Water absorption paper

A technology of absorbent paper and dust-free paper is applied in the field of absorbent paper to achieve the effect of improving the use effect and reducing the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

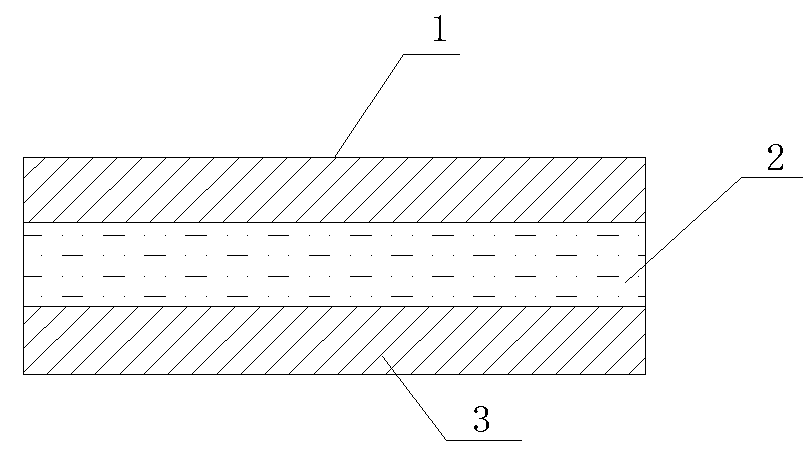

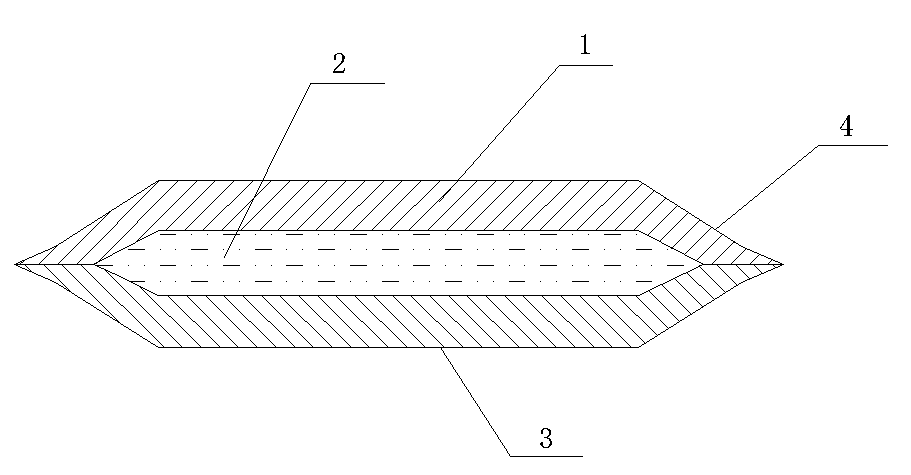

[0022] refer to figure 2 , a kind of water-absorbing paper, said water-absorbing paper comprises the first dust-free paper layer 1 on the upper layer, the non-woven fabric layer 2 on the middle layer and the second dust-free paper layer 3 on the lower layer, said first dust-free paper layer The paper layer 1 and the second dust-free paper layer 3 are hot-melt bonded along both sides of the non-woven fabric layer 2 to form an edge wrapping 4 .

[0023] Described hot-melt bonding adopts following equipment to carry out: with reference to Figure 4 , a water-absorbing paper cutting equipment, including a frame 5, the frame is sequentially provided with a paper feed roller 6, a tension roller 7, an ultrasonic cutting machine and a winding device. refer to Figure 5 and 6 , the ultrasonic cutter includes an ultrasonic generator 8, a cutting platform 9, several cylinders 10 and cutters 11, and a drive motor, and the ultrasonic generator 8 is arranged below the cutting platform 9...

Embodiment 2

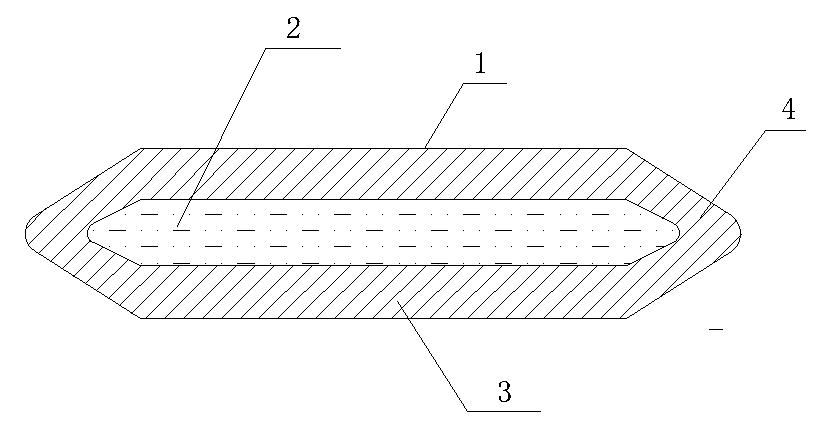

[0032] refer to image 3 , a kind of water-absorbing paper, said water-absorbing paper comprises the first dust-free paper layer 1 on the upper layer, the non-woven fabric layer 2 on the middle layer and the second dust-free paper layer 3 on the lower layer, said first dust-free paper layer The paper layer 1 and the second dust-free paper layer 3 are connected along both sides of the non-woven fabric layer to form an edge 4 . The first dust-free paper layer 1 , the second dust-free paper layer 3 and the edge wrapping 4 form an integral structure covering the paper-free dust layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com