Printed circuit board drying device

A printed circuit board and drying device technology, which is applied in drying gas arrangement, progressive dryer, drying and other directions, can solve the problem of circuit board dehydration and poor drying effect, strong wind knife can not adjust the size of the air, drying device Complex structure and other problems, to achieve the effect of improving the baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

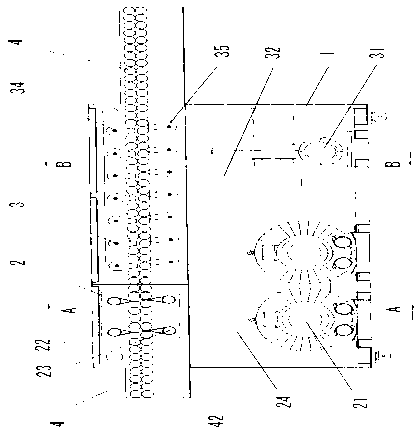

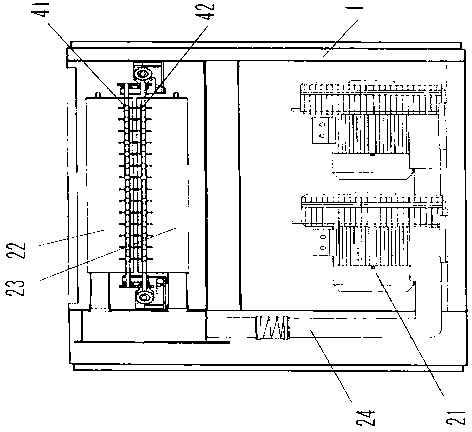

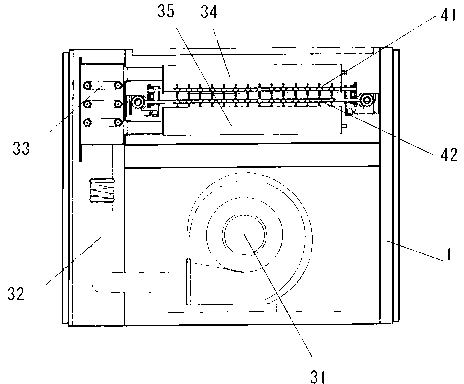

[0016] refer to figure 1 , figure 2 and image 3 As shown, a printed circuit board drying device includes a body 1, a blowing device 2, a hot air device 3 and a conveying device 4 are arranged in the body 1, and the conveying device 4 is an upper and a lower holder arranged on the body 1 Roller 41,42, the front end of conveying device 4 is provided with blowing device 2, and described blowing device 2 comprises air blower 21, and air blower 21 is connected with upper and lower strong wind wind knife 22,23 by air pipe 24, strong wind wind knife 22,23 The upper air outlet is located in the gap between the upper and lower rollers 41, 42. The rear end of the conveying device 4 is provided with a hot air device 3. The hot air device 3 includes a blower 31. The blower 31 passes through the air duct 32 and is heated. Device 33 is connected with upper and lower hot air air knives 34,35, and the air outlet on the hot air air knives 34,35 is positioned on the gap between upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com