Borehole high-concentration gas extraction and drainage method and device thereof

A high-concentration, gas-based technology, applied in the direction of gas discharge, safety devices, earthwork drilling, etc., can solve the problems of gas drainage concentration drop, affect the safety of the gas drainage system, reduce the utilization rate of drilling holes, etc., and save input costs , simple structure, high sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

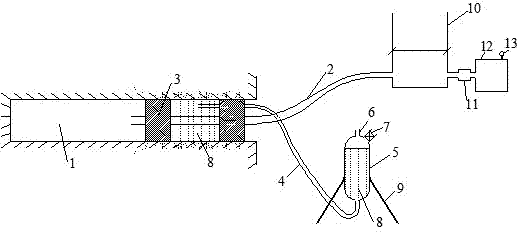

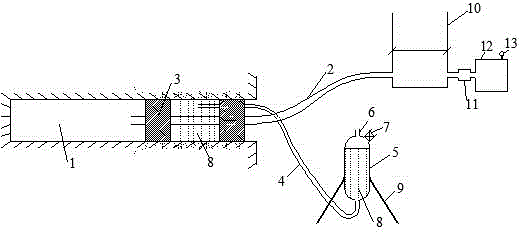

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] The pumping and drainage method for high-concentration gas in boreholes of the present invention:

[0019] a. After the drilling 1 for construction drainage or gas drainage is completed, fix two sealing capsules or polyurethane reaction bags 3 at the front and back on the drainage pipe or drainage pipe 2 at a distance of 0.5 to 5 m, and seal the hole at the latter Fix the liquid injection pipe 4 in the capsule or polyurethane reaction bag 3 at the same time, send the extraction pipe or drainage pipe 2 into the borehole 1, connect the exposed end of the drainage pipe or drainage pipe 2 with the atmospheric storage tank 10, The exposed end of the injection pipe 4 is connected with the mucus tank 5;

[0020] b. Connect the compressed air pipe under the coal mine with the compressed air interface 6 of the viscous tank 5, pour the prepared sealing mucus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com