Real-time pressure sensing method based on fiber bragg grating reflected light polarization parameter

A real-time pressure and fiber grating technology, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve problems such as difficult detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

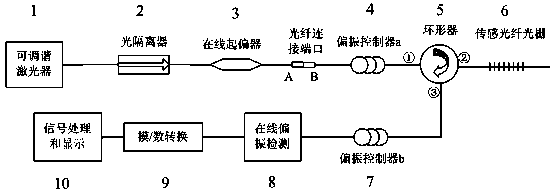

Method used

Image

Examples

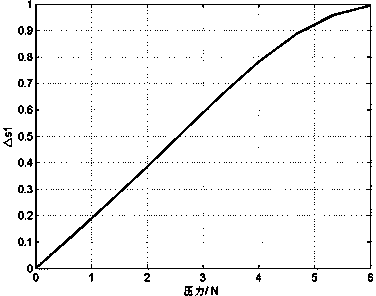

example 1

[0029] [Example 1] Design grating parameters: period Λ=535nm, fiber core refractive index n eff =1.448, length L=10mm, refractive index modulation coefficient δn=1×10 -4 . Adjust the polarization controller a4 and polarization controller b7 to perform phase compensation. Rotate the relative positions of the fiber connection ports A and B to make the polarization angle of the incident line polarized light be 45°. Selection of Tunable Laser Wavelength λ p =1549.54nm. When the sensing fiber grating 6 is affected by external pressure, the birefringence of the line will change, thus causing the first Stokes parameter of the reflected light to change. The reflected light detects the change of the polarization parameter through the linear polarization detection module 8, passes through the analog / digital conversion module 9, and displays the normalized first Stokes parameter value in real time in the signal processing and display module 10, and monitors the magnitude of the press...

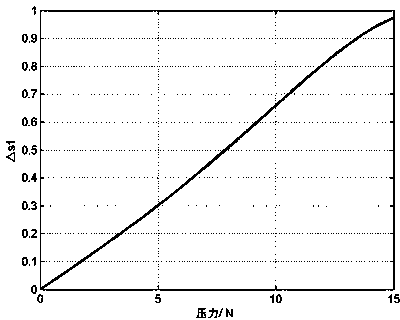

example 2

[0030] [Example 2] Design grating parameters: period Λ=535nm, fiber core refractive index n eff =1.448, length L=5mm, refractive index modulation coefficient δn=0.5×10 -4. Adjust the polarization controller a4 and polarization controller b7 to perform phase compensation. Rotate the relative positions of the fiber connection ports A and B to make the polarization angle of the incident line polarized light be 45°. Selection of Tunable Laser Wavelength λ p =1549.45nm. In this example, the normalized first Stokes parameter change Δs 1 Theoretical relationship with external pressure is as image 3 As shown, the dynamic range in this example is about 15N, and the sensitivity is about 0.0667 / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| grating period | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com