Portable metal compacting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

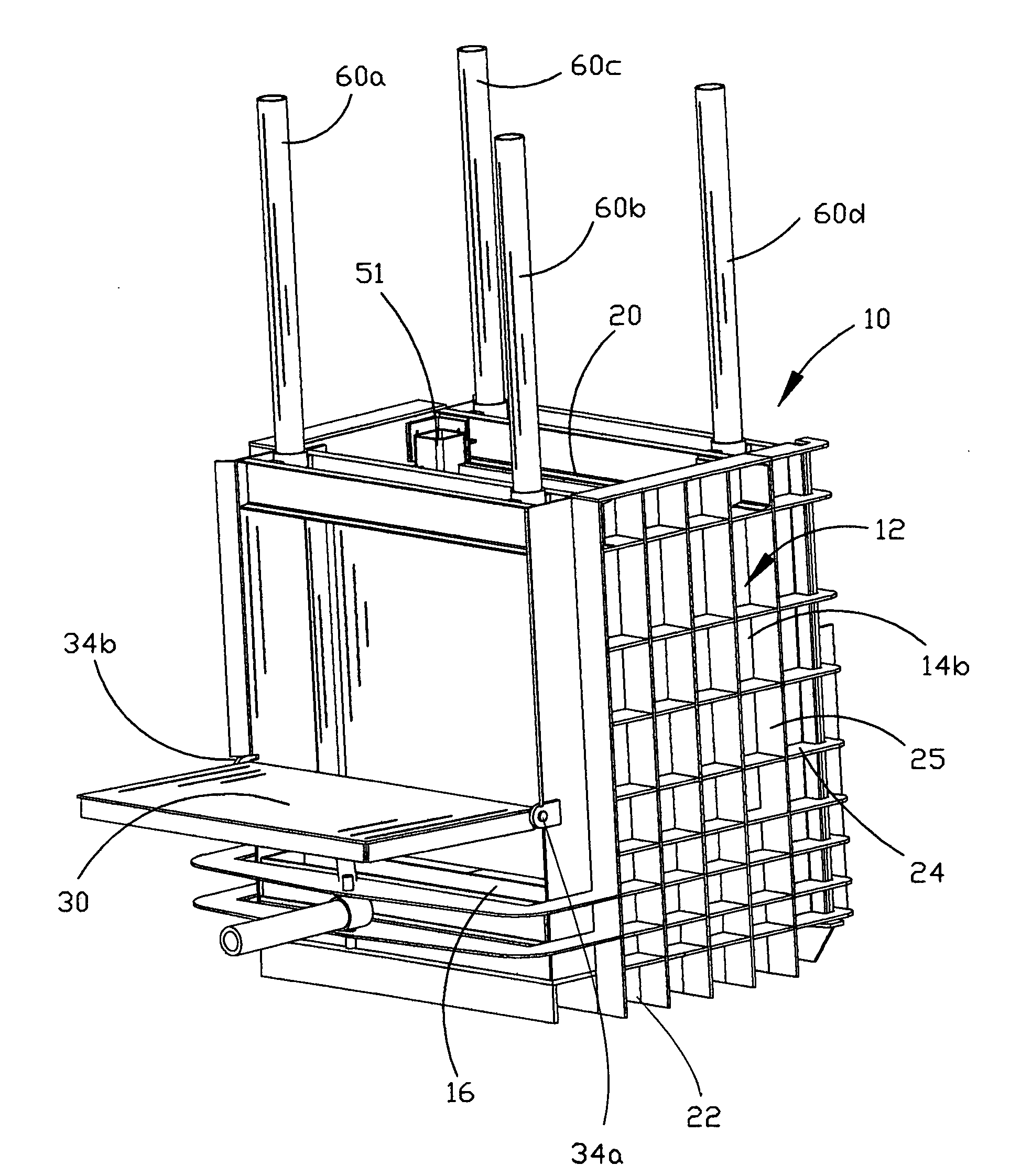

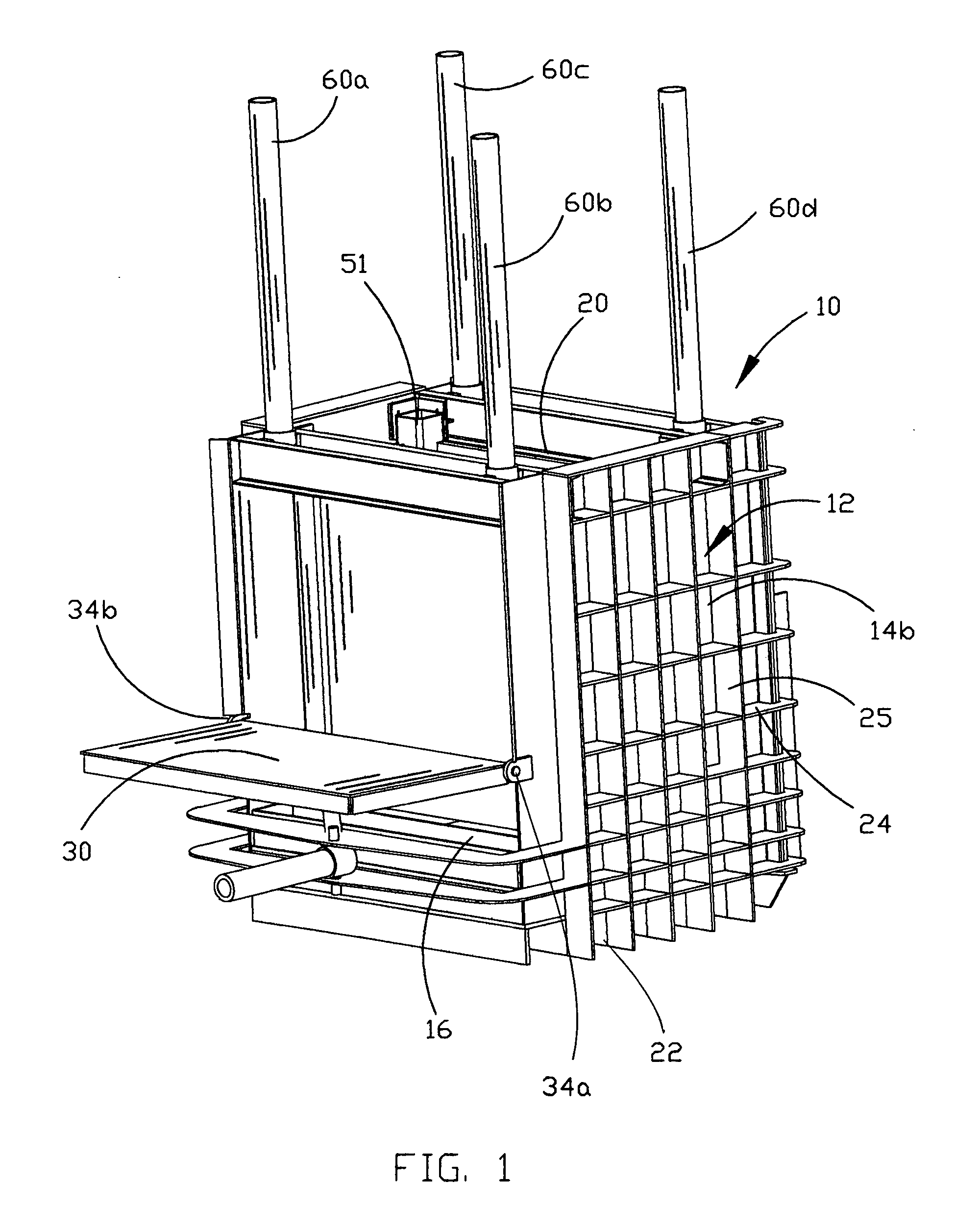

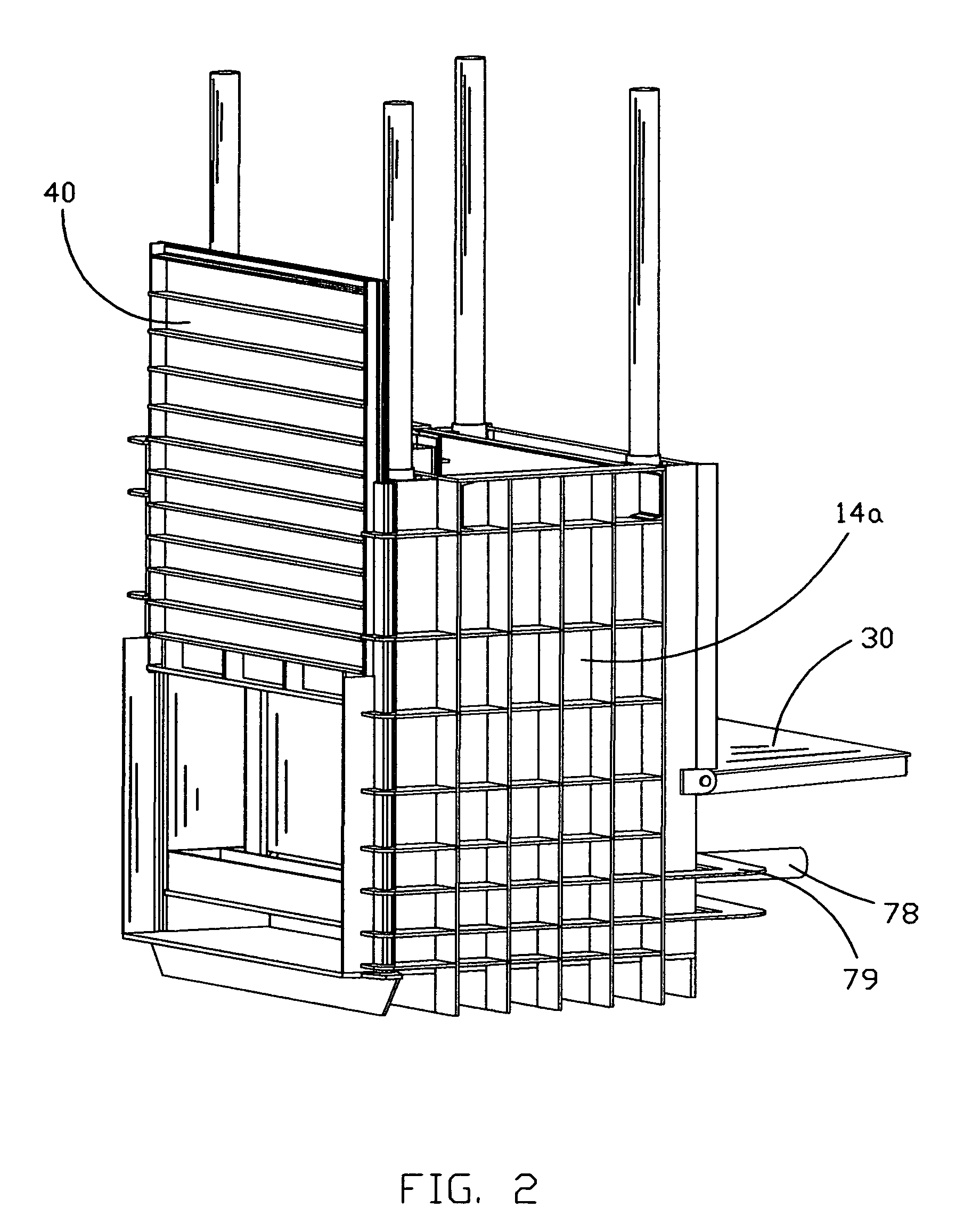

[0020]The metal crushing device 10 of the present invention is shown best in FIGS. 1-6 as including a generally rectangular box-shaped crush chamber 12 having left and right side walls 14a and 14b, a front wall 16, rear wall 18, a top wall 20, and base wall 22. In the preferred embodiment, the crush chamber 12 would have dimensions of approximately six to ten feet in height, six to ten feet in width, and six to ten feet in depth, depending on the materials with which the metal crushing device 10 is intended to be used. Also, it is expected that the crush chamber 12 will be constructed of sturdy metal panels which will resist the intense forces encountered by the walls of the crush chamber 12 when the crushing operation is being undertaken.

[0021]It is further preferred that each of the side walls 14a and 14b, front wall 16, rear wall 18, and base wall 22 be reinforced with a plurality of horizontally and vertically disposed wall strengthening ribs 24 and 25 which, in the preferred em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com