On-load continuous transformer

A transformer and font technology, applied in transformers, variable transformers, variable inductors, etc., can solve problems such as contact arcs and achieve the effect of eliminating arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

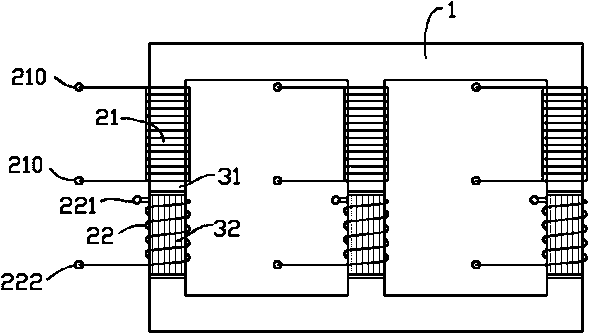

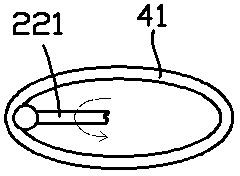

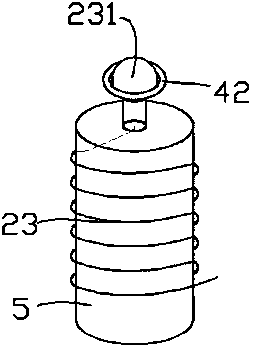

[0017] exist figure 1 — image 3 In the shown embodiment, the on-load continuous transformer includes a Japanese-shaped iron core 1, and primary coils 21 and secondary coils 22 wound on three parallel horizontal columns of the Japanese-shaped iron core 1; The horizontal column is composed of two sections, one of which is a fixed column 31 wound with the primary coil 21, the two terminals 210 of the primary coil are connected to the input voltage, and the other section is a freely rotatable rotating column 32 wound with a The secondary coil 22, one end of the secondary coil 22 is electrically connected to a brush head 221 fixed on the rotating column 32, and the brush head 221 is output through the conductive ring 41, as figure 2 As shown, in actual wiring, the conductive rings 41 corresponding to the secondary coils 22 are electrically connected as a common zer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com