Multi-row type omnidirectional wheel

An omnidirectional wheel and hub technology, applied in the field of robot movement, can solve the problems of large angular gap and poor rolling continuity, and achieve the effects of reducing weight, improving structural strength and expanding bearing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further illustrate the present invention below in conjunction with accompanying drawing.

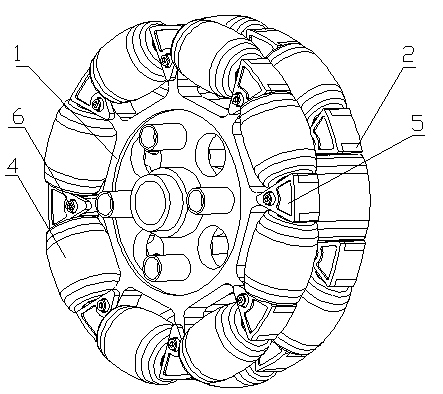

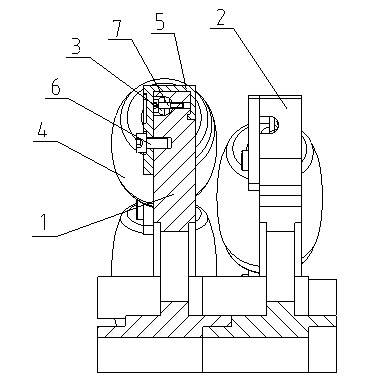

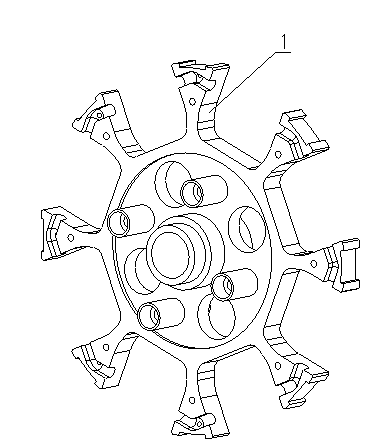

[0025] refer to figure 1 , figure 2 As shown, the omnidirectional wheel of the present invention is made up of outer hub bracket 1, inner hub bracket 2, support shaft 3, spindle driven wheel 4, fastening cover plate 5, M3 screw 6, and M1.6 screw 7. The outer hub bracket 1 and the inner hub bracket 2 are staggered at an angle of 22.5 degrees, and are directly connected through the hub center boss and 4 cylindrical bosses evenly distributed on the circumference, and then bolts (4 in total) pass through the cylindrical bosses hole for fixing. The supporting shaft 3 is installed in the U-shaped groove of the hub bracket, and the spindle driven wheel 4 is installed on the supporting shaft 3 and can freely rotate around the supporting shaft 3 . When the omnidirectional wheel rotates in the radial direction, the spindle driven wheels alternately land on the ground, and when the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com