Conveying roller assembly for solid tube blank loading frame

A technology for conveying rollers and tube blanks, applied in metal processing and other directions, can solve the problems of low production efficiency, inconvenient feeding and unloading, etc., and achieve the effects of simple structure, simple and fast feeding process, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

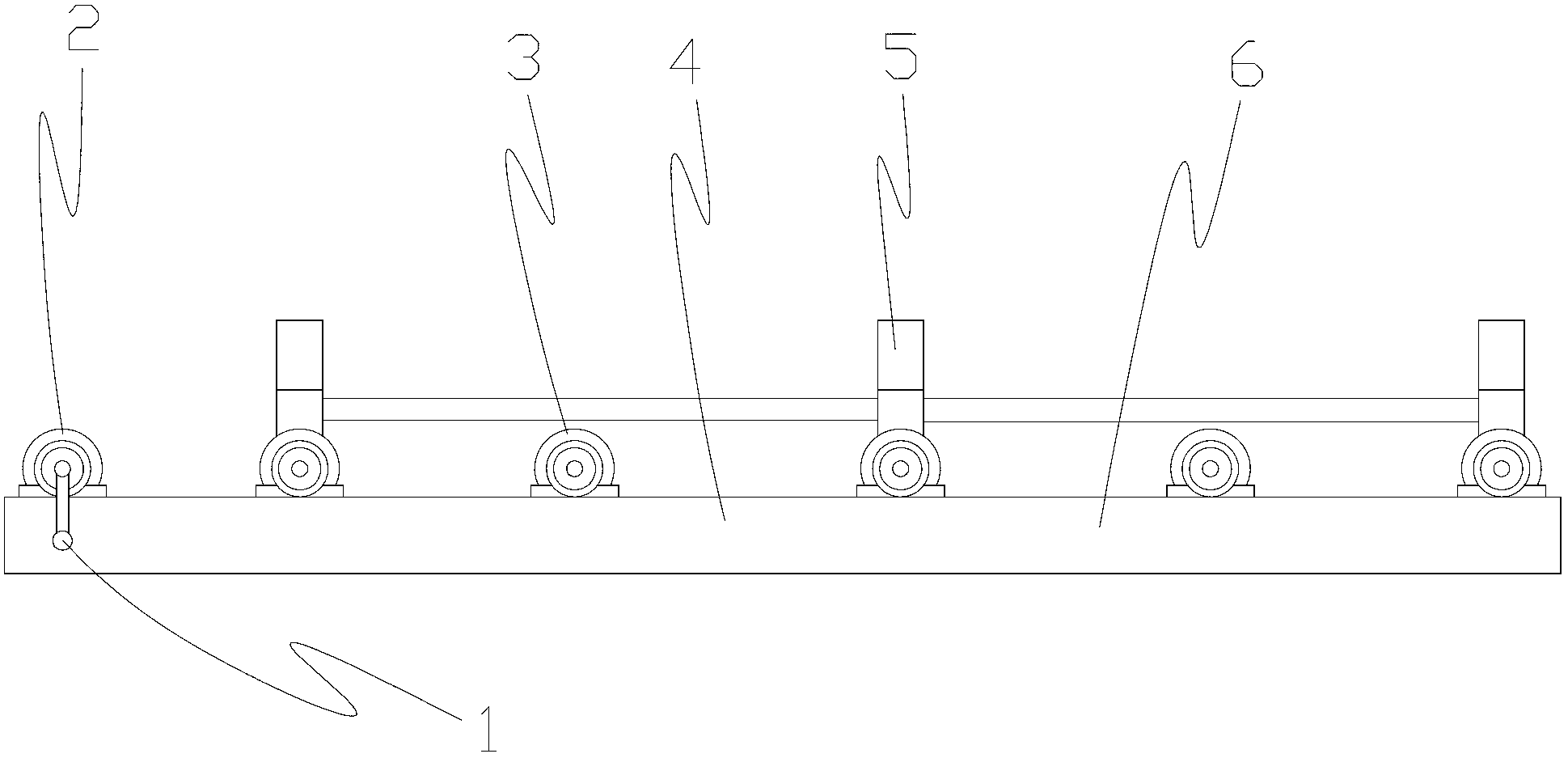

[0013] Such as figure 1 As shown, a conveying roller of a solid tube billet feeding rack includes a fixed frame 4, and a conveying roller is arranged on the upper end of the fixed frame 4. The conveying roller includes a driving roller 2 and a driven roller 3, and the outside of the driving roller 2 is connected with a hand Shake the handle 1, the inner side of the fixed frame 4 is provided with a placement frame 5, the upper surface of the placement frame 5 is higher than the conveying roller, the tube blank can be directly rolled from the placing frame 5 to the conveying roller, and then passed forward by the conveying roller For conveying, the driving roller 2 is arranged at the leftmost end of the conveying roller. When the tube blank is loa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap