Patents

Literature

50results about How to "Easy and quick loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

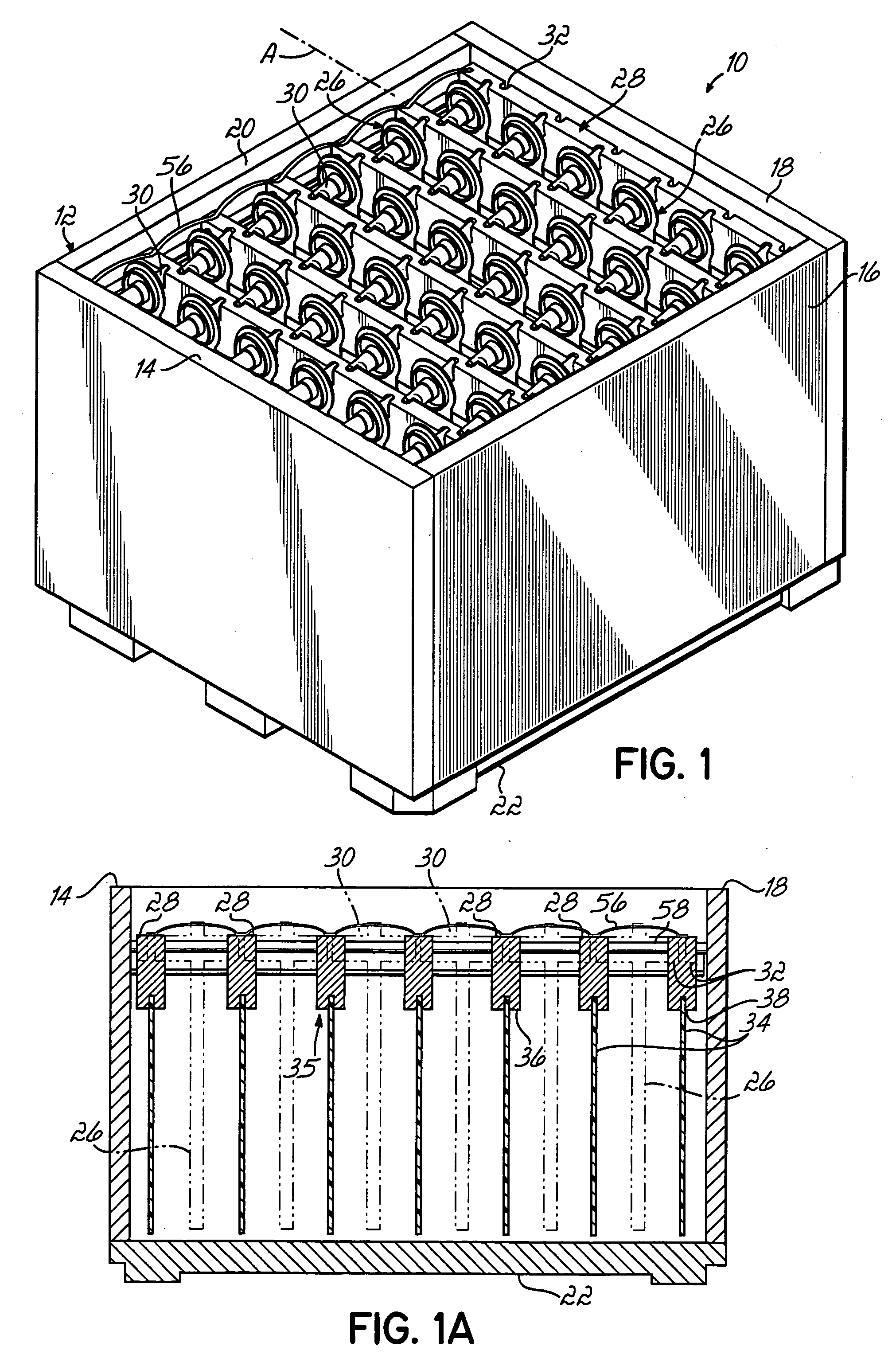

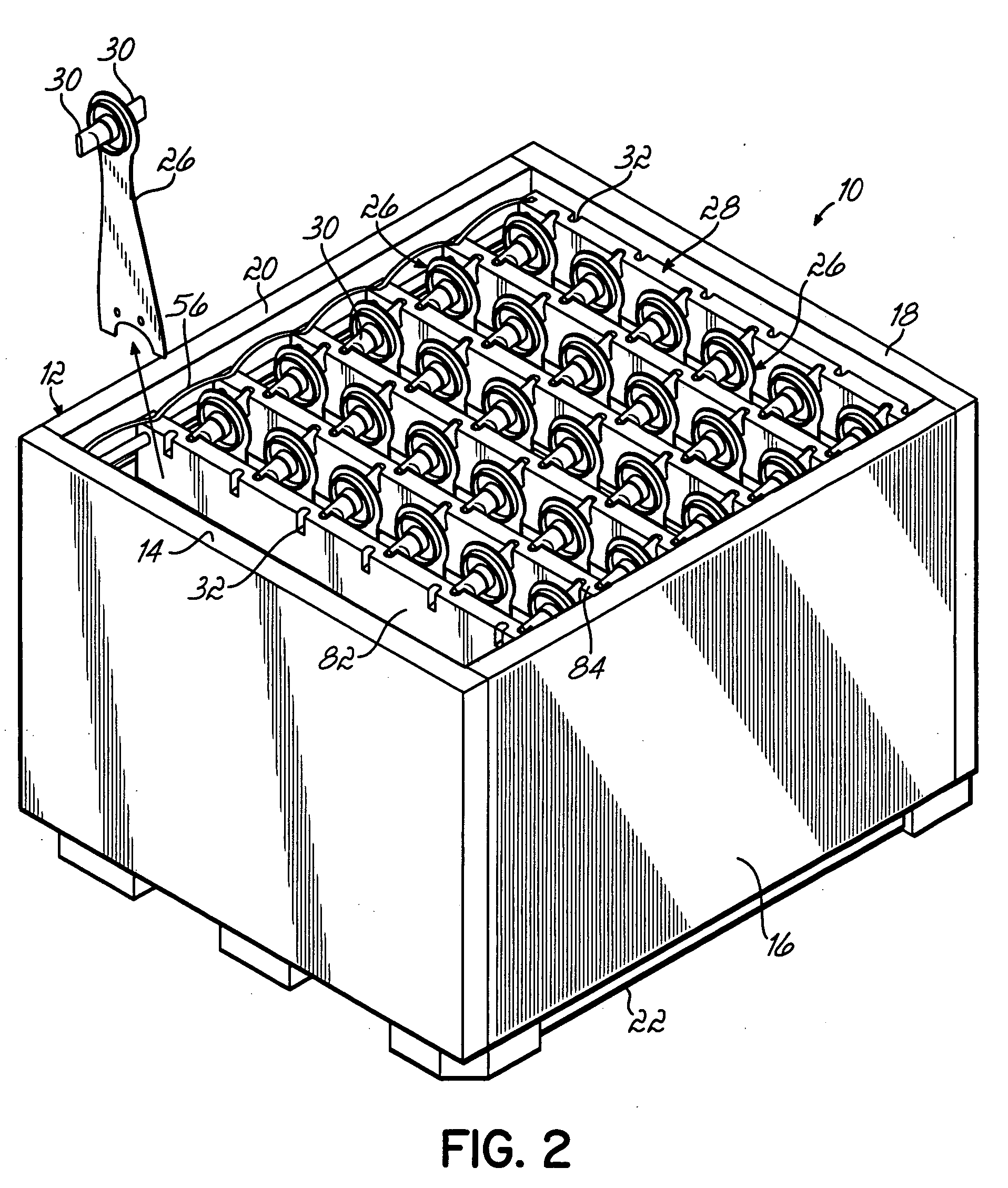

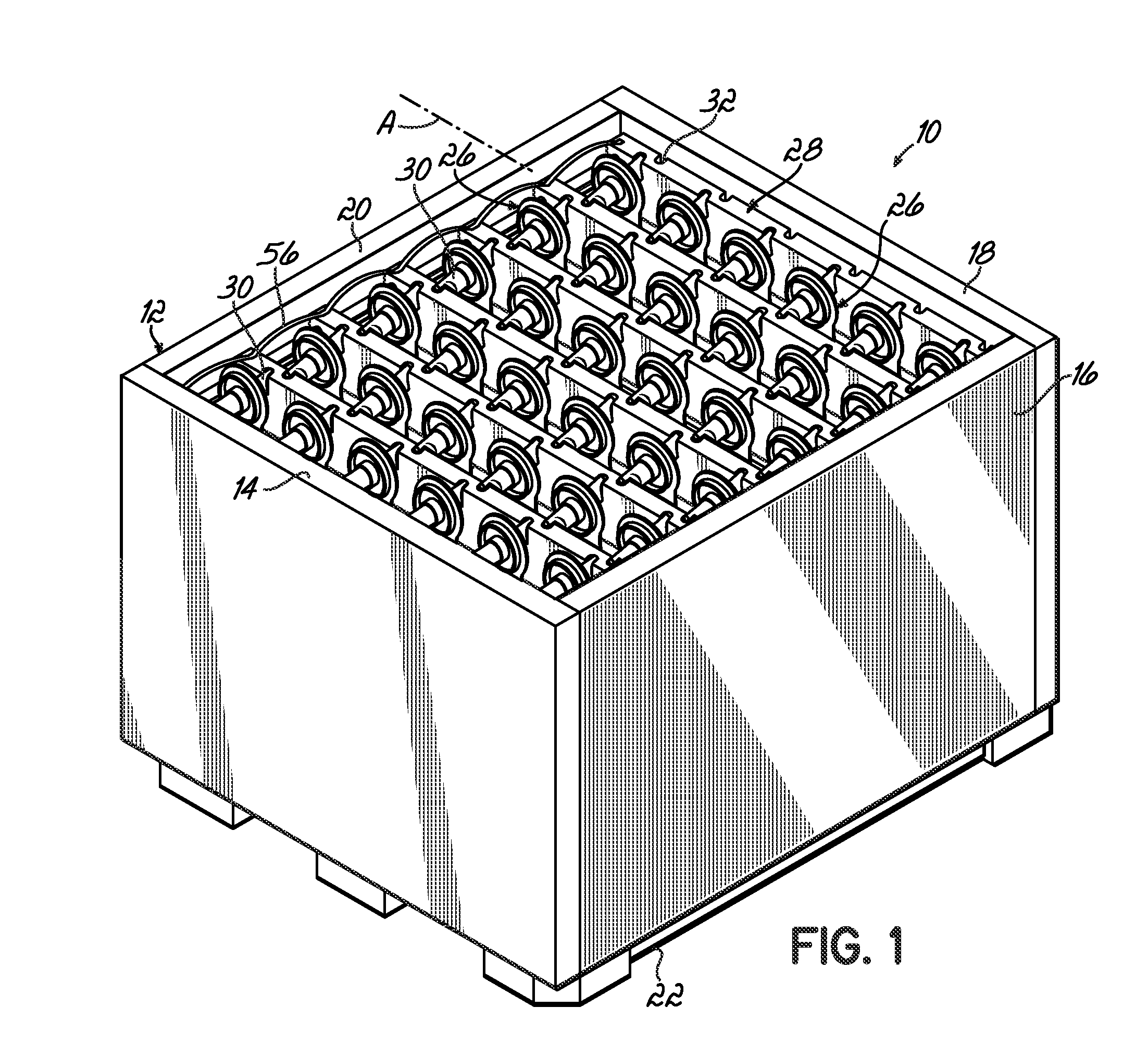

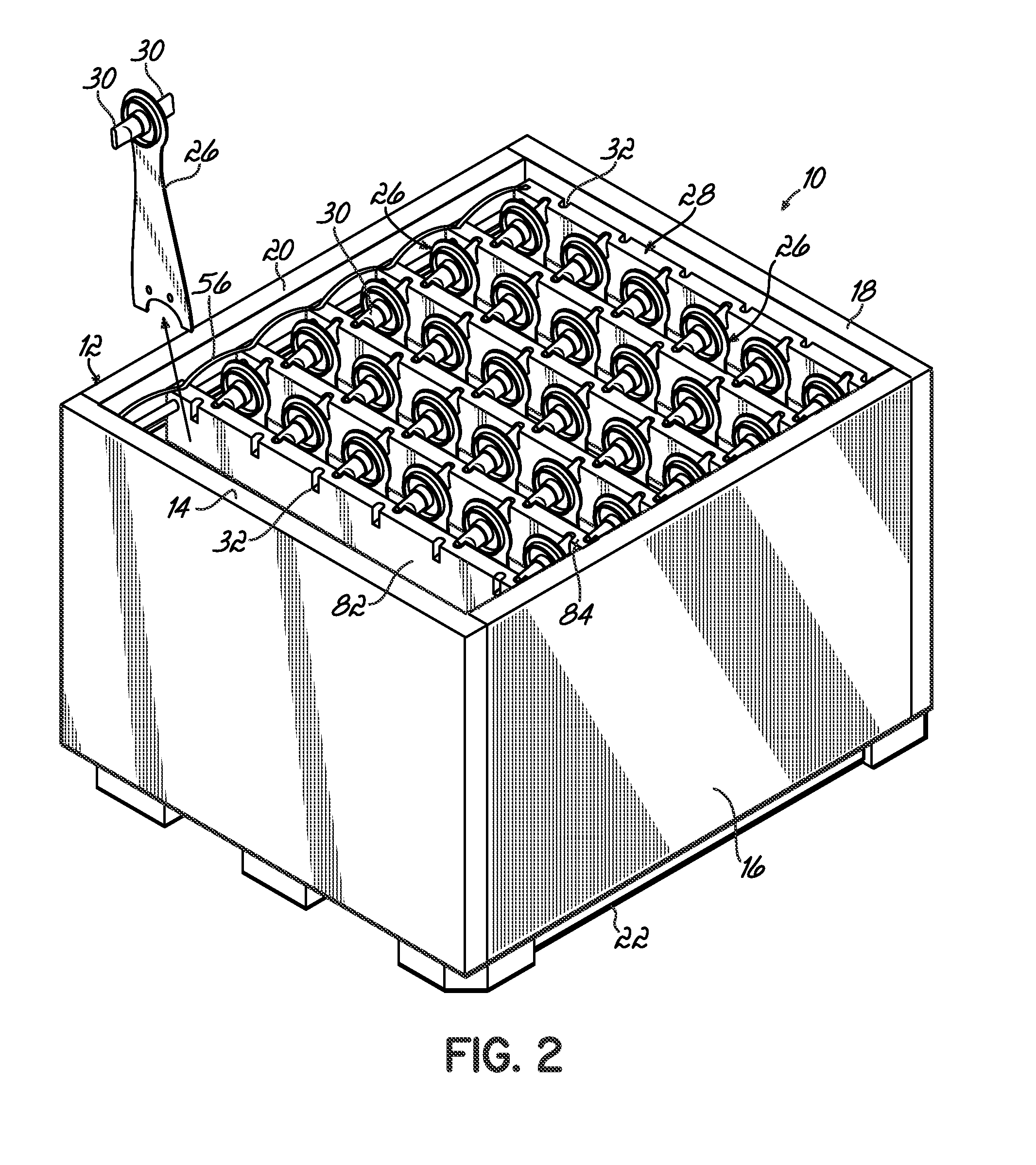

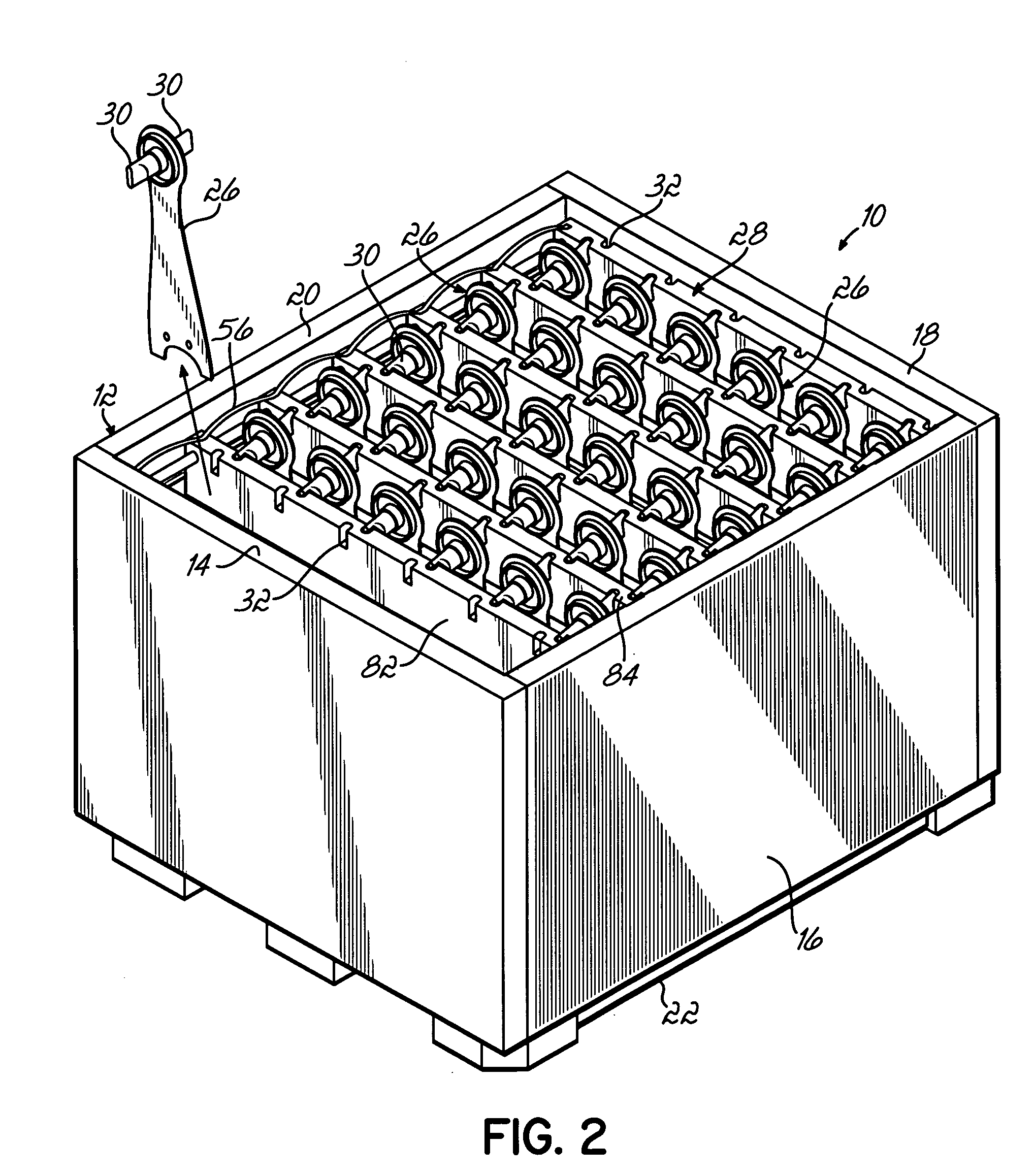

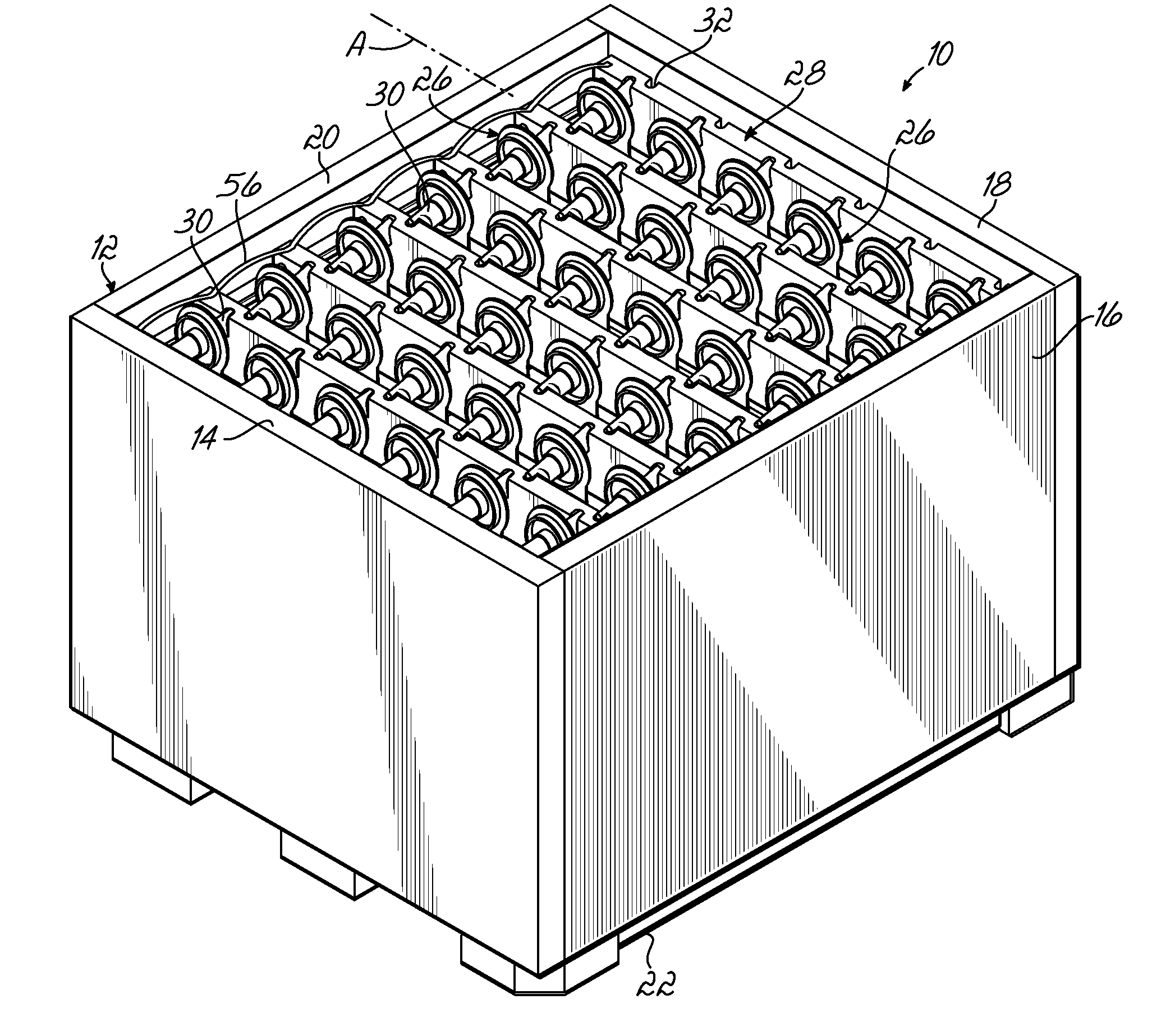

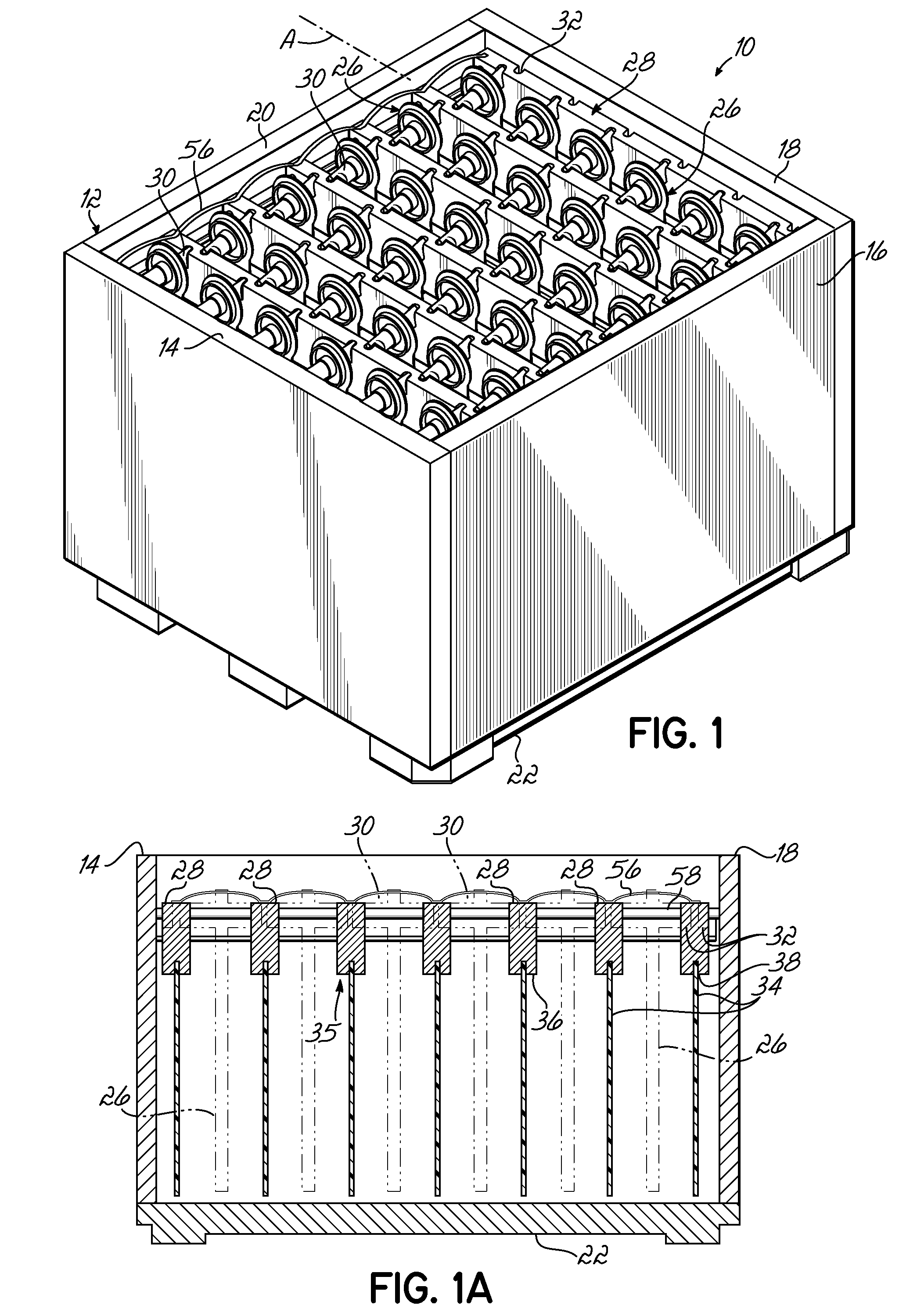

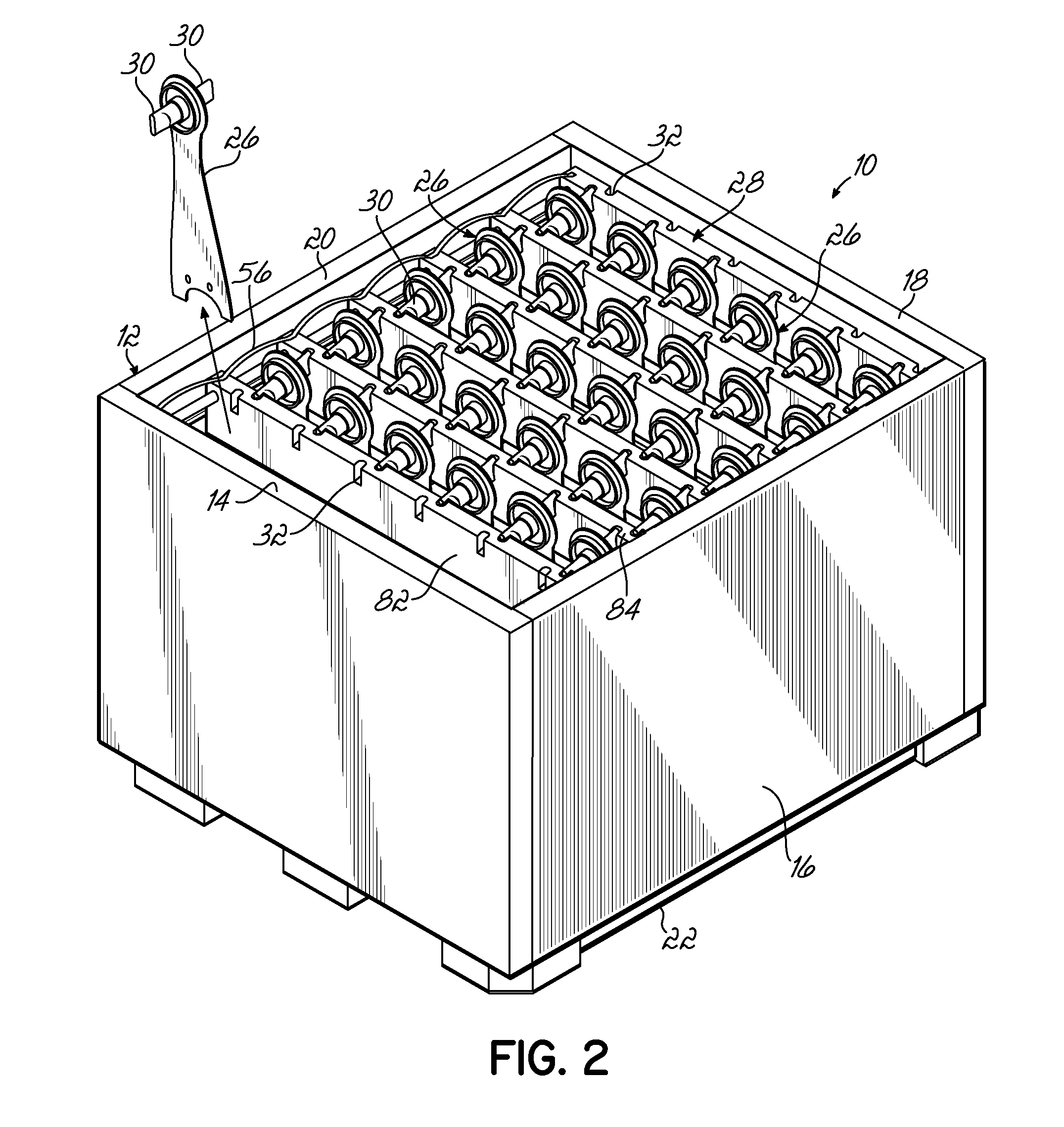

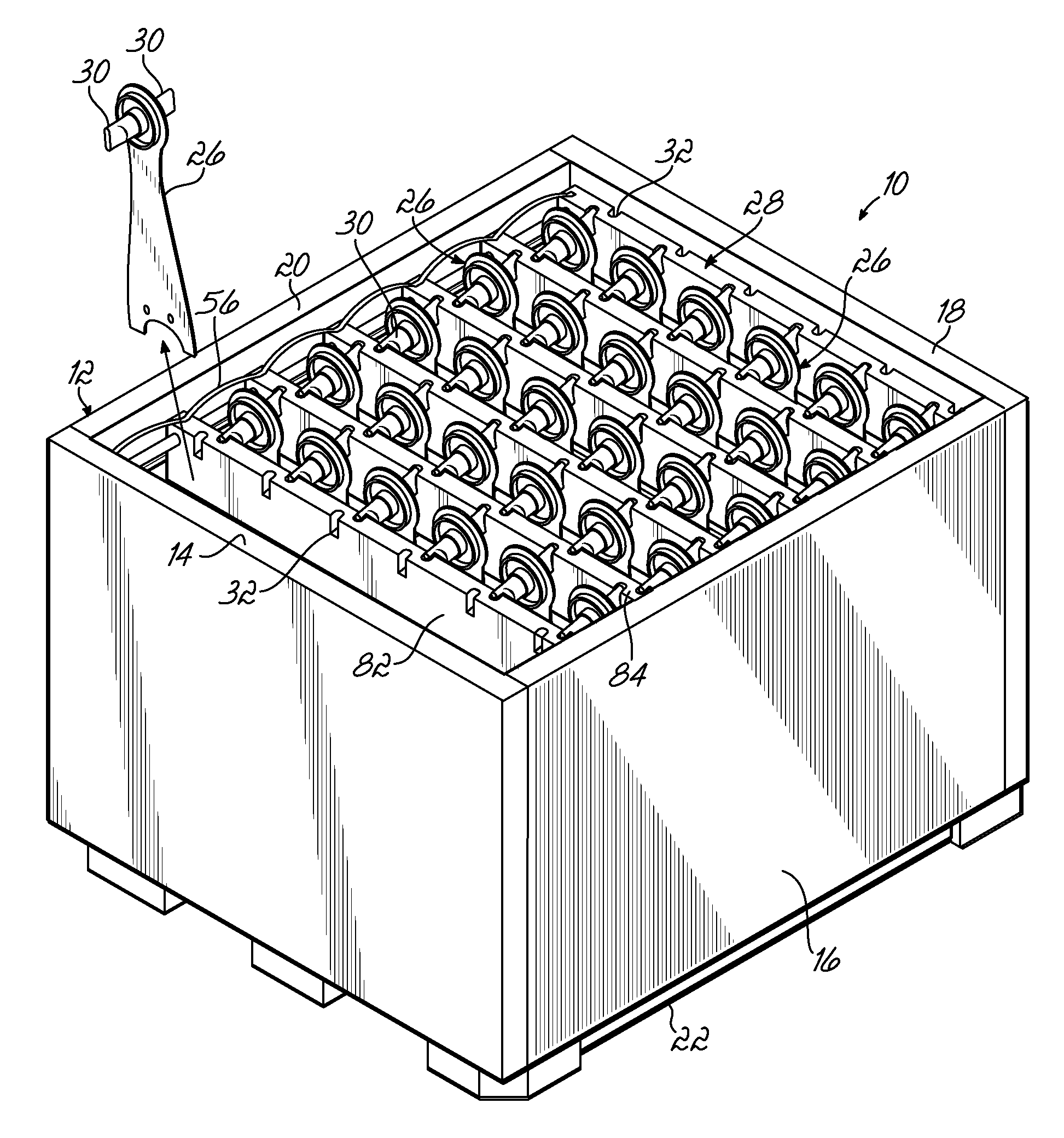

Container having non-linear support members for supporting dunnage

A container for holding product therein during shipment and being returned for reuse that has a body, tracks supported by the body, and a plurality of support member assemblies, each having a pair of end members engaged with and moveable along the tracks and a non-linear support member extending between and connected to the end members. The support member assemblies support dunnage for supporting products for storage or shipment.

Owner:BRADFORD CO

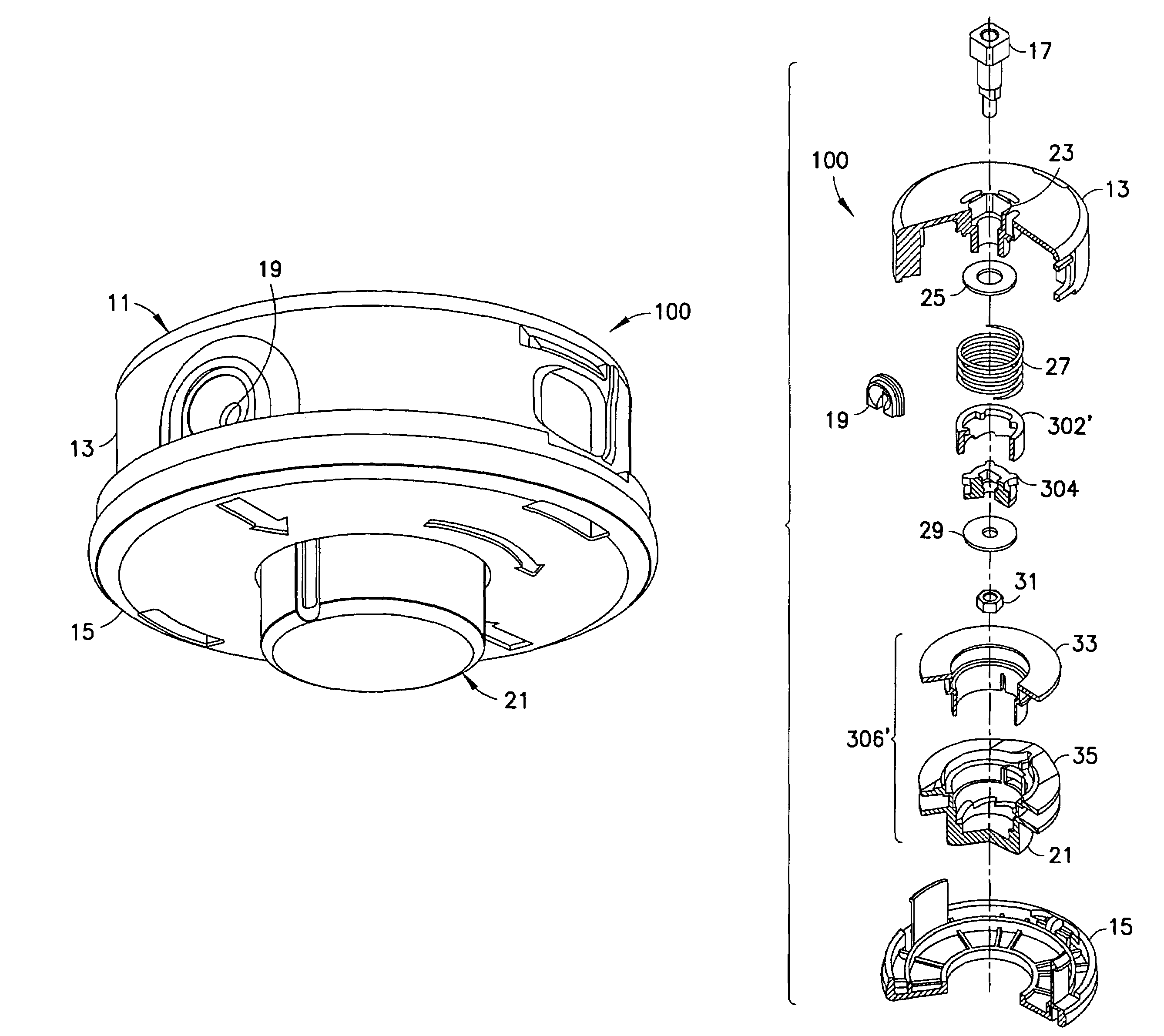

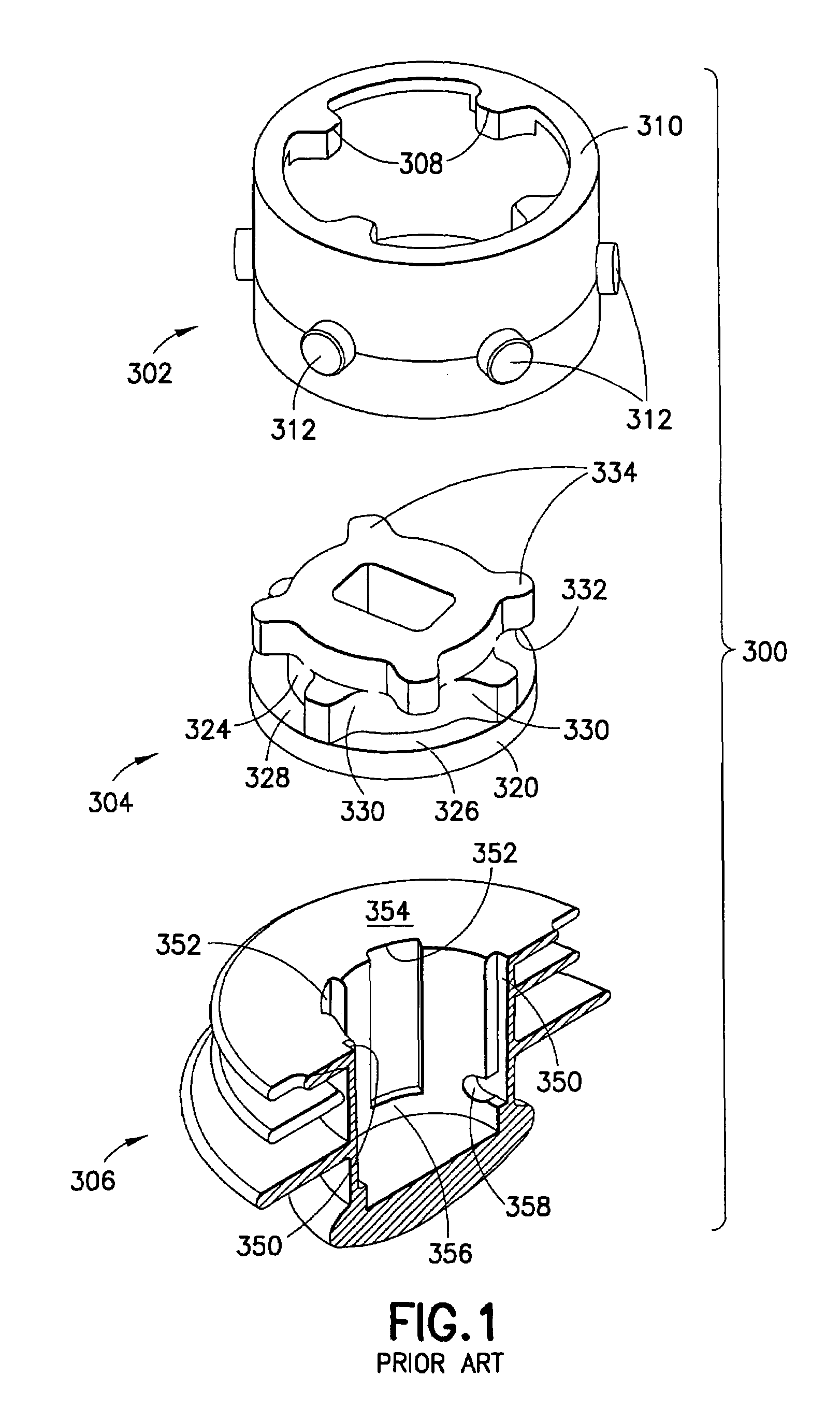

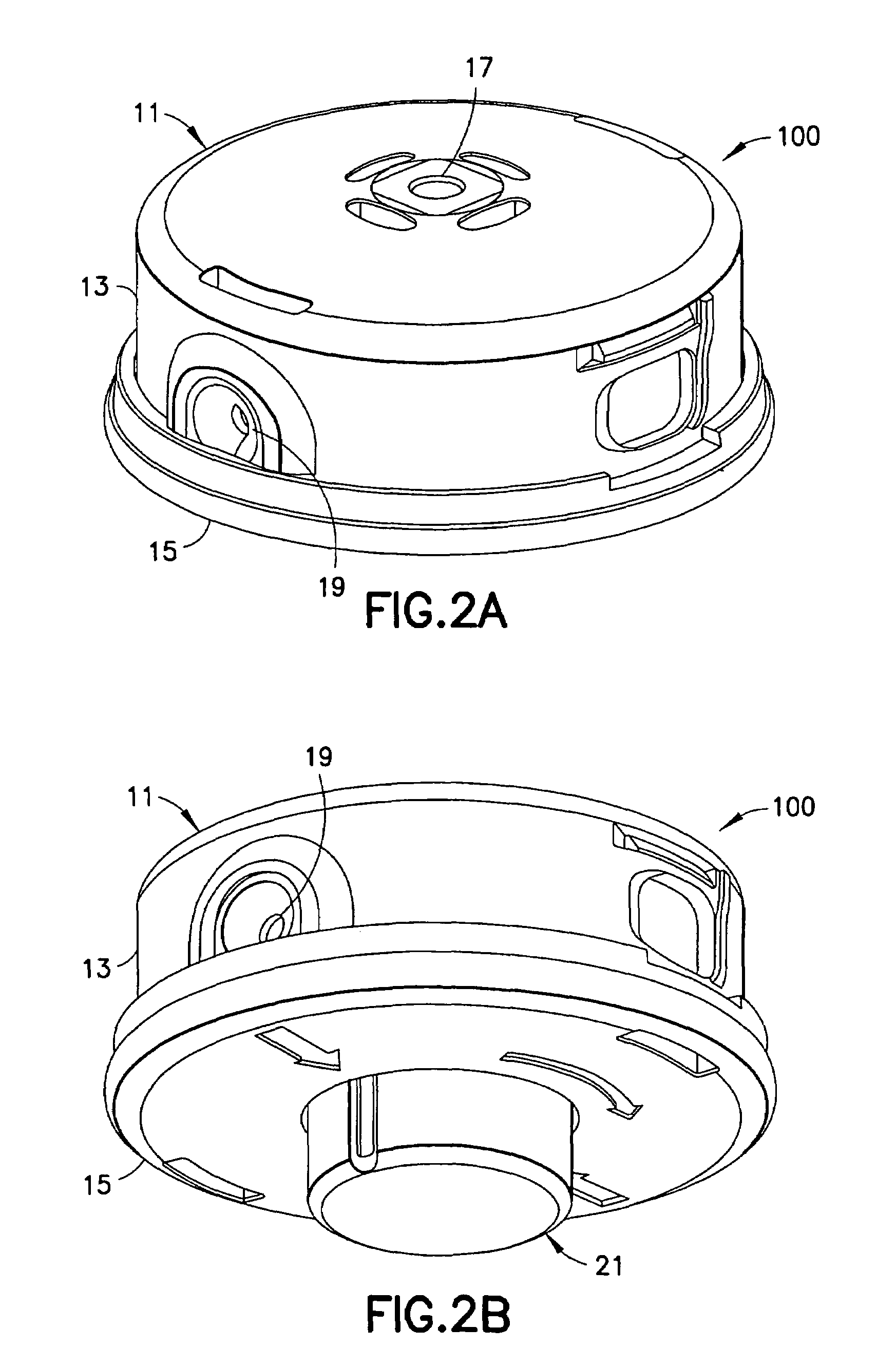

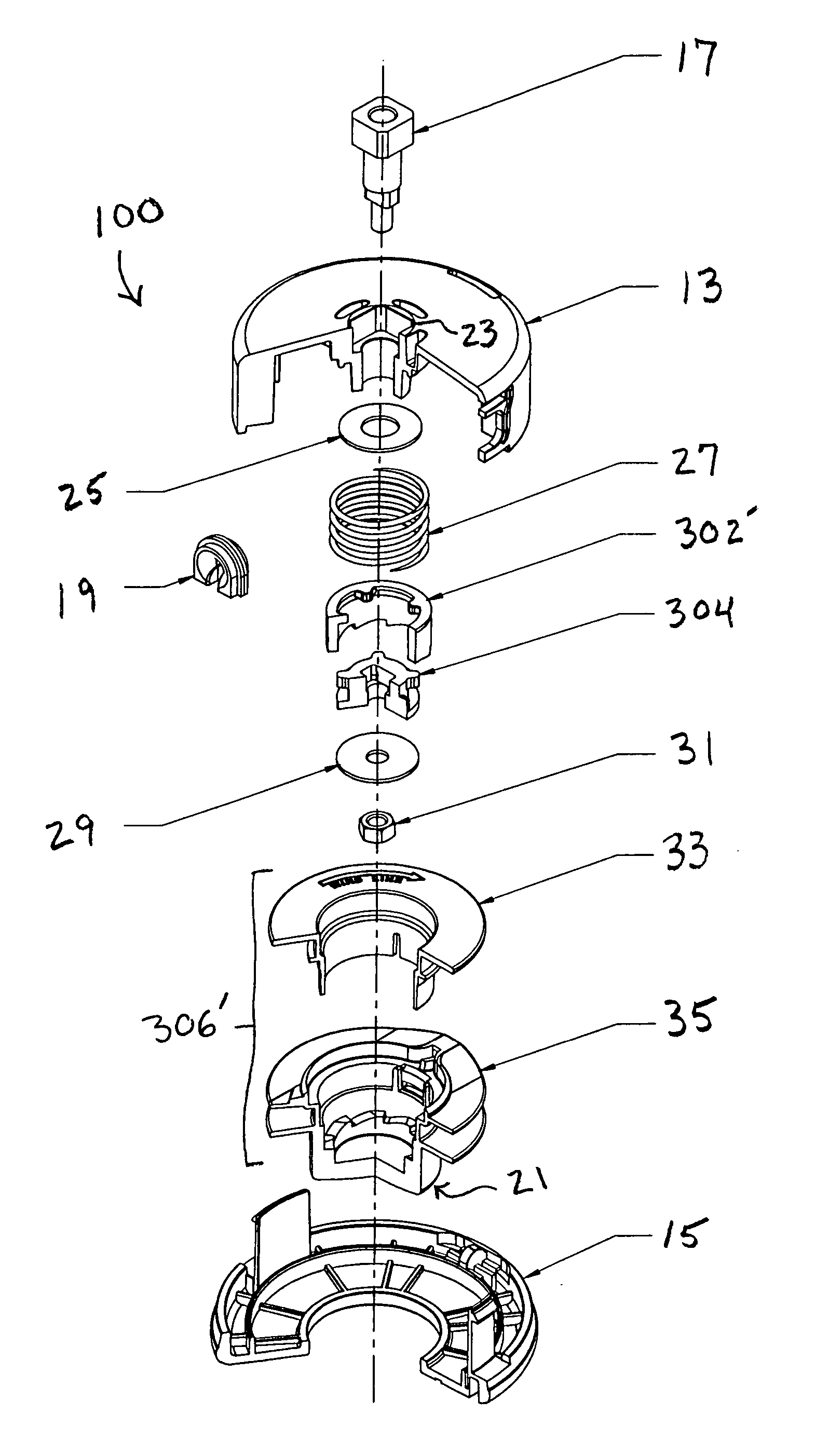

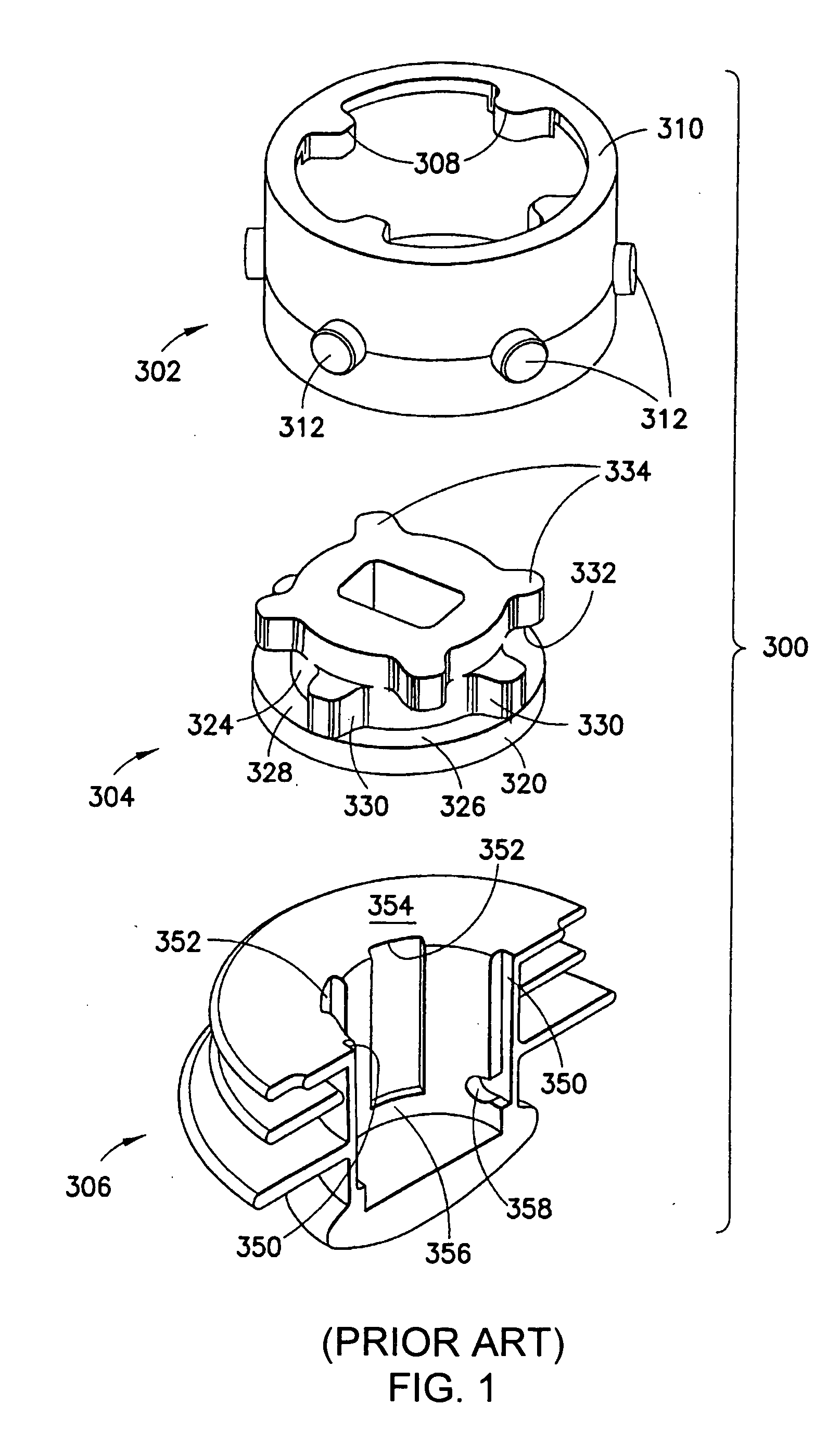

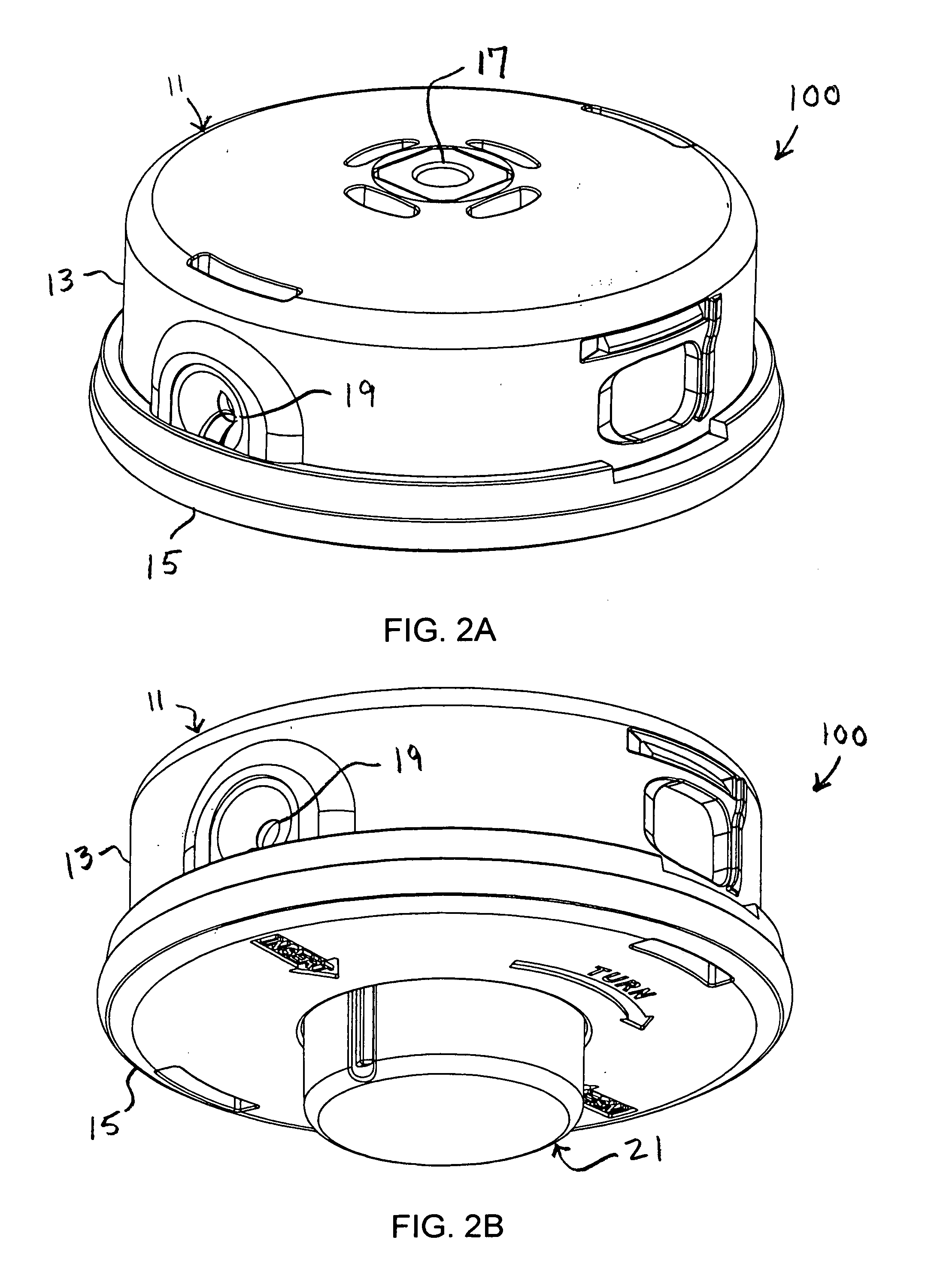

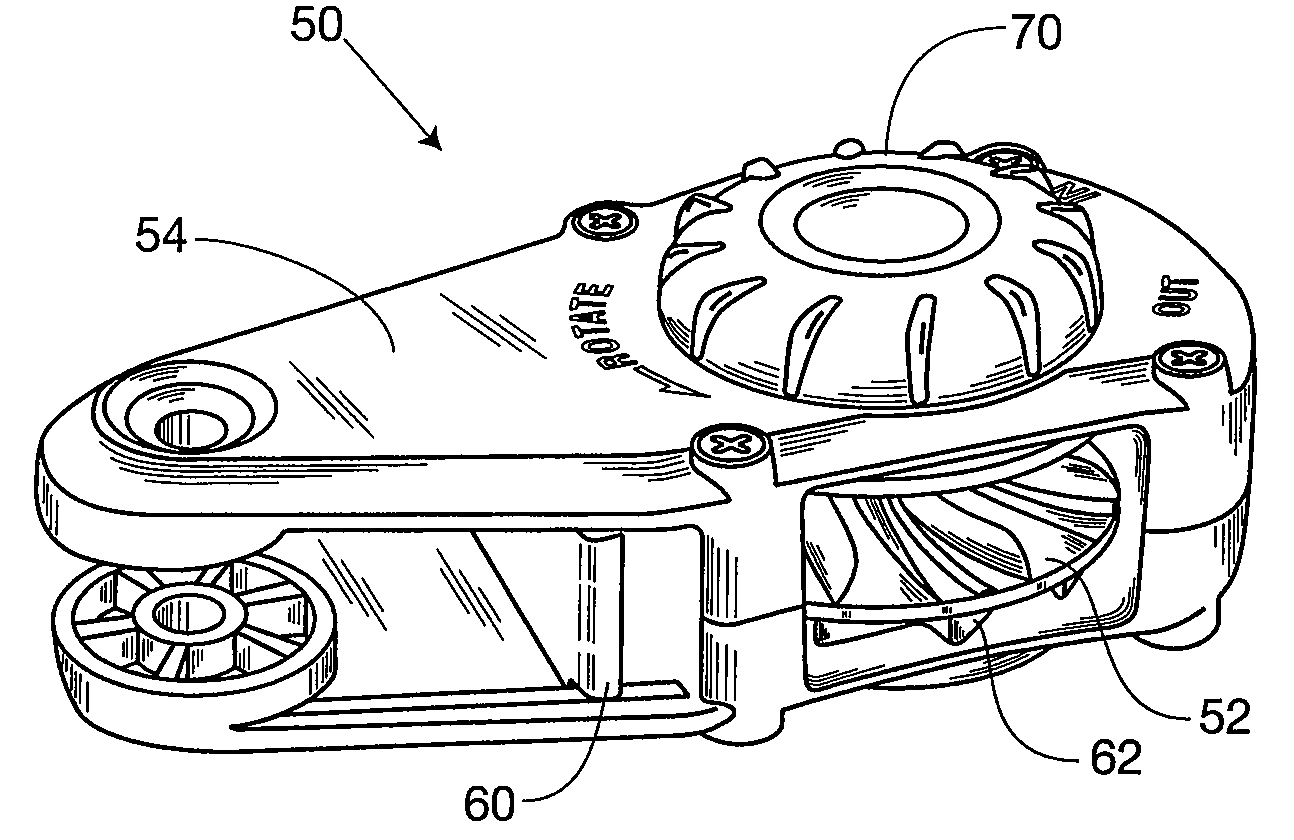

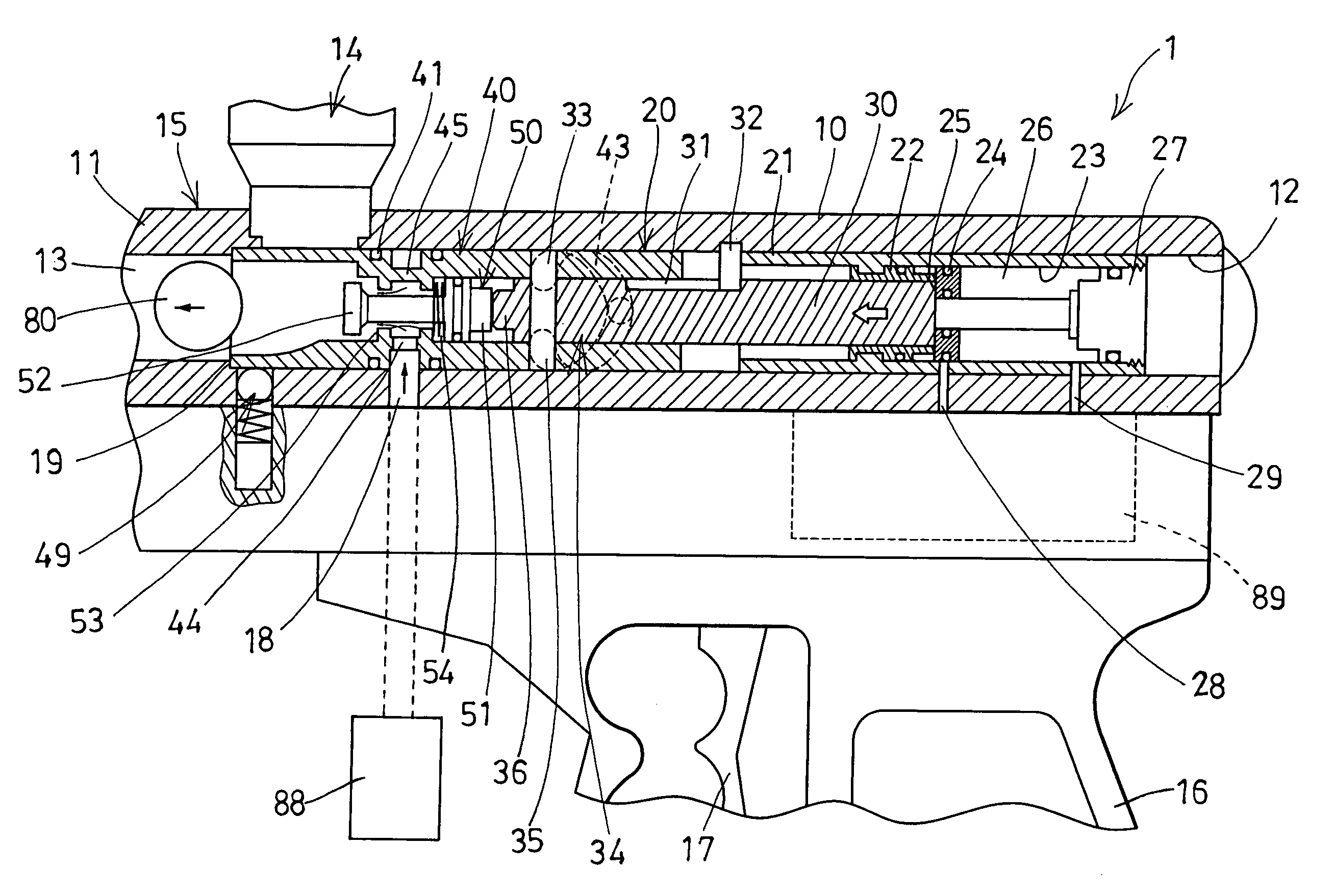

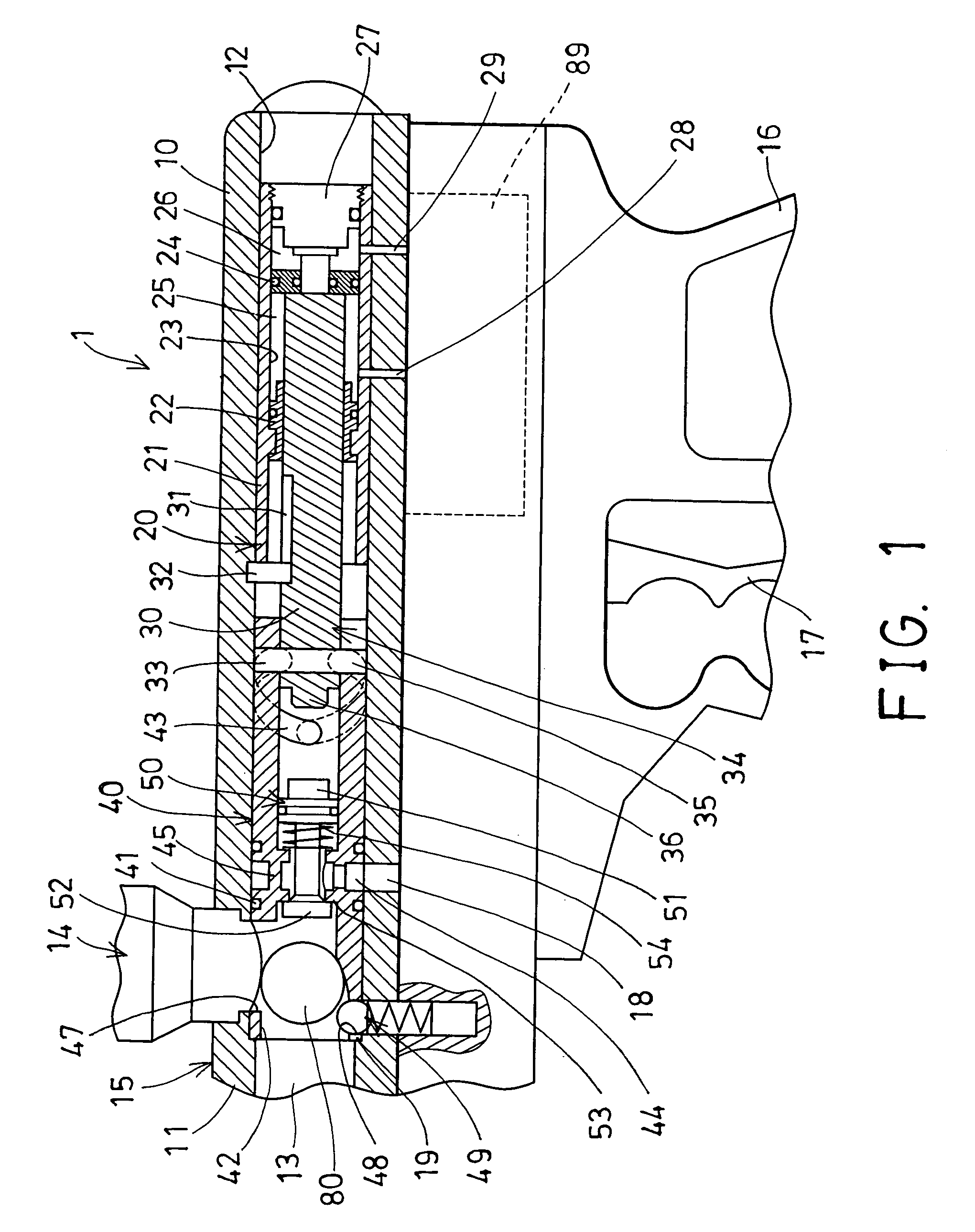

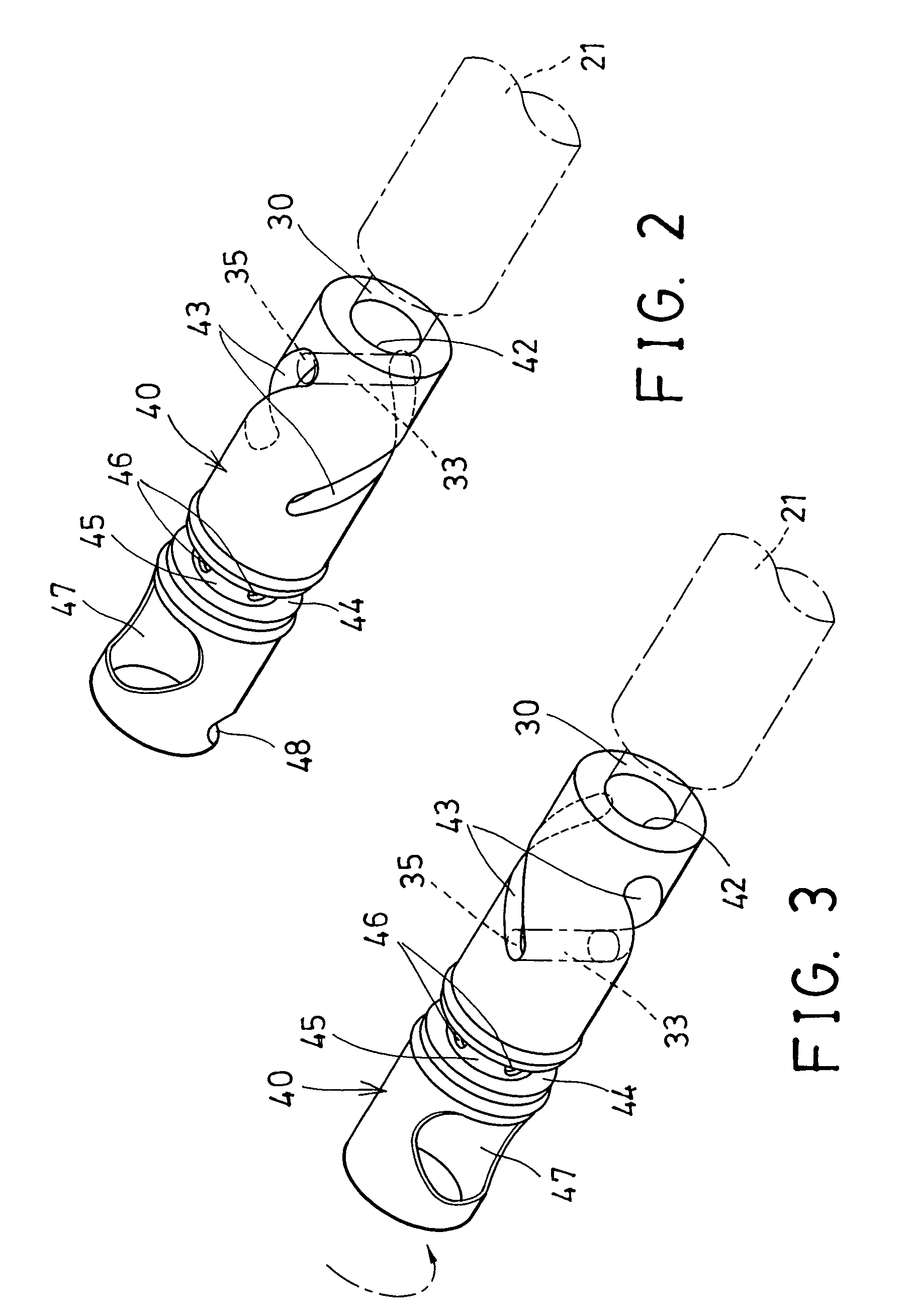

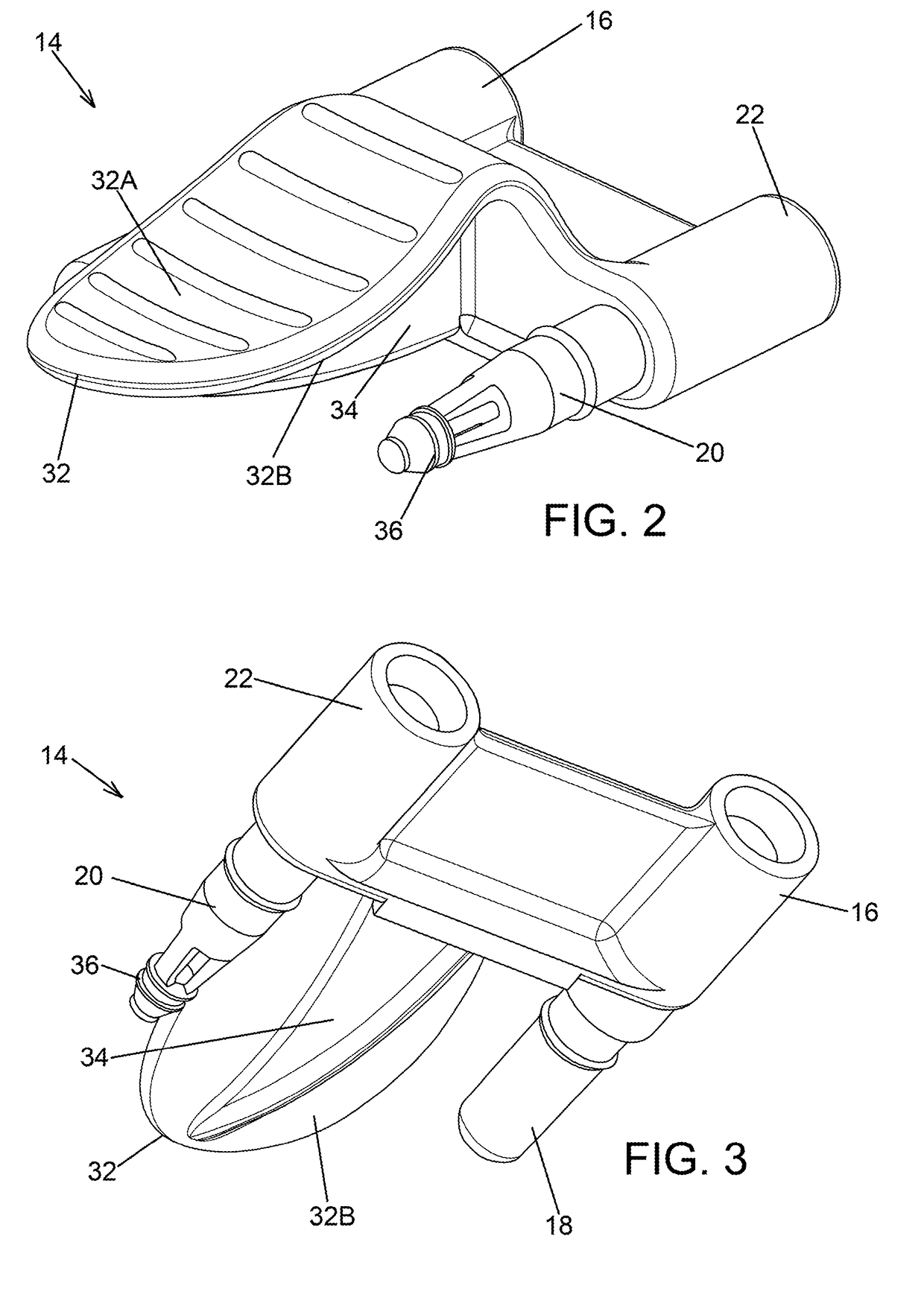

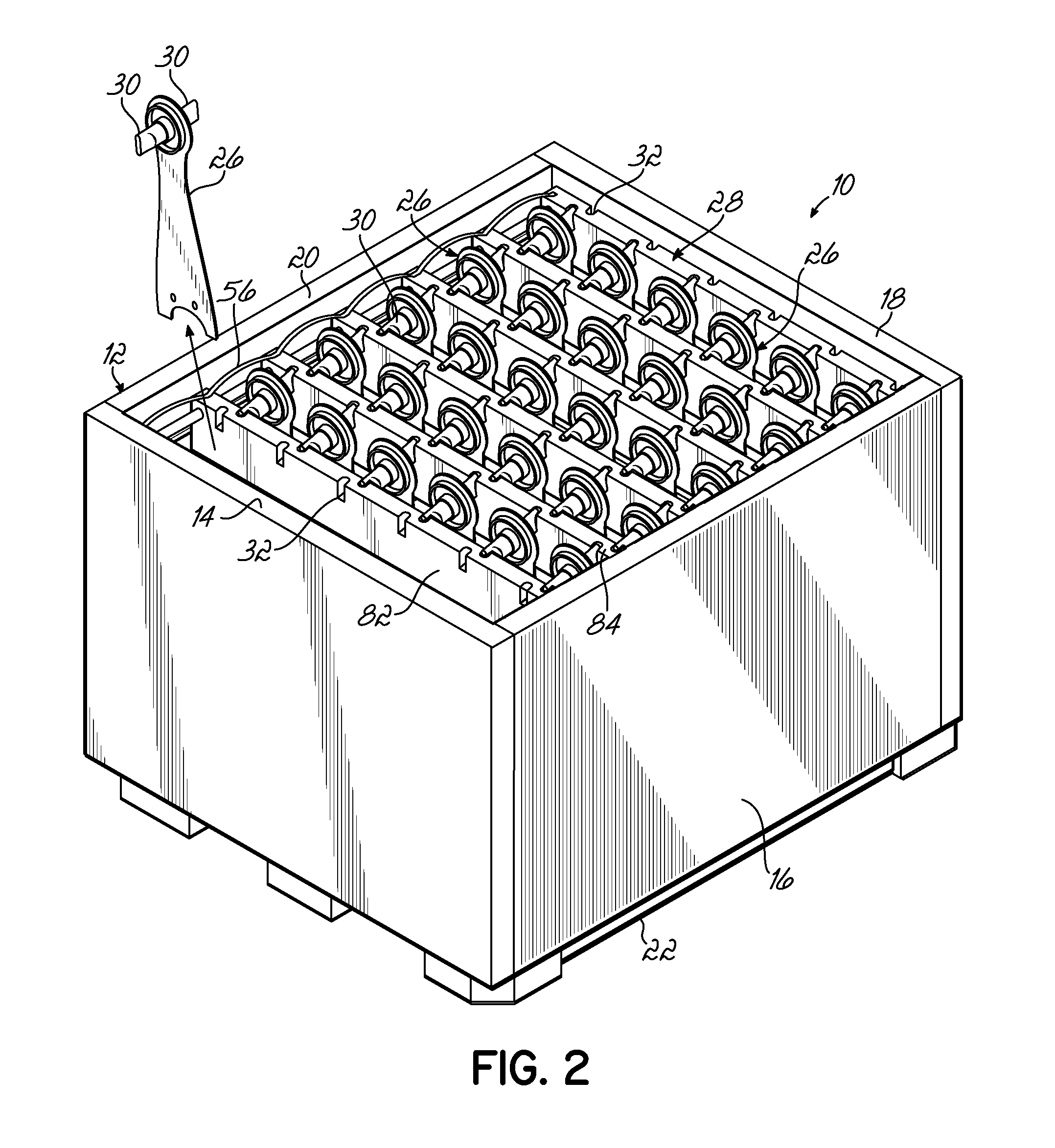

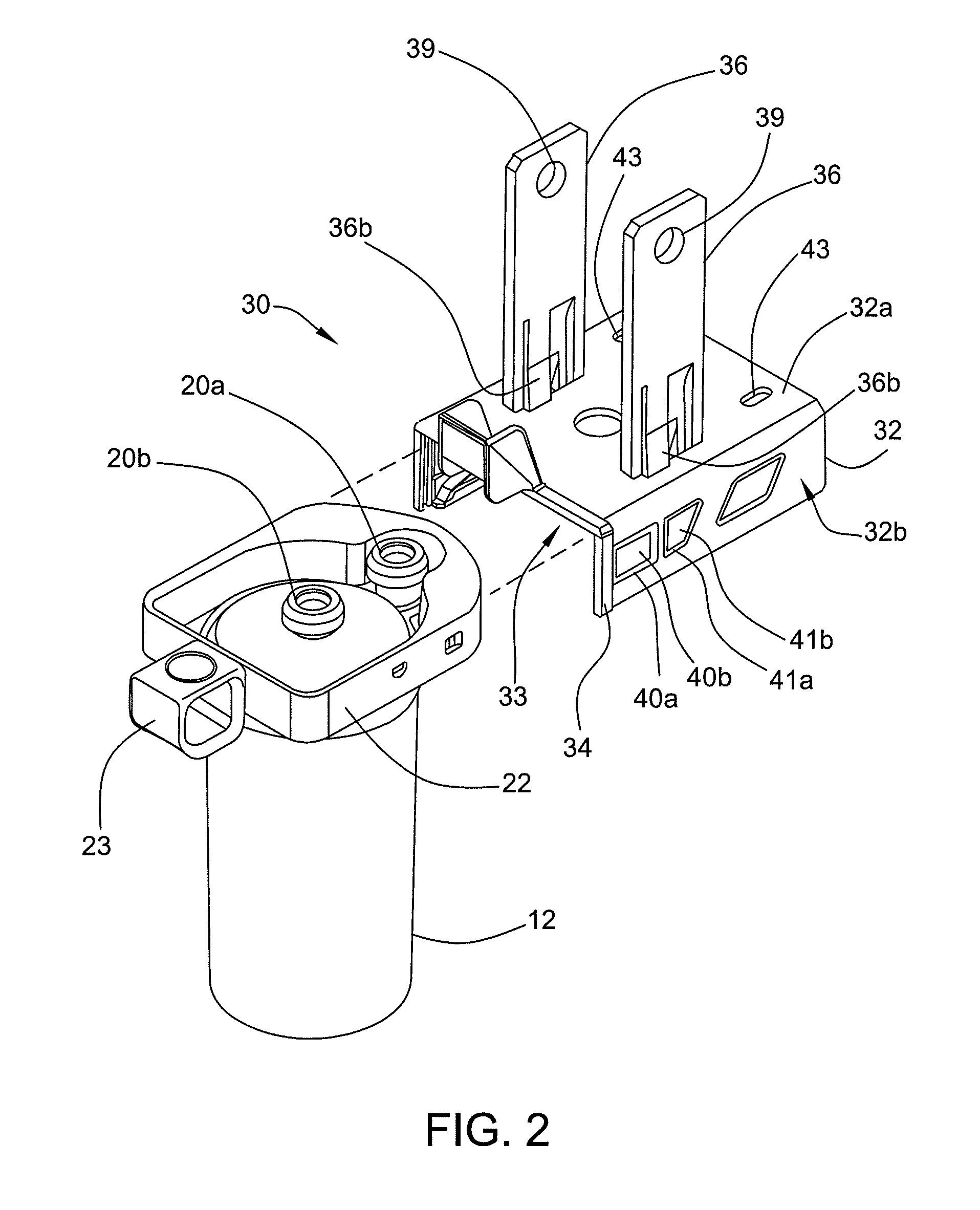

Quick loading cutting head for a rotary trimmer

InactiveUS7640668B2Easy and quick loadingReduce fatigueMowersMetal working apparatusEngineeringClockwise

A cutting head for a rotary trimmer is provided. The cutting head of the present disclosure provides a control mechanism for loading a spool member of the cutting head quickly and efficiently without having to disassemble the cutting head. In one embodiment, a control mechanism is provided in the cutting head interacting between a follower member and a spool member so as to provide for one way rotational loading of flails, e.g., cutting line, into the cutting head; in other words, to load the flails, the spool member is rotated continuously 360° in one direction only, e.g., clockwise. In another embodiment, a cutting head allows the flails to be loaded by a ratcheting-type operation, i.e., a back and forth rotational movement, which is less fatiguing and even more efficient in its loading operation.

Owner:KWIK PRODS

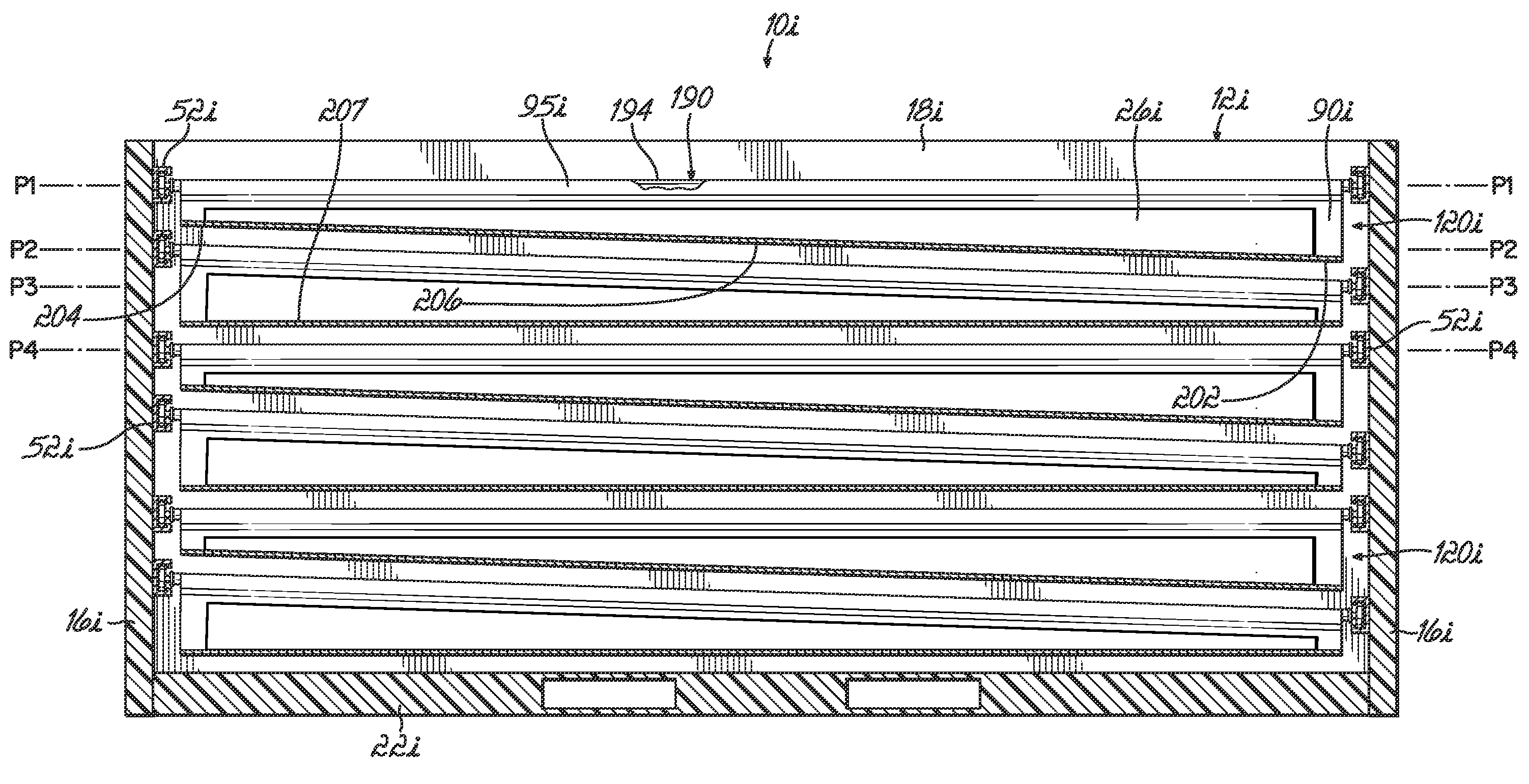

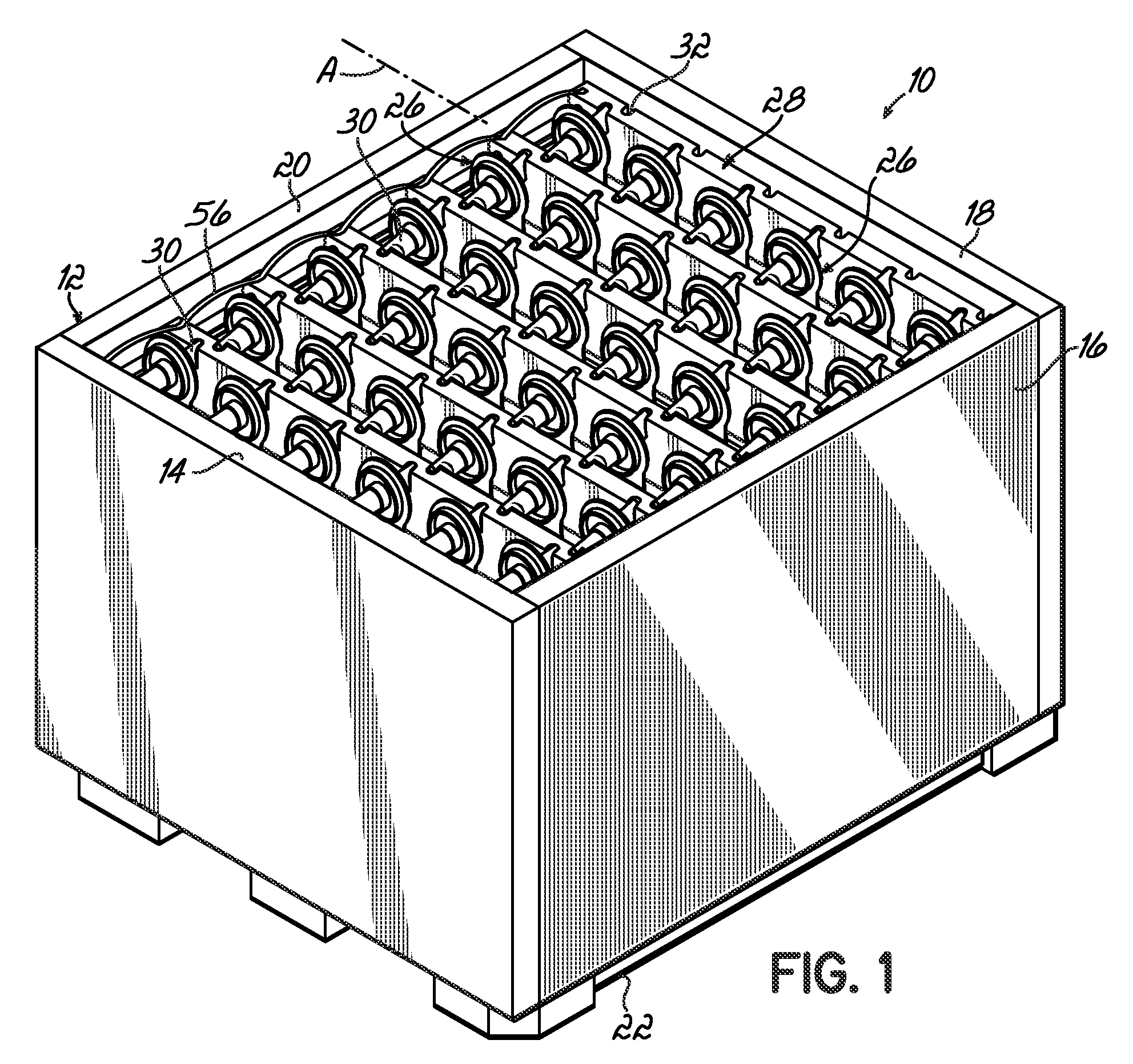

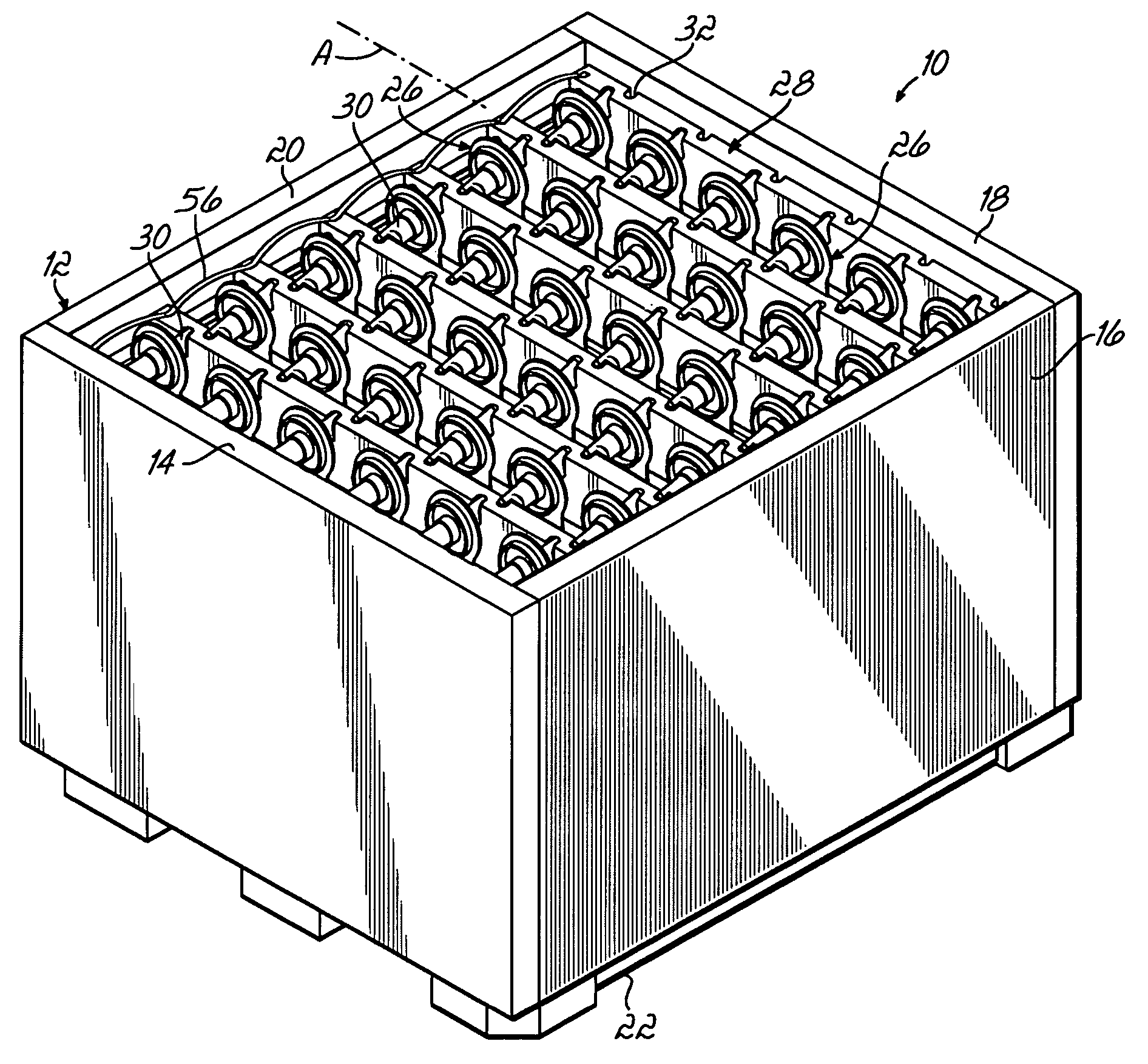

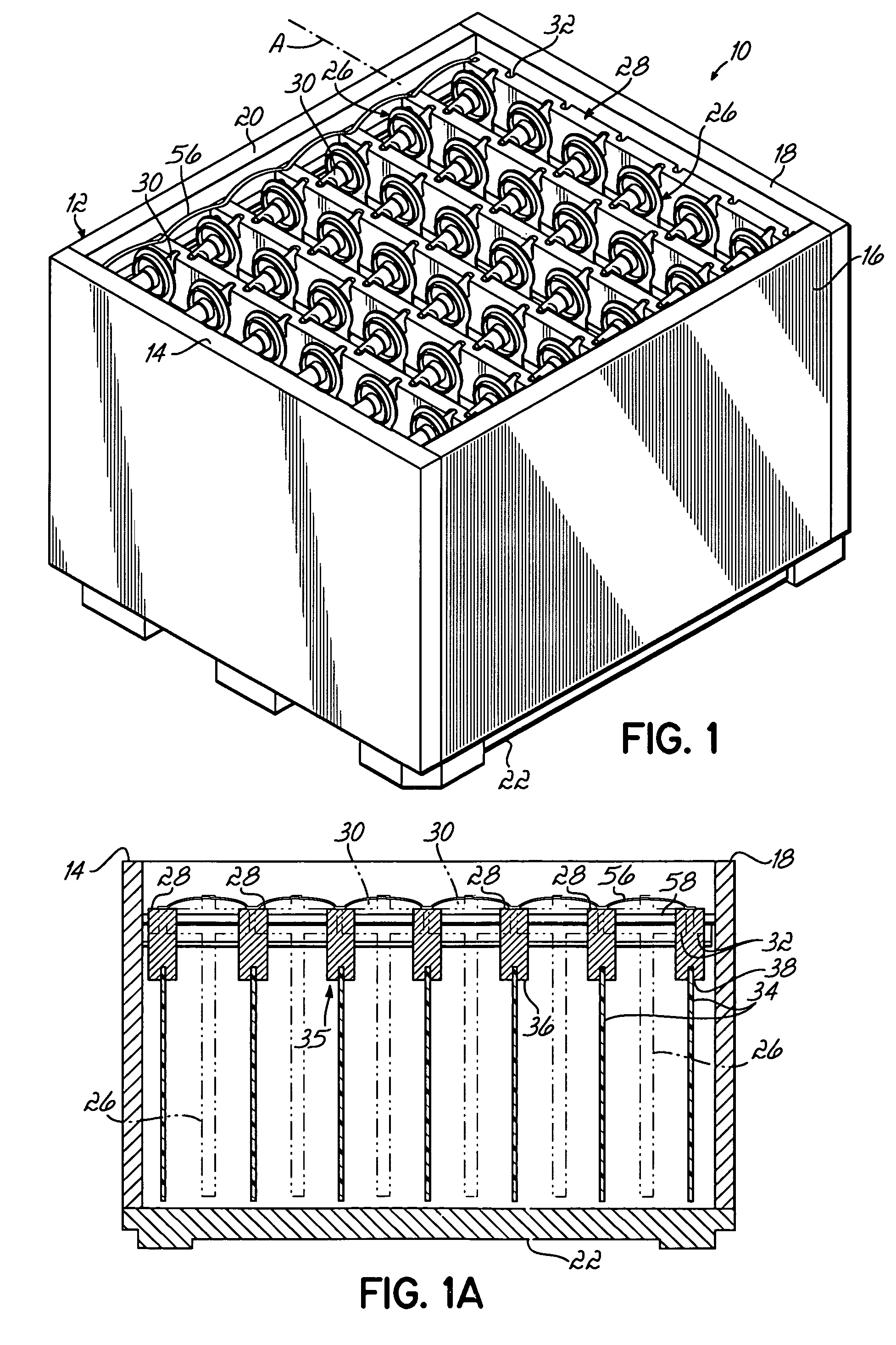

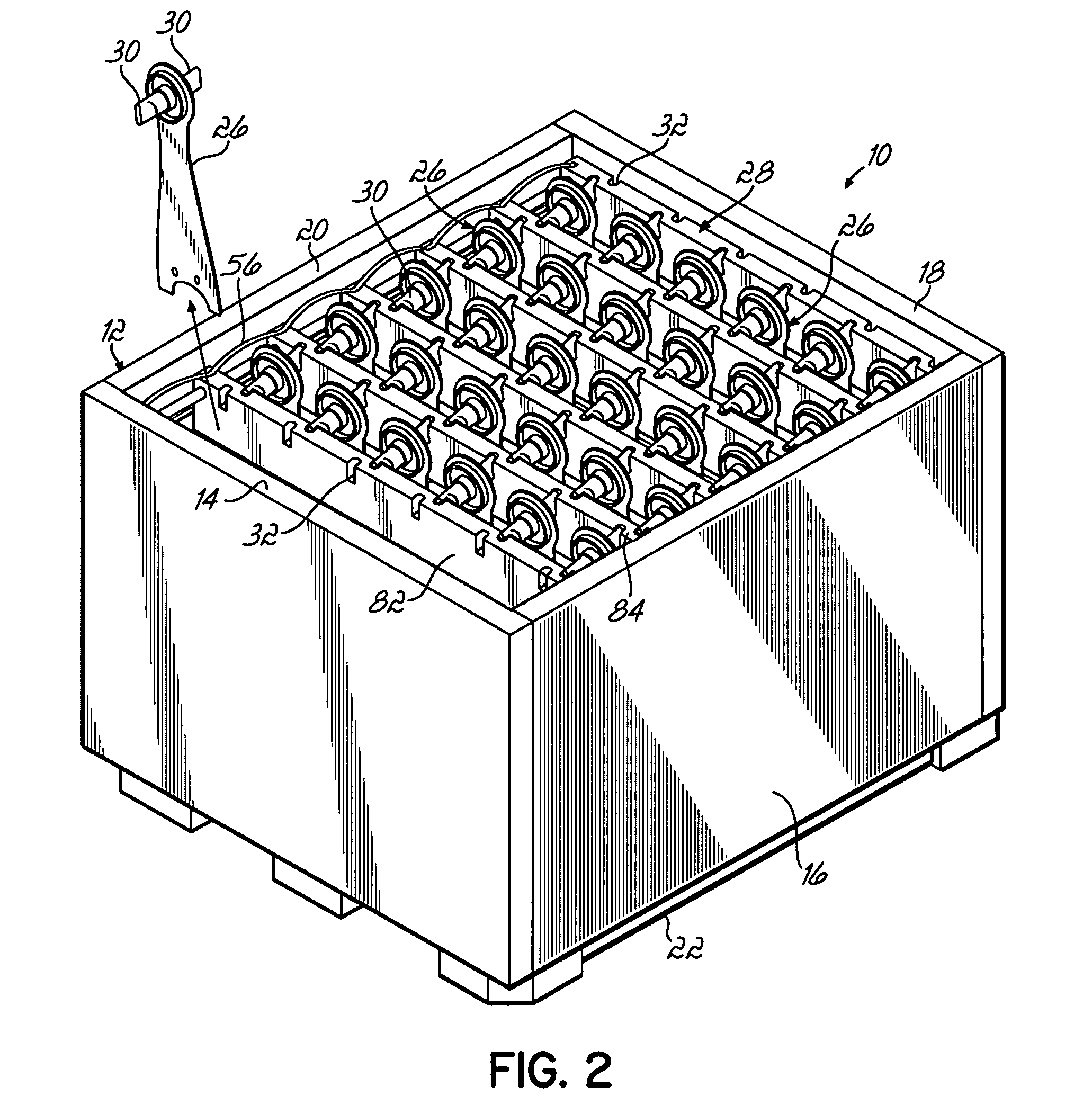

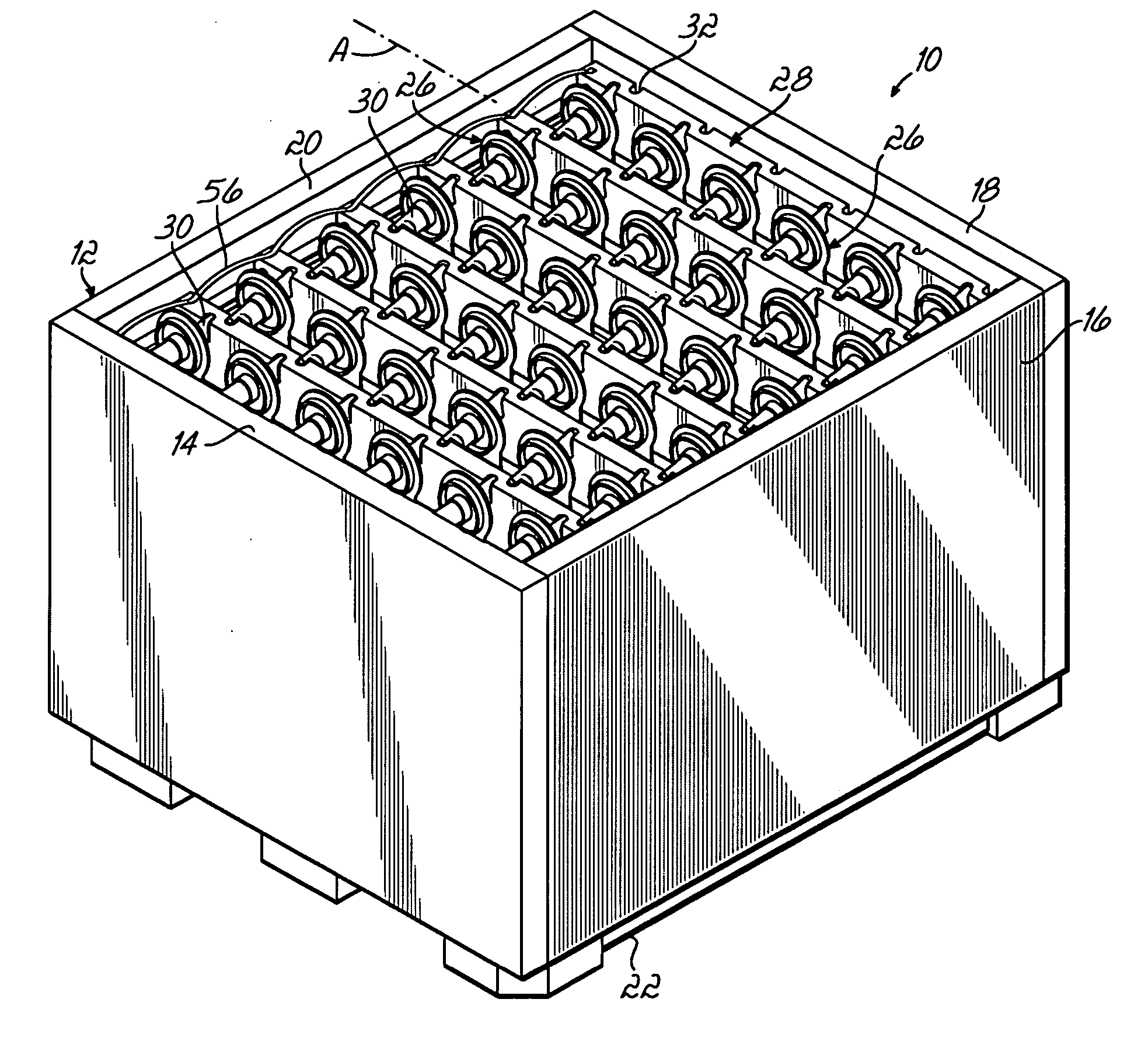

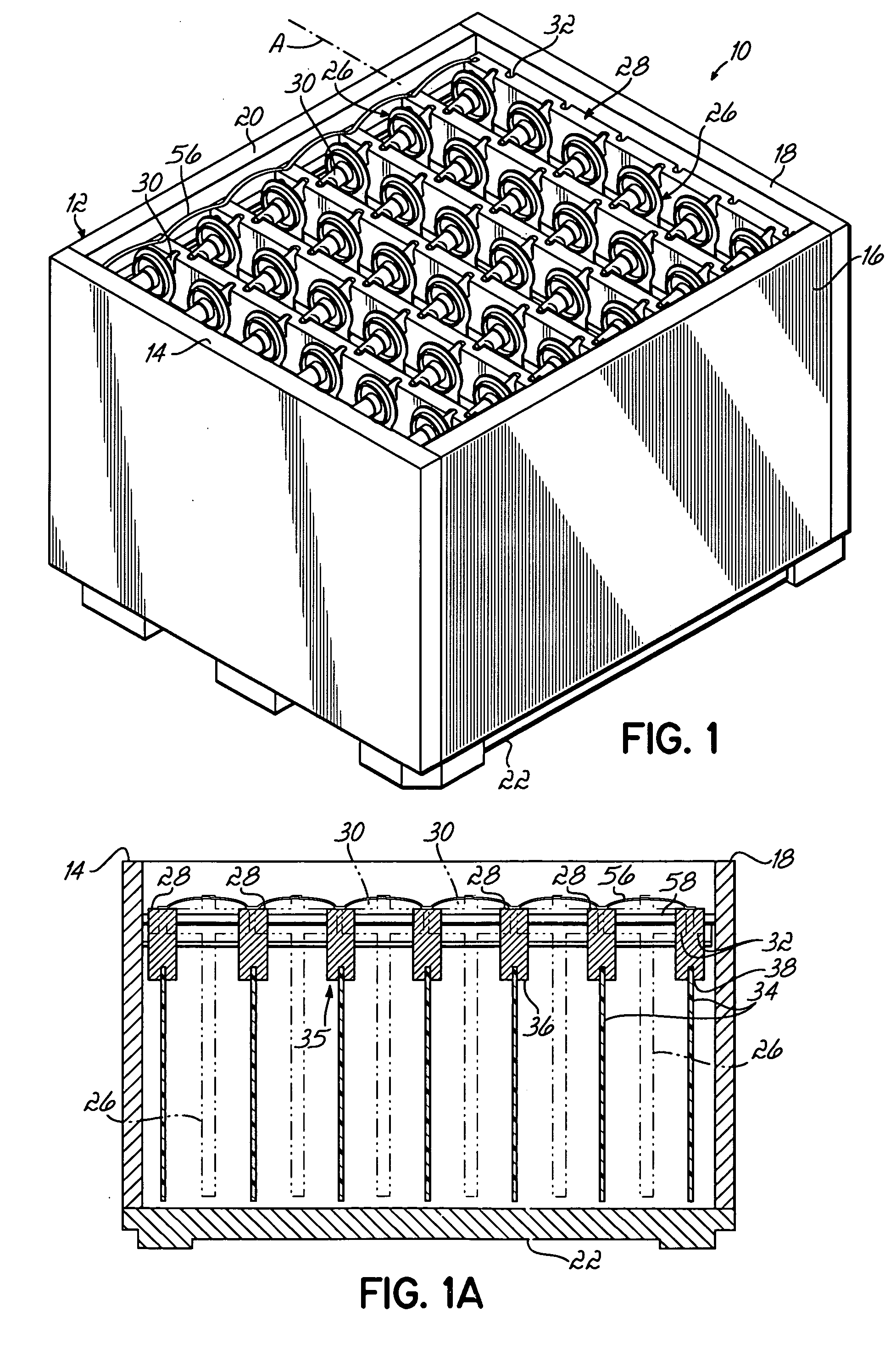

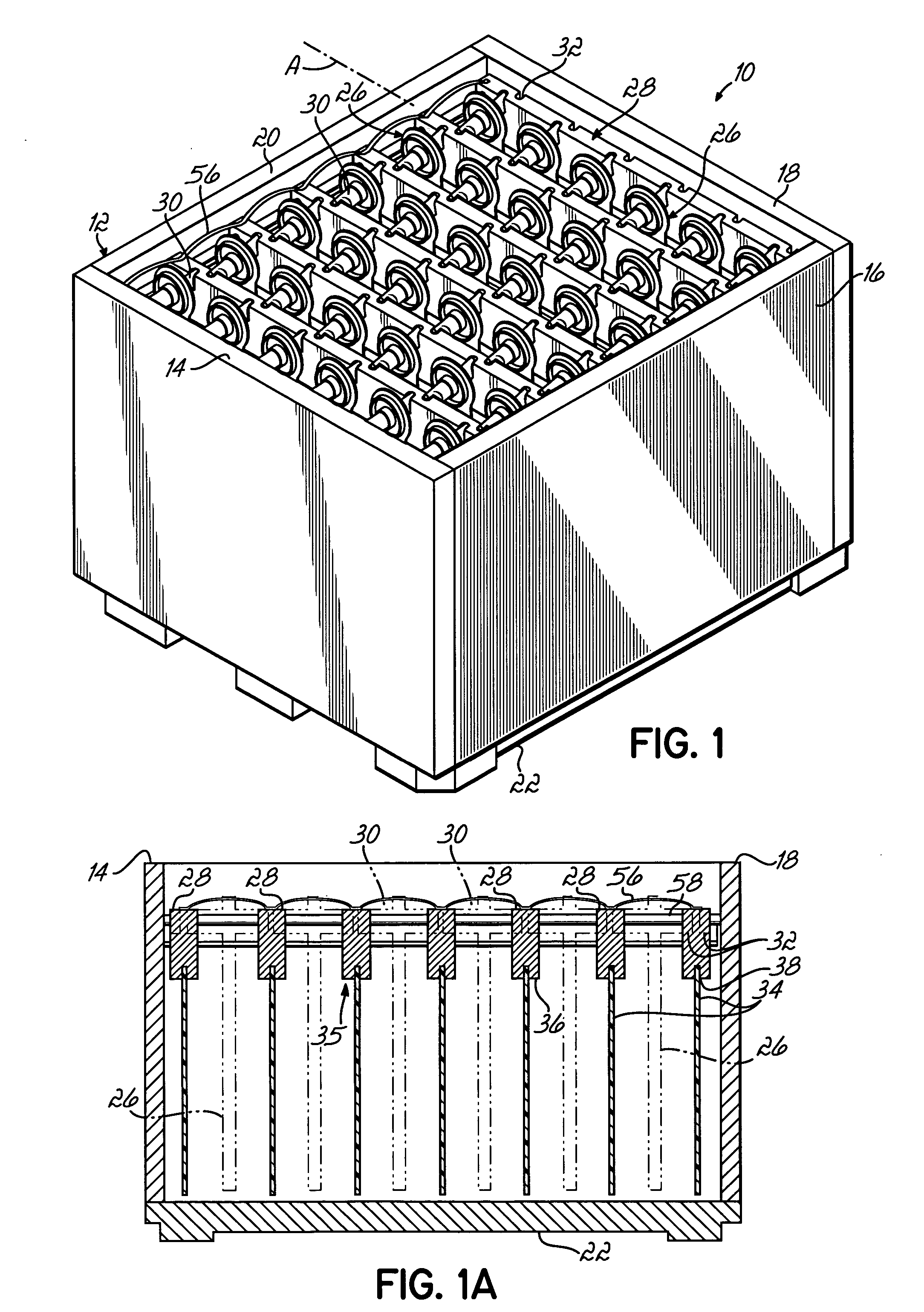

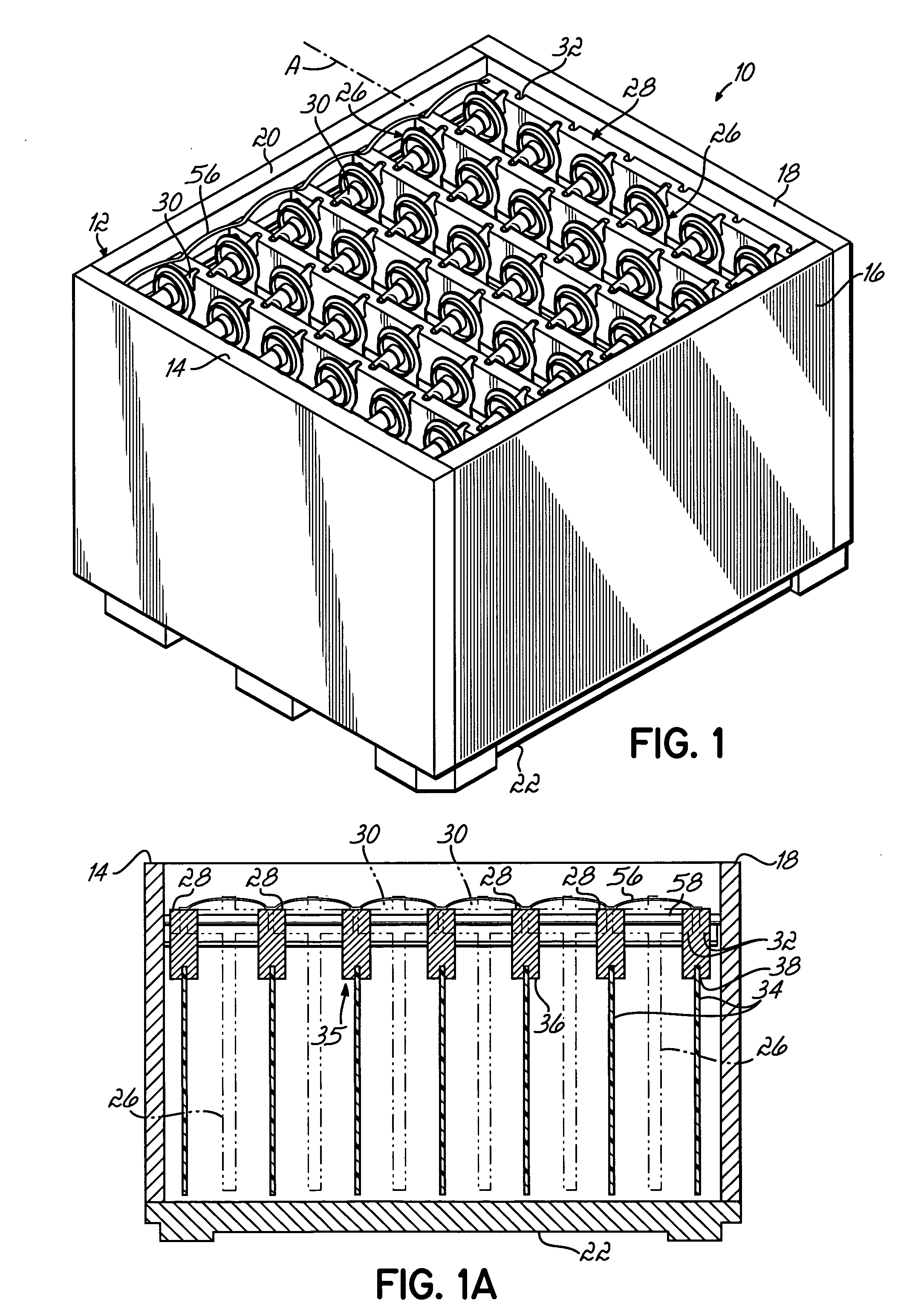

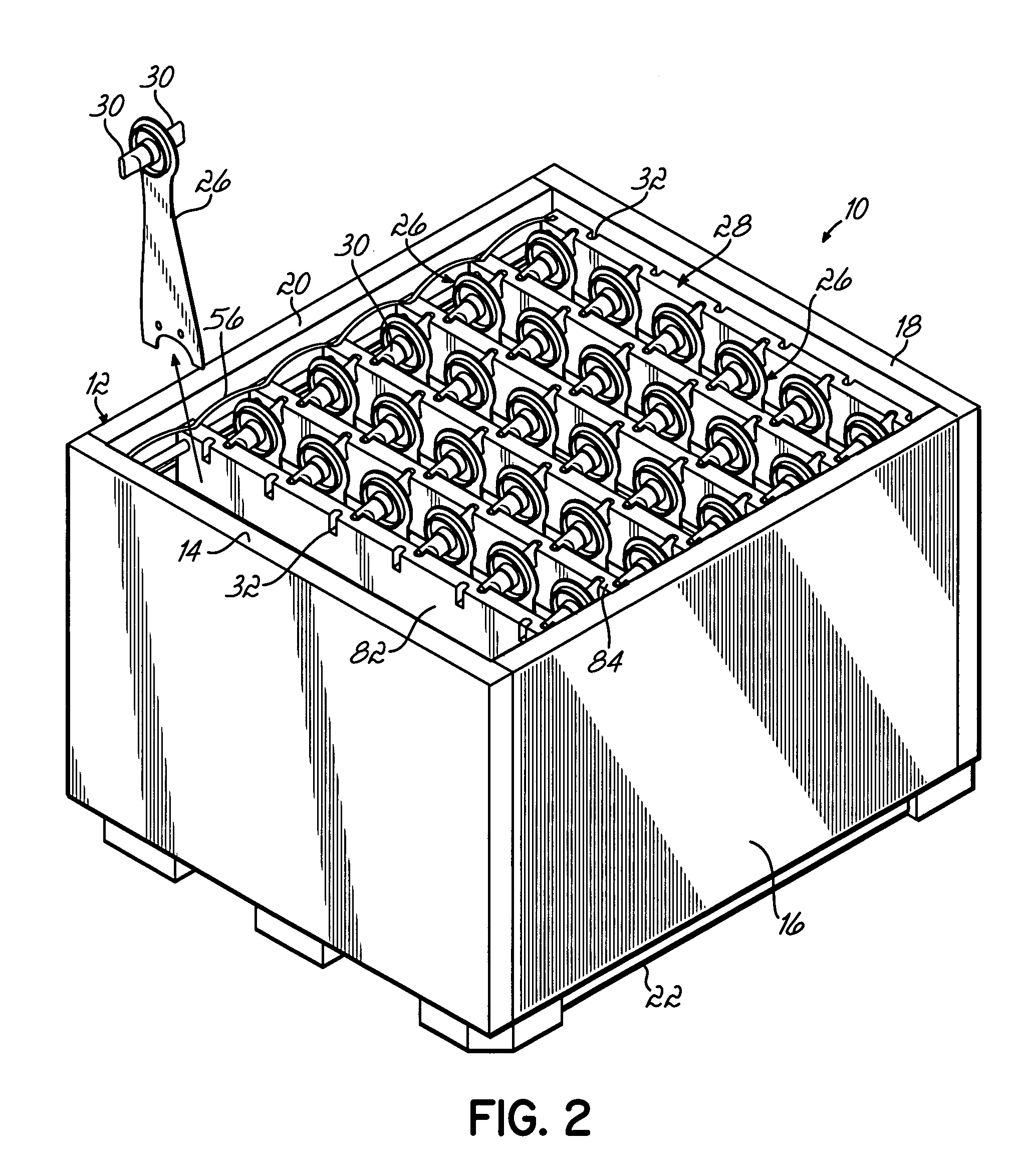

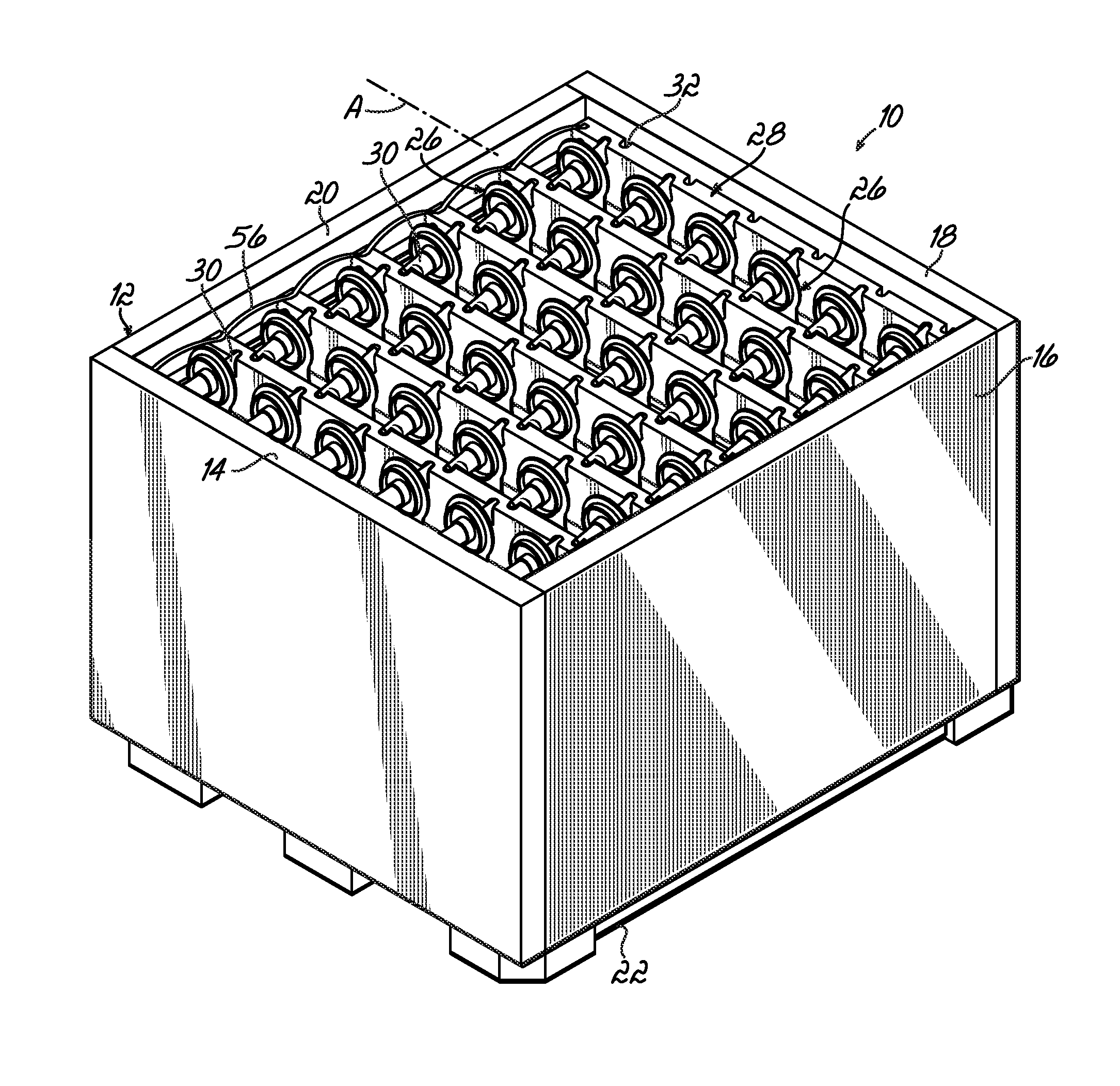

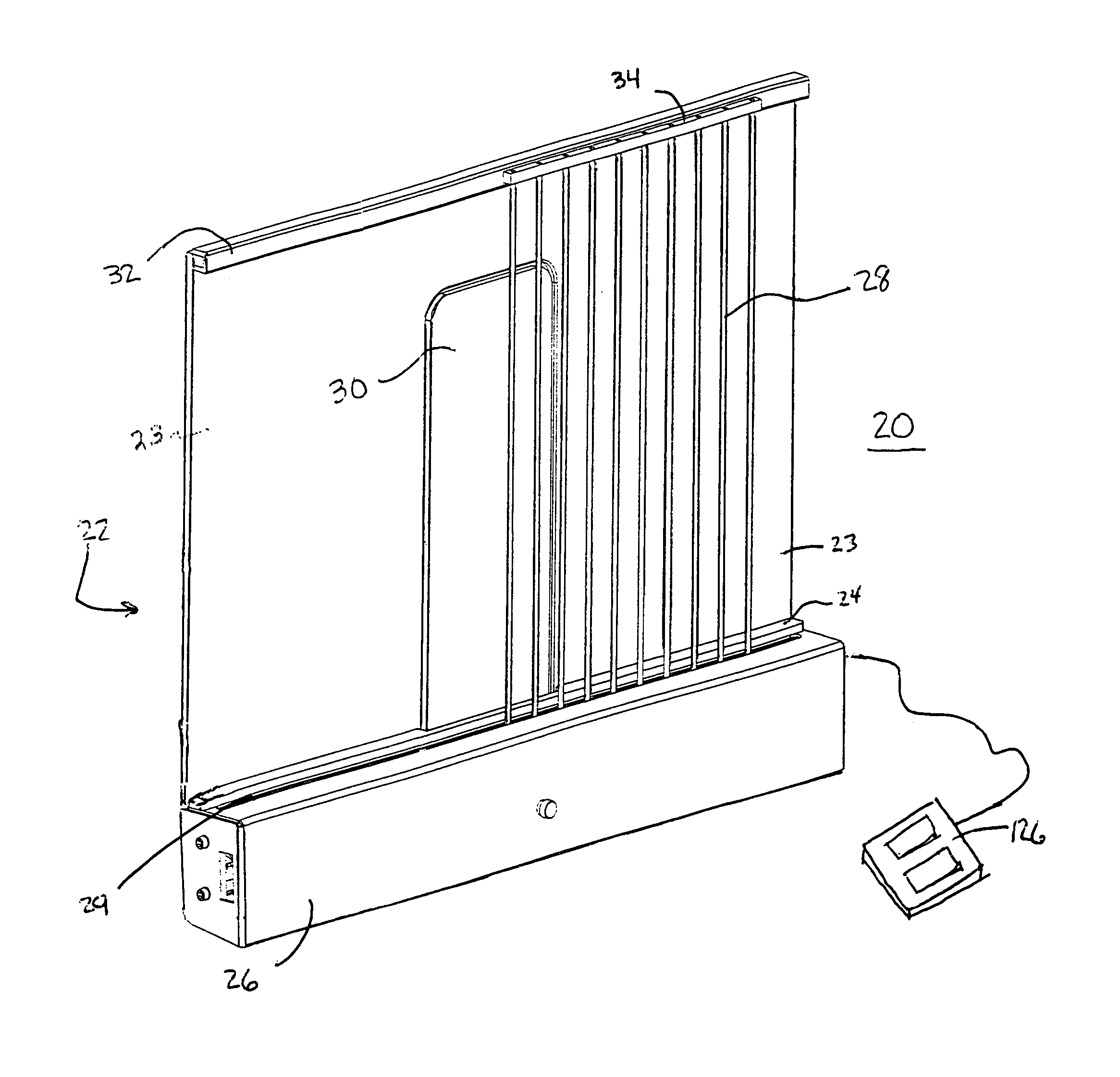

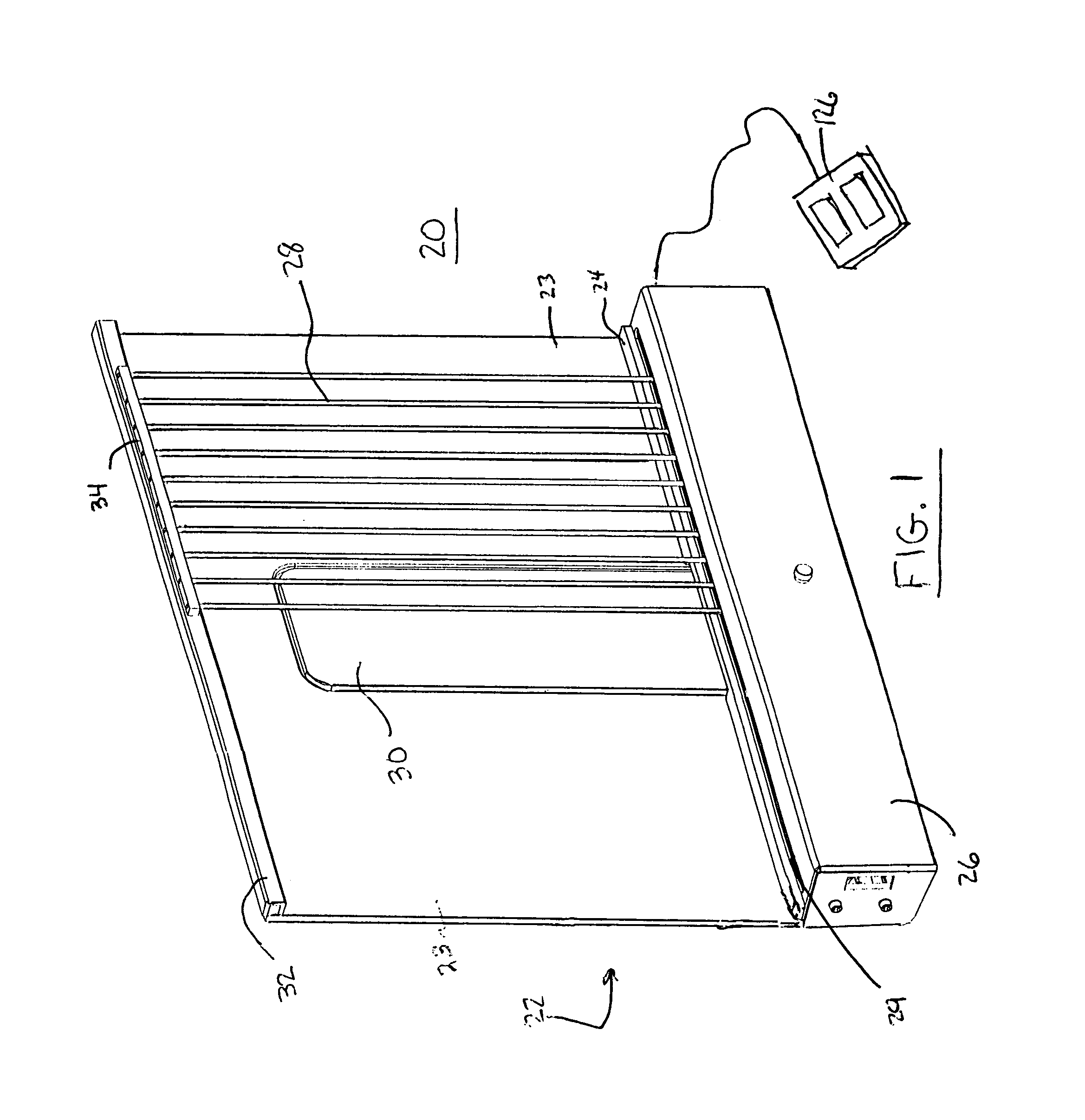

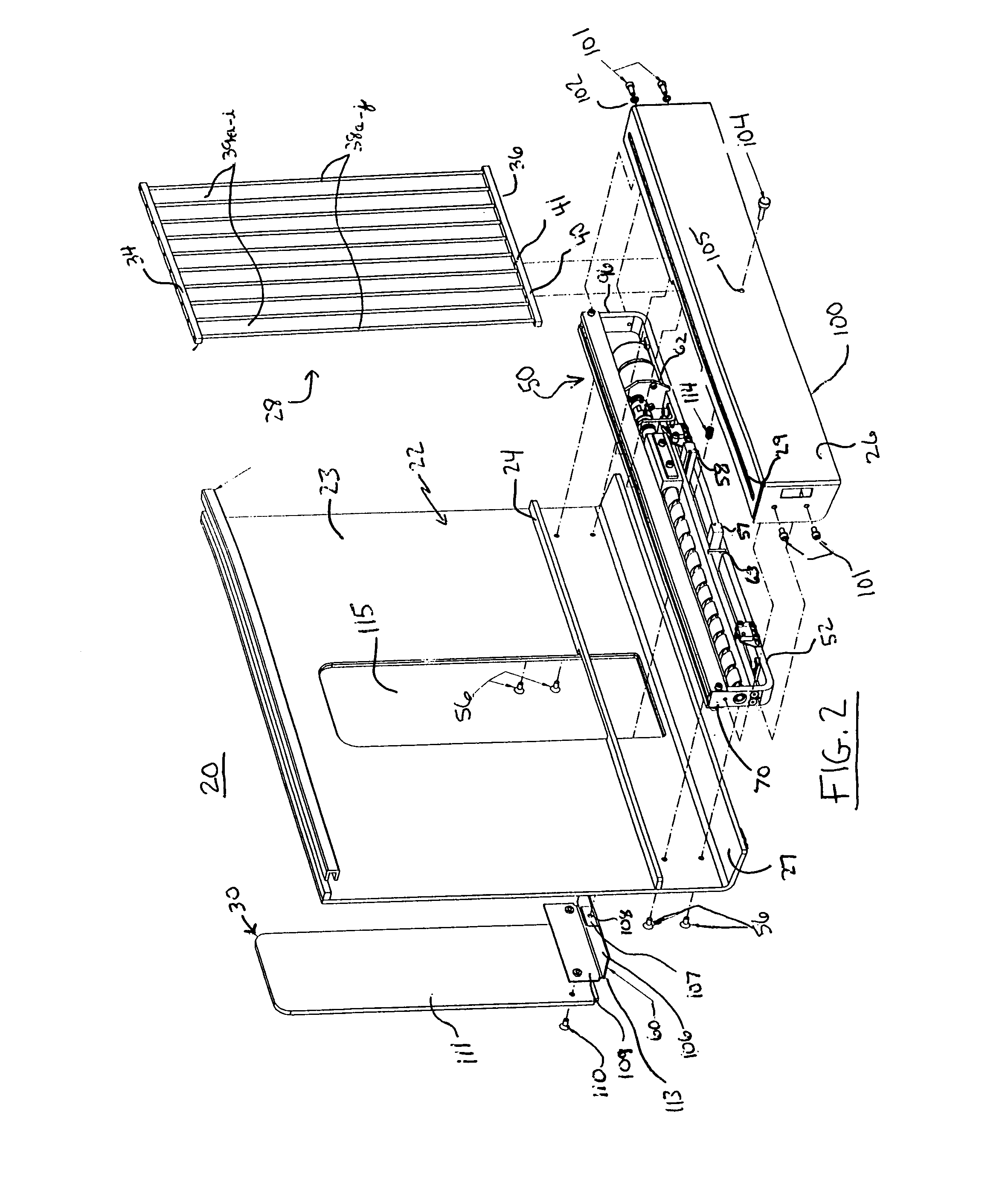

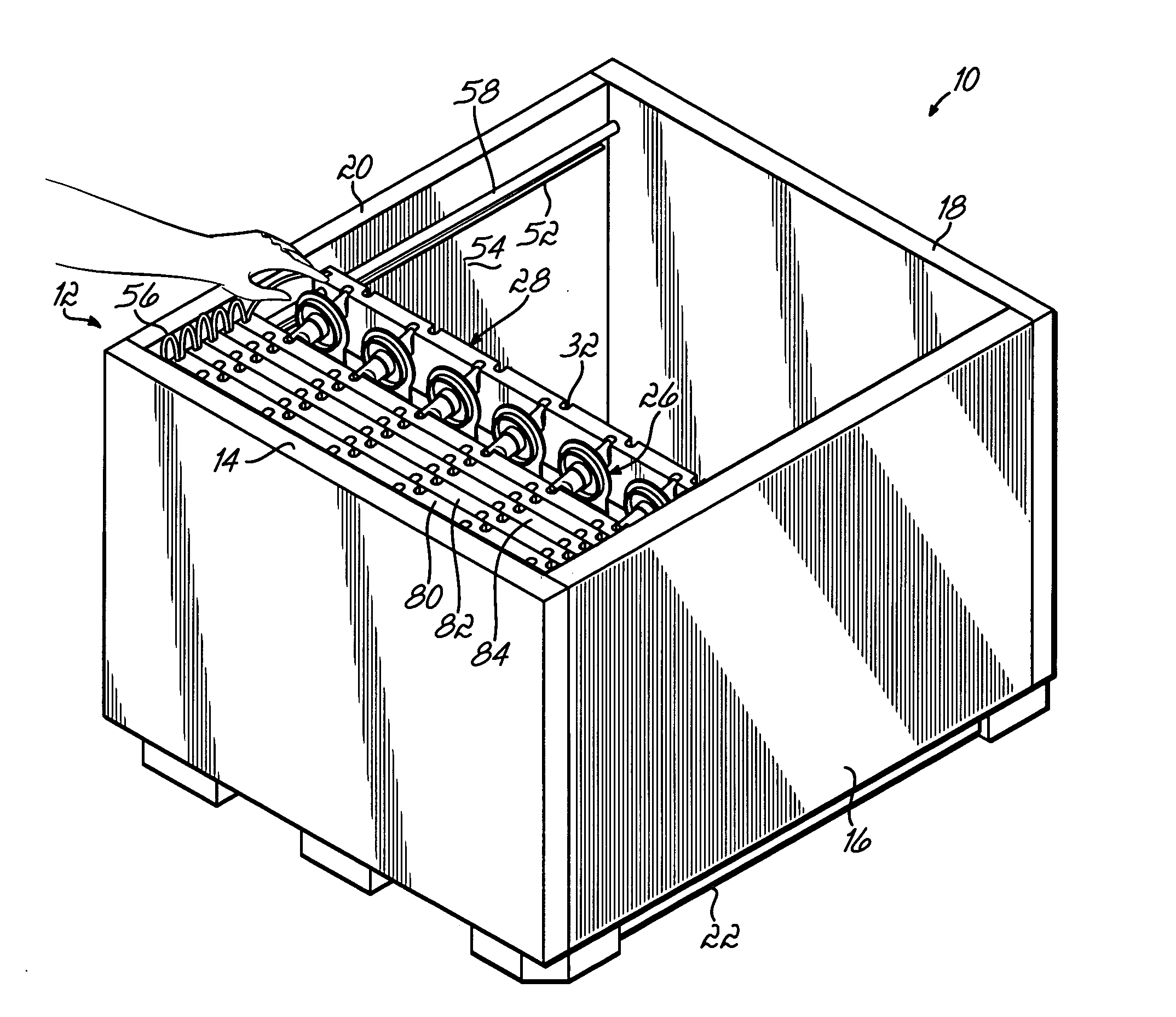

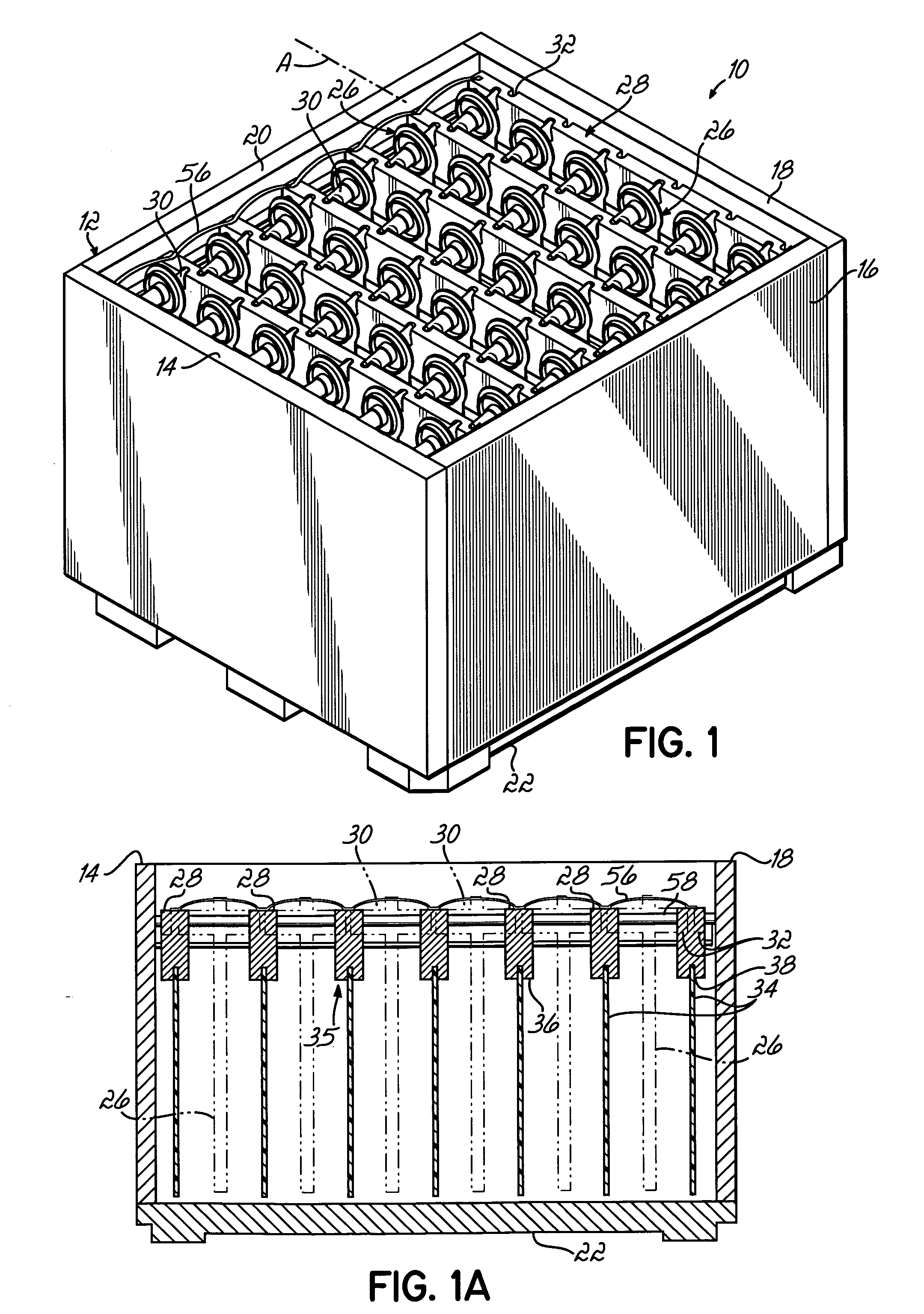

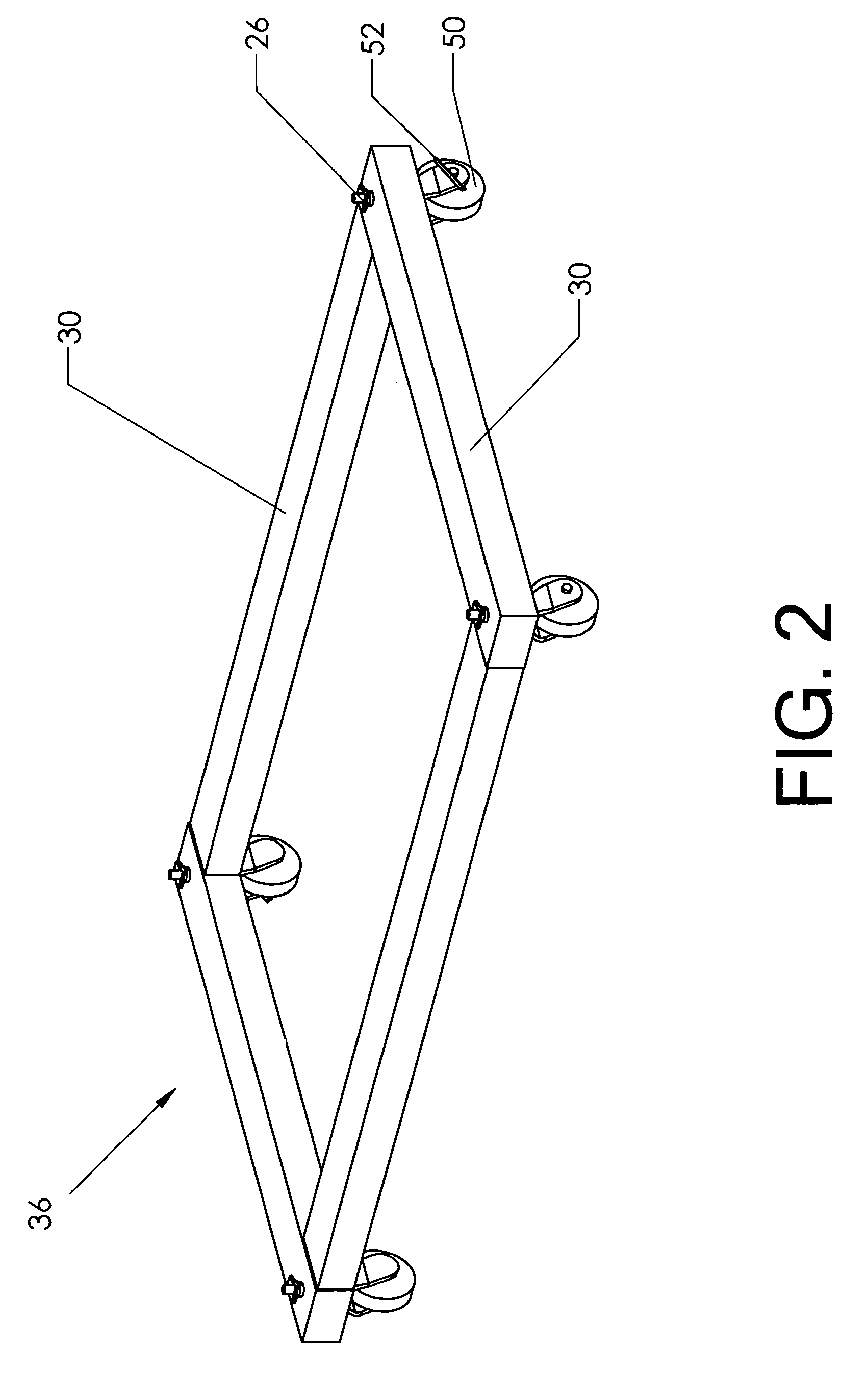

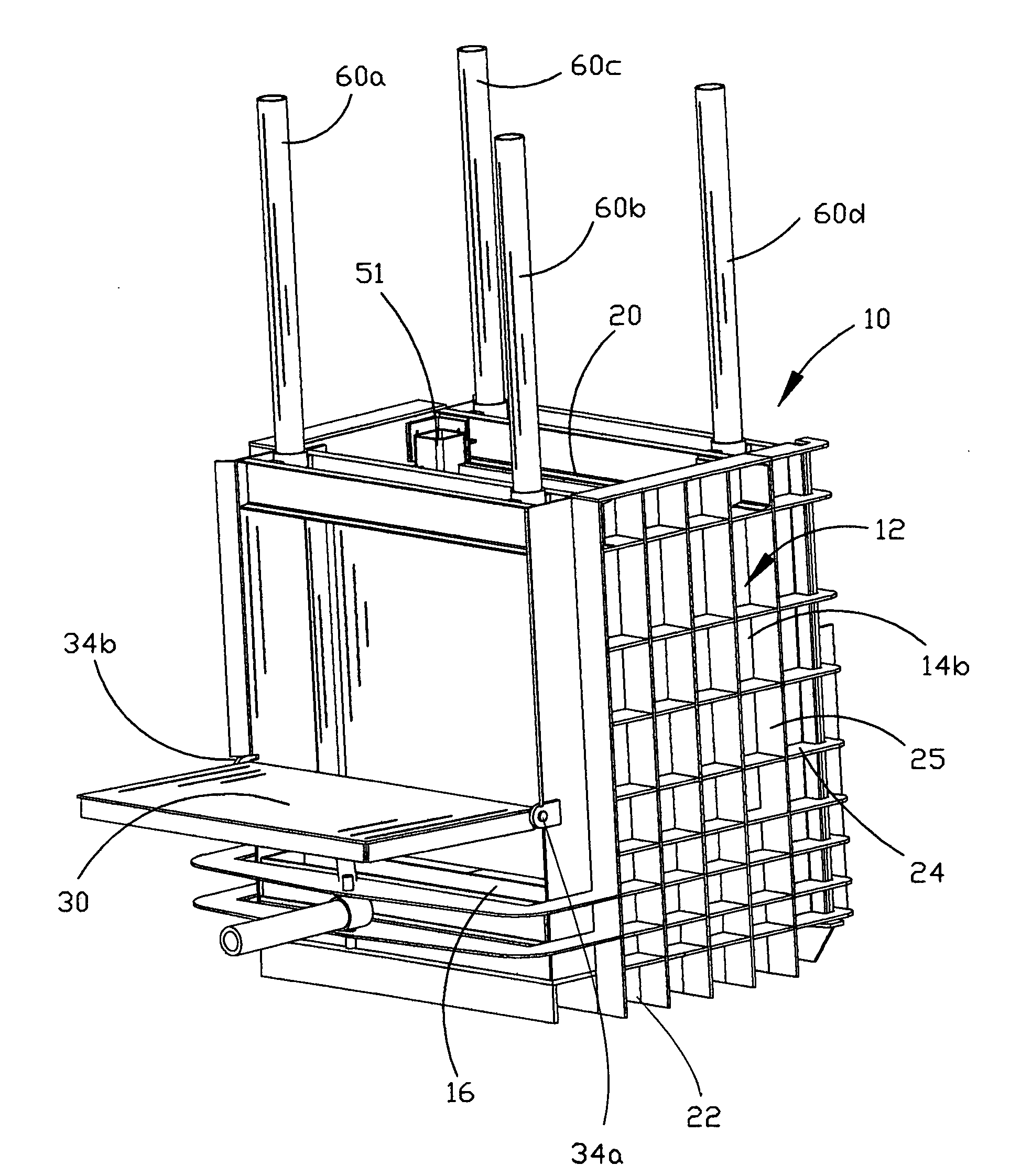

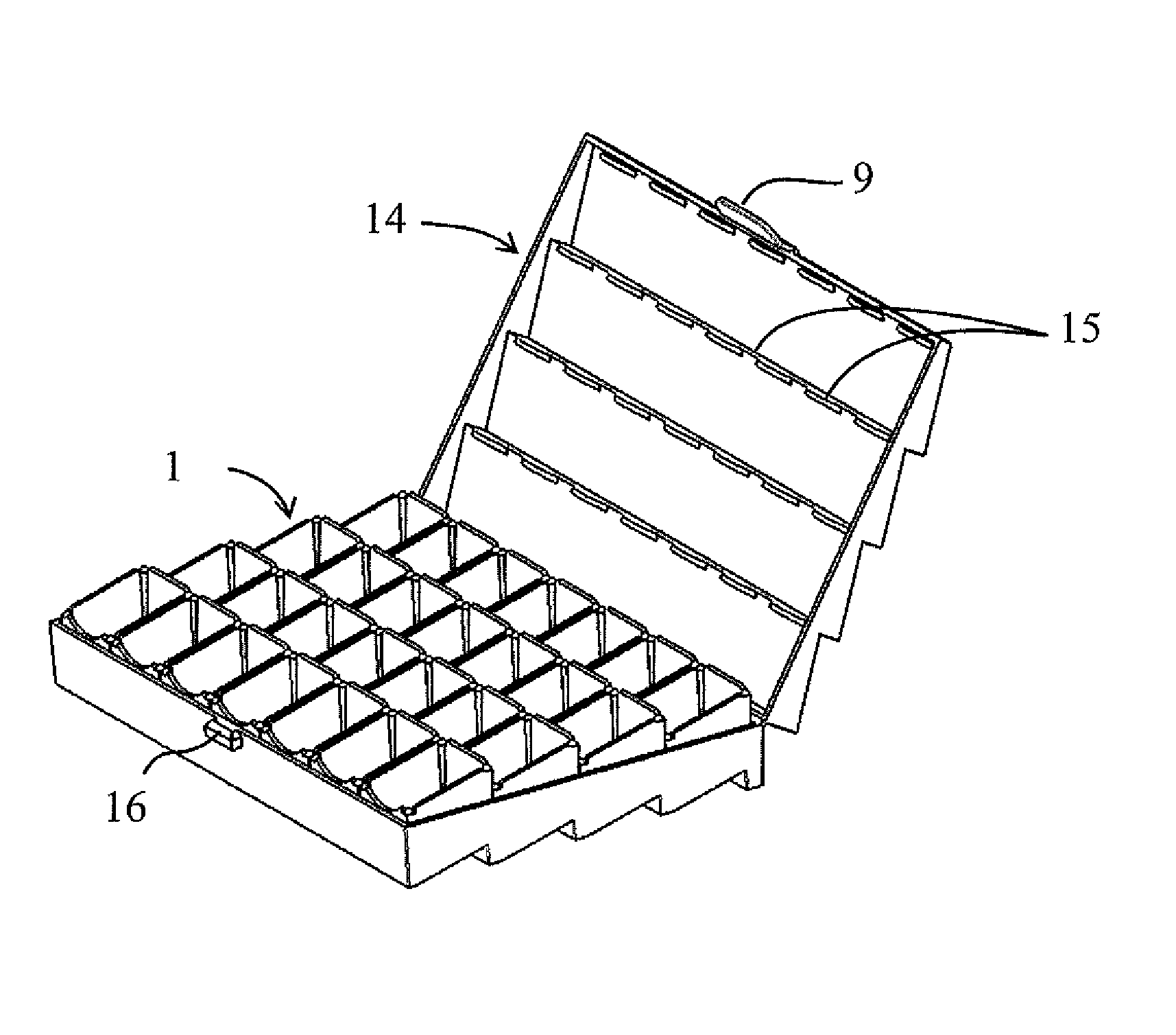

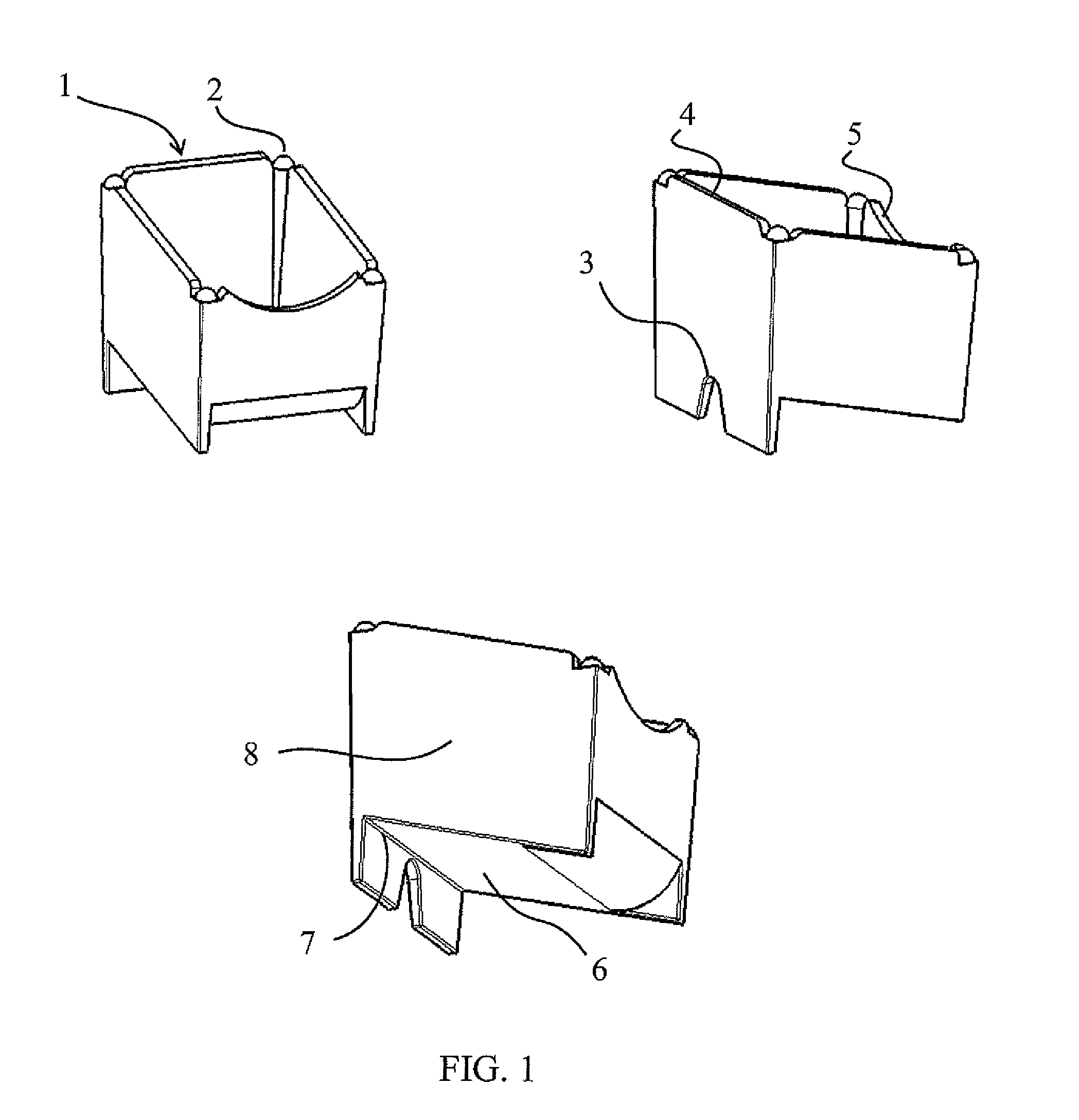

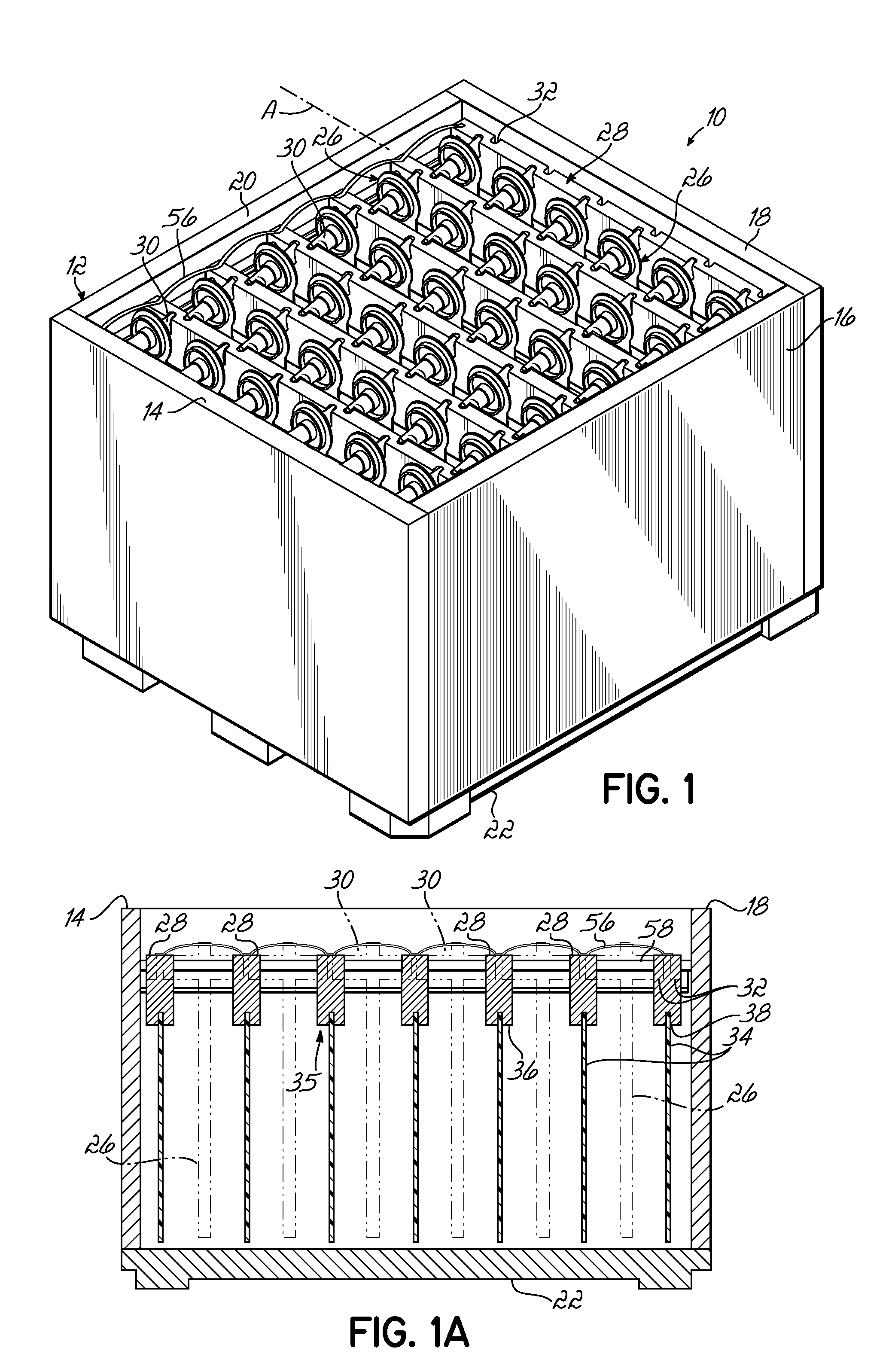

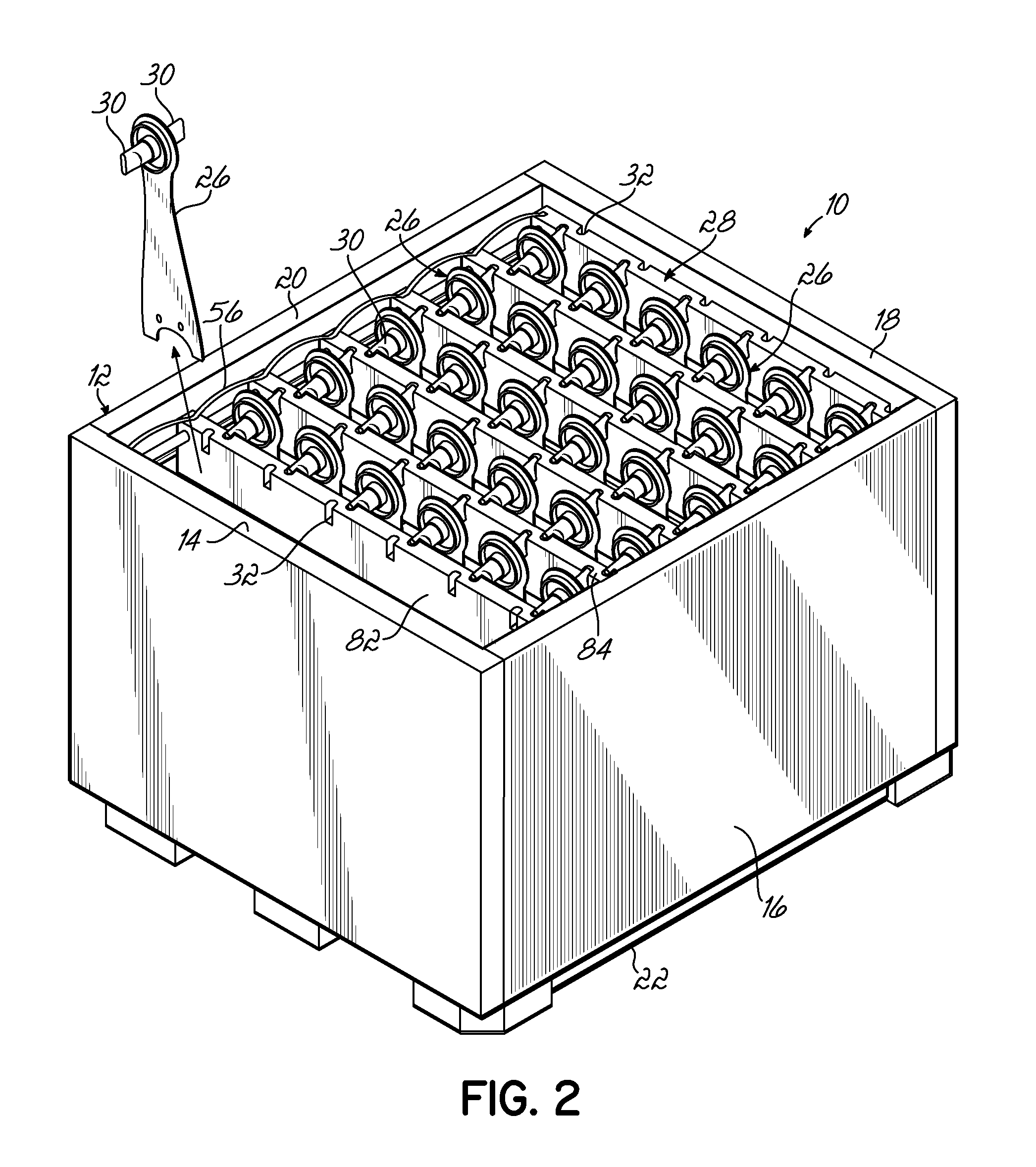

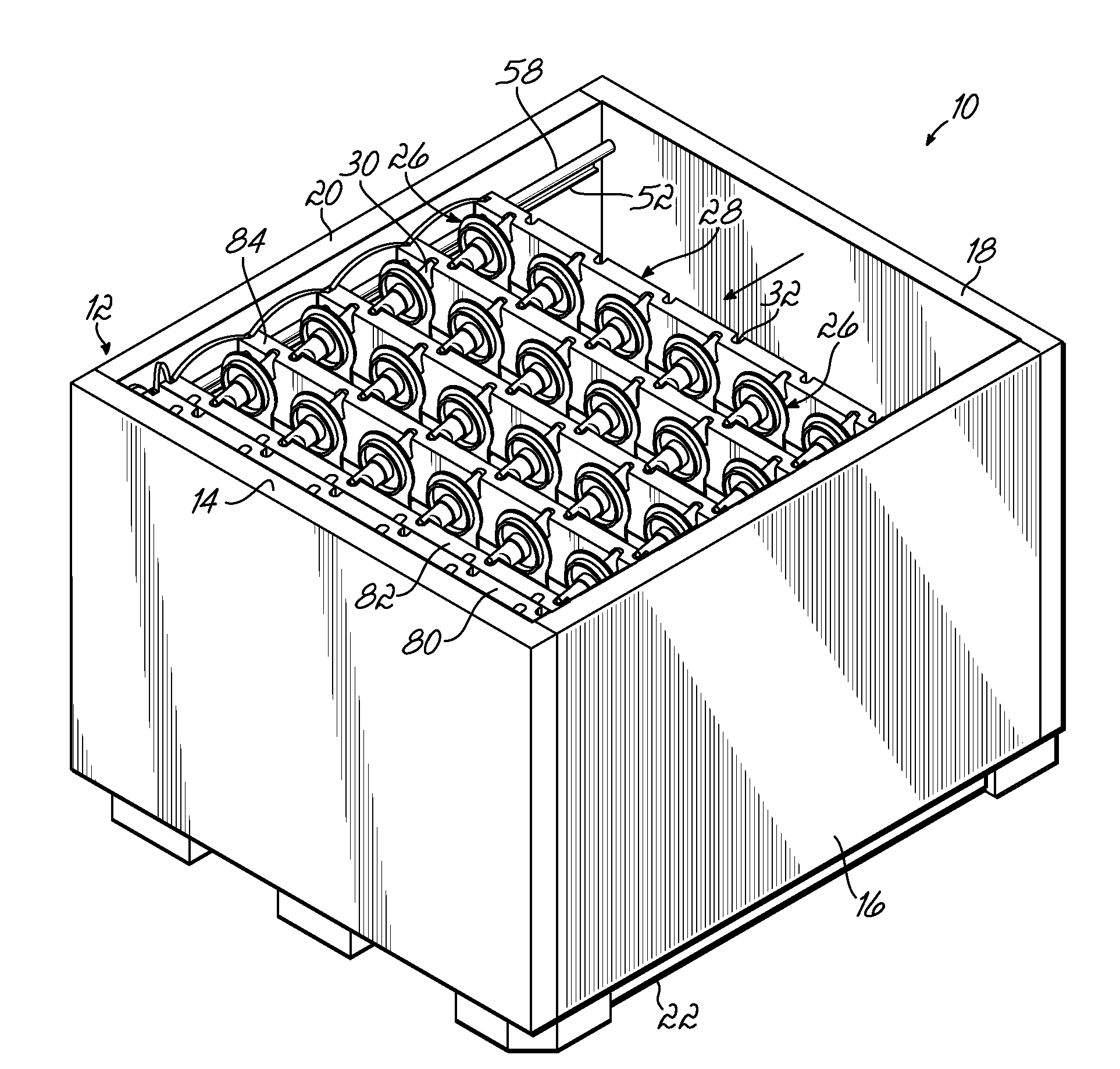

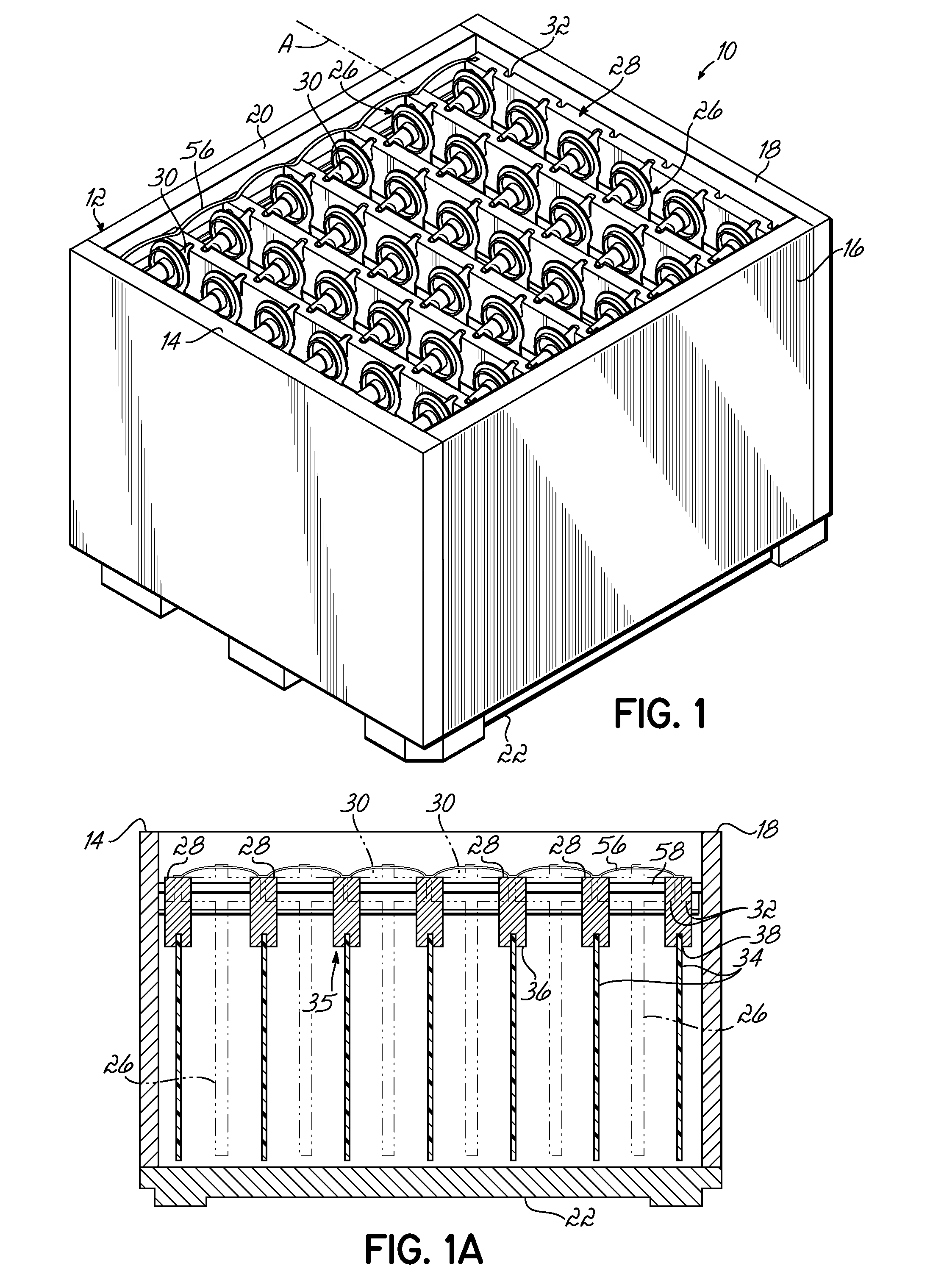

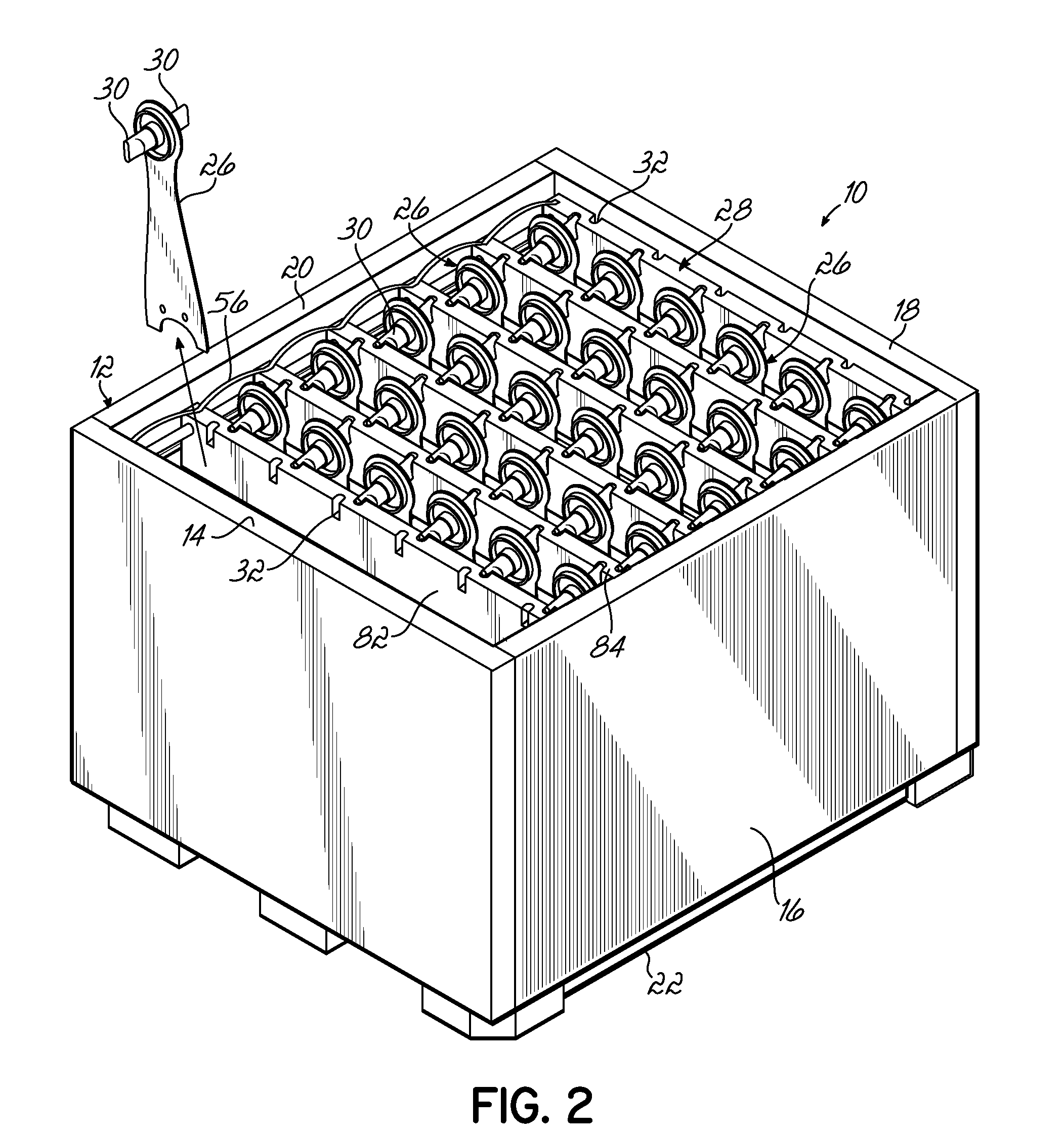

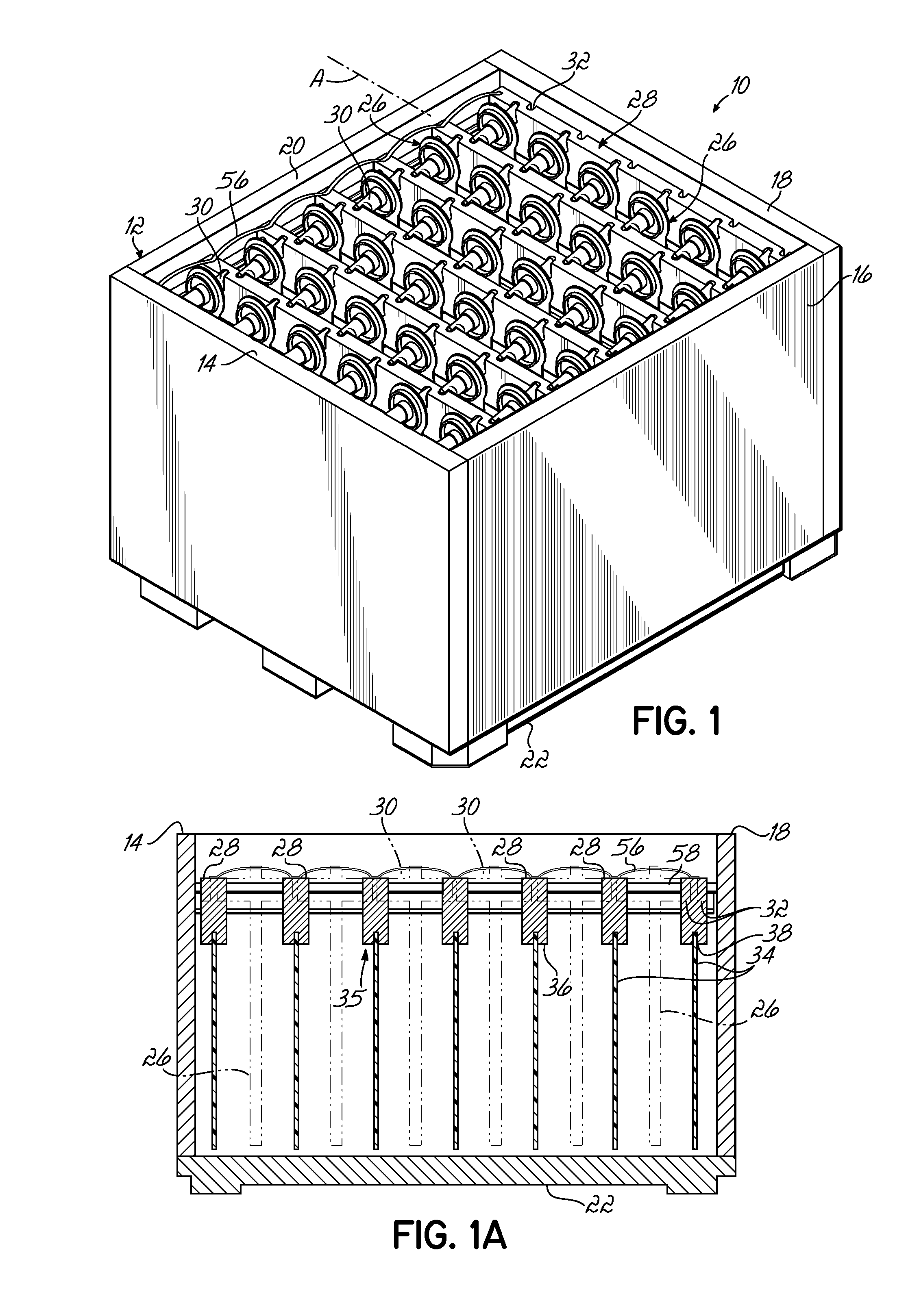

Container having sliding support member assemblies for supporting dunnage

InactiveUS20060249514A1DistanceHigh densityPackaging vehiclesContainers for machinesDunnageEngineering

The present invention provides a container for holding product therein during shipment and being returned for reuse that has a body, tracks attached to opposite sides of the body, and a plurality of support members extending between the tracks. Sliders are located at the ends of tubular supports, the sliders being slidable in the tracks to move the support members. The support members support dunnage for supporting products for storage or shipment.

Owner:BRADFORD CO

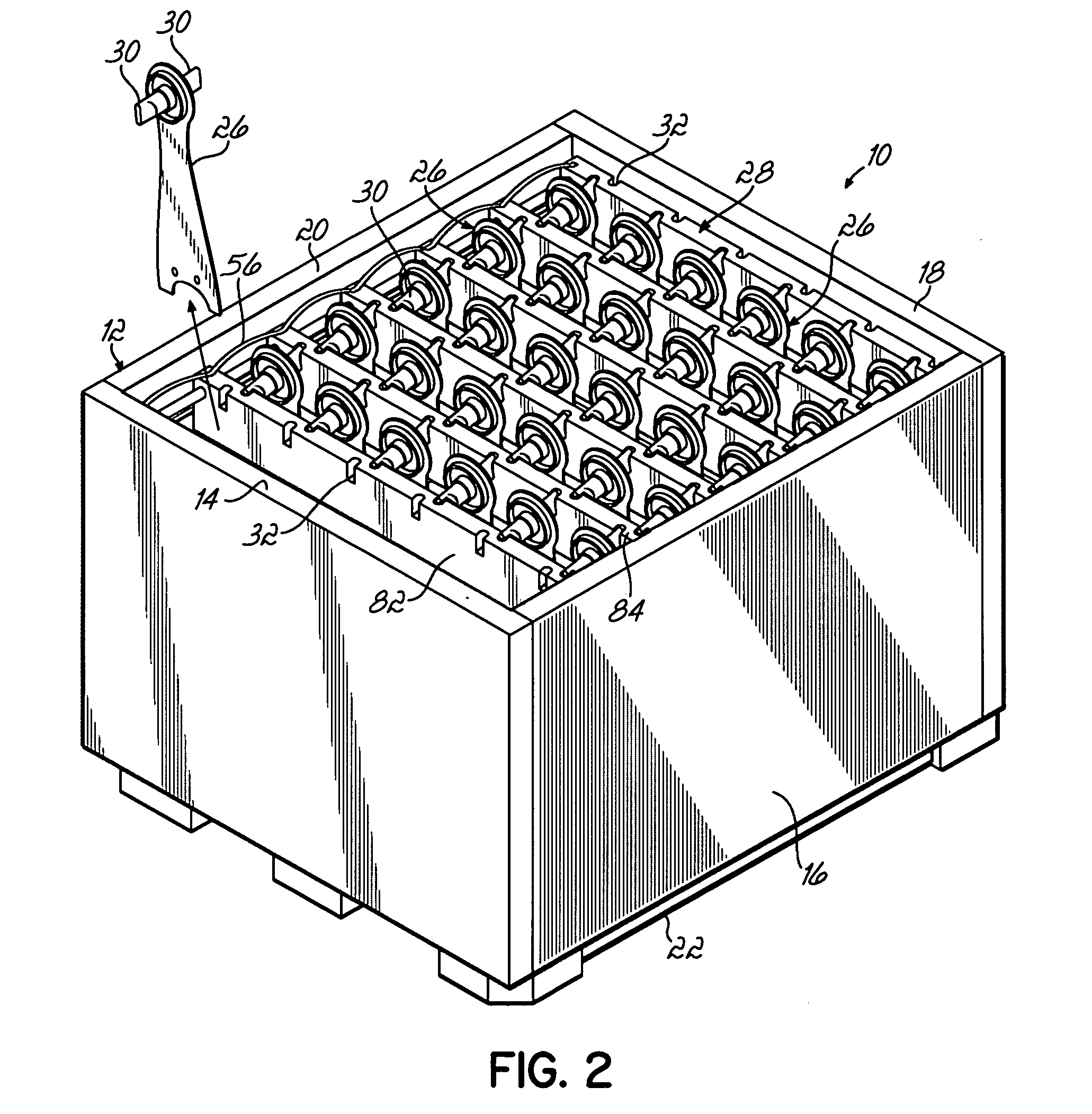

Container having non-linear support members for supporting dunnage

The present invention provides a container for holding product therein during shipment and being returned for reuse that has a body, tracks supported by the body, and a plurality of support member assemblies, each having a pair of end members engaged with and moveable along the tracks and a non-linear support member extending between and connected to the end members. The support member assemblies support dunnage for supporting products for storage or shipment.

Owner:BRADFORD CO

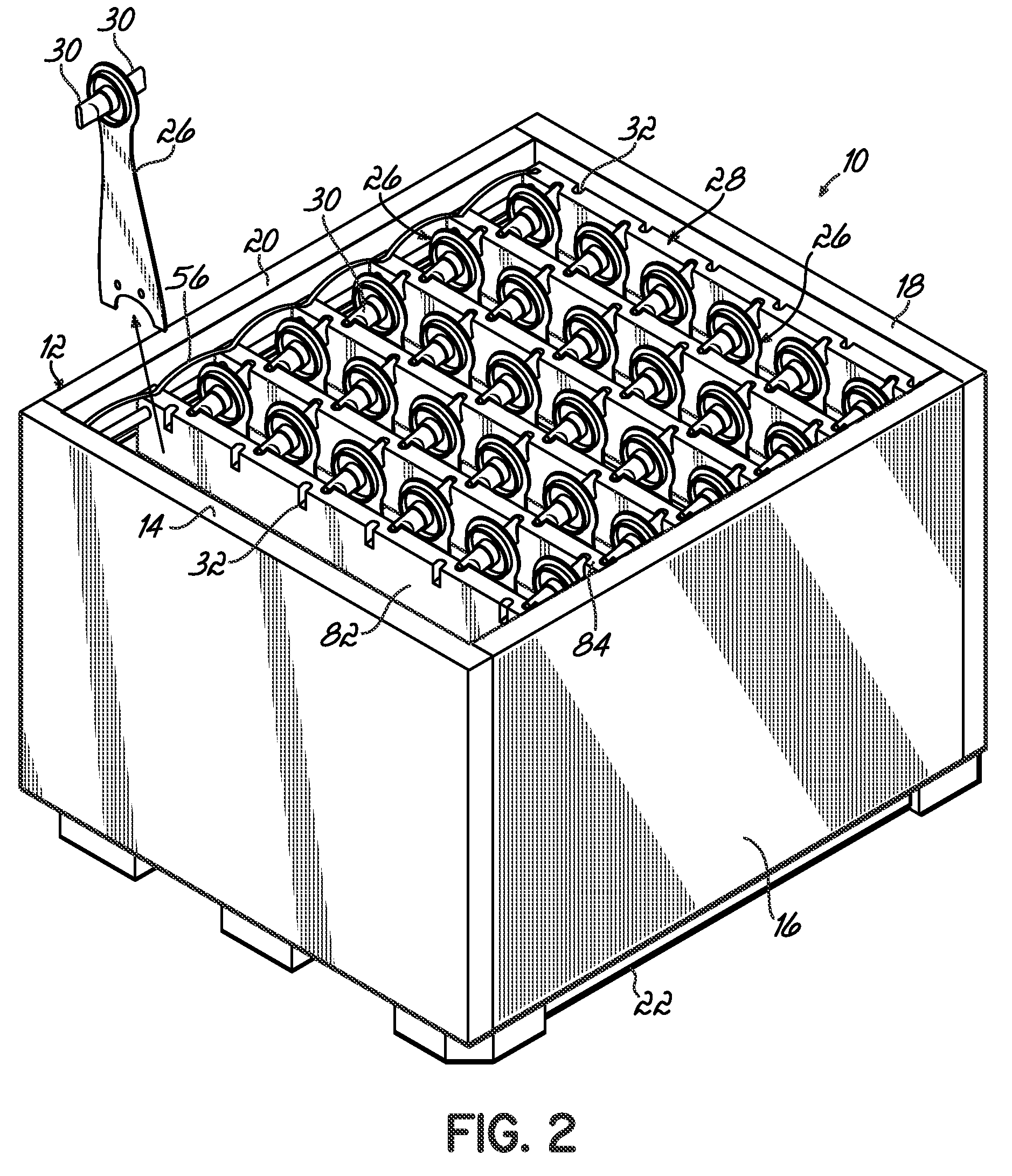

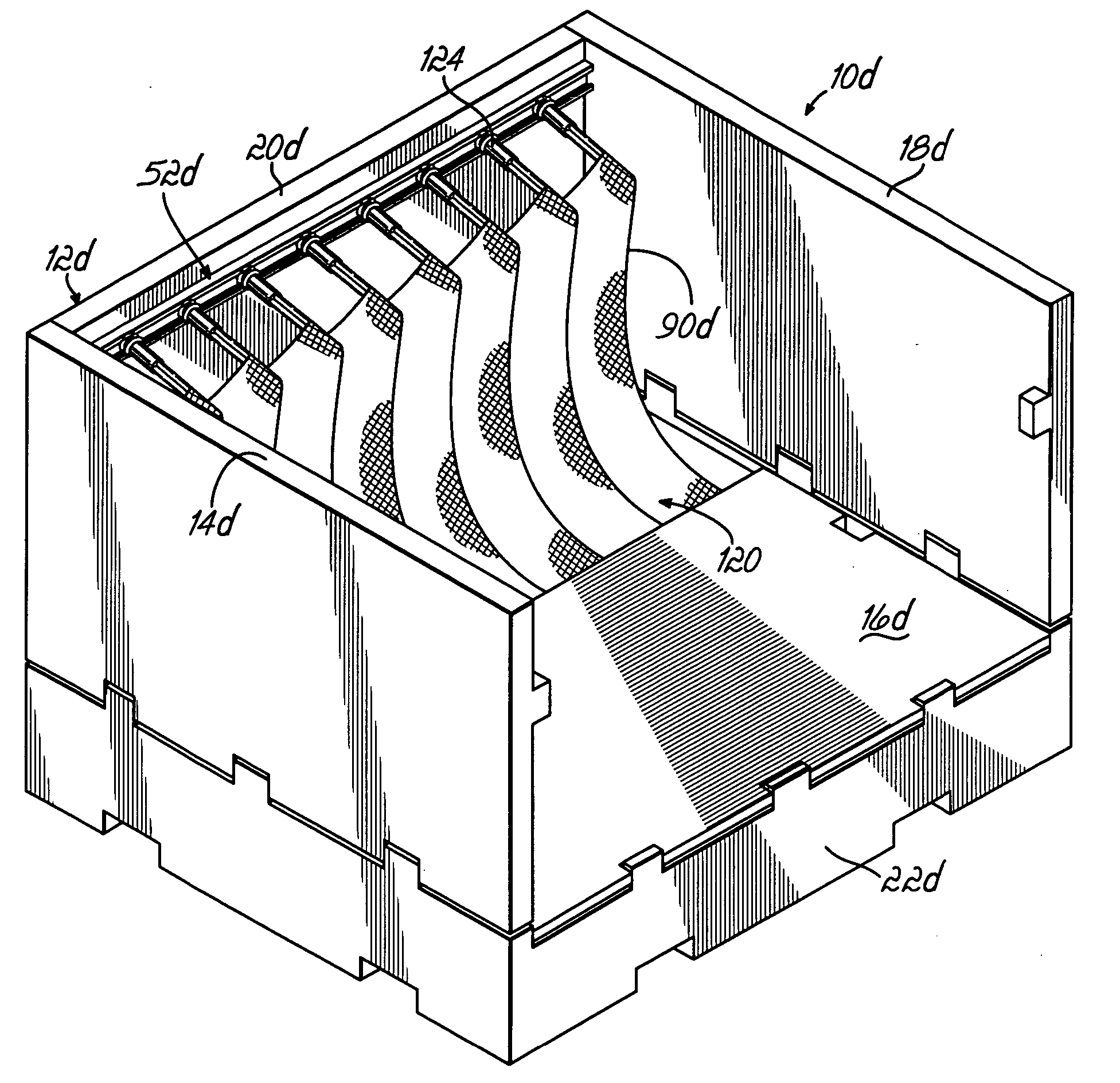

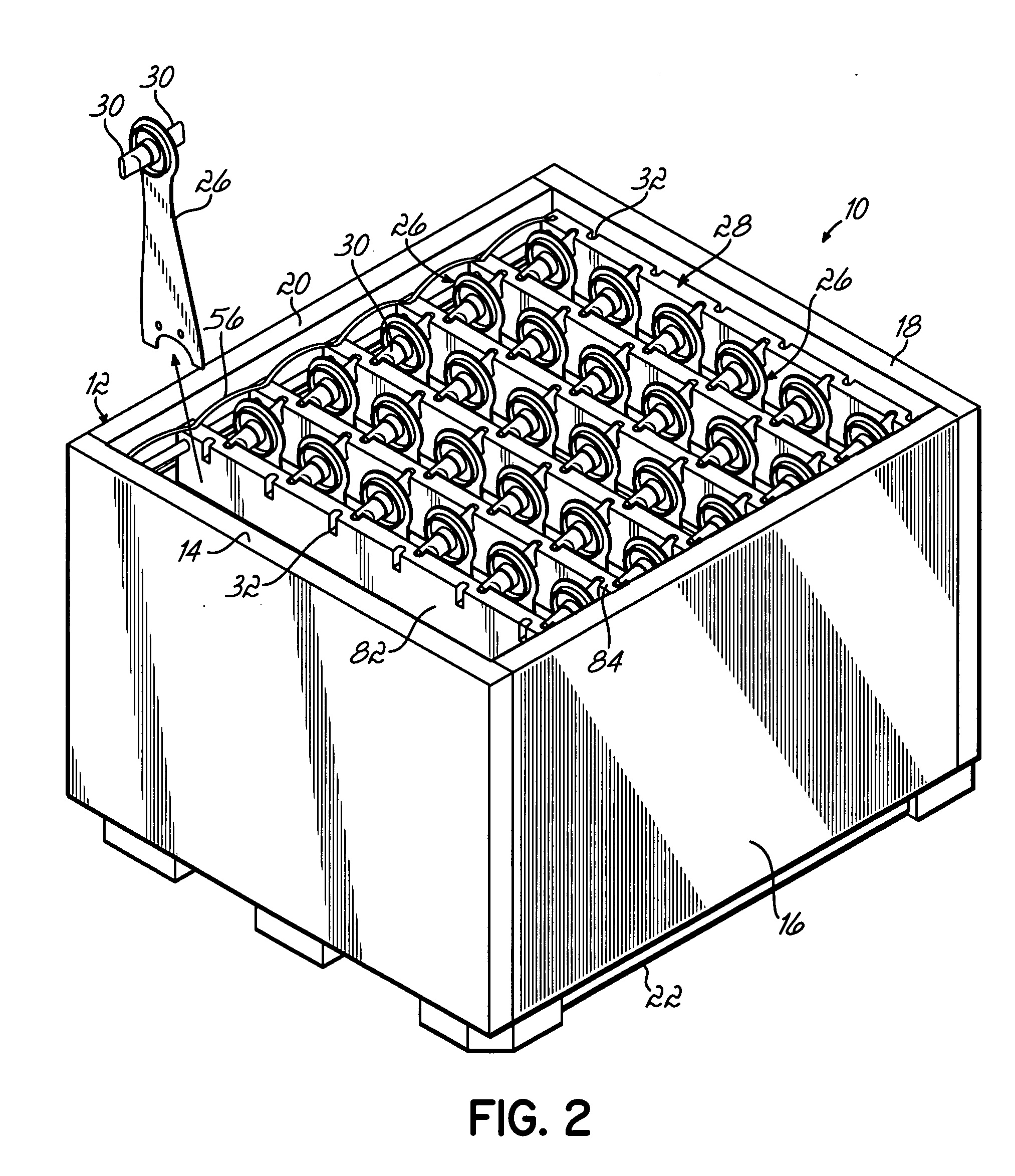

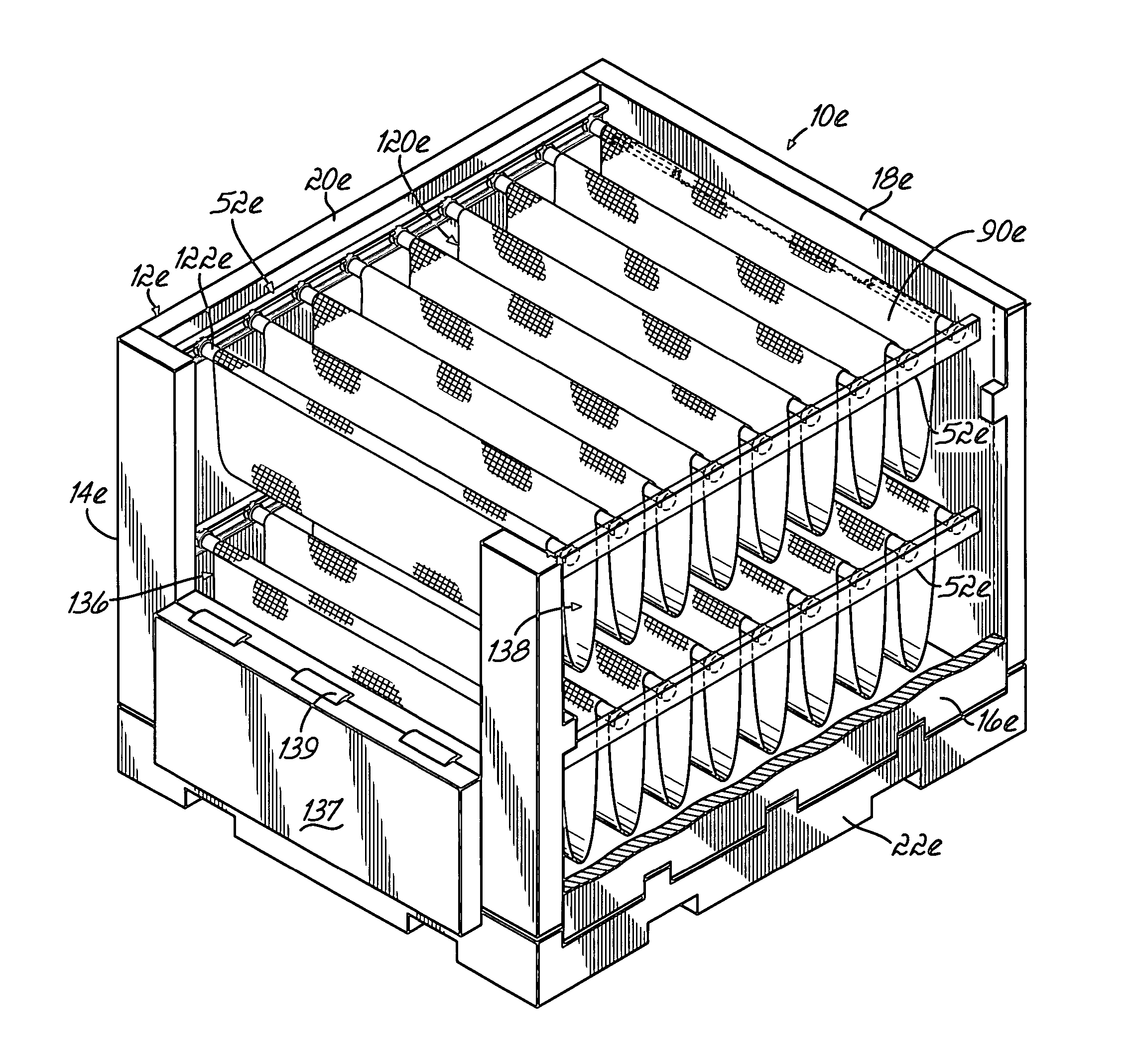

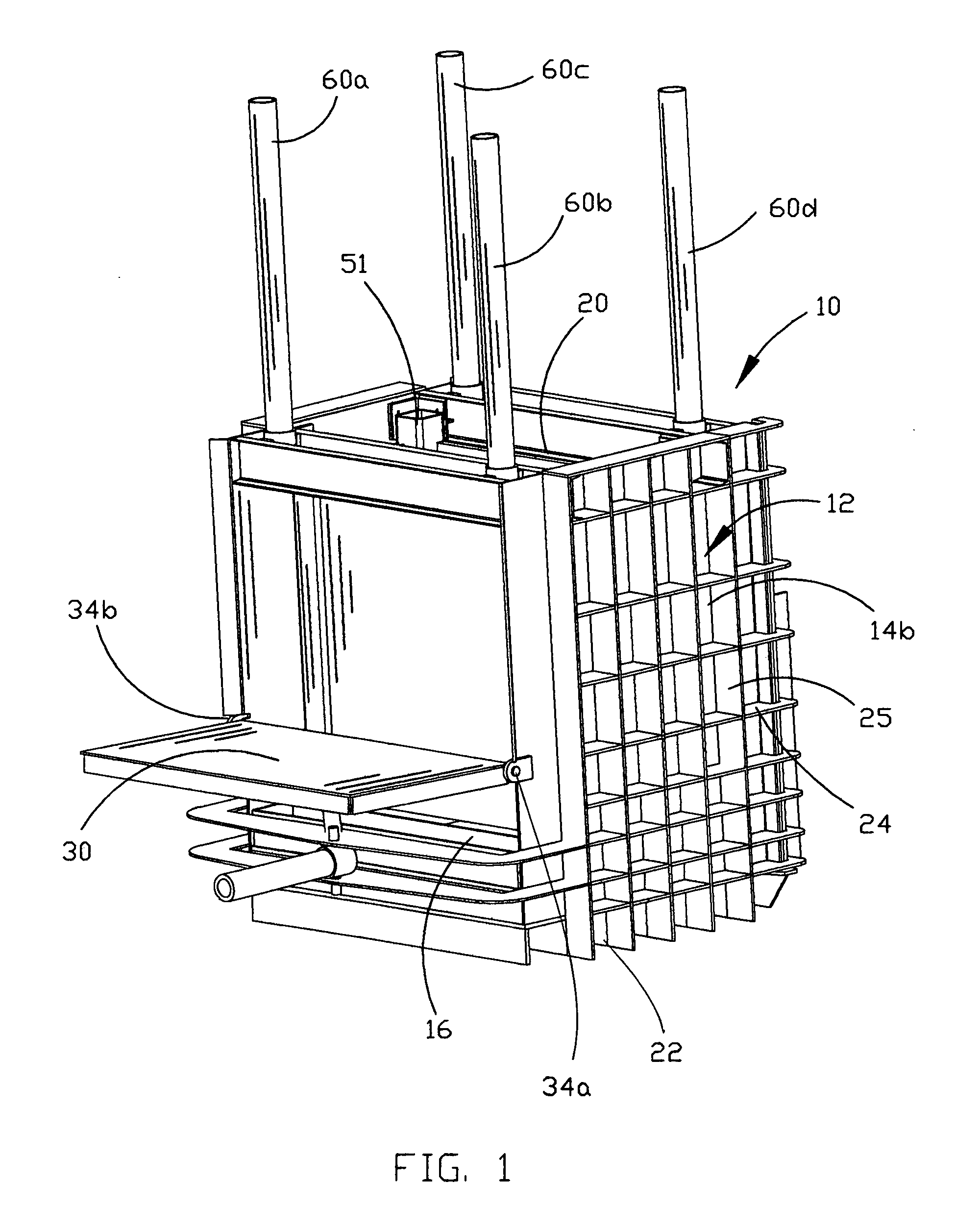

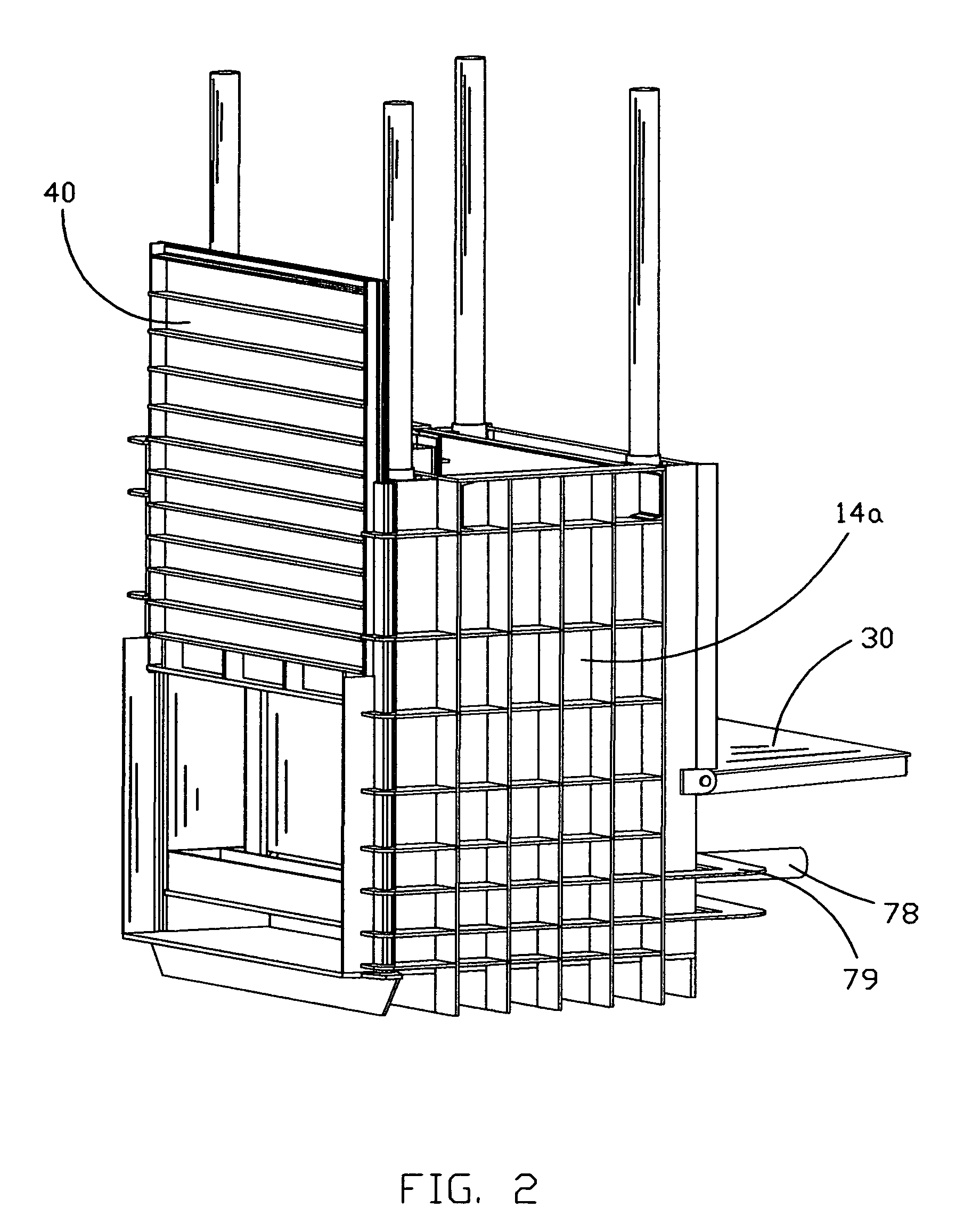

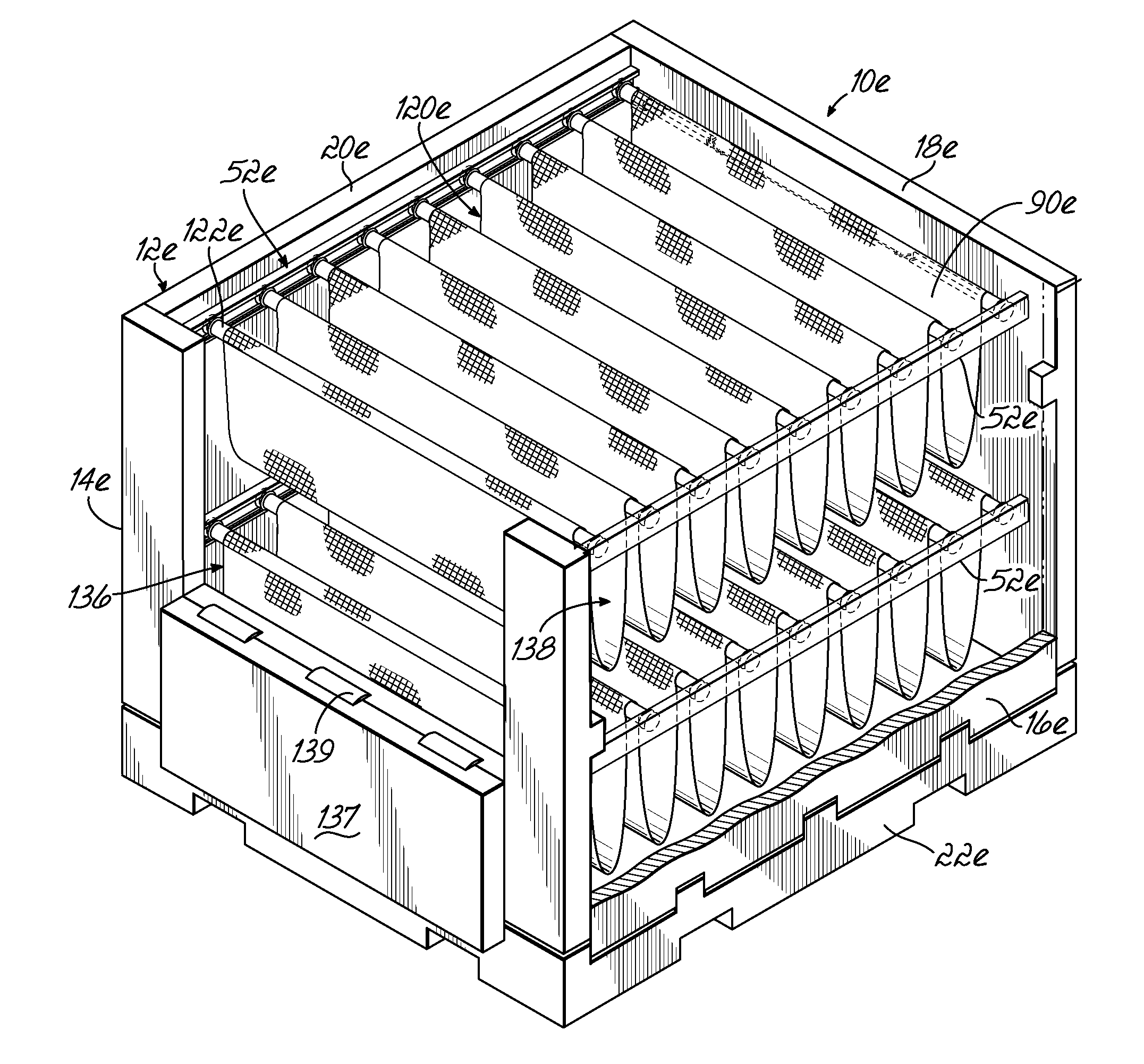

Collapsible container having sliding support member assemblies for supporting dunnage

The present invention provides a collapsible container for holding product therein during shipment and being returned for reuse that has a collapsible body, tracks attached to opposite sides of the collapsible body, and a plurality of support members extending between the tracks. Sliders are located at the ends of flexible supports, the sliders being slidable in the tracks to move the support members. The support members support dunnage for supporting products for storage or shipment.

Owner:BRADFORD CO

Quick loading cutting head for a rotary trimmer

InactiveUS20070130781A1Easy and quick loadingReduce fatigueMowersMetal working apparatusEngineeringClockwise

A cutting head for a rotary trimmer is provided. The cutting head of the present disclosure provides a control mechanism for loading a spool member of the cutting head quickly and efficiently without having to disassemble the cutting head. In one embodiment, a control mechanism is provided in the cutting head interacting between a follower member and a spool member so as to provide for one way rotational loading of flails, e.g., cutting line, into the cutting head; in other words, to load the flails, the spool member is rotated continuously 360° in one direction only, e.g., clockwise. In another embodiment, a cutting head allows the flails to be loaded by a ratcheting-type operation, i.e., a back and forth rotational movement, which is less fatiguing and even more efficient in its loading operation.

Owner:KWIK PRODS

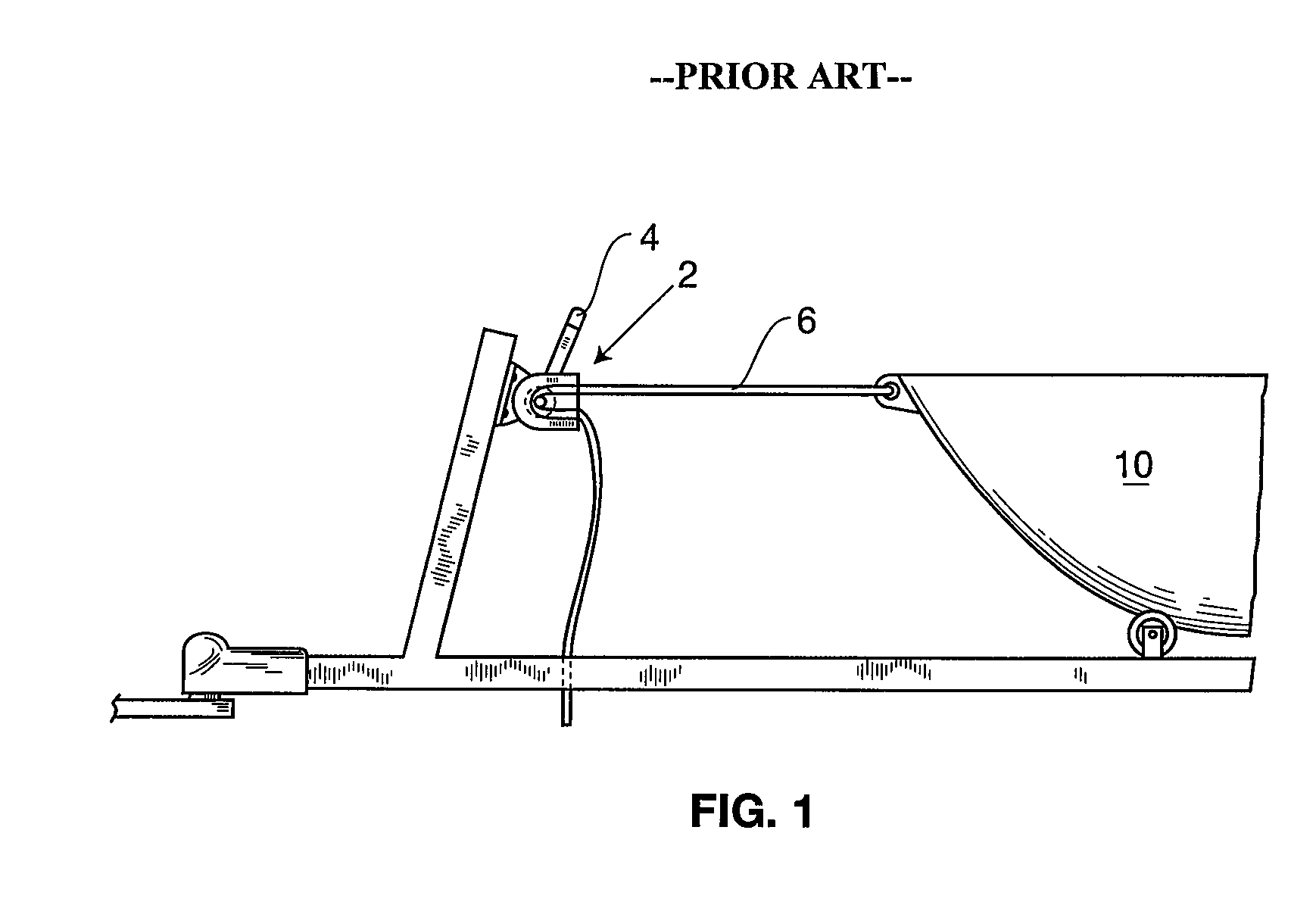

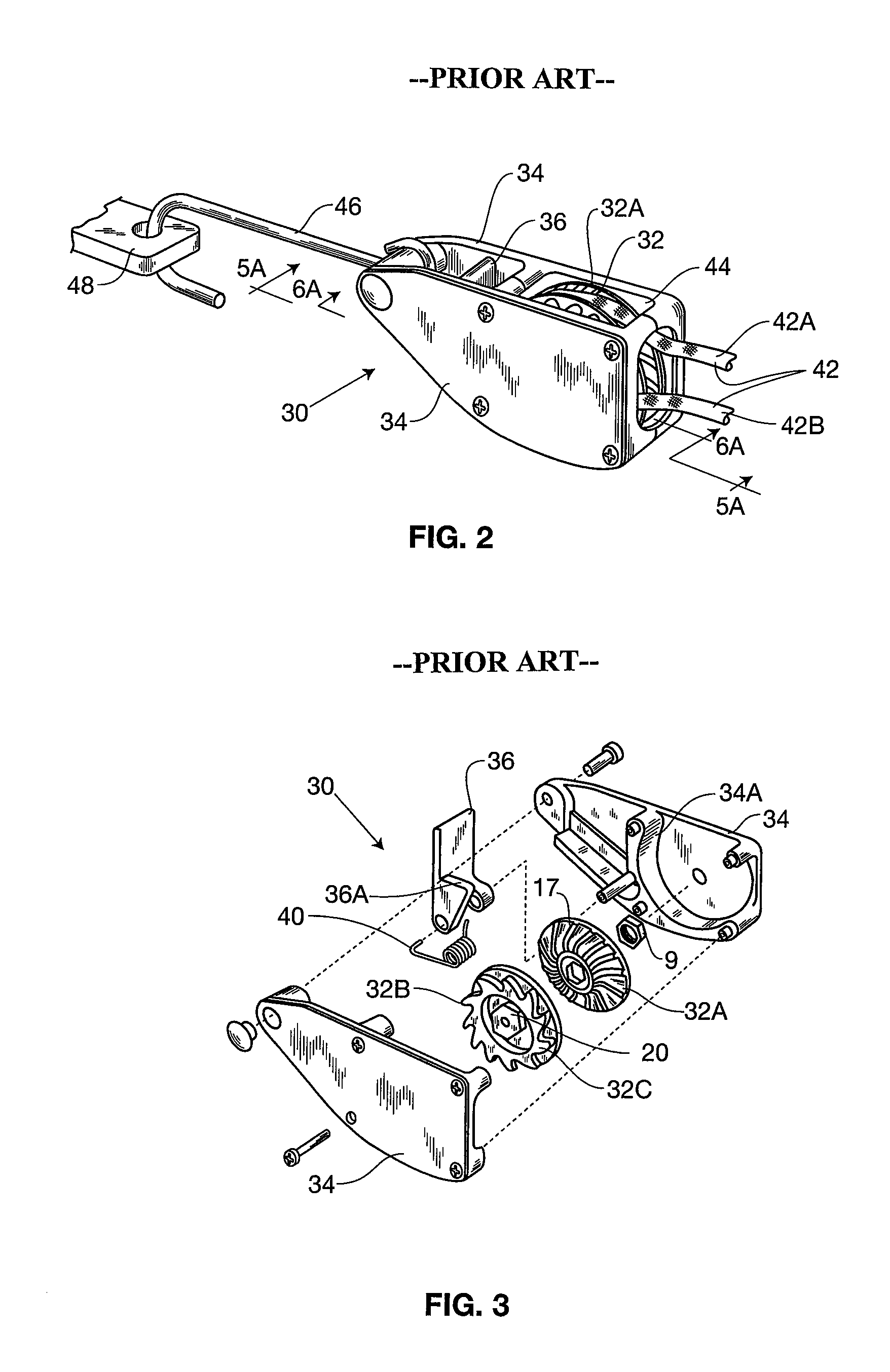

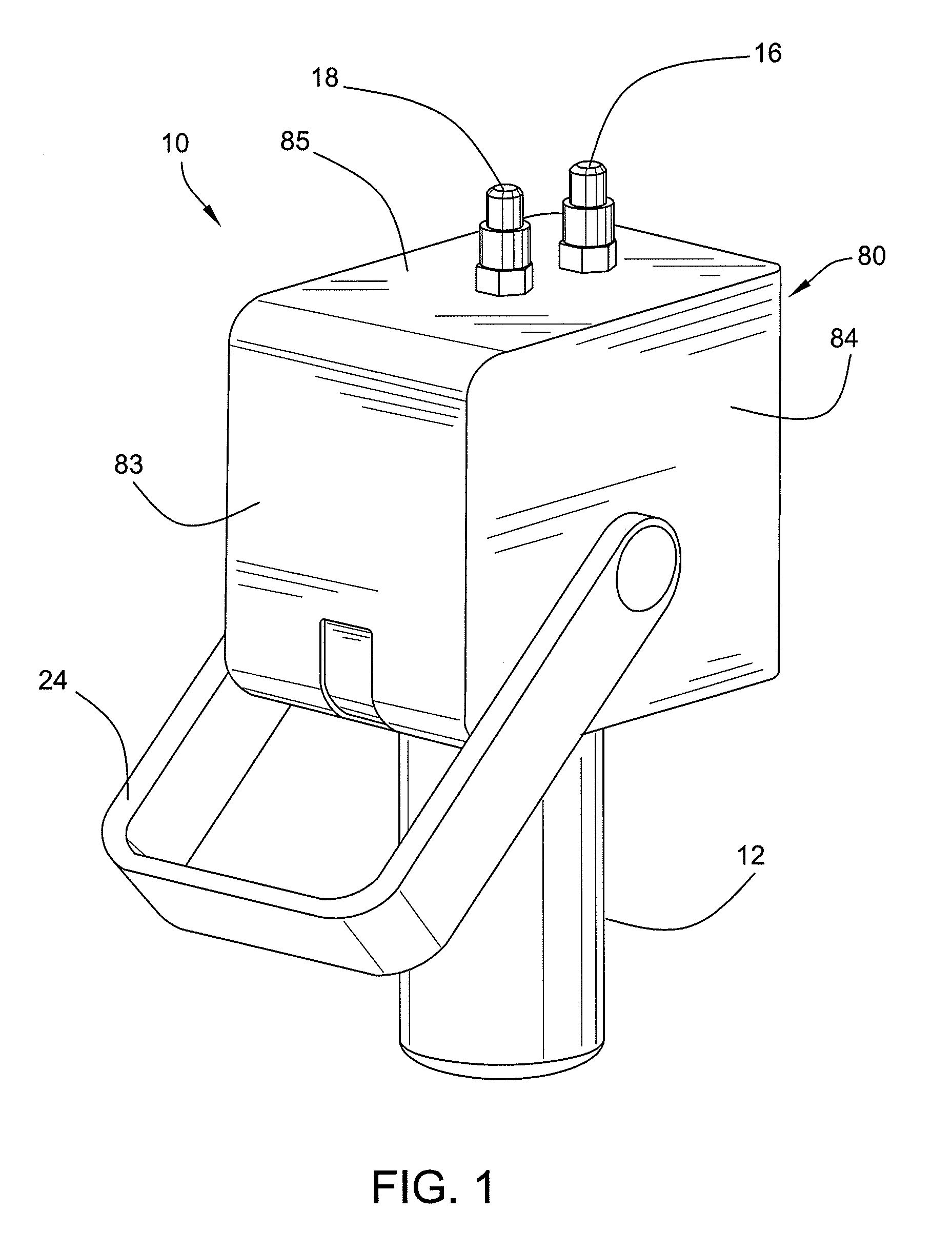

Ratchet pulley device for tightening cords or ropes

ActiveUS7537199B1Easy and quick loadingReduce the possibilityPortable liftingLifting devicesFree rotationEngineering

A ratcheting pulley device is shown and described. In one embodiment, the device includes a sheave rotatably mounted in a housing. The housing defines an opening for ingress and egress of a rope or cord into the housing and around the sheave. The device includes a releasable ratchet mechanism, which, when engaged, permits rotation of the sheave in one direction but not the other, and which, when released, permits free rotation of the sheave. A loading-disk is mounted on the exterior of the housing and is in rotational communication with the sheave. The loading-disk allows rope or cord to be operably and quickly loaded into the device.

Owner:CAROLINA NORTH MFG

Collapsible container having sliding support member assemblies for supporting dunnage

Owner:BRADFORD CO

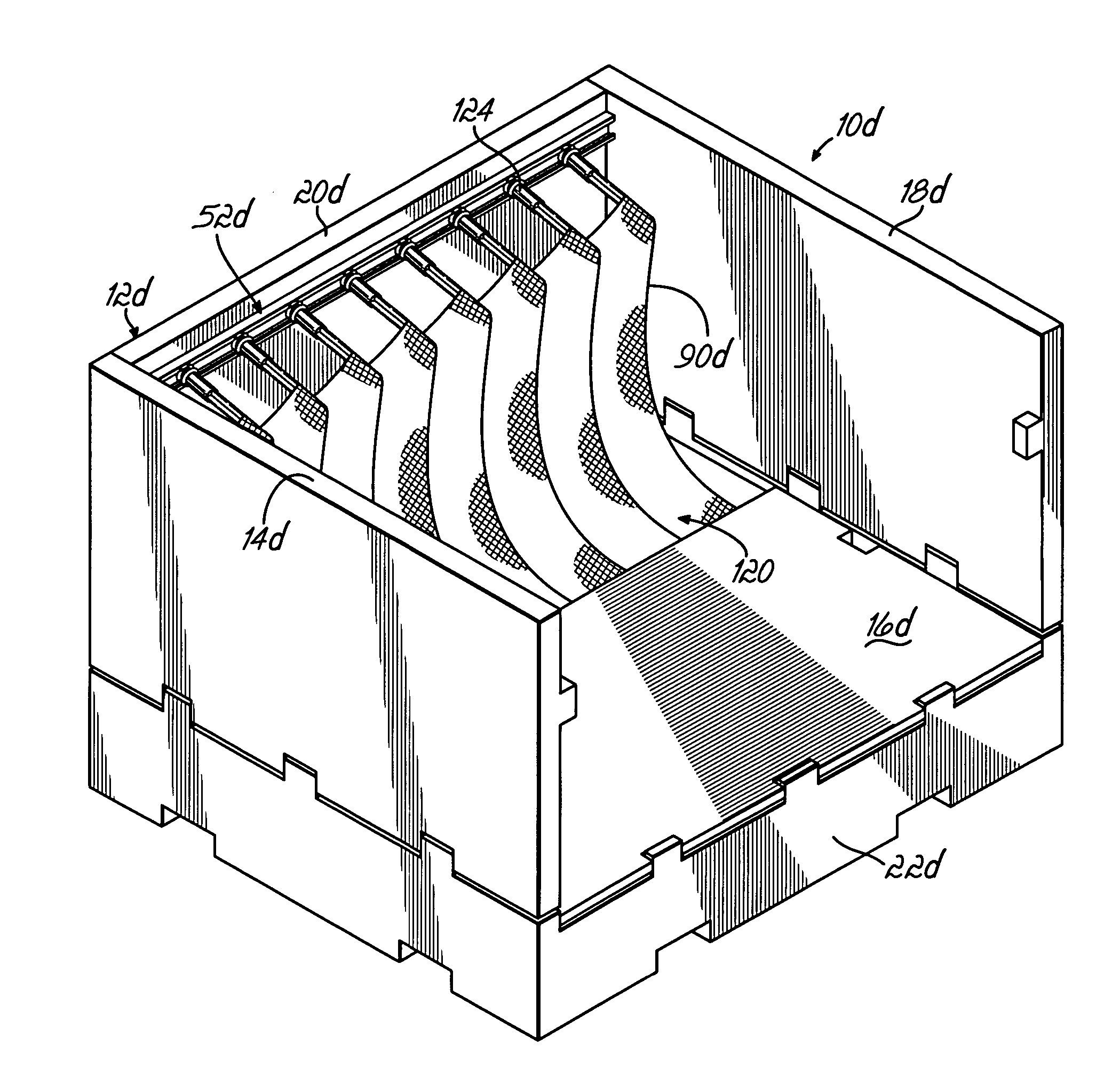

Container having sloped movable support member assemblies for supporting dunnage

The present invention provides a container for holding product therein during shipment and being returned for reuse that has a body, tracks attached to opposite sides of the body, and a plurality of support member assemblies extending between the tracks for supporting dunnage. End members are located at the ends of supports, the end members being movable in the tracks to move the supports inside the container. The supports are oriented in a sloping, non-horizontal position and movable in such orientations to maximize product density inside the container.

Owner:BRADFORD CO

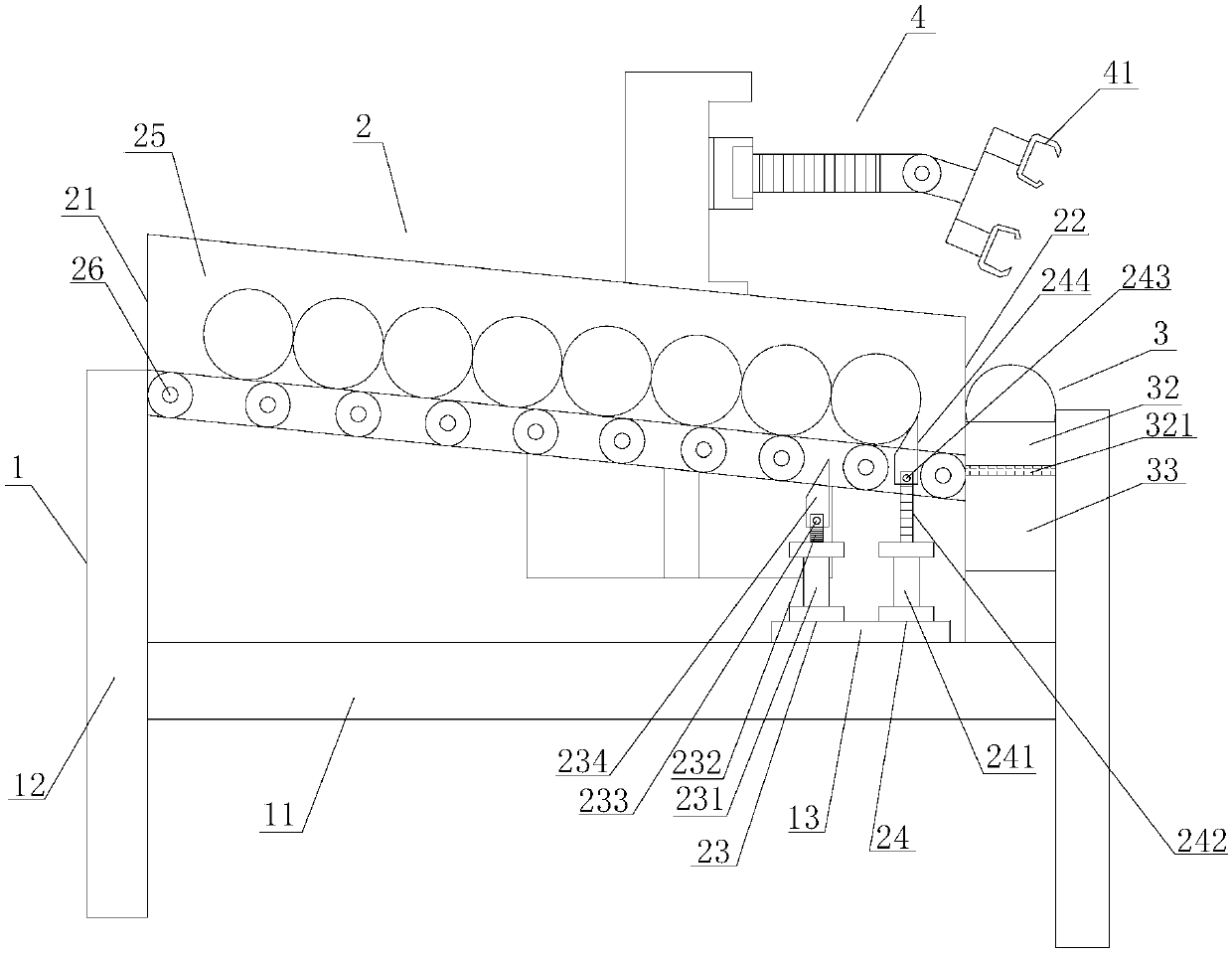

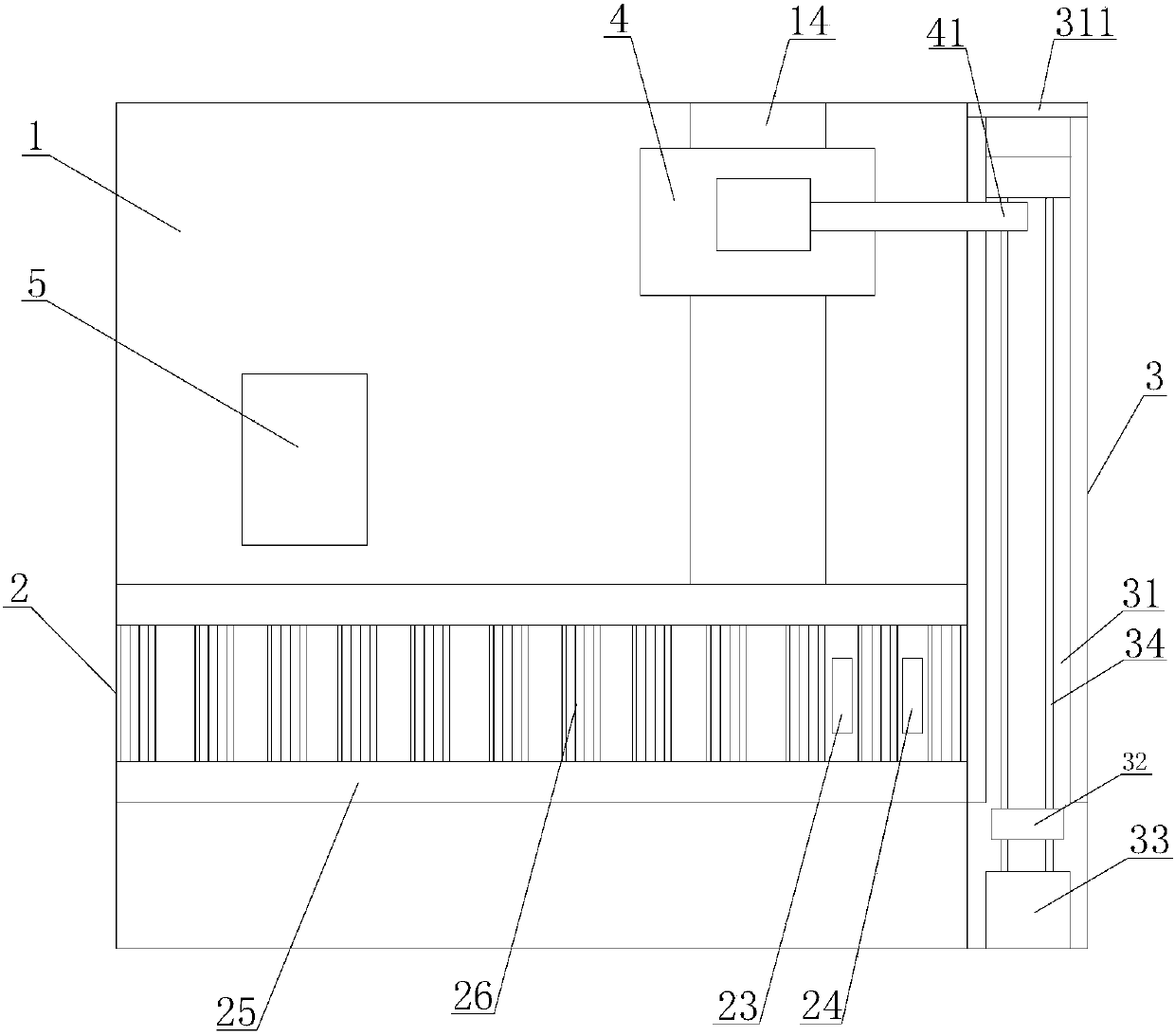

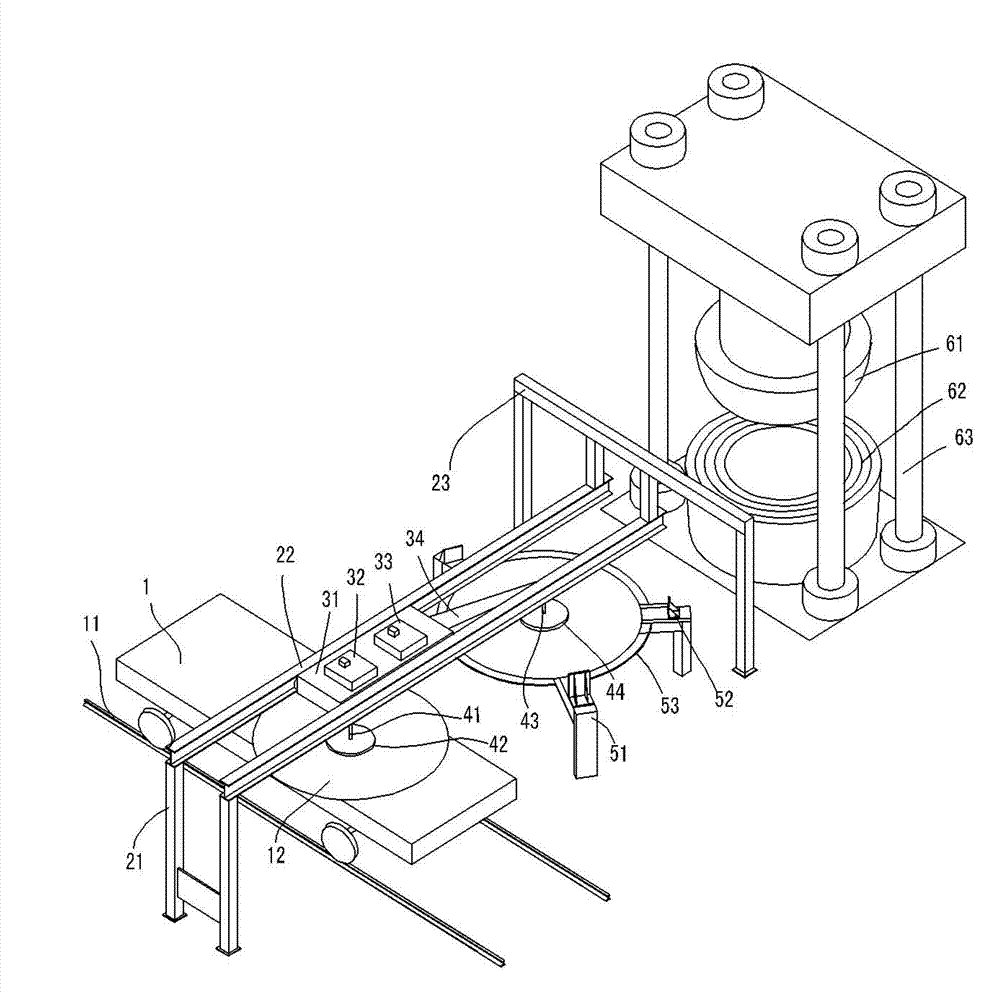

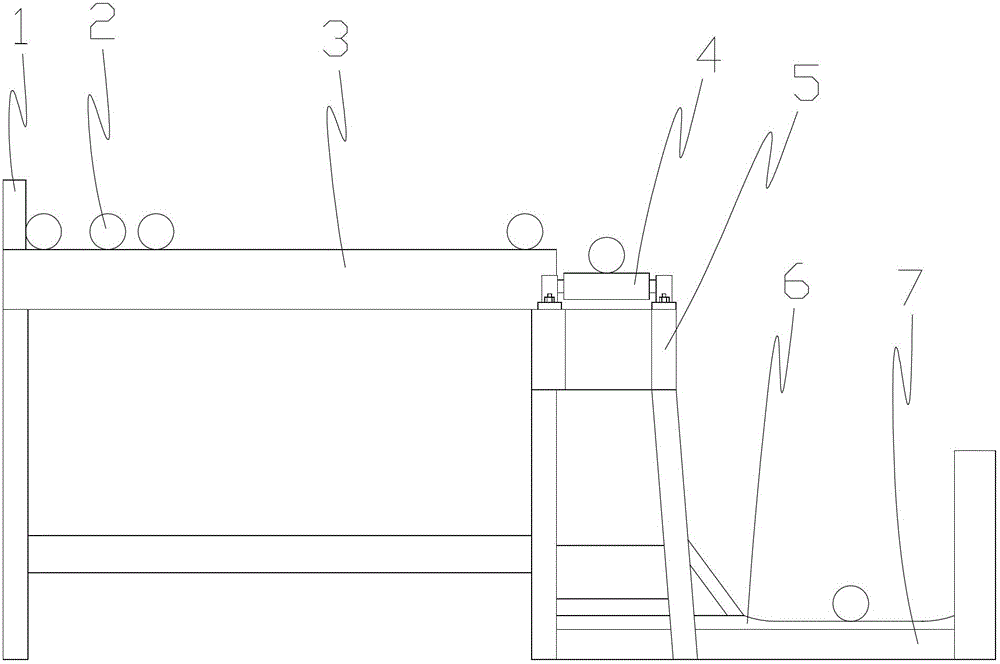

Automatic feeding device for jack cylinder machining

PendingCN107695771ASimple and fast operationReduce labor intensityMetal working apparatusEngineeringTransfer mechanism

The invention discloses an automatic feeding device for jack cylinder machining. The automatic feeding device comprises a base, a feeding mechanism, a conveying mechanism, a clamping mechanism and a control mechanism, wherein a blocking assembly and a discharging assembly cooperate with each other to feed products into the conveying mechanism one by one, the conveying mechanism is provided with aconveying rail and a cart, and the clamping mechanism is provided with clamping jaws capable of clamping to-be-machined cylinders on the conveying mechanism. According to the automatic feeding devicefor jack cylinder machining, through cooperation of the feeding mechanism, the conveying mechanism and the clamping mechanism, one to-be-machined cylinder is precisely fed every time, the material preparing process and the feeding process are continuous, the control mechanism is easy and convenient to operate, the labor intensity of operating personnel is reduced, the production cost is reduced, and the production efficiency is improved; through cooperation of a servo motor and a ball screw, the material conveying accuracy and stability of the cart on the conveying rail are guaranteed; and theto-be-machined cylinders which are conveyed orderly on the conveying rail are precisely clamped into a machining device through the clamping jaws of the clamping mechanism, and therefore the feedingprocess is easy and quick.

Owner:JIAXING LINSHENG HYDRAULIC TOOLS

Music page score turner

InactiveUS7238872B1Easy to useAccommodate and successfully and efficientlyBook markersMusic aidsElectric motorEngineering

A mechanical page turner using a removable rack with space page turning bars operated by preloading the rack with pages of a musical score or the like, mounting the rack in the page turning apparatus and then moving the rack by a spiral rod driven by an electric motor from one portion of the apparatus to another.

Owner:EDWARDS ROBERT W

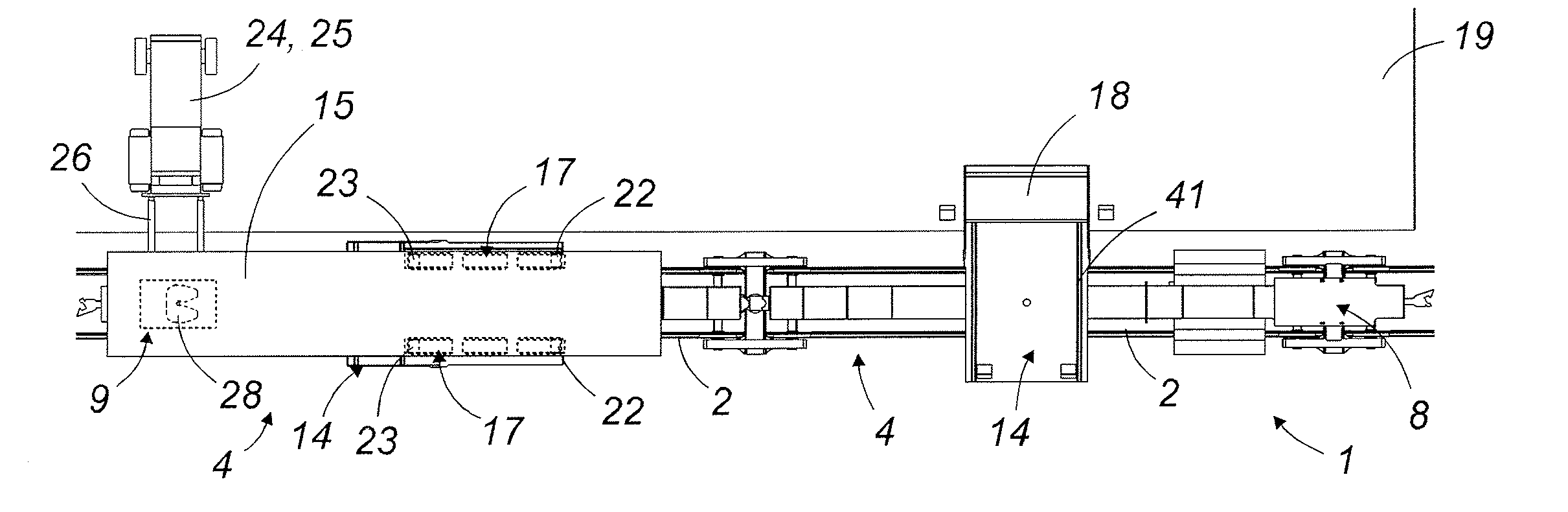

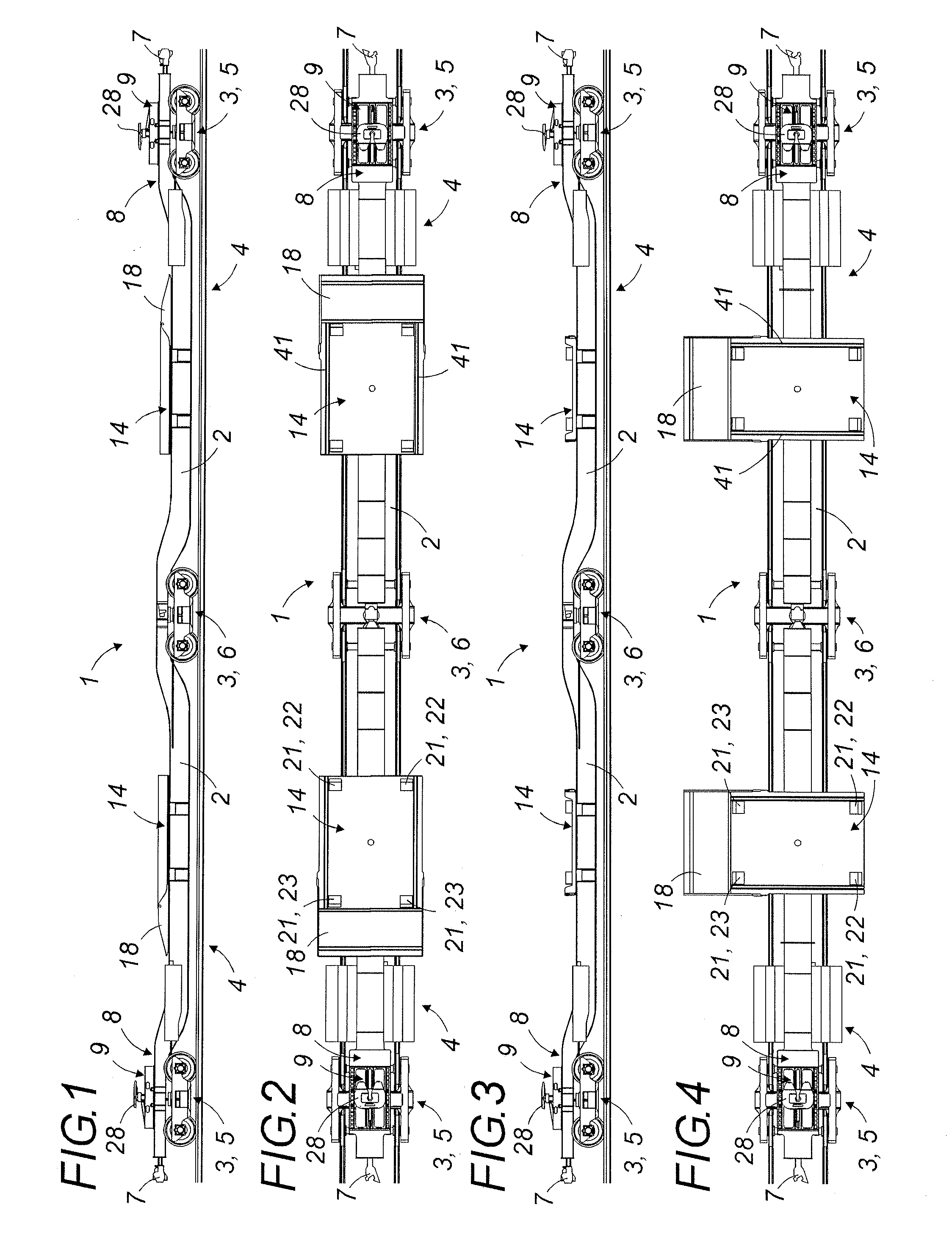

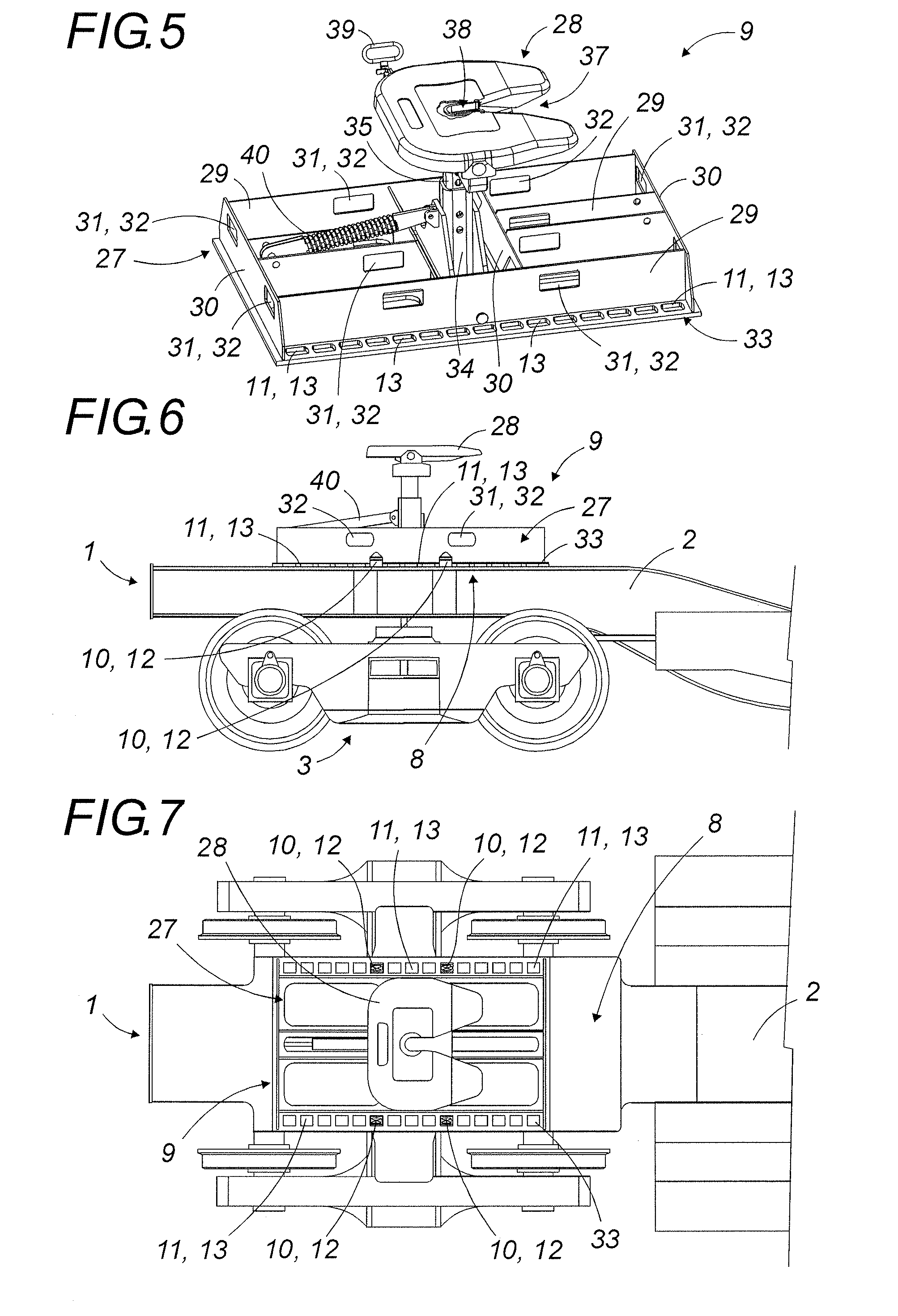

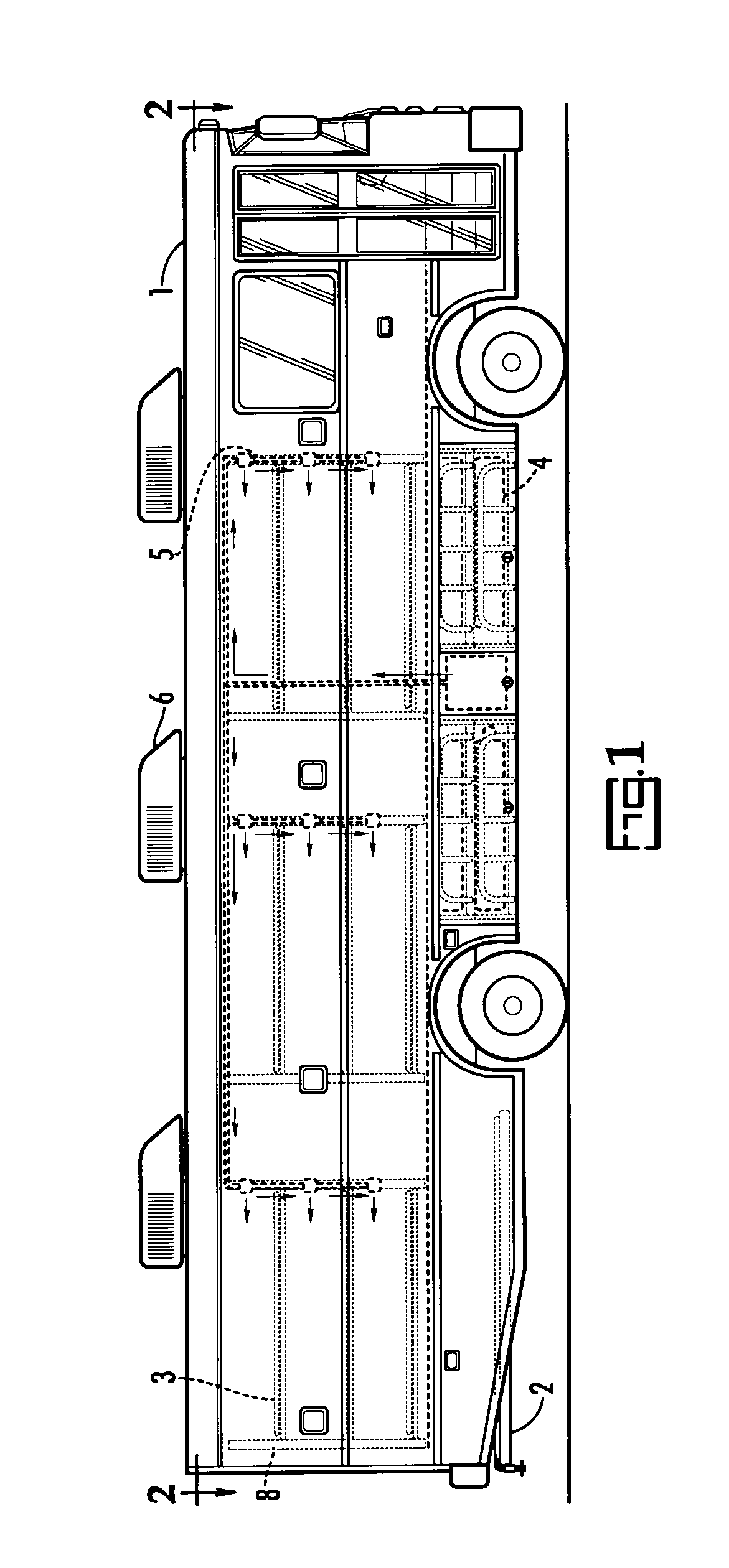

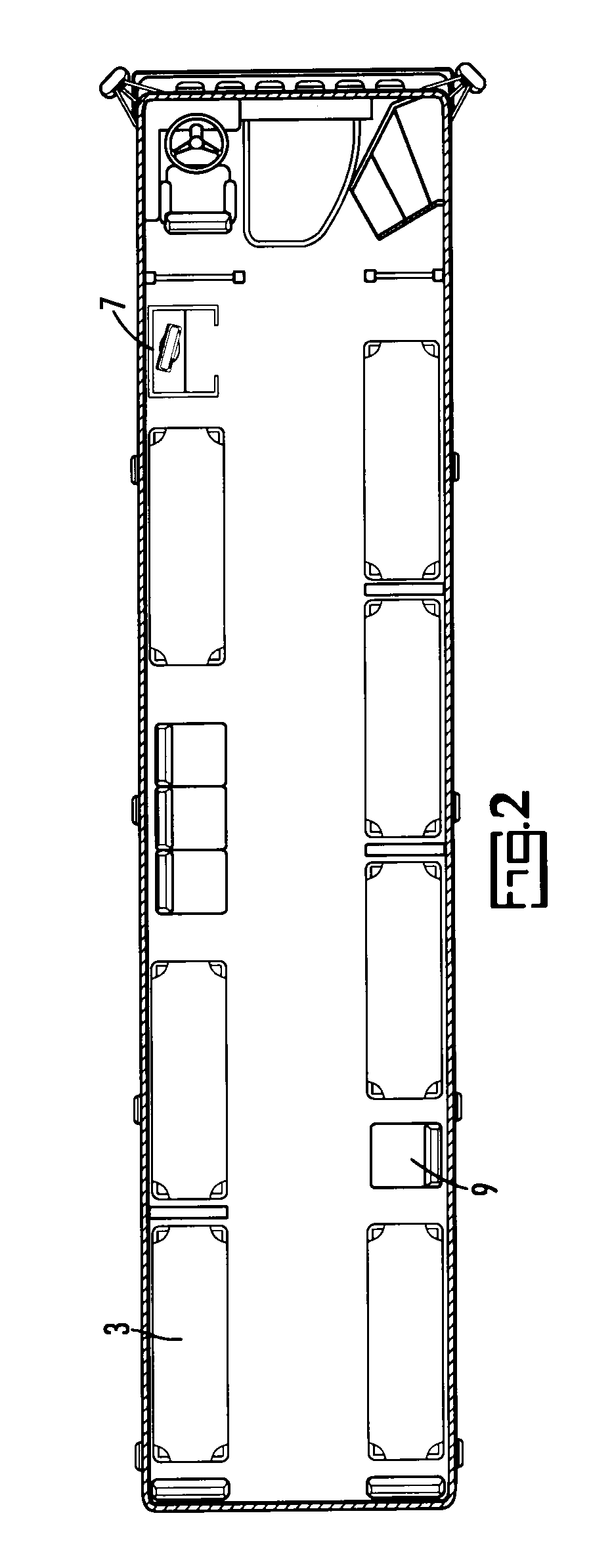

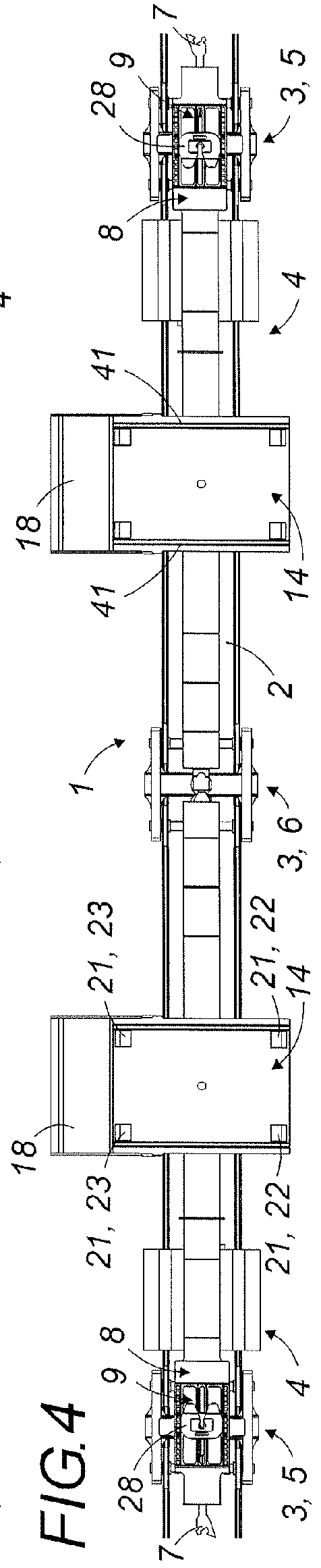

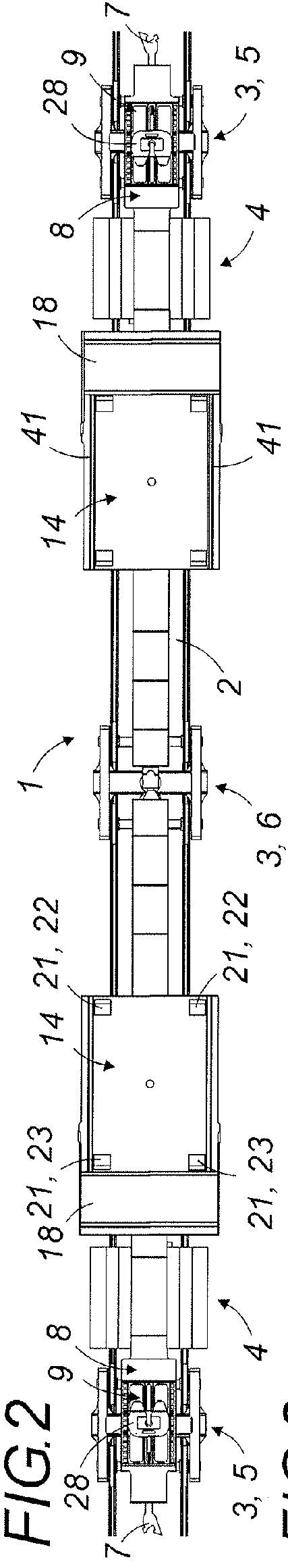

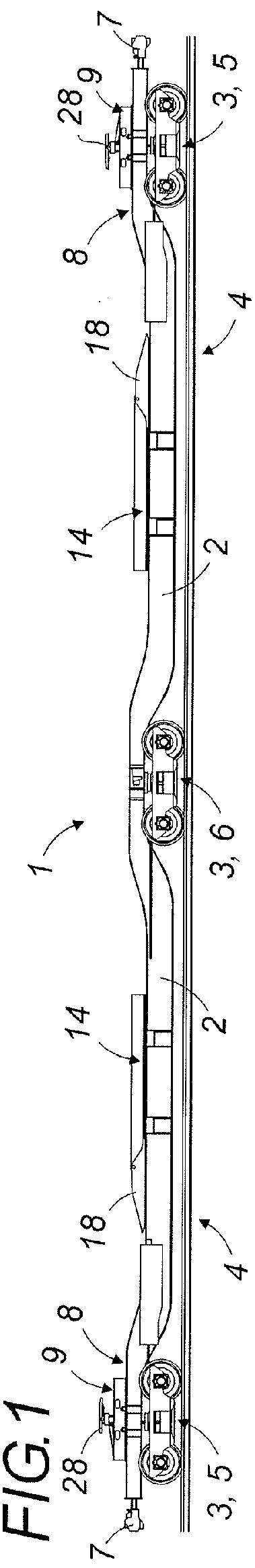

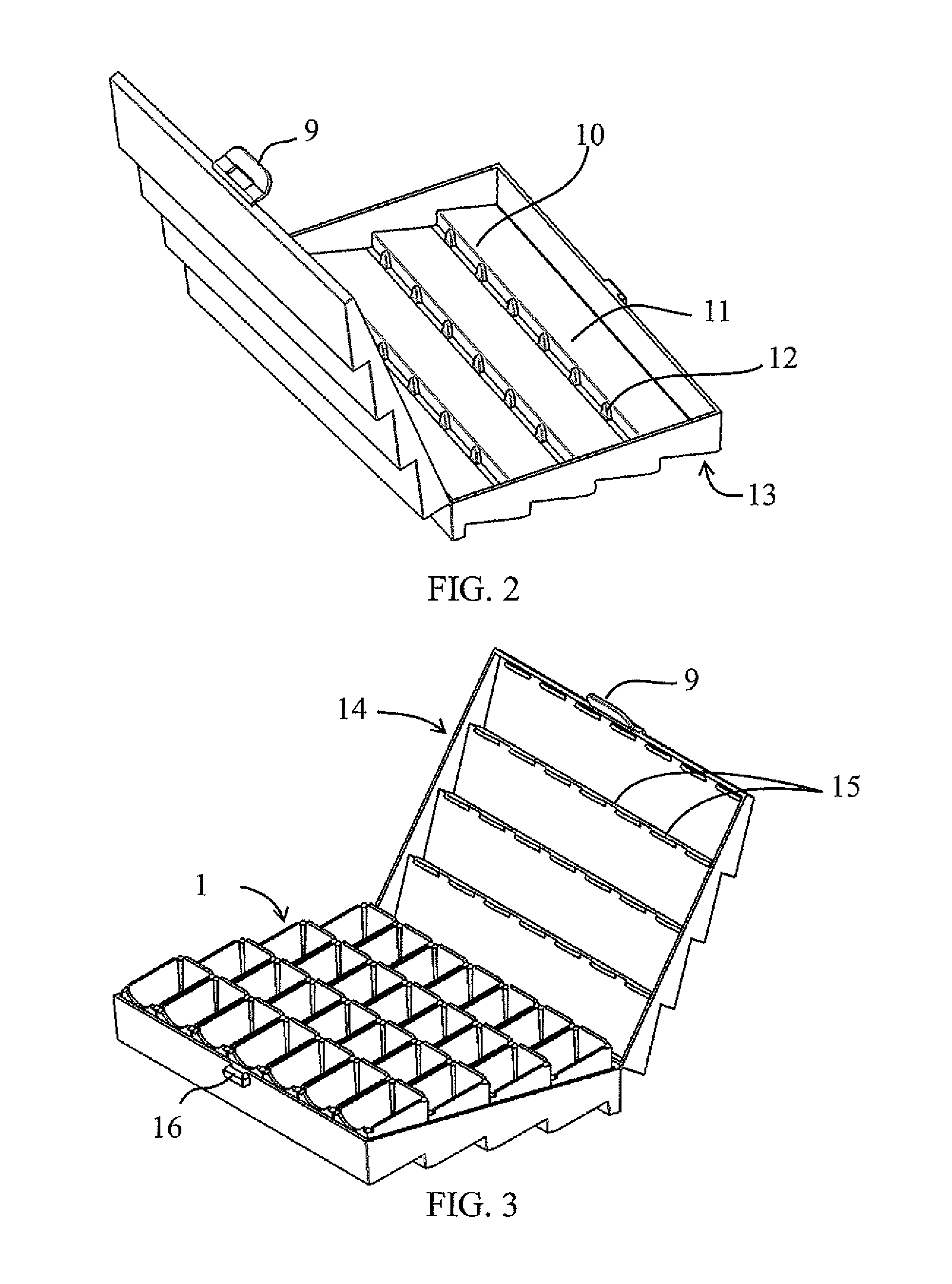

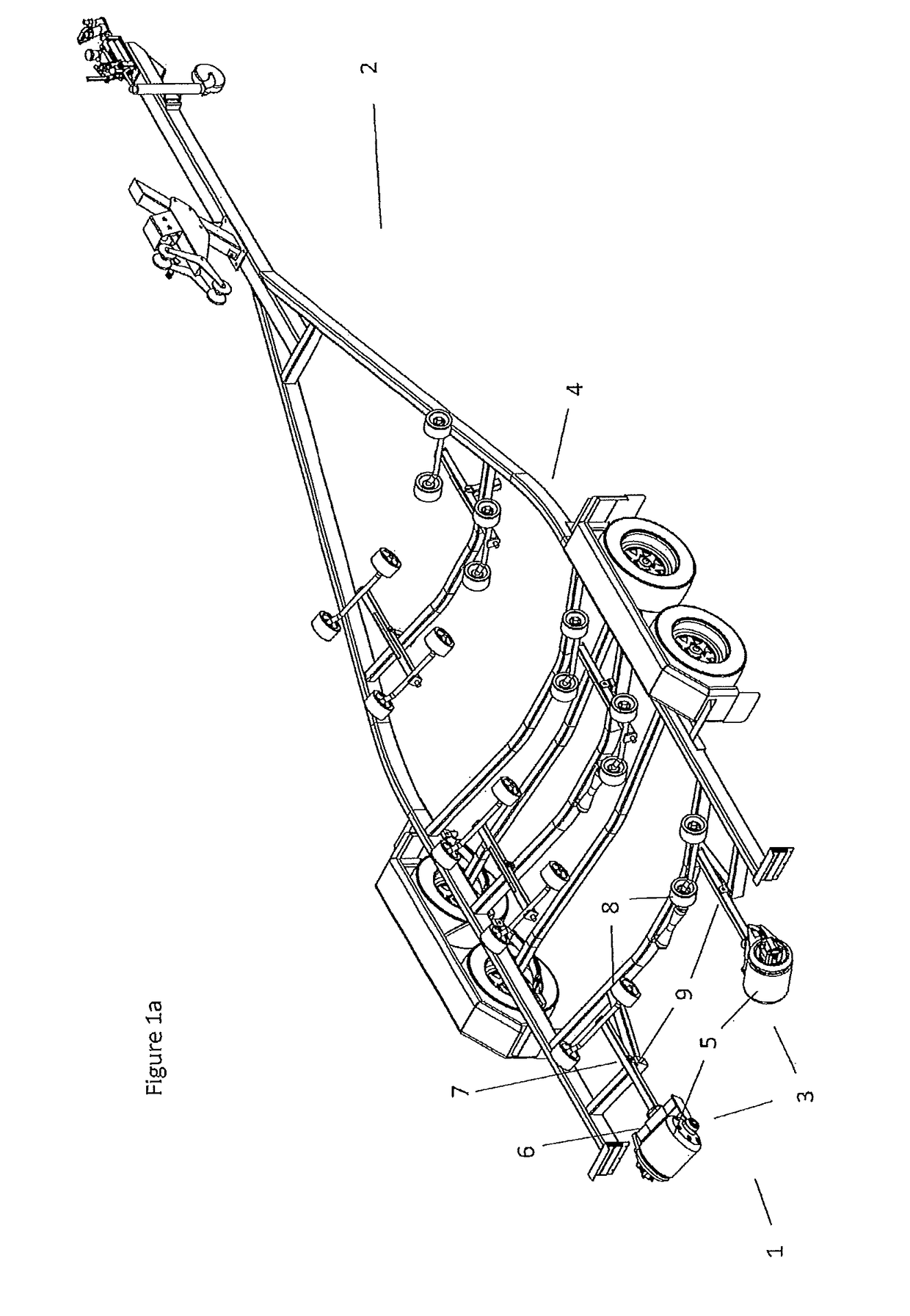

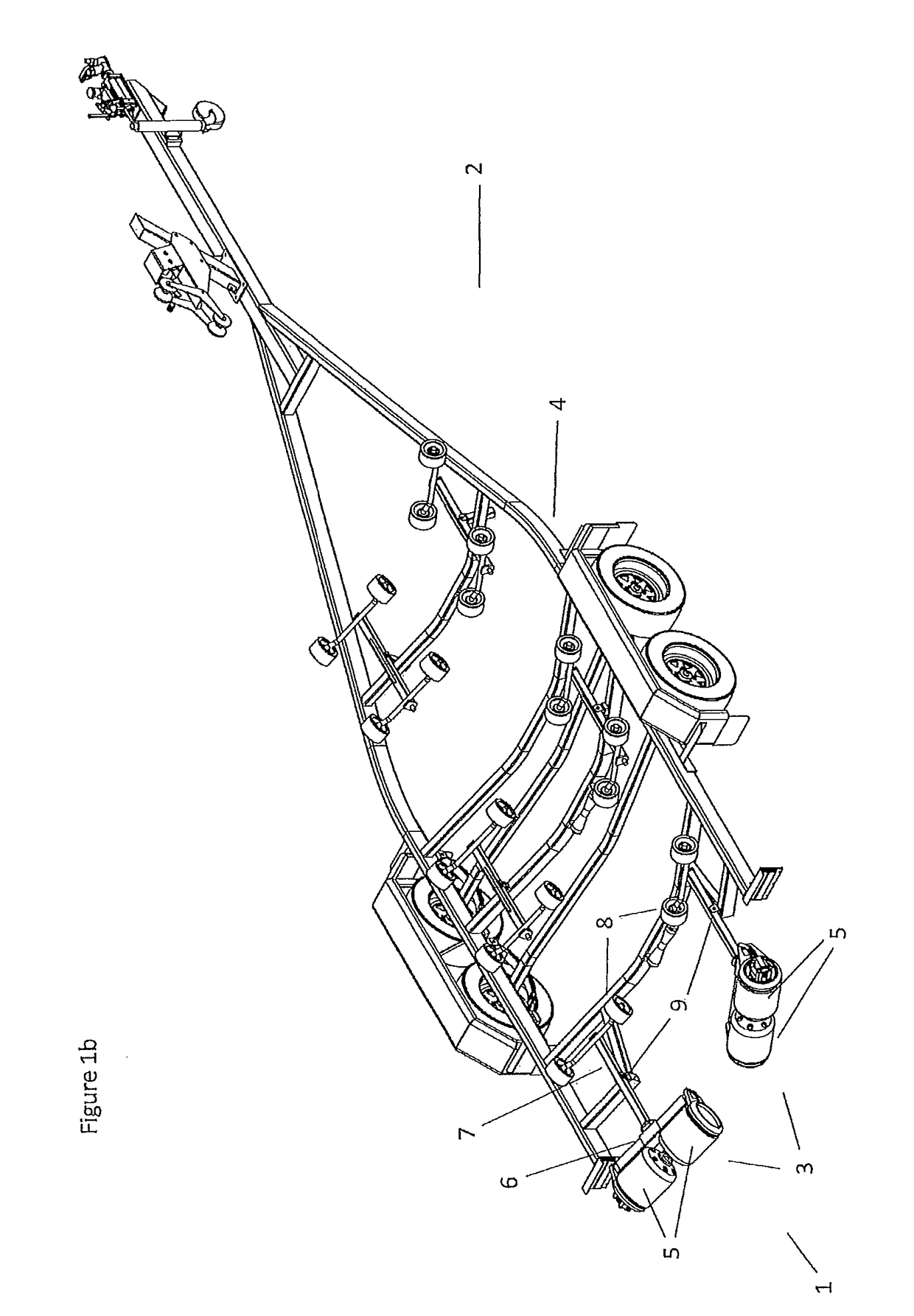

Universal system for the loading/unloading and rail transport of road semitrailers

ActiveUS20130272828A1Simpler and less-costlyEasy constructionRefuse transferringRailway transportMachineSemi-trailer

A system for loading, unloading and rail transportation of road-hauled semi-trailers, having multiple wagons (1) constituting a railway train, with each of them incorporating at least one pivotable turntable (14) for accommodating a semi-trailer via its wheel assembly. The system also comprises a detachable hitch mounting (9) that can be gripped by a handling machine which carries the detachable mounting and assembles it, after adjustment on the semi-trailer's pivoting turntable. The hitch mounting is assembled on an accommodating platform (8) that is secured immobile to the wagon chassis (2) and independently of the pivoting turntable, in order to support the front of the semi-trailer during rail transportation. This invention is of interest to rail carriers and railway transport equipment manufacturers.

Owner:LOHR IND

Container having sliding support members

InactiveUS20060249415A1Efficiently and safely removedEasy accessOther accessoriesTray containersMechanical engineering

Owner:BRADFORD CO

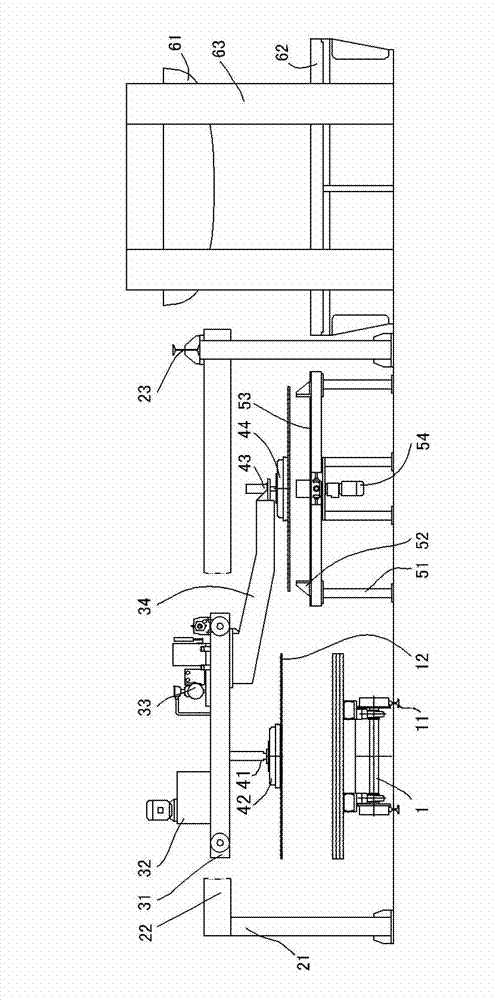

Seal head automatic centering feed device and feed method

ActiveCN103042127ALow technical requirementsReduce manufacturing costMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to a seal head automatic centering feed device which is characterized in that a feed frame is disposed, and a pair of 'X'-direction 'I'-shaped beam rails is disposed between an 'n'-shaped frame at the front end and an 'H'-shaped standing column at the rear end, a press system is located in front of the feed frame, a feed trolley which can move along the 'I'-shaped beam rails is disposed on the 'I'-shaped beam rails, a front-end sucker and a rear-end sucker in tandem are disposed below the feed trolley through a front oil cylinder and a rear oil cylinder, and a centering mechanism is disposed below the front-end sucker. The centering mechanism is characterized in that a pushing plate is disposed on the periphery of a centering platform in a three-claw manner, and the pushing plate is a movable plate which is driven by a centering motor and can move towards the center of the centering platform synchronously. By the seal head automatic centering feed device, seal head automatic centering and automatic feed are achieved, and production efficiency is improved greatly.

Owner:HEFEI GENERAL MACHINERY RES INST

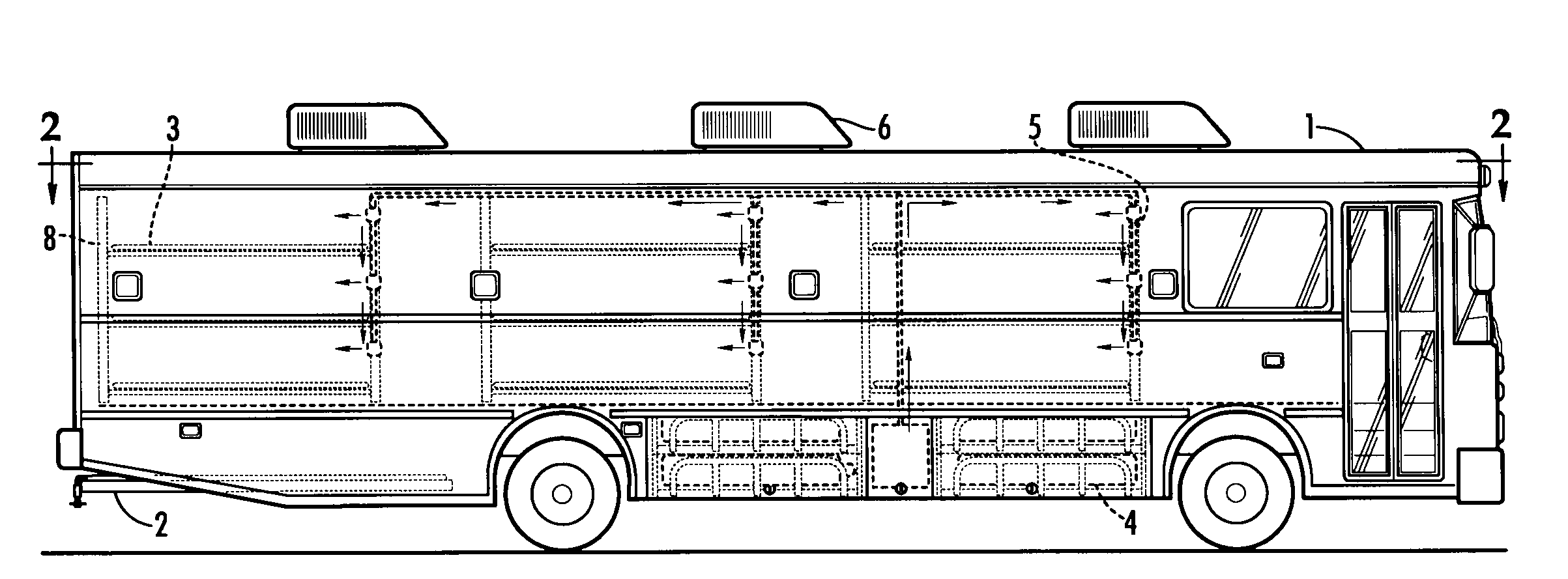

Emergency response vehicle

The invention relates to a vehicle used in transporting or treating large numbers of victims or patients from a mass-casualty incident to or from a hospital in an evacuation situation. The typical vehicle contains a stacked stretcher system, a loading ramp system, and an oxygen system. This vehicle must have an independent energy source or must be capable of being powered by an outside energy source. The vehicle can be flexible enough to provide facilities for treatment of victims either at the site of a disaster, in route from the disaster, at any remote site, or near a healthcare facility. A variation of the vehicle contains refrigeration or freezer units and is capable of transporting or maintaining casualties until mortuary services can be obtained. Variations of the equipment include trays made of stainless steel, stretchers that can be easily cleaned and that allow for easy drainage of liquids.

Owner:ACES HLDG

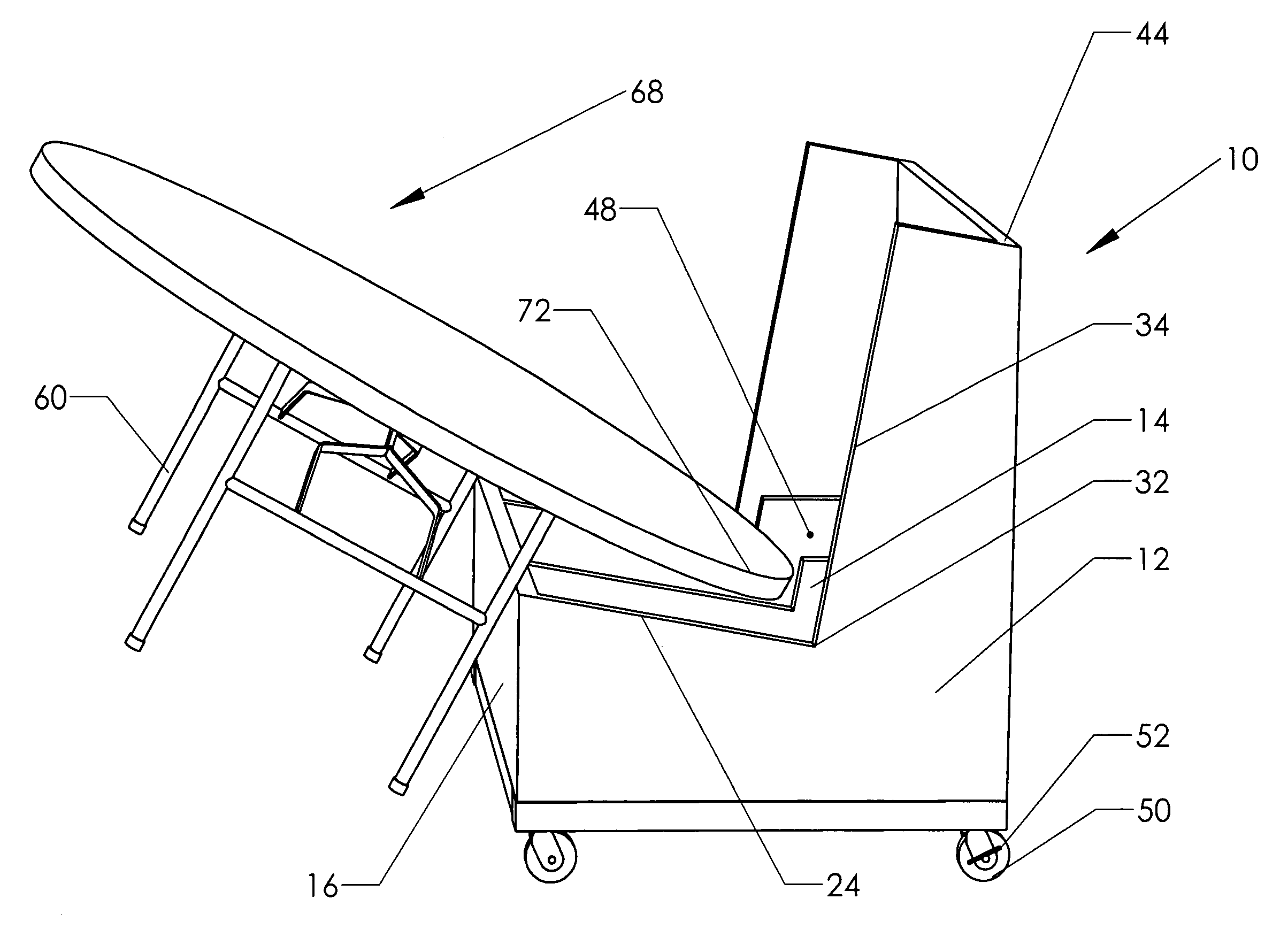

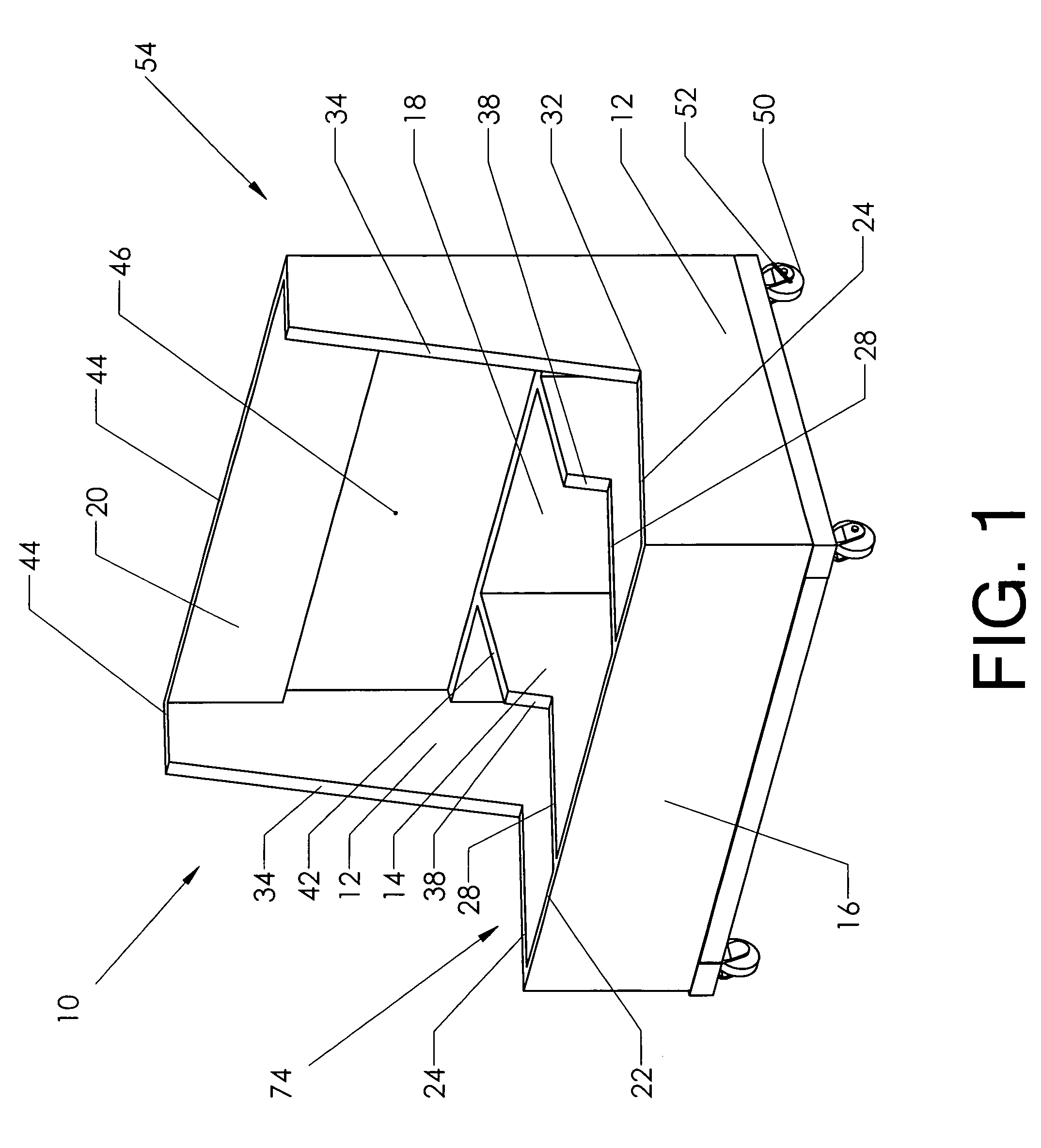

Folding table cart

InactiveUS7992883B2Easy to dumpEasy and quick loadingHand carts with one axisShow shelvesStructural engineeringMechanical engineering

The present invention comprises a cart for collecting, moving and storing folding tables. The cart is generally comprised of a front panel, back panel and two side members. The two side members connect the front panel to the back panel in a rectangular frame shape. The front panel has a receiving edge that is shorter than the height of a conventional table top. Each side member has an outer table bed runner and a backrest runner that meet at a wedge. The outer table bed runner slopes downward from the receiving edge of the front panel to the wedge.

Owner:BRANDON THOMAS K

Pneumatic paintball gun

InactiveUS7686004B2Simplified loading and firing mechanismEasy and quick loadingAmmunition loadingCompressed gas gunsEngineeringGas supply

A gun device includes a housing having a gas supplying passage communicating with an inner chamber of the housing for coupling to a pressurized gas supplying source, a feed tube attached to the housing for feeding a bullet into the housing, a tubular member rotatably received in the housing and having an opening communicated with a bore of the tubular member for aligning with the feed tube and for selectively receiving the bullet into the bore of the tubular member. The opening of the tubular member is movable or disengageable from the feed tube when the tubular member is rotated relative to the housing for preventing the other bullet from entering into the housing.

Owner:GAN YIAUGUO

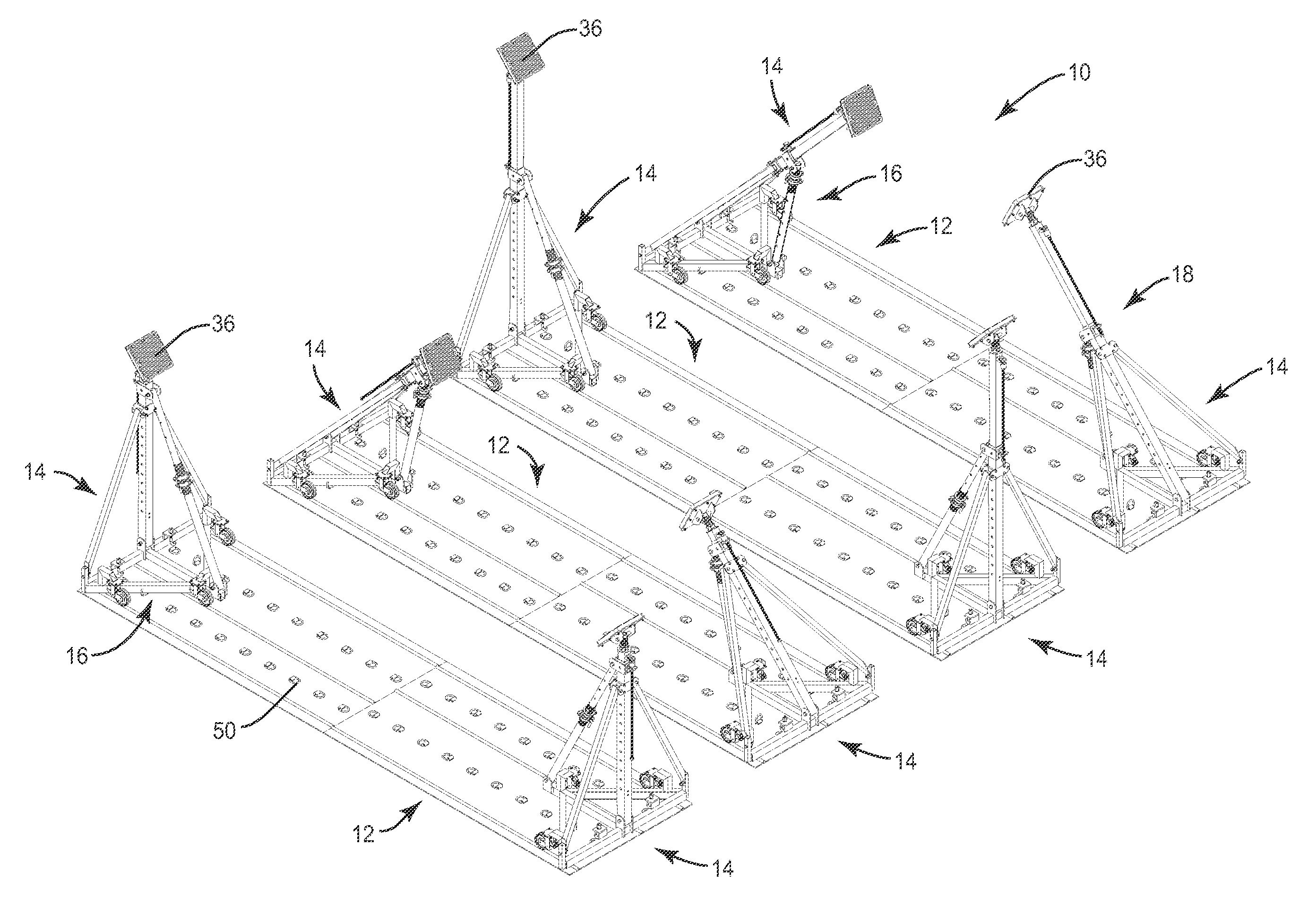

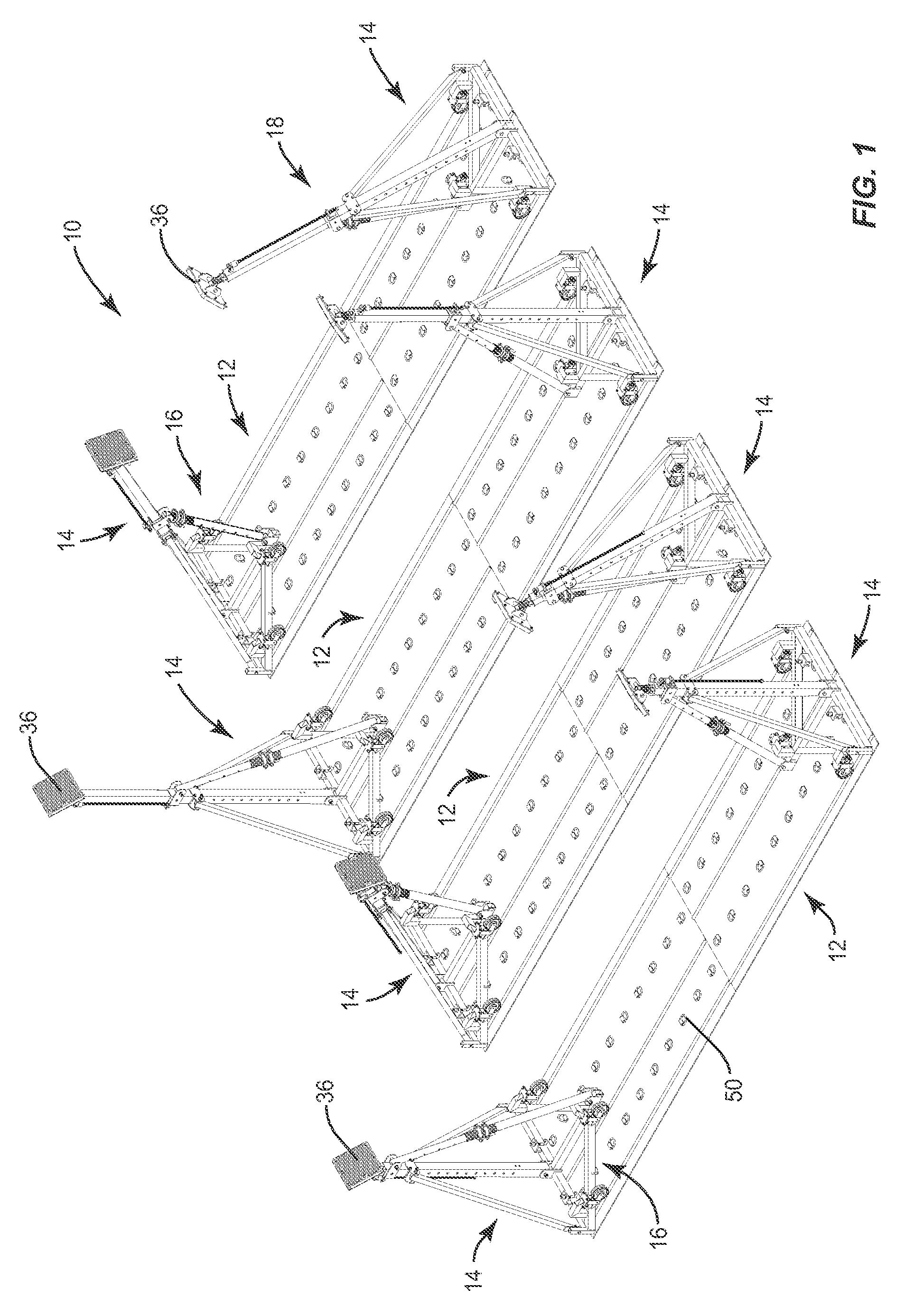

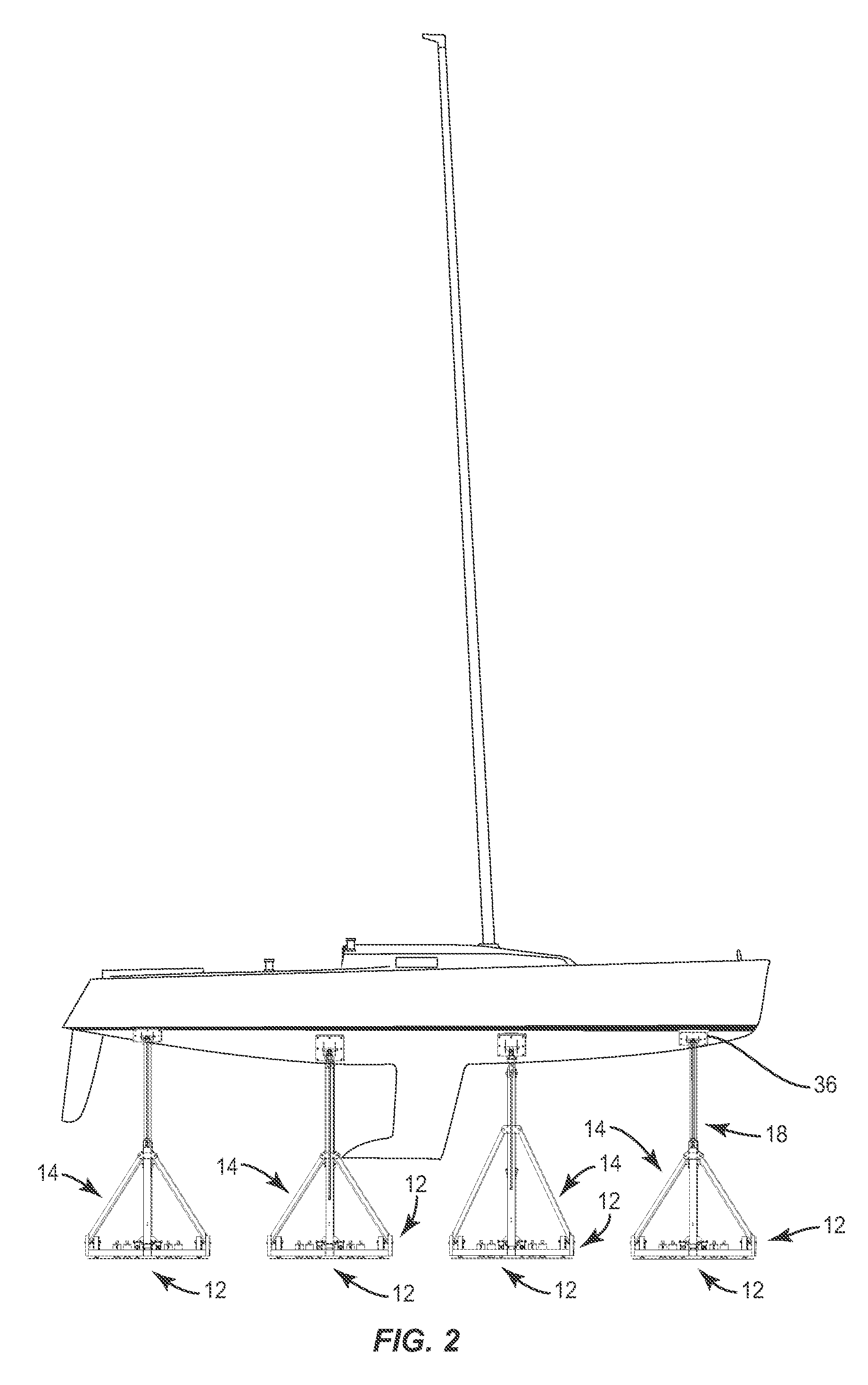

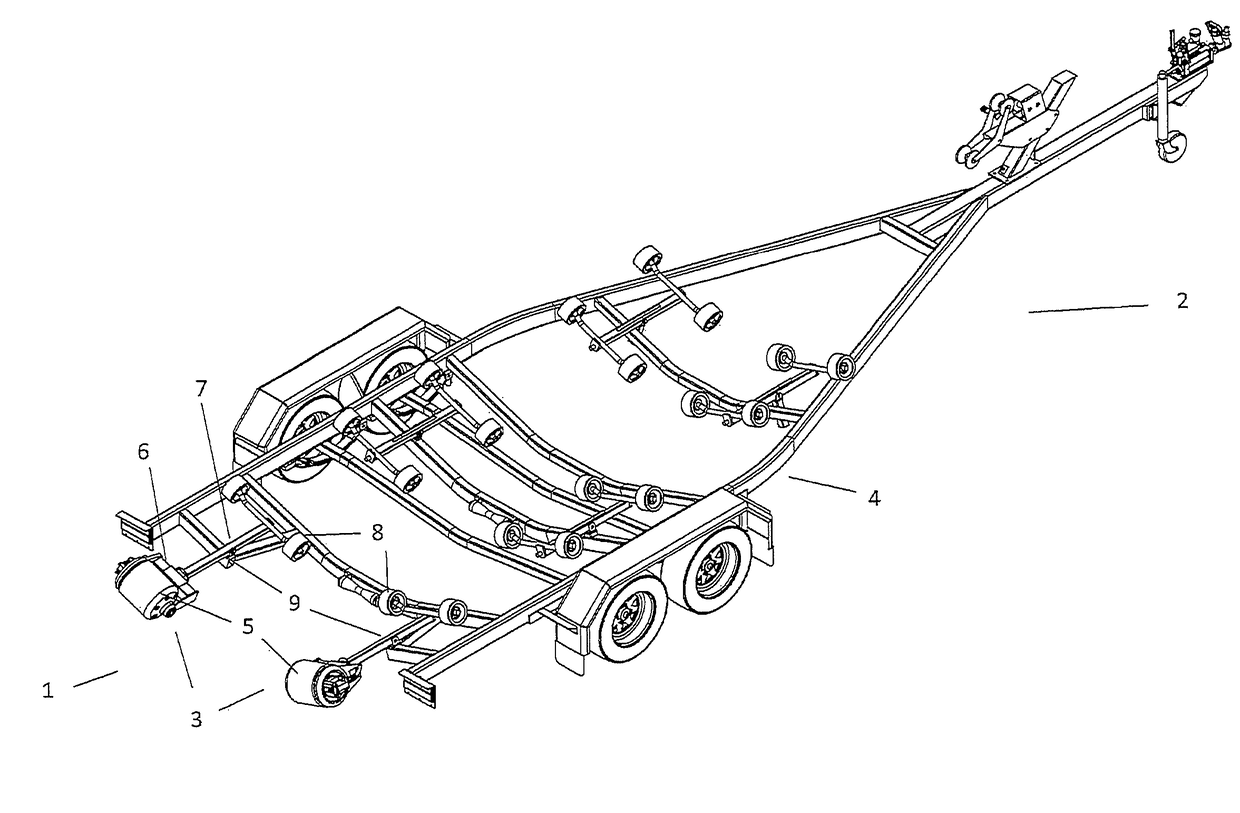

Boat cradle system

A boat cradle system for securely supporting boats, even in hurricane conditions, comprising one or more decks anchored to the ground or to an underlying structure. Moveably mounted on the deck or decks is a series of mobile boat supports that move back and forth between an inoperative position and an operative position.

Owner:SMITH GRADY F

Portable metal compacting device

InactiveUS20080061121A1Reduce wearQuickly and easily loadRigid containersPressesEngineeringWall mount

A metal crushing device includes a crush chamber having front and rear walls, side walls, a top wall and a base wall and a movable inner top wall mounted within the crush chamber and extending generally parallel with the base wall and four hydraulic cylinders mounted on the top wall and having extendable piston rods. The piston rods connect to the movable inner top wall through the top wall generally adjacent the corners thereof. Front and rear doors provide for loading and unloading of the crush chamber, and a lift device is mounted beneath the crush chamber for raising and lowering the crush chamber. An hydraulic actuator is operatively connected to the four hydraulic cylinders to extend the piston rods downwards forcing the movable inner top wall downwards to crush items within the crush chamber between the movable inner top wall and the base wall.

Owner:RAILSBACK DAN

Method of Loading/Unloading Product From Container Having Movable Pouches

ActiveUS20130239526A1DistanceHigh densityPackaging vehiclesContainers for machinesDunnageEngineering

Owner:BRADFORD CO

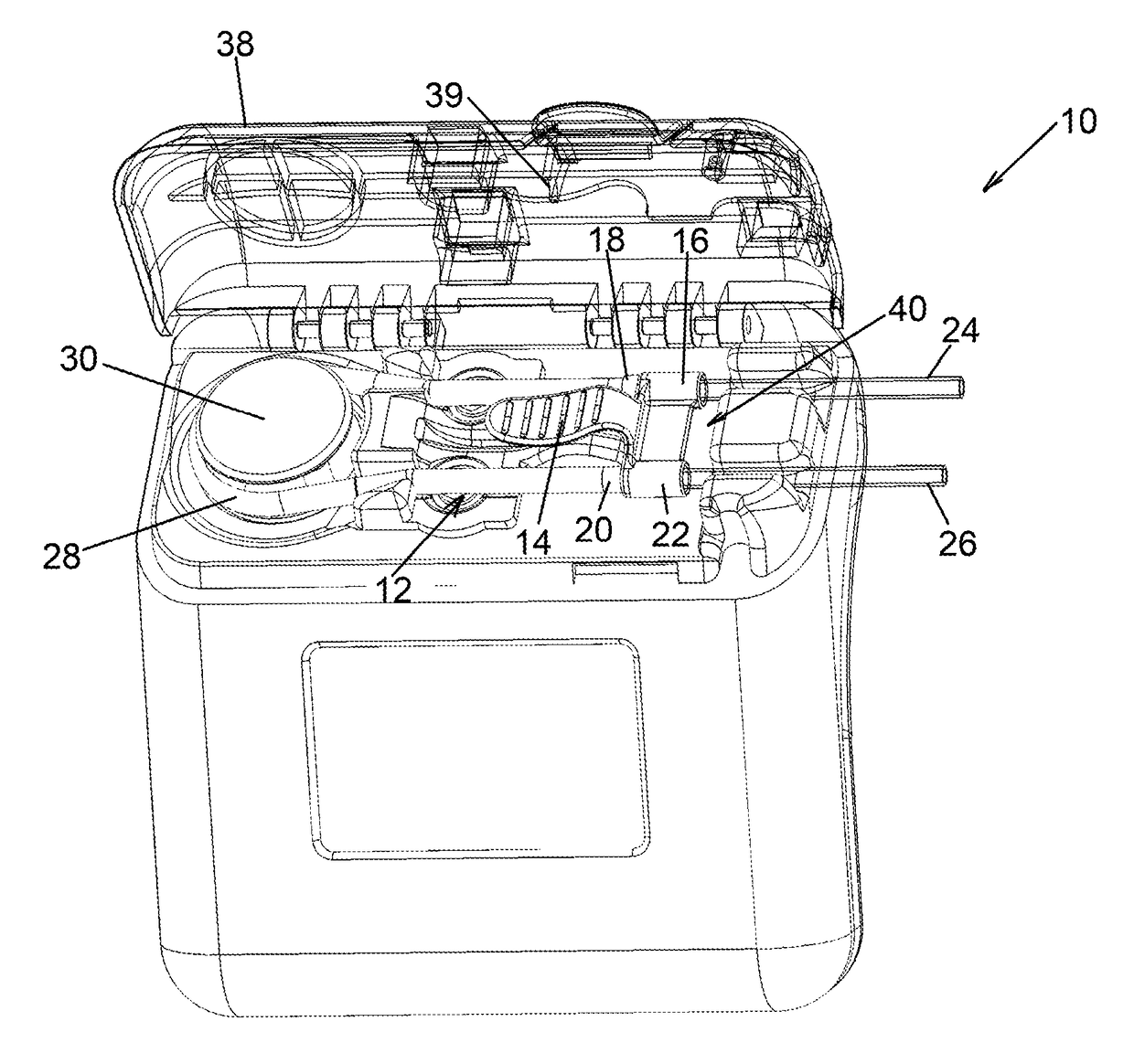

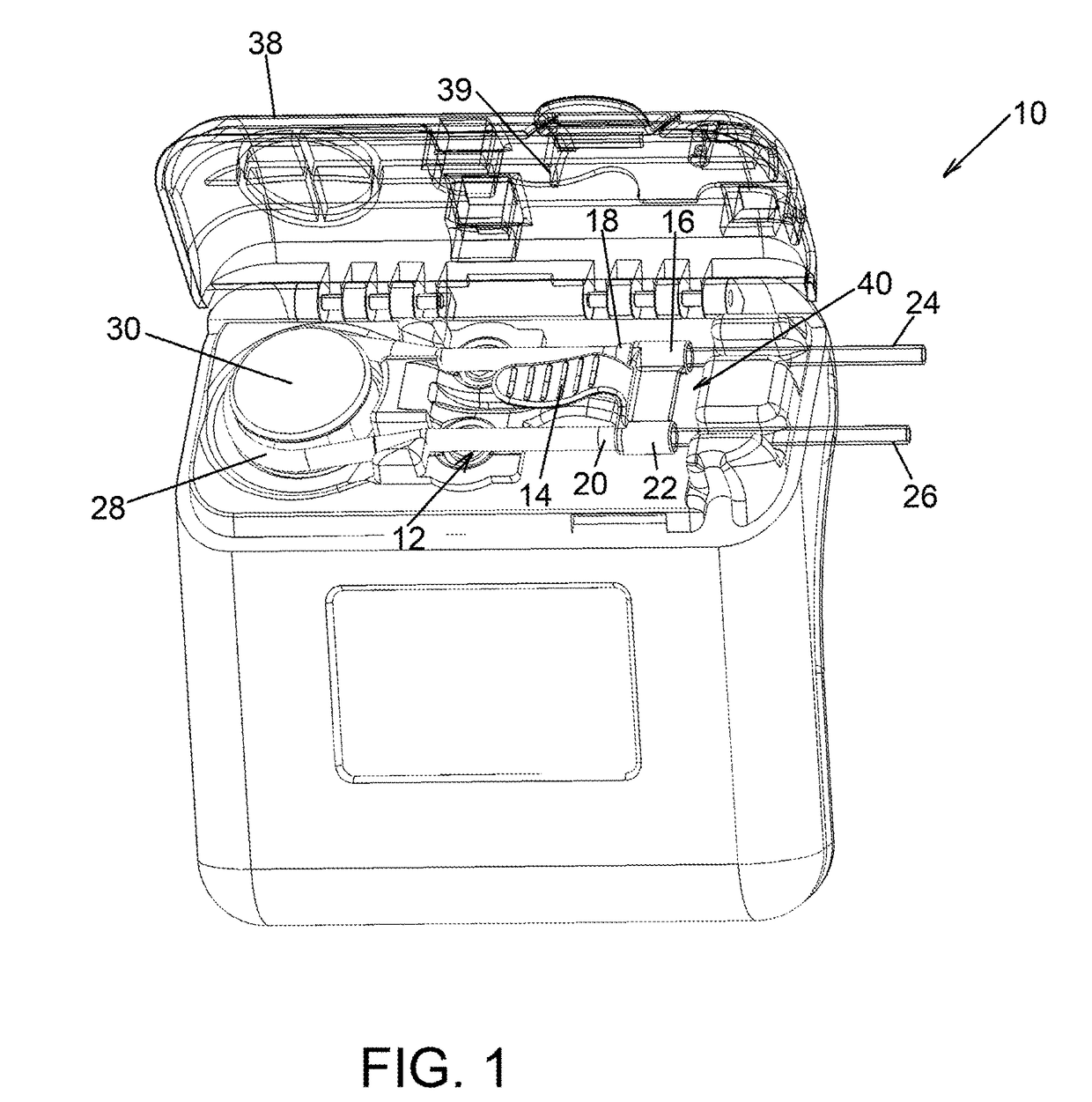

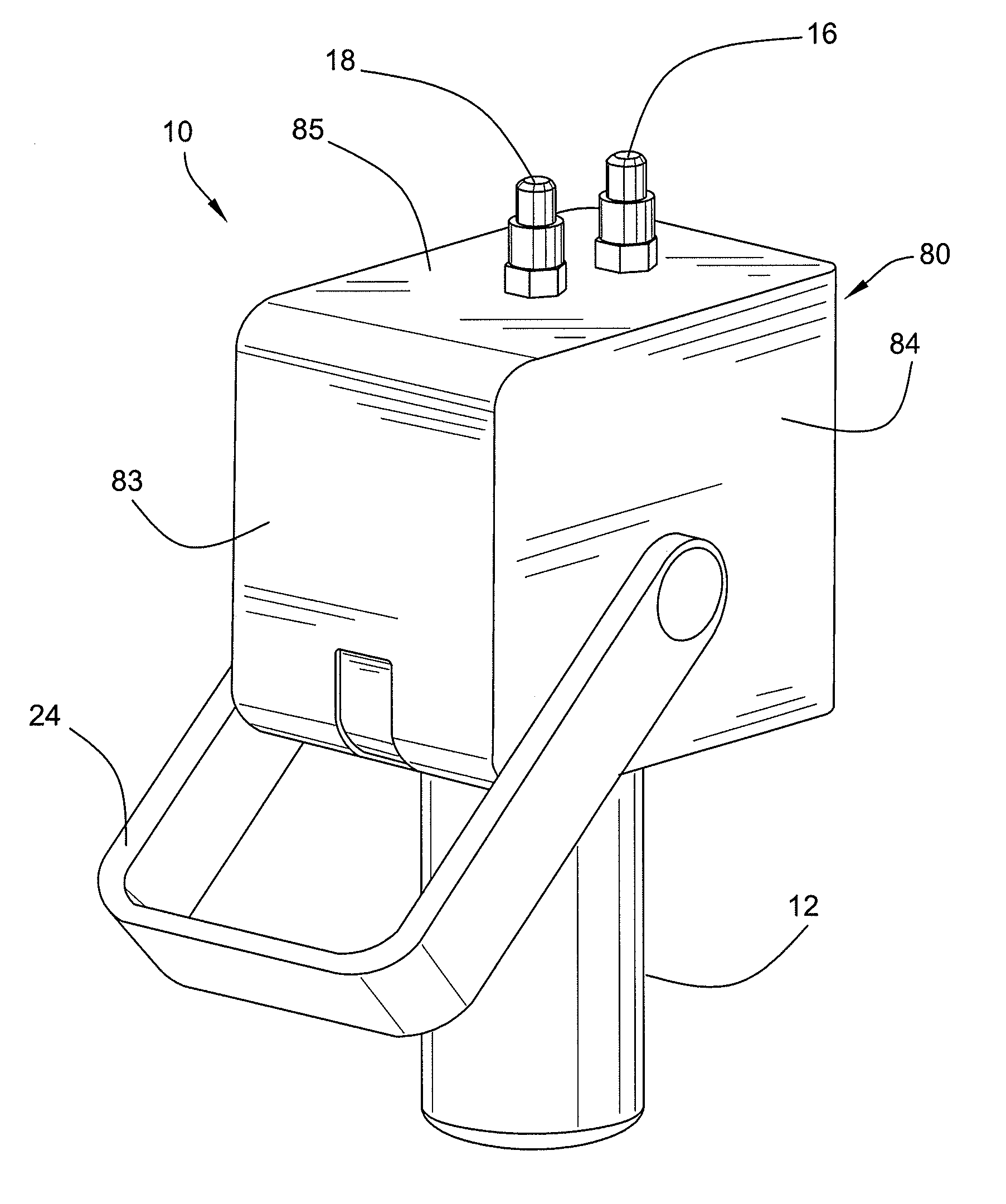

Infusion pump cassette and cassette interface configured to assist cassette removal

ActiveUS9642965B2Easy and quick loadingEasy to removeFlexible member pumpsMedical devicesMagnetic tapeInfusion pump cassette

Owner:ZEVEX

Universal system for the loading/unloading and rail transport of road semitrailers

ActiveUS9248984B2Simpler and less-costlyEasy constructionRefuse transferringRailway transportEngineeringSemi-trailer

A system for loading, unloading and rail transportation of road-hauled semi-trailers, having multiple wagons (1) constituting a railway train, with each of them incorporating at least one pivotable turntable (14) for accommodating a semi-trailer via its wheel assembly. The system also comprises a detachable hitch mounting (9) that can be gripped by a handling machine which carries the detachable mounting and assembles it, after adjustment on the semi-trailer's pivoting turntable. The hitch mounting is assembled on an accommodating platform (8) that is secured immobile to the wagon chassis (2) and independently of the pivoting turntable, in order to support the front of the semi-trailer during rail transportation. This invention is of interest to rail carriers and railway transport equipment manufacturers.

Owner:LOHR IND

Damping discharge chute of solid tube blank feeding frame

InactiveCN102717294APrevent rollingPlay a shock absorbing roleMetal working apparatusHeight differenceMechanical engineering

The invention provides a damping discharge chute of a solid tube blank feeding frame and relates to the field of seamless steel tube production equipment. The damping discharge chute comprises a material holding frame, a material conveying frame is connected to the right side of the material holding frame, a discharge limit frame is connected to the right side of the material conveying frame, a material stop plate is fixed at the left end of the material holding frame, a conveying roller is arranged at the upper end of the material conveying frame, a damping block is arranged at the bottom of the discharge limit frame, the material conveying frame is lower than the material holding frame, and an arc-shaped limiting groove is manufactured at the upper end of the damping block. The damping discharge chute of the solid tube blank feeding frame is simple in structure and reasonable in design, the material holding frame and the material conveying frame are designed to be a stepped form with height differences, tube blanks can directly roll from the material holding frame onto the conveying roller of the material conveying frame, and then feeding is performed by the aid of the conveying roller, so that feeding process is simple, fast and high in efficiency. In addition, the damping block can play a role in damping and can limit the off-line tube blanks during tube blank discharging so as to prevent the tube blanks from rolling and to eliminate potential safety hazards.

Owner:ANHUI XIANGYU STEEL IND GROUP

Pill cup with optical markers for improved medication adherence

InactiveUS20160342854A1Without sacrificing simplicityLighten the taskImage enhancementImage analysisMedication adherenceIndividual dose

Pill cups are described for containing individual doses of various pills. Per-dose pill cups include locating features for precise placement and alignment on open trays or within outer pill boxes with lids. Individual per-dose pill cups can be contained on or within a plurality of trays or outer pill boxes, providing the option for pills or pill cups to be easily moved from one tray or outer pill box to another. Additionally, each per-dose pill cup has optical markers. These markers can be used to provide fiduciary references or measurements within the field of vision of recorded images, such as photographs, and relative to multiple pills contained within a given per-dose pill cup. Optical markers calibrate analysis of pill size, shape, color, markings, shading, position, and presence or absence within each per-dose pill cup.

Owner:LOVELESS RICHARD WHITCOMB +3

Container Having Sliding Support Members

ActiveUS20110284551A1Efficiently and safely removedEasy accessInternal framesOther accessoriesMechanical engineering

Owner:BRADFORD CO

Boat support frame loading and unloading apparatus

ActiveUS20170072828A1Increase torqueSimple drive systemsSlipwaysItem transportation vehiclesBraced frameEngineering

In one aspect the invention provides a boat support frame loading and unloading apparatus configured to draw a boat on to and off a boat support frame. This boat support frame has a loading end and a terminal end opposite to the loading end. The apparatus provided includes at least one roller assembly mounted to the support frame adjacent to the loading end of the support frame, said at least one roller assembly incorporating at least one roller element. The apparatus also includes at least one drive mechanism configured to rotate one or more roller elements to draw a boat onto and off the support frame through the loading end of the support frame. The roller assembly also includes a hull contact surface formed by a flexible belt which has a circumference greater than the circumference of the said at least one roller element incorporated into the roller assembly.

Owner:BALEX MARINE DEV LTD

Container Having Sliding Support Members

ActiveUS20100018887A1Efficiently and safely removedEasy accessInternal framesOther accessoriesMechanical engineeringEngineering

Owner:BRADFORD CO

Method of loading product from container having movable pouches

The present invention provides a container for holding product therein during shipment and being returned for reuse that has a body, tracks attached to opposite sides of the body, and a plurality of support members extending between the tracks. Sliders are located at the ends of tubular supports, the sliders being slidable in the tracks to move the support members. The support members support dunnage for supporting products for storage or shipment.

Owner:BRADFORD CO

Filter manifold

ActiveUS9527021B2Easy and quick loadingDispersed particle filtrationMembrane filtersParticulatesInlet manifold

A filter manifold is provided for filtering particulates in fluid and gas streams. The filter manifold seals the inlet and outlet valves in a closed position until a filter capsule is loaded into a carriage assembly. The inlet and outlet valves are opened only when a filter capsule is properly loaded into the carriage assembly.

Owner:PALL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com