Packaging device for backlight modules

A technology for backlight modules and holders, which is applied in transportation and packaging, packaging of vulnerable items, types of packaged items, etc. It can solve the problem of large fixation of the light guide plate, insufficient pressing force of the middle frame on the light guide plate, and affecting optical quality, etc. problem, to ensure the safety of transportation and prevent displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

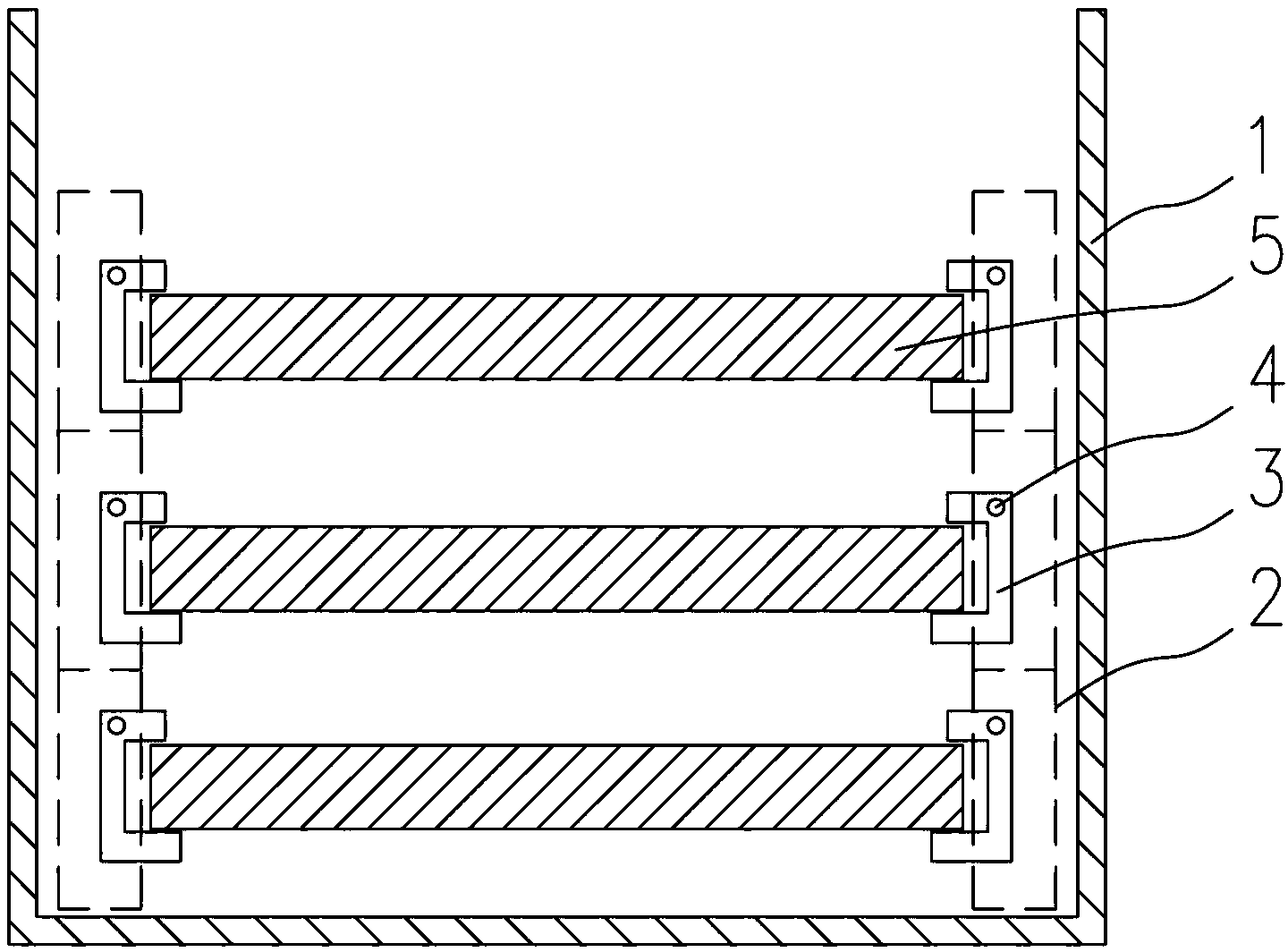

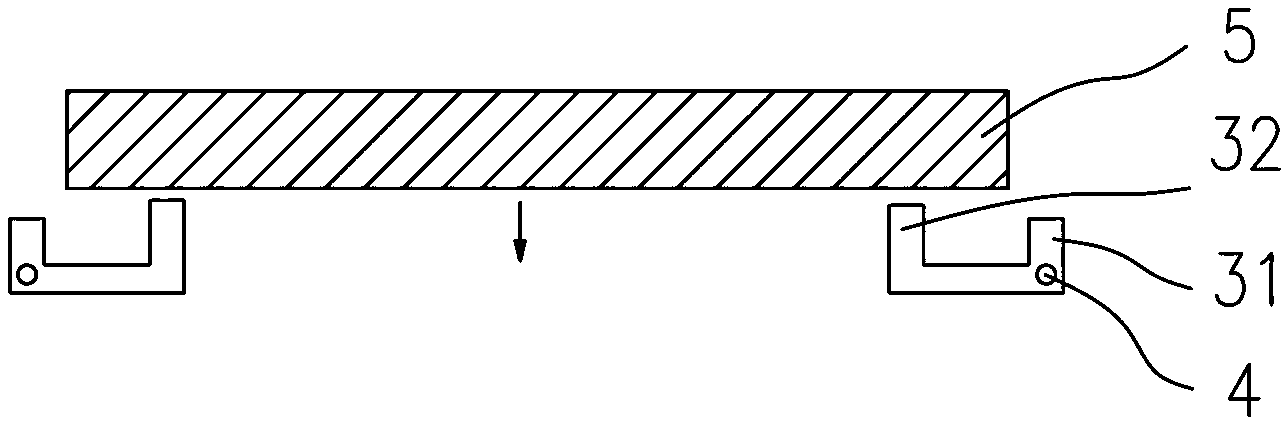

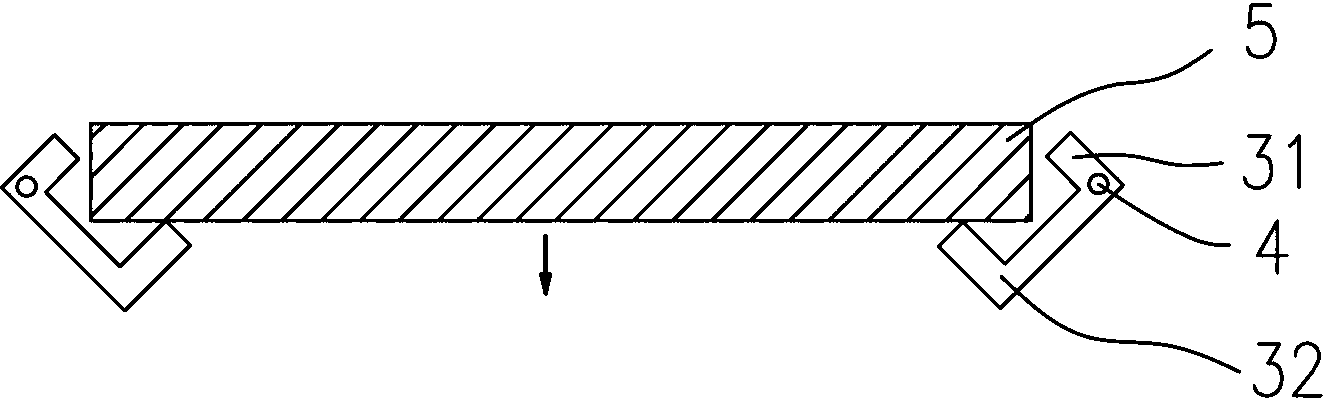

[0024] The invention discloses a packaging device for a backlight module, such as Figure 1 to Figure 5 As shown, it includes a fixed frame 2, a rotating shaft 4 and a holding member 3 that can rotate around the rotating shaft 4. The rotating shaft 4 is fixed on the fixing frame 2, and the holding member 3 includes an upper arm 31 and a lower arm 32. The upper arm 31 and the lower arm 32 are respectively used to hold the upper and lower surfaces of the backlight module 5 .

[0025] In this embodiment, the packaging device also includes an outer box 1, and the fixing frame 2 is placed in the outer box 1. There are four fixing frames 2 and clamping parts 3, which are divided into two rows and used for clamping respectively. Two parallel sides of the backlight module 5 . The upper arm 31 of the clamping member 3 is straight, the lower arm 32 is L-shaped, and the upper arm 31 and the lower arm 32 form a C-shaped structure. The rotating shaft 4 is arranged at the junction of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com