Permanent magnet synchronous motor with dual annular rotation heat tube for cooling rotor

A permanent magnet synchronous, double-ring technology, applied to synchronous motors with stationary armatures and rotating magnets, electric components, cooling/ventilation devices, etc., can solve the problems of permanent magnet demagnetization, poor heat dissipation conditions, and scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing.

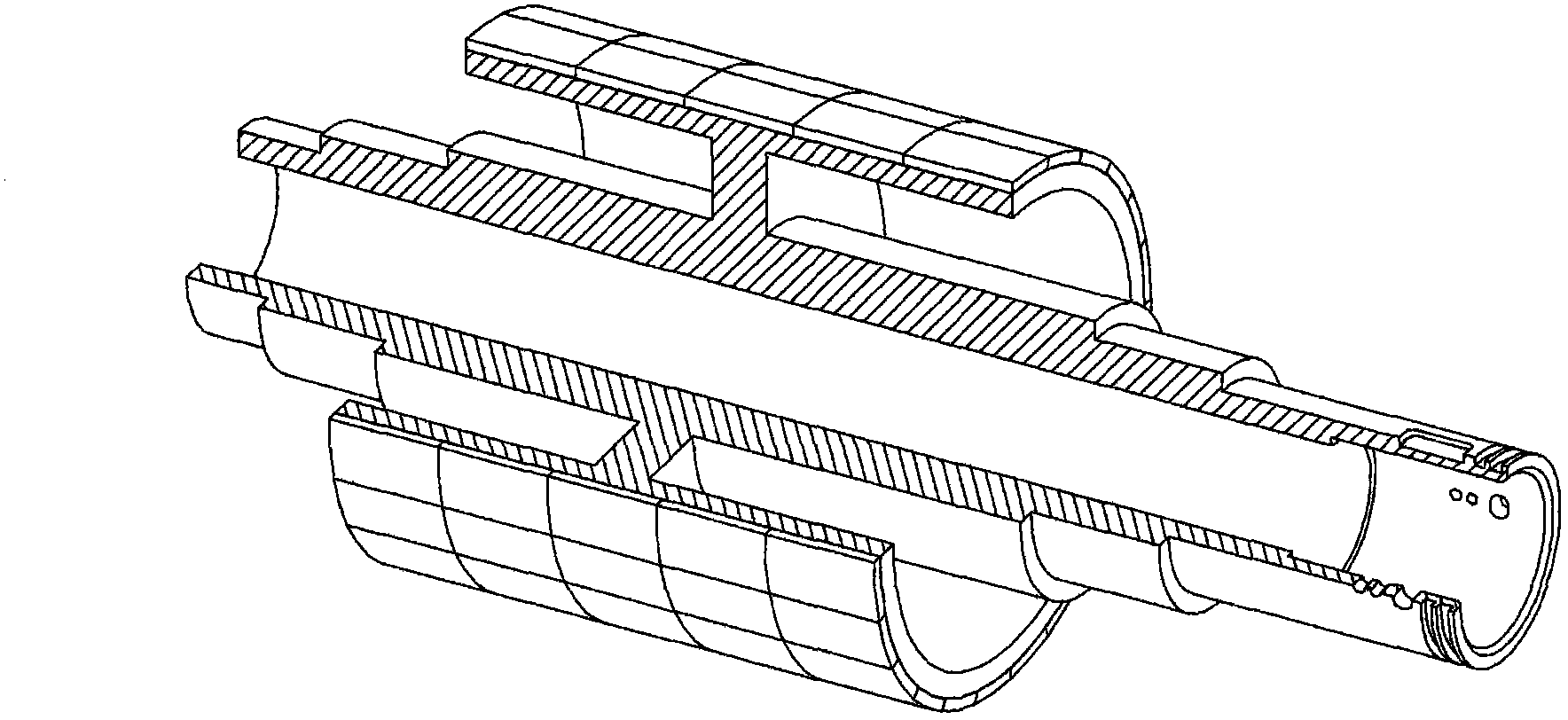

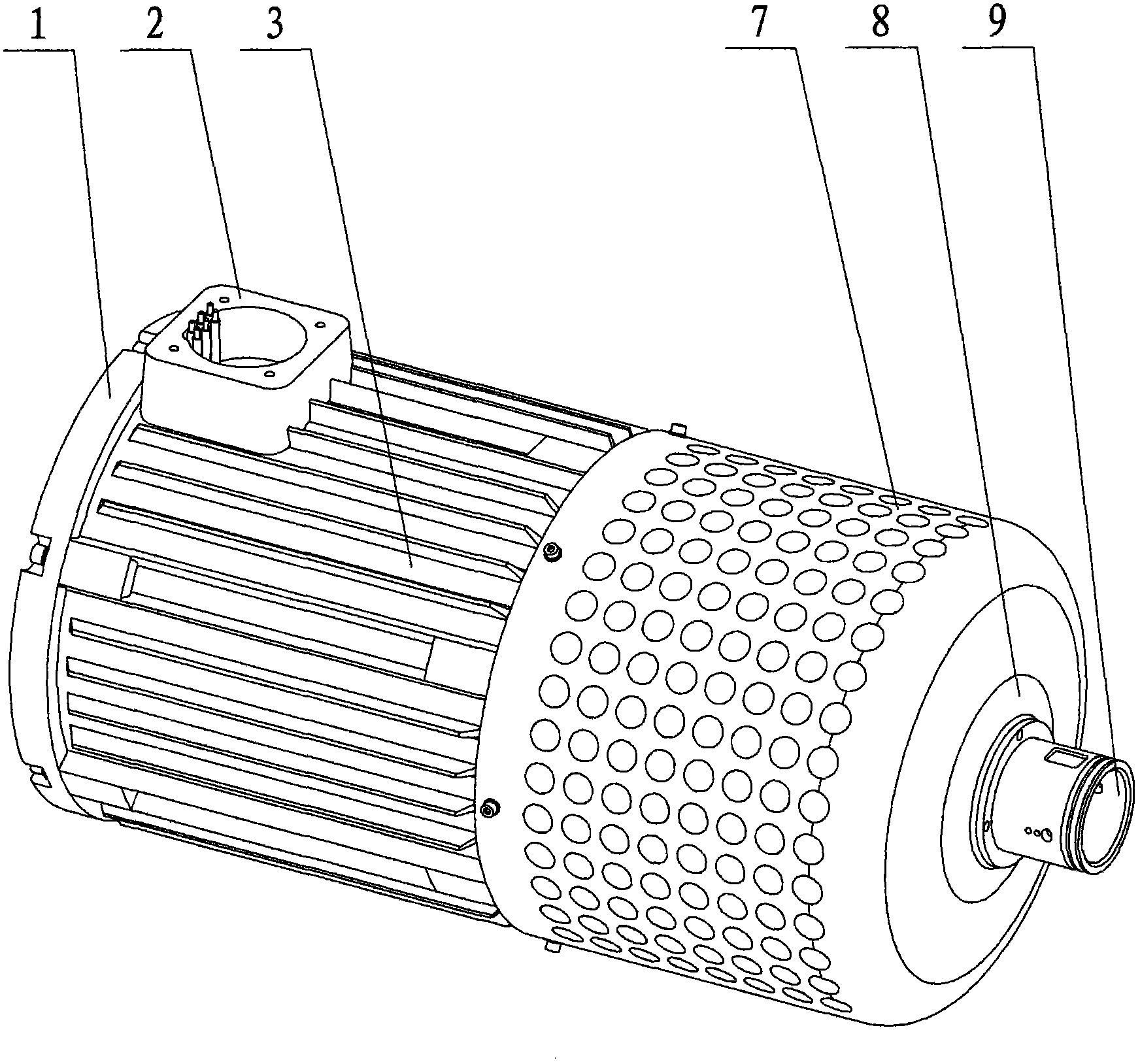

[0030] refer to image 3 , Figure 4 with Figure 26 , The permanent magnet synchronous motor with dual annular rotating heat pipes cooling the rotor is composed of a base end cover part 1, a base part 3, a cooling end cover part 4, a rotor part 9 and a protective part. The base end cover part 1 and the cooling end cover part 4 are installed on the two ends of the base part 3 respectively, and the rotor part 9 is installed on the axis of the base end cover part 1, the base part 3 and the cooling end cover part 4, and the protection The components are mounted on the cooling cover part 4 and the rotor part 9 .

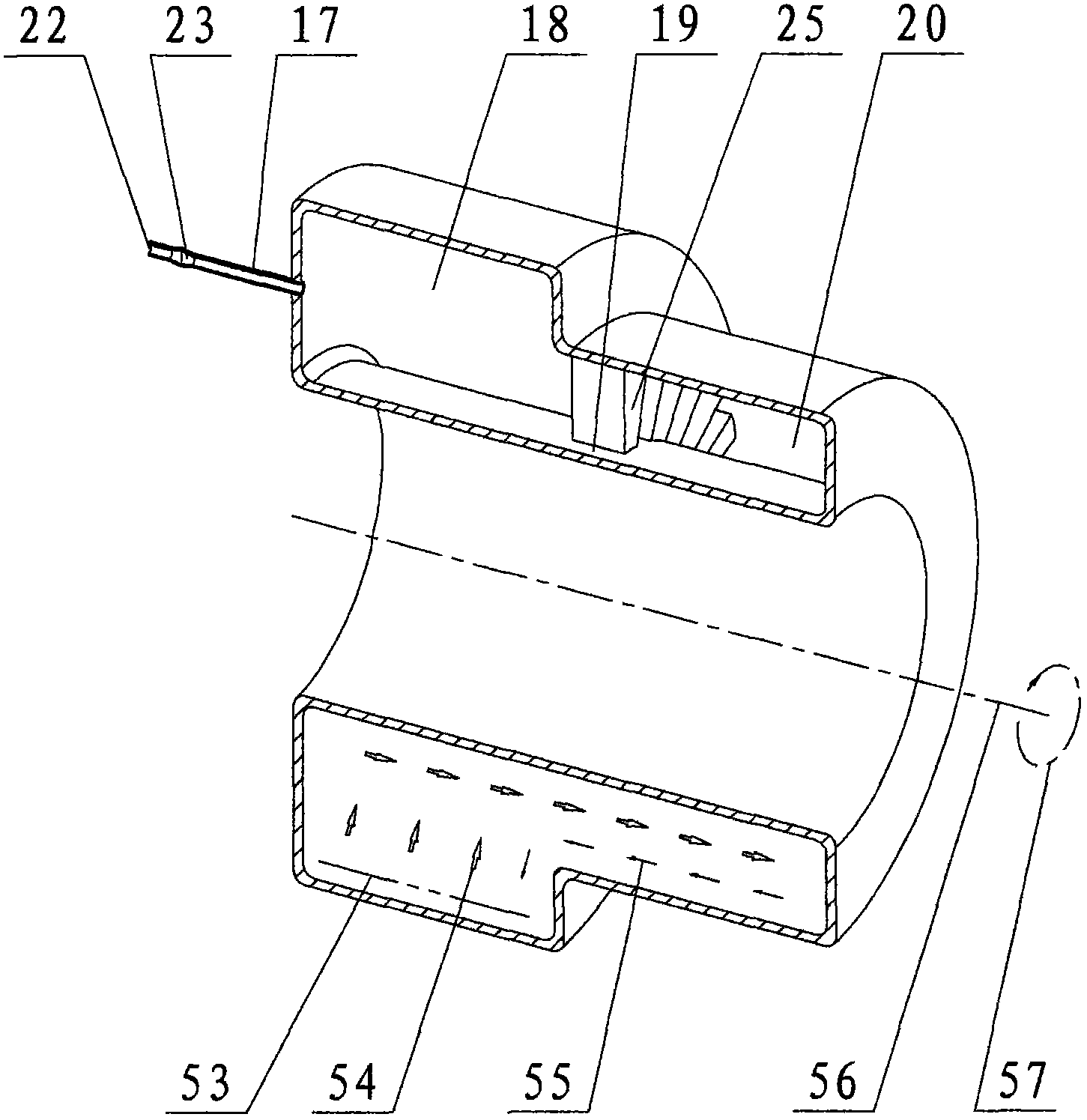

[0031] refer to Figure 5 , Image 6 ,with Figure 7 , The rotor component 9 is composed of a rotor weldment, a bearing 11, a permanent magnet magnetic steel 14, a rotor sealing ring 16, and a double-ring rotating heat pipe cooler. The rotor weldment is welded toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com