Automatic collection device of honeycomb paperboard machine

An automatic collection, honeycomb cardboard technology, applied in the stacking receiving device, transportation and packaging, sending objects, etc., can solve the problem of long production line equipment, unfavorable short-distance slope transportation, restricting market development and application, etc. Achieve the effect of realizing automation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

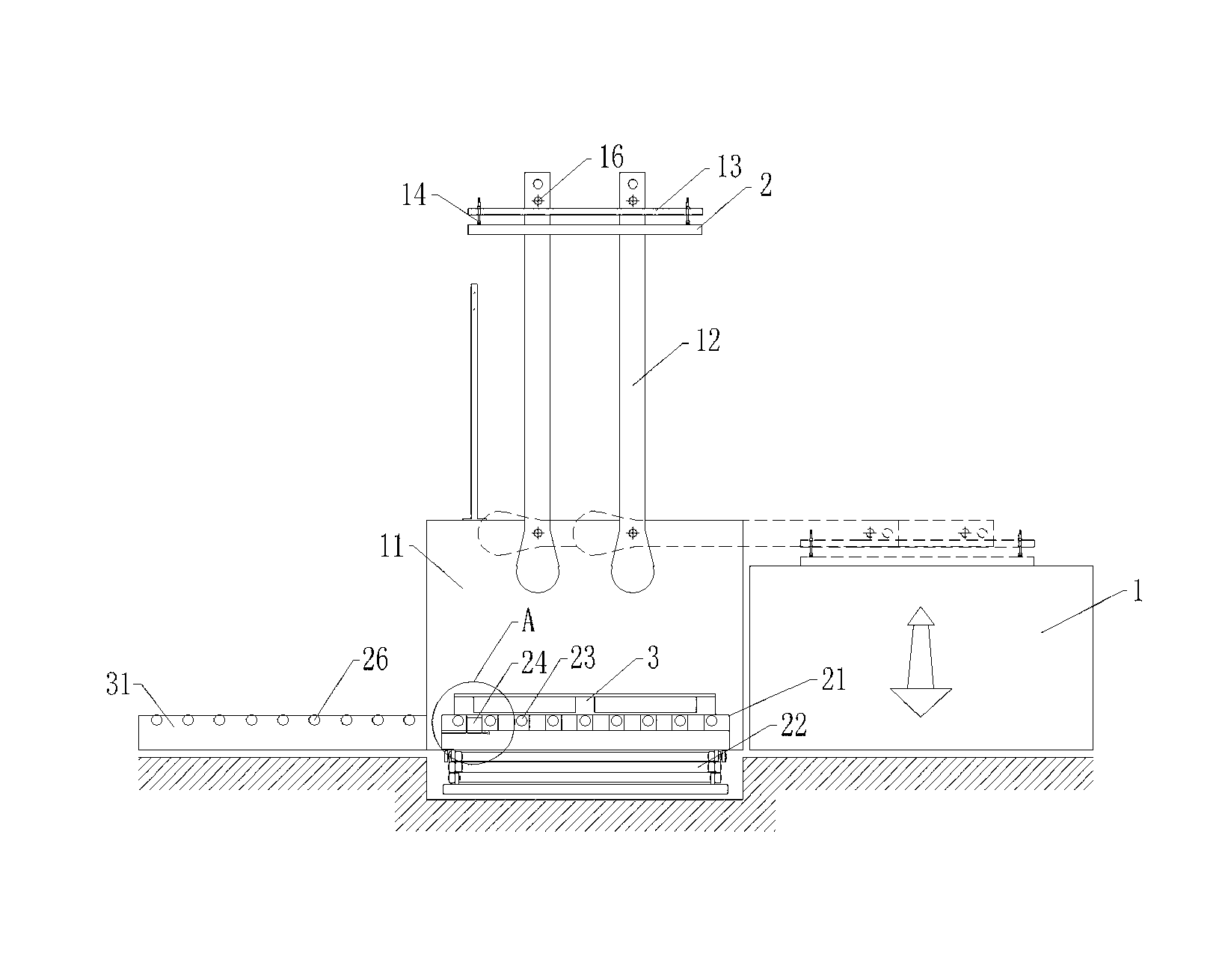

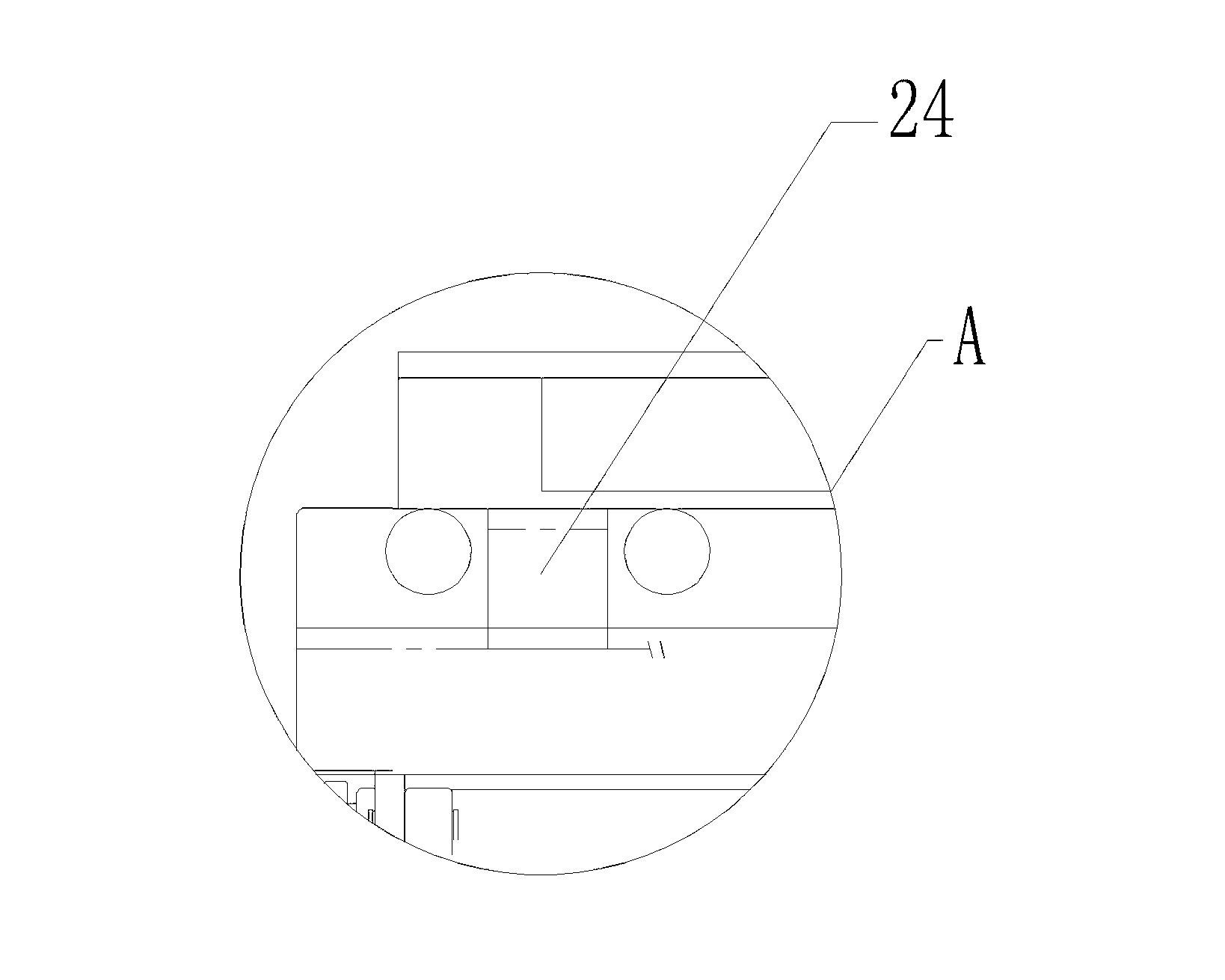

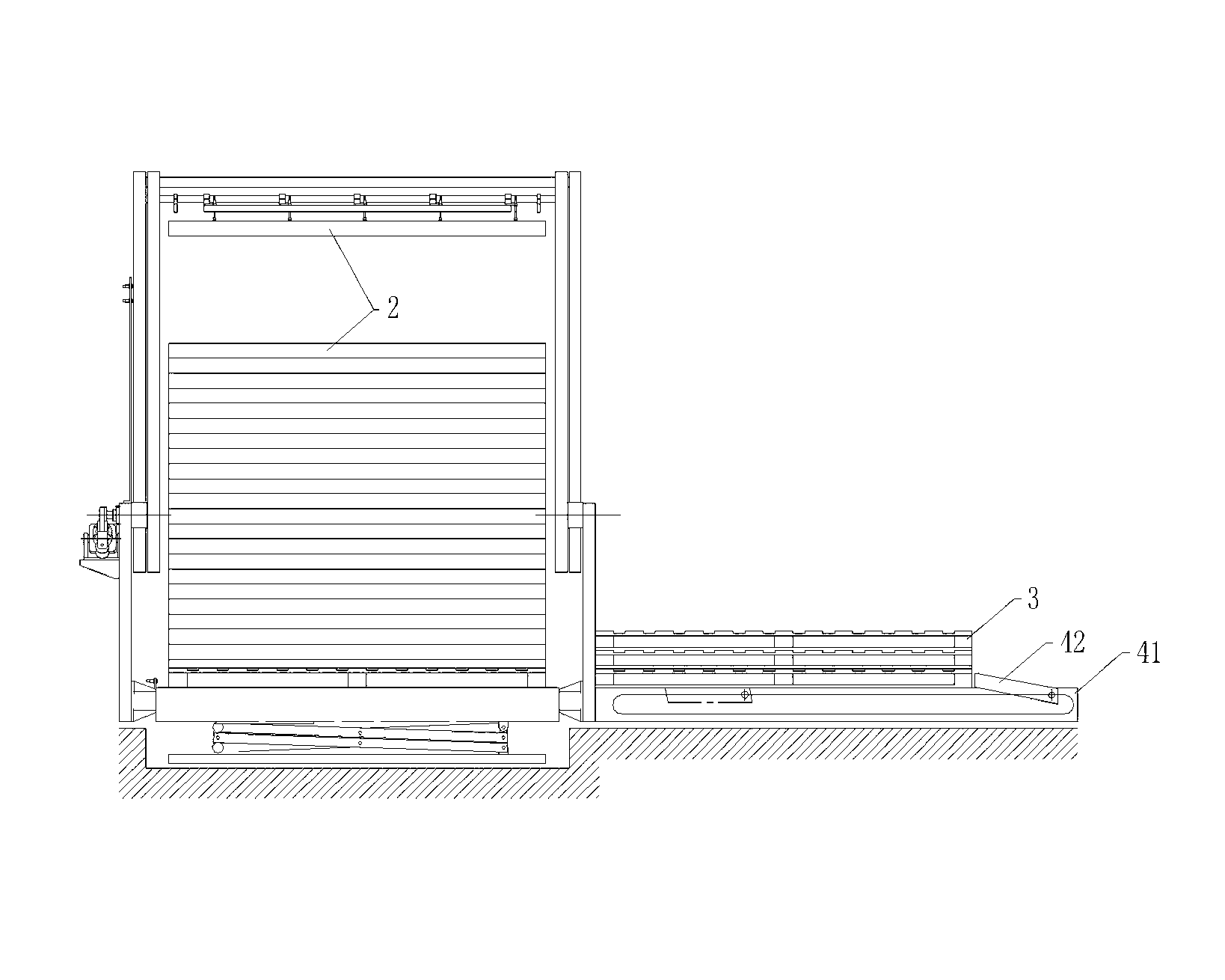

[0017] Accompanying drawing has shown the structure of the present invention and its embodiment, and describes each relevant detail of its embodiment below again in conjunction with accompanying drawing, the automatic collecting device of this honeycomb cardboard machine, comprises frame 11, is provided with in the frame 11 Stacking frame 21, described frame 11 is provided with fork 12, and described fork 12 is hinged on frame 11, and is connected with power source, and described power source can be transmission motor, also can be hydraulic press; Described power source is connected with induction device, and described induction device is photoelectric eye, and described fork 12 is provided with at least 2, can be set to 4, and is connected by cross bar 16, and fork 12 and cross bar 16 just can be connected like this. Form a four-bar linkage in the form of a parallelogram, the crossbar 16 is provided with a suction cup bracket 13, and the suction cup bracket 13 is provided with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap