Automatic feeding device for jack cylinder machining

An automatic feeding and jacking technology, which is applied in metal processing and other directions, can solve problems such as low production efficiency, influence on the operation ability of staff, and high labor cost, so as to ensure accuracy and stability, the feeding process is simple and fast, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

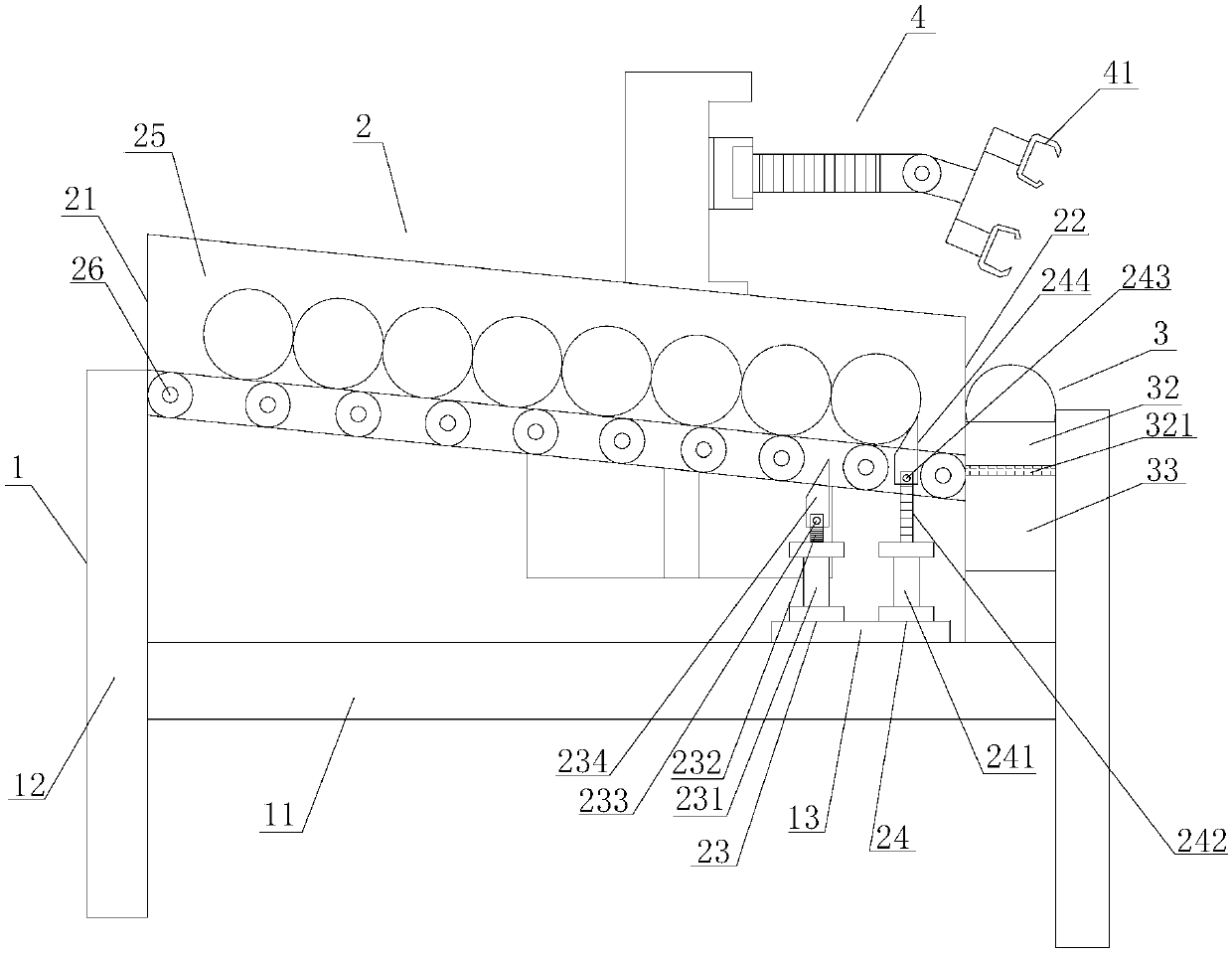

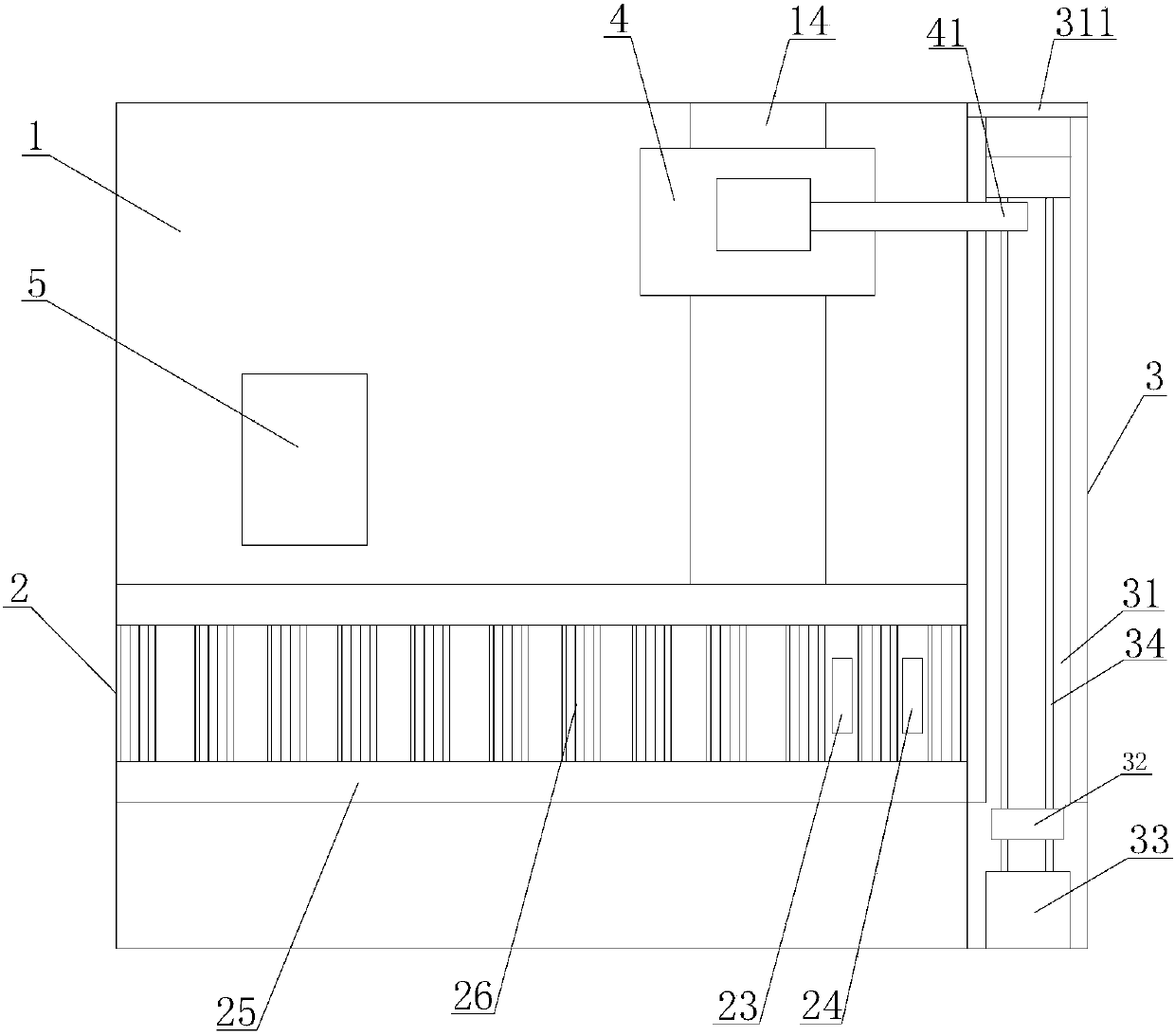

[0013] refer to figure 1 and figure 2 , the present invention is an automatic feeding device for jack oil cylinder processing, comprising a base 1, a feeding mechanism 2, a transmission mechanism 3, a clamping mechanism 4 and a control mechanism 5, the feeding mechanism 2, the transmission mechanism 3, the clamping mechanism The mechanism 4 and the control mechanism 5 are installed and fixed on the base 1, the feeding mechanism 2, the transmission mechanism 3, and the clamping mechanism 4 cooperate with each other, and the feeding mechanism 2, the transmission mechanism 3, and the clamping mechanism 4 are connected with the control mechanism 5 , the feeding mechanism 2 includes a first feeding end 21, a second feeding end 22, a blocking assembly 23 and a feeding assembly 24, the first feeding end 21 is higher than the second feeding end 22, and the second feeding end 22 is connected with the conveying mechanism 3, and the said retaining assembly 23 and the discharging assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com