Ring type earhole universal joint as well as connector and jaws thereof

A connector and ear hole technology, applied in the field of universal joints, can solve the problems of inability to overcome stress concentration, complex structure, etc., and achieve the effects of light weight, good mechanical performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

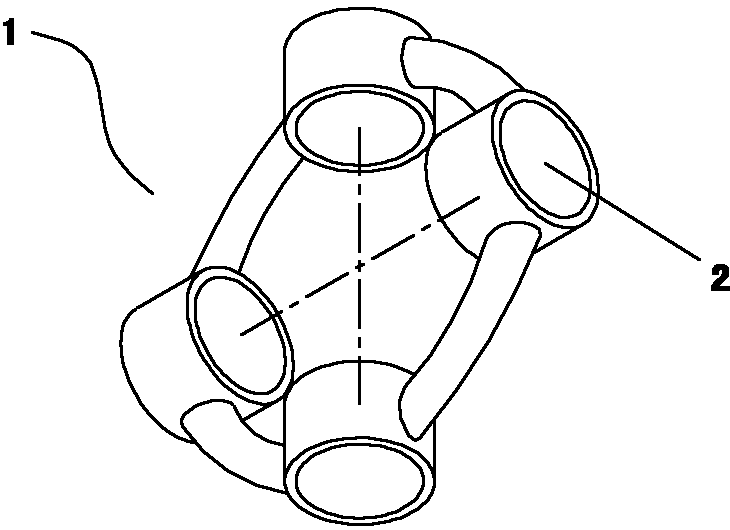

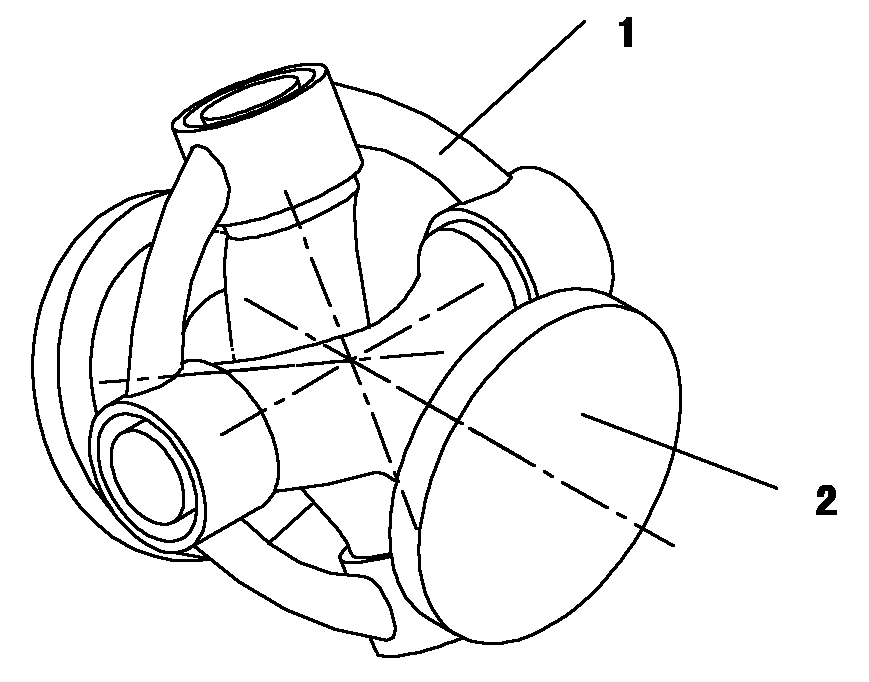

[0022] like figure 1 Shown is a schematic structural diagram of an embodiment of the connector of the present invention. The connector 1 of this embodiment is in the shape of a ring, and the connector 1 is provided with four ear holes 2 evenly distributed in a ring, the axes of the two opposite ear holes 2 coincide and are located in the radial direction, and the two axes of the four ear holes 2 are in the on the same plane and perpendicular to each other.

[0023] By setting the connector 2 in a ring shape, the force applied to the connector when the universal joint rotates is also located in the circumferential direction, thereby avoiding stress concentration and enhancing the force bearing performance of the connector 1 .

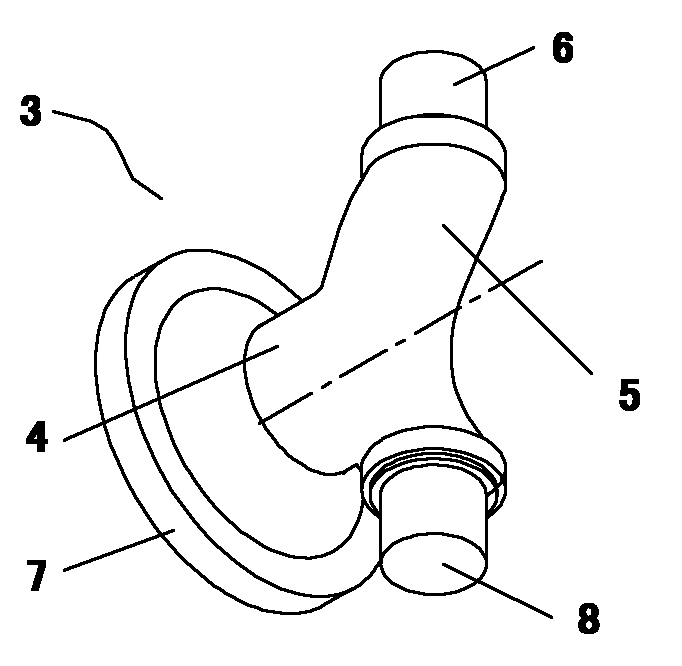

[0024] like figure 2 Shown is a schematic structural view of a fork head embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com