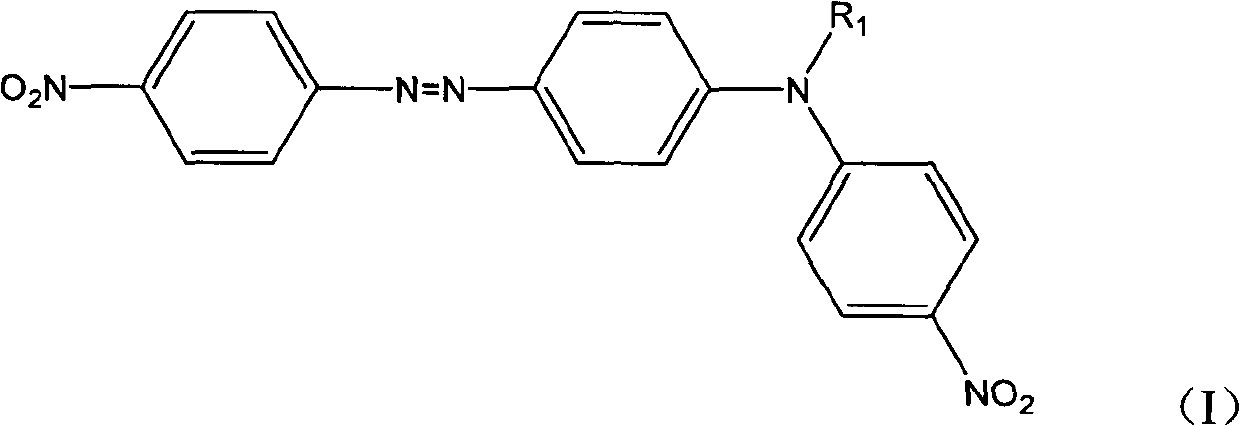

Dispersed azo dye mixture

A technology of dye mixtures and azo dyes, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of deep dyeing, insufficient lifting power, serious staining on white background, poor level dyeing, etc., and achieve excellent sublimation Good fastness, good dyeability, and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

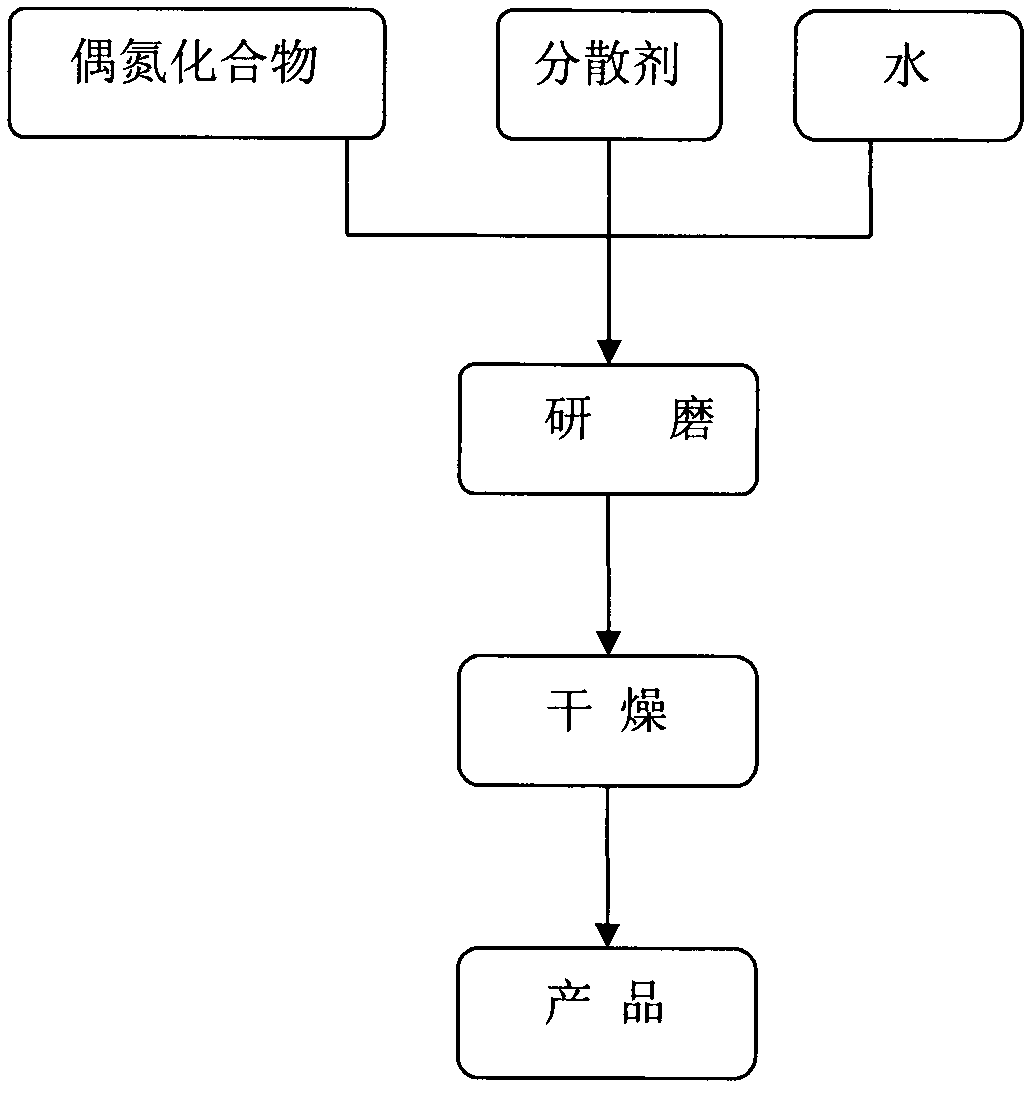

Method used

Image

Examples

Embodiment 1

[0063] With the dyestuff of 13.3 grams of formula (Ia), 11 grams of dyestuff of formula (IIa), the dyestuff of 13.7 grams of formula (IIIa), the dyestuff of 6 grams of formula (Va), the sodium lignosulfonate of 44 grams, add 300 milliliters of water After mixing, grind and disperse with a grinder, spray dry (inlet temperature 130° C., outlet temperature 60° C.) to obtain 100 grams of finished product. 0.4 gram of this product was dyed at pH 4.5 and 130°C to 10 gram of polyester fiber for 60 minutes, then washed, rinsed and dried to obtain a bright black dyed product with excellent fastness properties.

[0064]

Embodiment 2

[0066] With the dyestuff of 12 grams formula (Ia), the dyestuff of 11 grams formula (IIa), the dyestuff of 13 grams formula (IIIa), the dyestuff of 6 grams formula (Va), the sodium lignosulfonate of 98 grams, add 300 milliliters of water After mixing, the dye mixture was prepared according to the method of Example 1.

Embodiment 3

[0068] After mixing 5 grams of the dye of formula (Ia), 10 grams of the dye of formula (IIb), and 10 grams of sodium lignosulfonate with 75 milliliters of water, grind and disperse with a grinder to obtain a water-containing dye product. 1 gram of this product is dyed according to the embodiment 1 method to 10 gram of polyester fiber, obtains the dyed product of the bright navy blue that has excellent washing and each fastness performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com