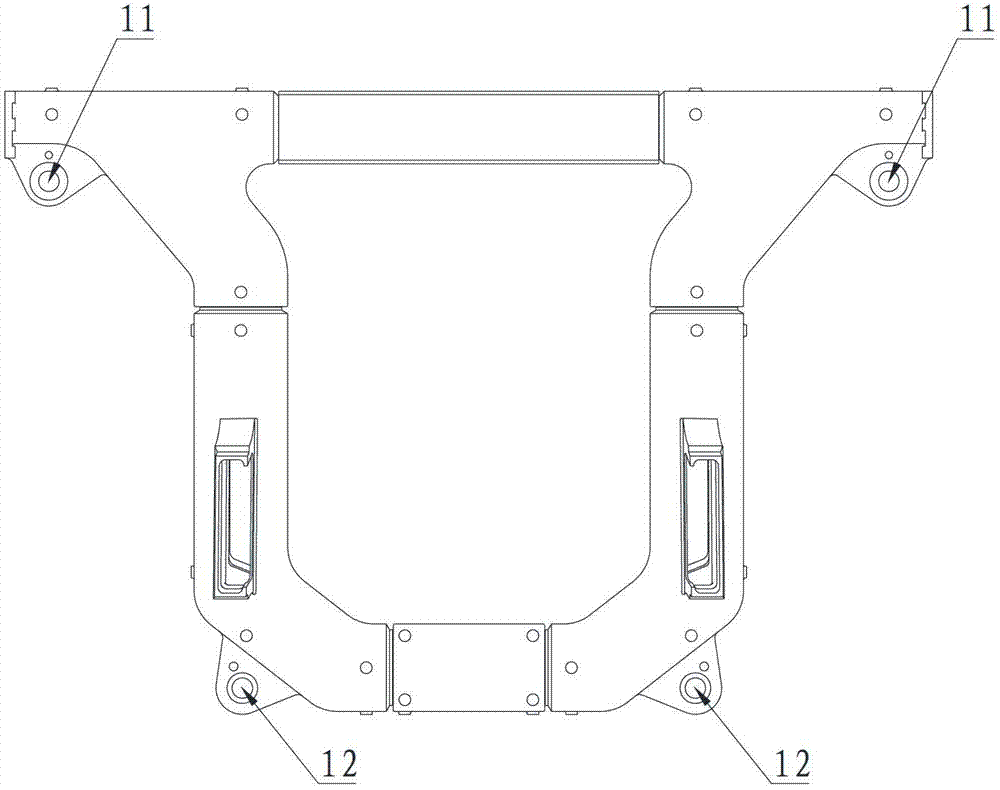

[0041] figure 1 , Figure 2A , Figure 2B It is a related drawing of the ring beam 1, as shown in the figure, the position of the ring beam 1 on the basic frame is inclined, and the whole ring beam 1 is a combined structure that is cast separately and welded together, only the The upper ear holes 11 on both sides of the upper end of the ring beam 1 and the lower ear holes 12 on both sides of the lower end have been finished and can be used as a positioning reference plane. The upper ear holes 11 and the lower ear holes 12 each include two lugs.

[0042] Figure 3A , 3B , 3C are respectively the front view, the left view and the top view of the ring beam 1 support of the present invention. ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com