Bulk ship device

A bulk ship and bulk machine technology, applied in the field of mechanical equipment, can solve problems such as production dust, environmental pollution, and inconvenient control of output volume, and achieve the effects of environmental protection, good sealing effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

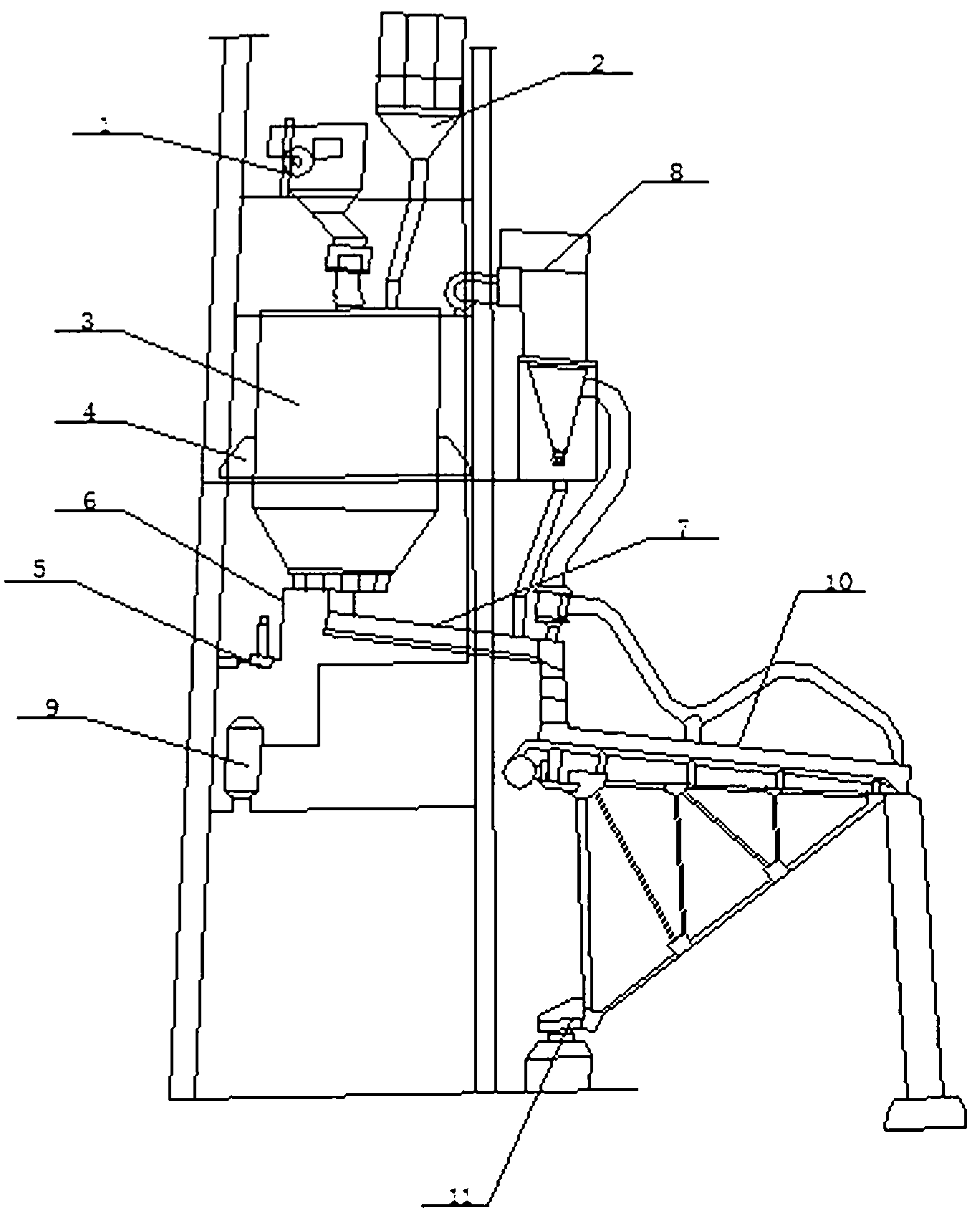

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: a bulk ship device, which includes a warehouse top feeding device 1, a warehouse top dust collection device 2, a material bin 3, a metering device 4, a Roots blower 5, and a Roots blower to the warehouse. Pipeline 6, unloading device 7, marine dust collector 8, compressed air pipeline device 9 and marine bulk machine 10, a silo 3 is arranged below the storage top feeding device 1, and the storage silo 3 is connected to the storage top The dust collection device 2 is connected, and a metering device 4 is provided on one side of the silo 3, and the Roots blower 5 is connected with the silo 3 through the Roots blower to the silo pipeline 6, and the bottom of the silo 3 is connected with a discharge The material device 7, the compressed air pipeline device 9 is connected with the unloading device 7, the unloading device 7 is connected with the marine dust collector 8, and the unloading dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com