Seal head automatic centering feed device and feed method

A heart-feeding and automatic technology, which is applied in the field of automatic head-centering and feeding equipment and feeding, can solve the problems of difficulty in ensuring the position accuracy of blanks, restricting production potential, wasting manpower and material resources, etc., and achieves high production efficiency and high feeding efficiency. Reasonable setting and layout, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

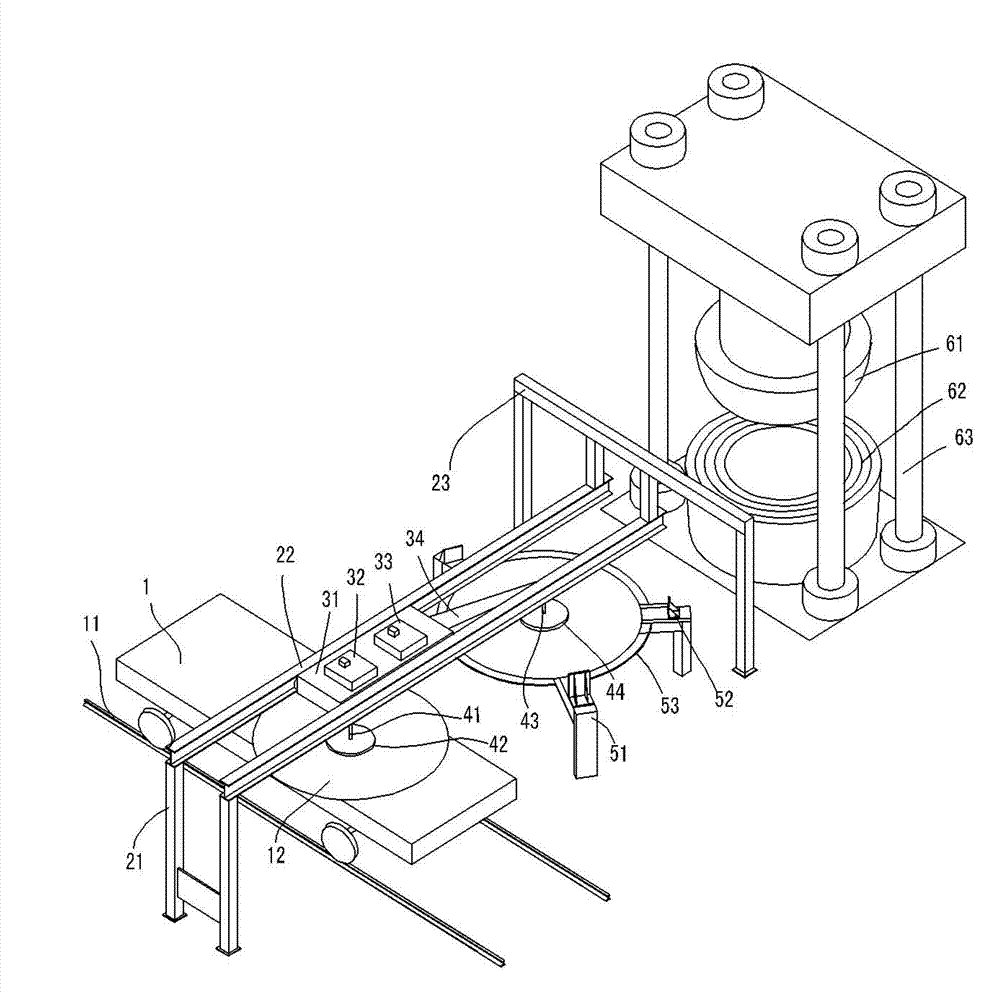

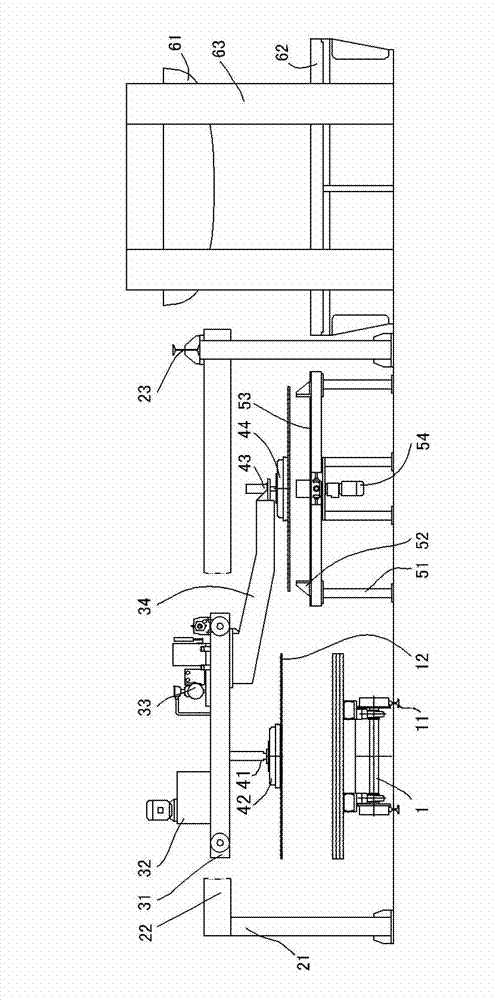

[0022] See figure 1 , The structure of the head automatic centering feeding equipment in this embodiment is:

[0023] The feeding rack is provided with a pair of "X"-direction "I" beam rails 22 in parallel between the front "door" frame 23 and the rear "H" column 21;

[0024] A loading trolley 31 capable of moving along the I-shaped beam rail 22 is set on the "I" beam rail 22. Below the small material trolley 31, a front-end suction cup is provided through the front cylinder 43 and the rear cylinder 41, respectively. 44 and rear suction cup 42;

[0025] A "Y" moving rail 11 is set below the front suction cup 44, the blank car 1 is supported on the "Y" moving rail 11, and the blank plate 12 placed on the blank car 1 moves in the "Y" direction with the blank car 1 The rail 11 is pushed under the rear suction cup 42 to complete the feeding;

[0026] A centering mechanism is provided under the front suction cup 41; the centering mechanism is a three-claw push plate 52 arranged on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com