Shed upper beam device of I-beam shed for coal mine laneway

A technology for coal mine tunnels and steel sheds, which is applied in the directions of roof beams, mining equipment, pillars/brackets that support the roof of mines, etc., to achieve the effects of flexible adjustment, reducing labor intensity of employees and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

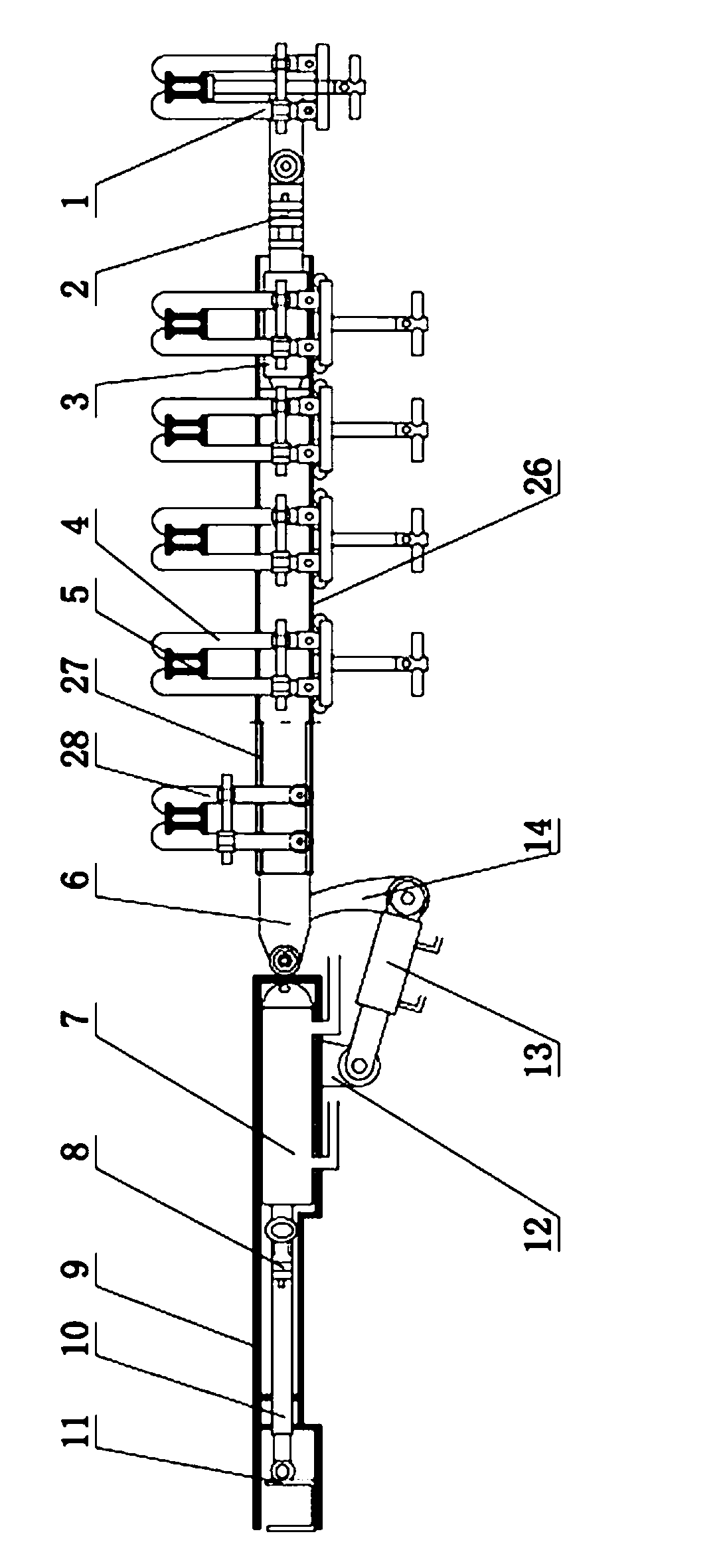

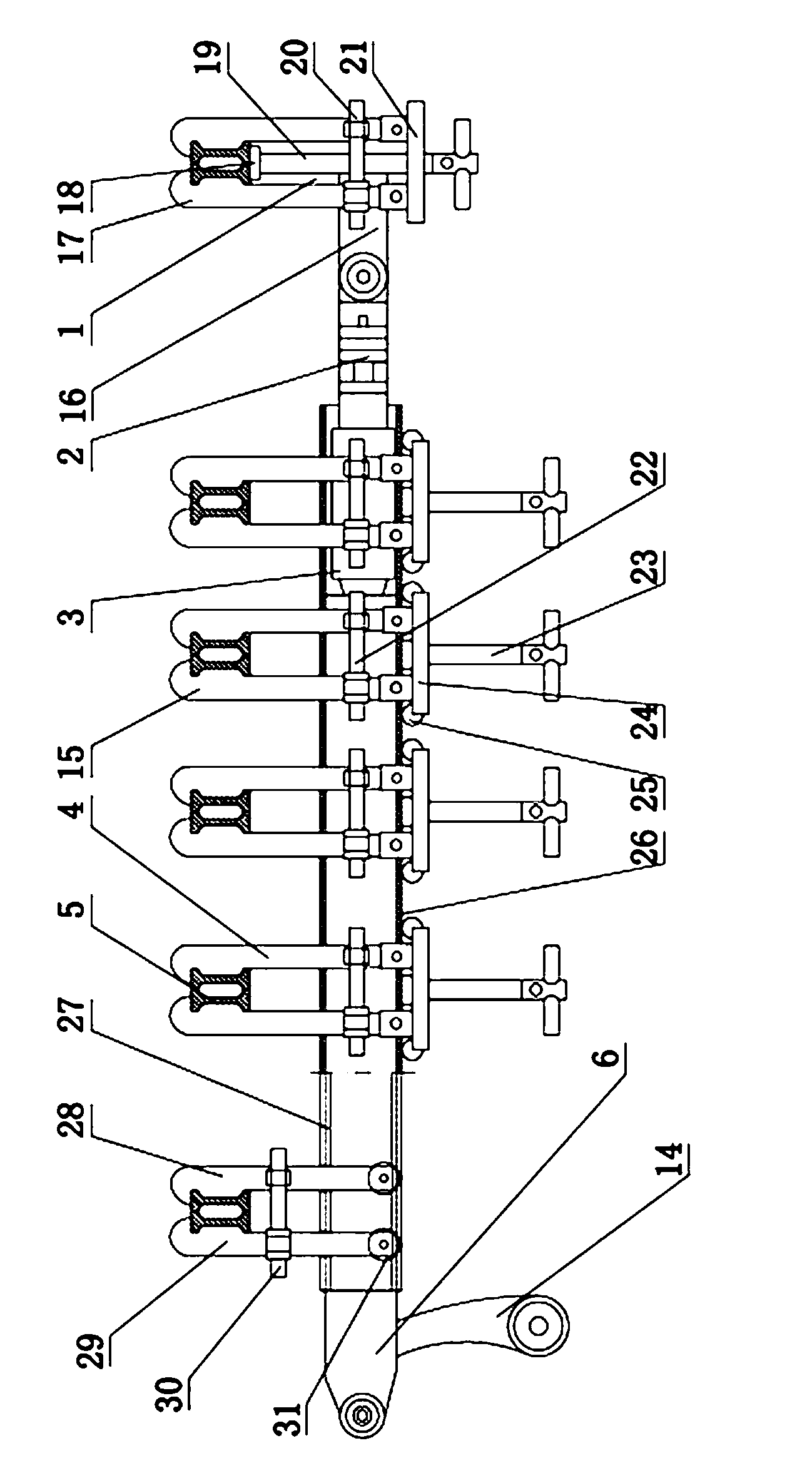

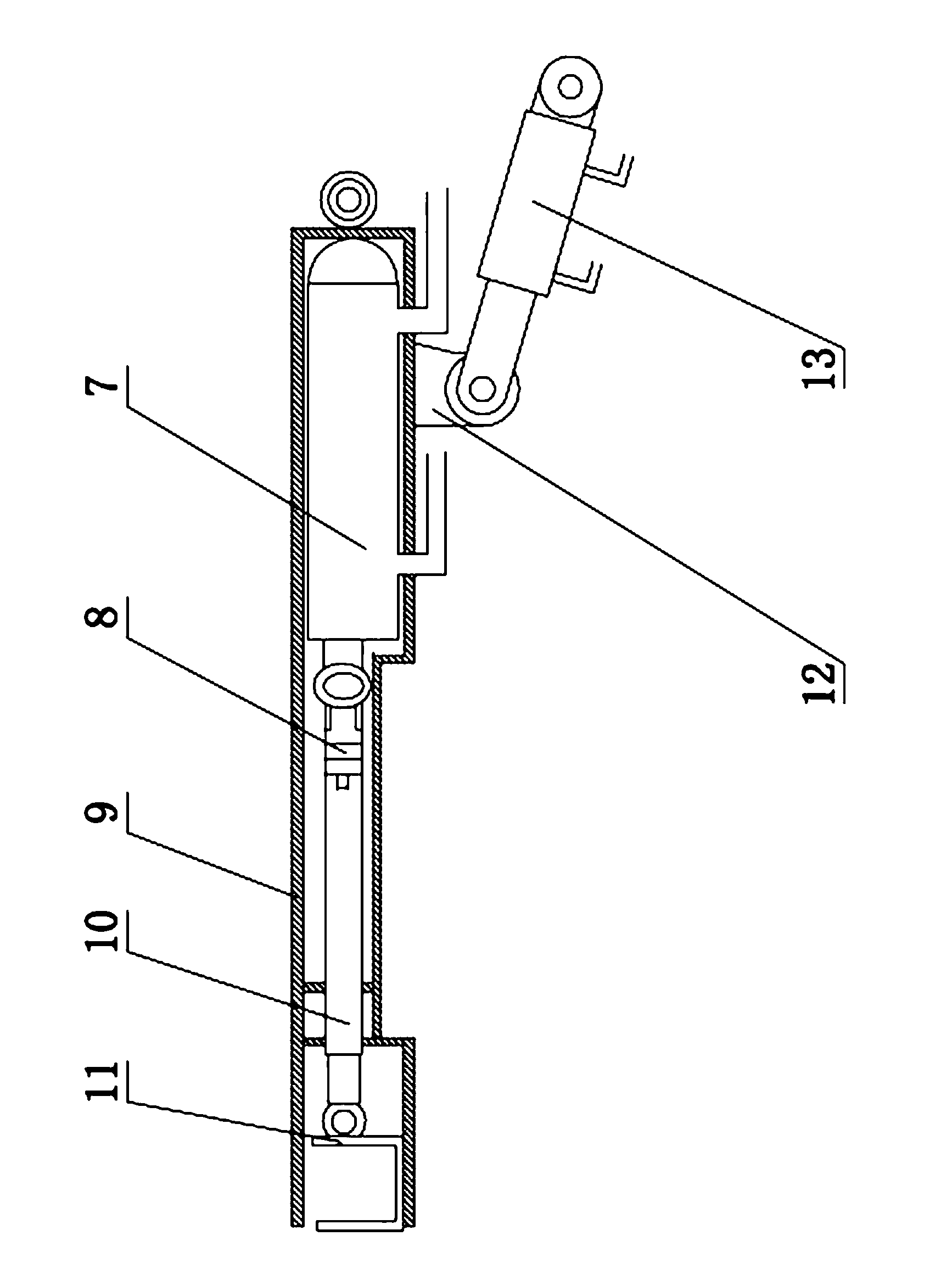

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 , figure 2 , image 3 As shown in the figure, a shed upper beam device for an I-shaped steel shed for a coal mine roadway includes a cantilever 6, a casing 26, a fixer 4, a propulsion support 1, a propulsion device 3, a height adjustment arm 9, a height adjustment device 13, a width The adjusting device 7 and the beam lifter 11, the propelling device 3 is a propelling cylinder, the height adjusting device 13 is a height adjusting cylinder, the width adjusting device 7 is a width adjusting cylinder, the cantilever 6 is arranged in the casing 26, and the casing 26 is fixed by four The fixture 4 is suspended on the upper beam 5 of the erected I-shaped steel shed. The fixture 4 includes a fixed bottom plate 24, a fixed hook arm 15, a fixed top wire 23, a fixed locking bolt 22 and a roller 25, and the fixed bottom plate 24 is hinged. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com