Vehicle-mounted oily sludge pyrolysis system

A vehicle-mounted, pyrolysis technology, which is applied in pyrolysis treatment of sludge, petroleum industry, special forms of dry distillation, etc., can solve the problems of large amounts of cooling water, uneconomical, difficult feeding, transportation, heating and desorption, etc., to achieve treatment Thorough, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

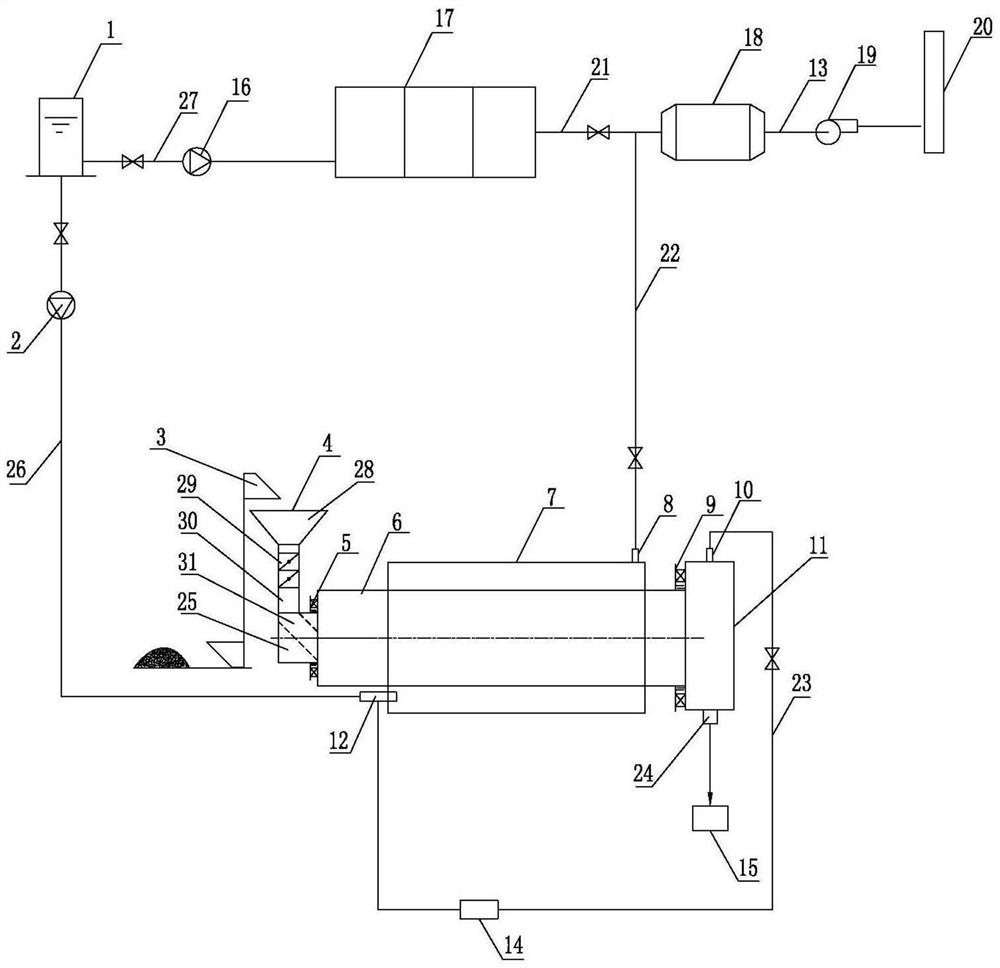

Method used

Image

Examples

Embodiment 1

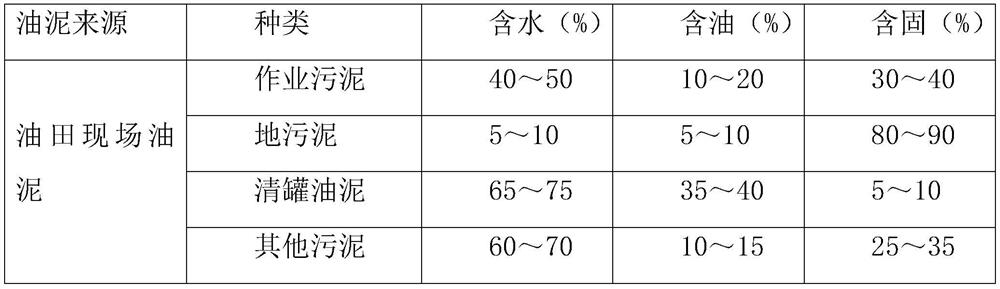

[0033] The composition of oily sludge in oil and gas fields is extremely complex, containing a large amount of aged crude oil, waxes, asphaltene, colloids, suspended solids, bacteria, salts, acid gases, corrosion products, etc., as well as a large amount of flocculation added in the production process Water treatment agents, corrosion inhibitors, scale inhibitors, fungicides, etc. The oil sludge also contains sediment, scale, weeds, gravel, construction waste, etc. The typical composition is shown in Table 1.

[0034] Table 1: Typical composition of oil sludge in an oilfield

[0035]

[0036] According to the characteristics of the above materials, the following points can be summarized in the implementation of this scheme:

[0037] 1) The oil-containing components in the material are complex, and only high-temperature pyrolysis (above 650°C) can pyrolyze various complex heavy oil components (macromolecular organic substances such as colloids, asphaltenes, waxes, and long-cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com