Soliton frequency comb self-generation system and method based on negative thermo-optical coefficient chalcogenide microcavity

A negative thermo-optic coefficient and chalcogen-based technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as difficult locking, poor stability, and short soliton generation area at the red detuning place, so as to increase the generation area and stabilize High performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For the step numbers in the following embodiments, it is only set for the convenience of illustration and description, and the order between the steps is not limited in any way. The execution order of each step in the embodiments can be adapted according to the understanding of those skilled in the art sexual adjustment.

[0026] A soliton frequency comb self-generation method based on a negative thermo-optic coefficient chalcogenide microcavity, comprising:

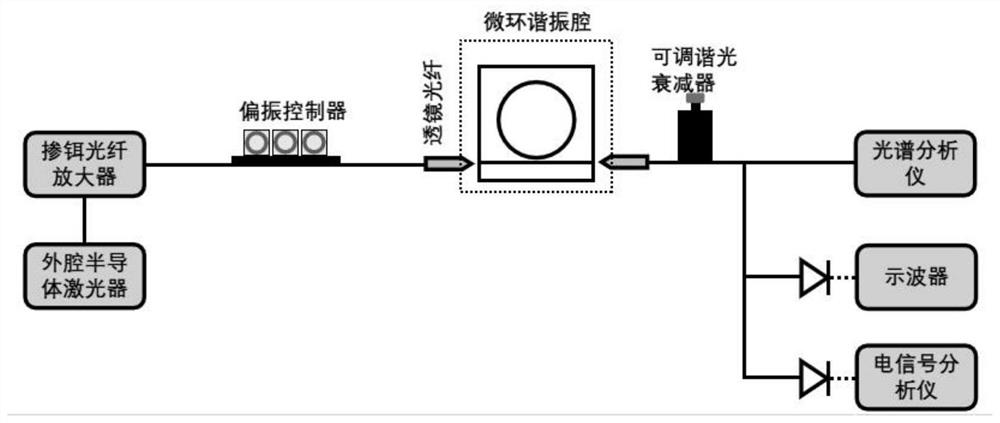

[0027] The tunable optical device emits the pump light with a preset wavelength and power, and after the power is adjusted by the fiber amplifier, it is input to the polarization controller. The design polarization mode is consistent, and the pump light is controlled to enter the negative thermo-optic coefficient microring resonator through the tunable optical attenuator;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com