Two-dimensional visualized test device of work mechanism of anchoring system

A test device and anchoring system technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulty in accurate monitoring, small contact area, and the uniformity of force on the sample, so as to ensure stability, reasonable structure, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

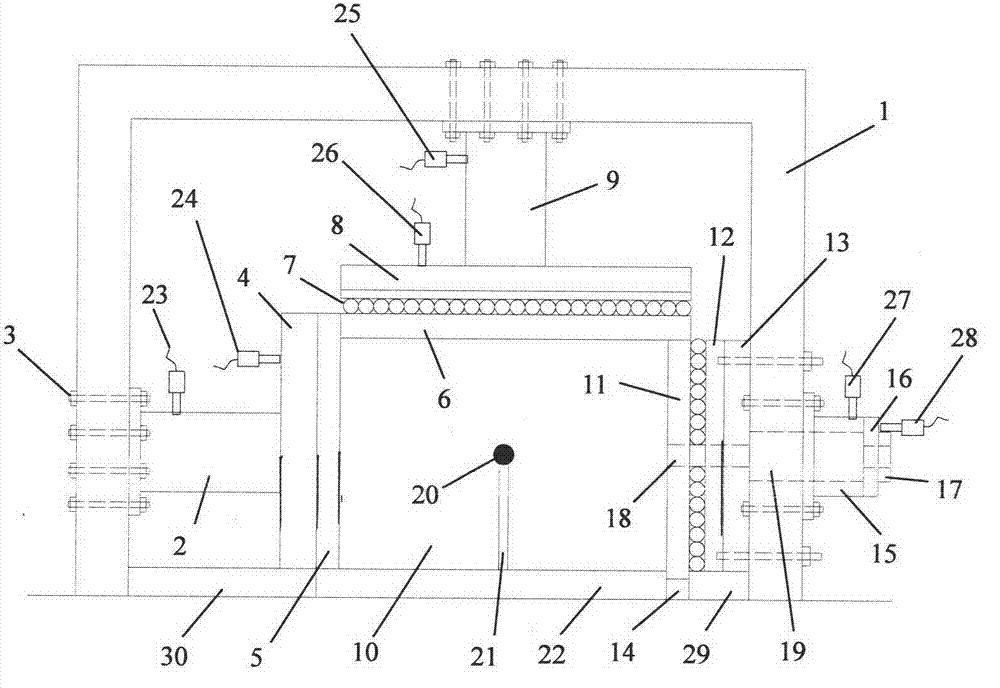

[0010] The following is a further detailed description of the two-dimensional visualization test device for the working mechanism of the anchoring system of the present invention in conjunction with the accompanying drawings.

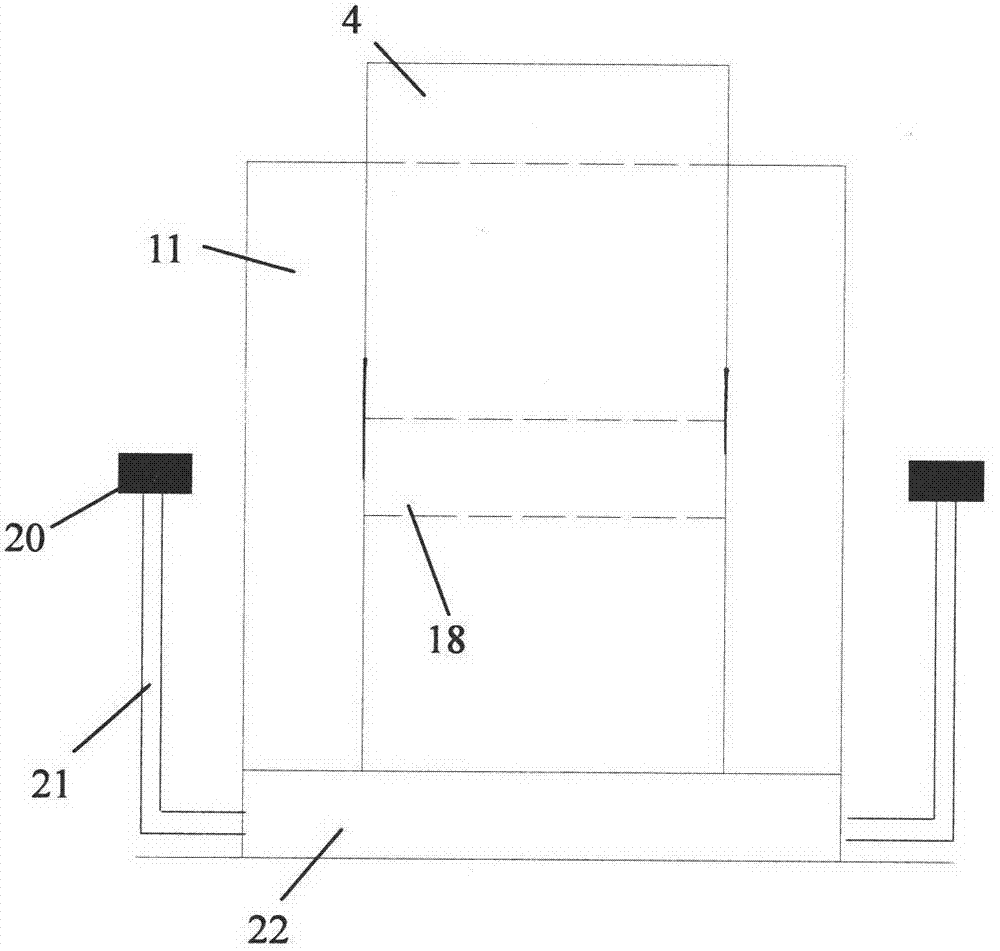

[0011] Referring to the accompanying drawings, the two-dimensional visualization test device of the present invention is composed of a sample chamber 10, a horizontal loading system, a vertical loading system, a horizontal fixing system, an anchor rod pulling system and a monitoring system.

[0012] The sample chamber 10 has a frame structure and is composed of a left loading plate 5, a top loading plate 6, a right fixing plate 11, a bottom plate 22 and a corner plate 14. The bottom plate 22 is placed horizontally, and the left loading plate 5 and the right fixing plate 11 are parallel to each other, the left loading plate 5 is vertically placed above one end of the bottom plate 22, the corner plate 14 is positioned on the other side wall of the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com