Preheating energy saving distillation device

A distillation device and distilled water technology, applied in the direction of heating water/sewage treatment, etc., can solve the problems of unsustainable generation of steam, increase of heating core power, power consumption, etc., to reduce production and maintenance costs, quickly produce distilled water, and save energy The effect of power-saving distilled water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

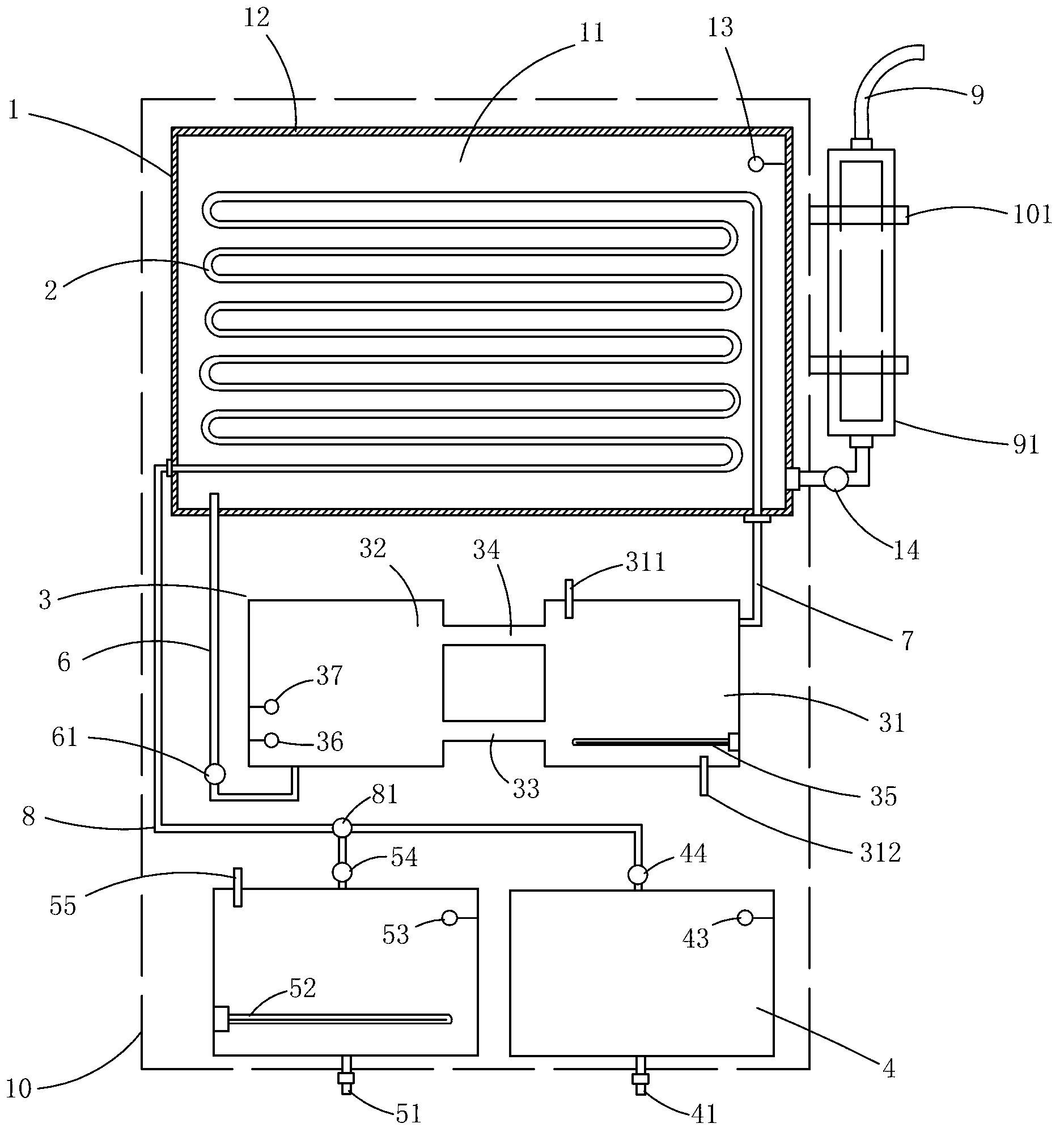

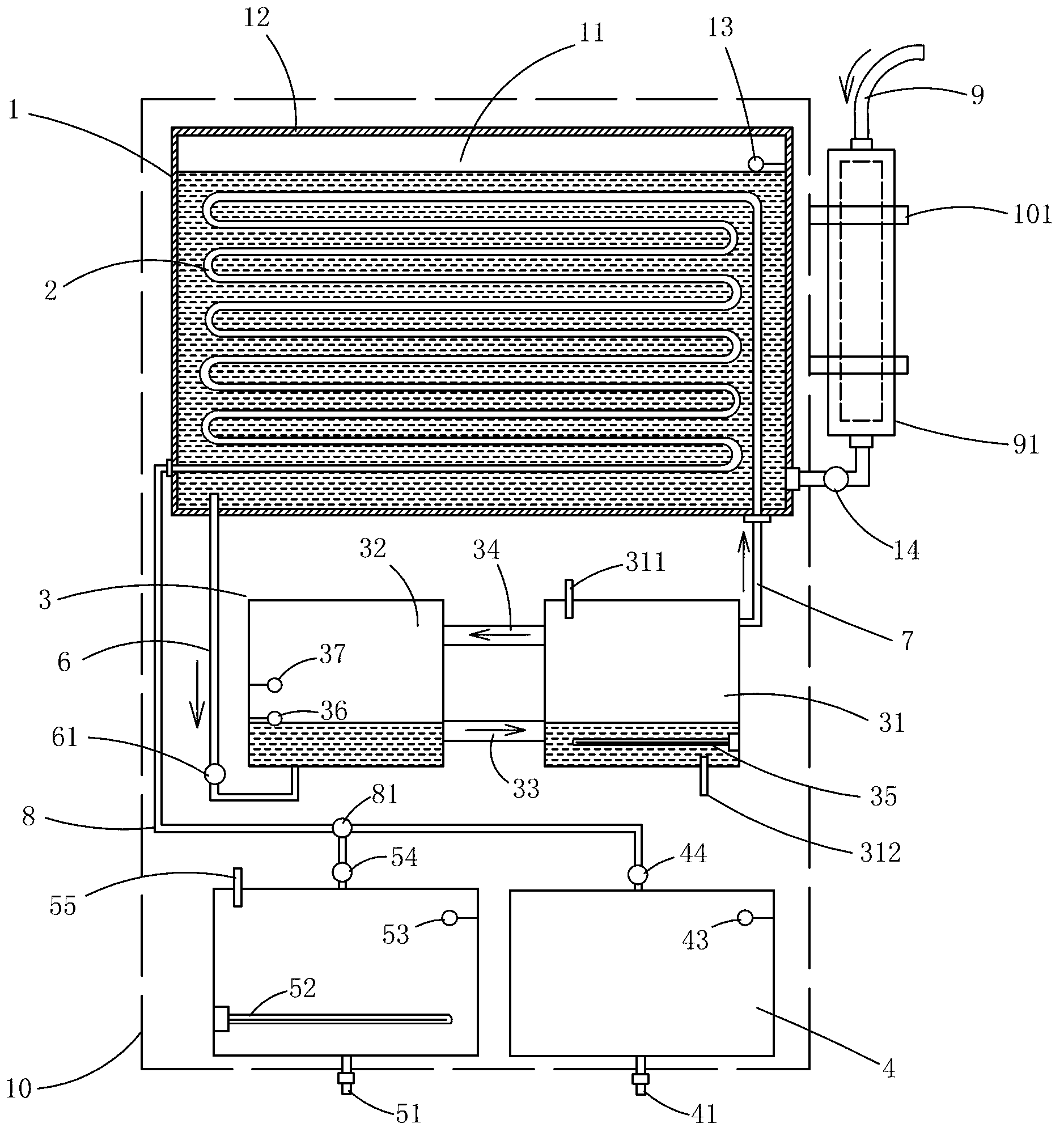

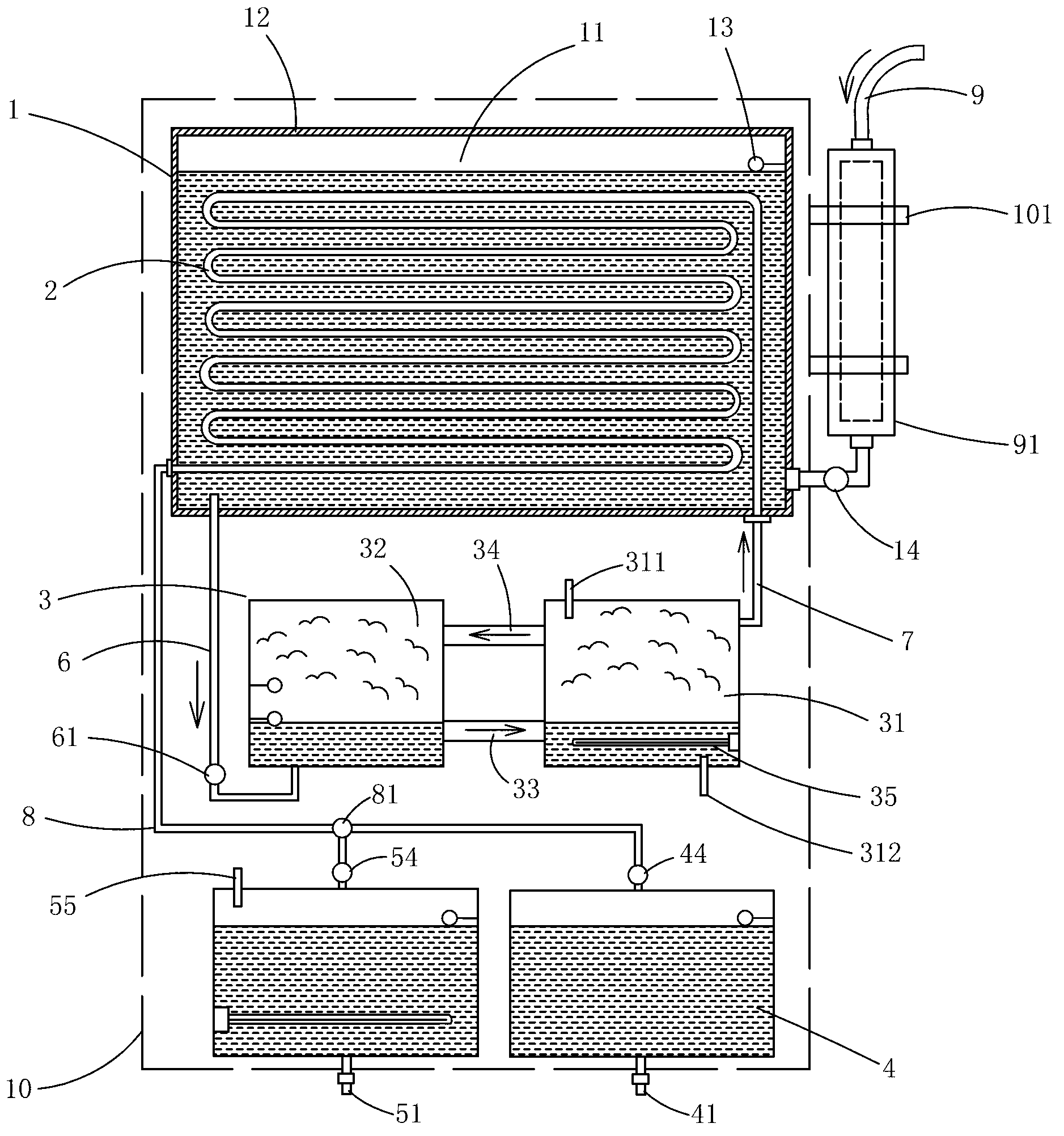

[0014] refer to figure 1 , the preheating energy-saving distillation device of this design, its preferred embodiment includes preheating water tank 1, condensation pipe 2, heating main body 3, normal temperature water tank 4, reheating water tank 5, water outlet pipe 6, water supply pipe 9, steam pipe 7 and condensing pipe Drip pipe 8, of which:

[0015] The inside of the preheating water tank 1 is provided with a hollow cavity 11 for storing cold water at normal temperature, and a large amount of cold water at normal temperature can be stored in the hollow cavity 11, and at the same time, the preheating water tank 1 is provided with a heat insulating material covering the hollow cavity 11. Layer 12 to prevent heat loss. The preheating water tank 1 is provided with a replenishment pipe 9 connected to the hollow cavity 11 for replenishing normal temperature water, the replenishment pipe 9 is provided with a water filter 91, and a filter element is arranged in the water filter ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap