High voltage direct current cable having an impregnated stratified insulation

A high-voltage direct current and insulator technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of low-viscosity oil impregnation that is not suitable for overall impregnation of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

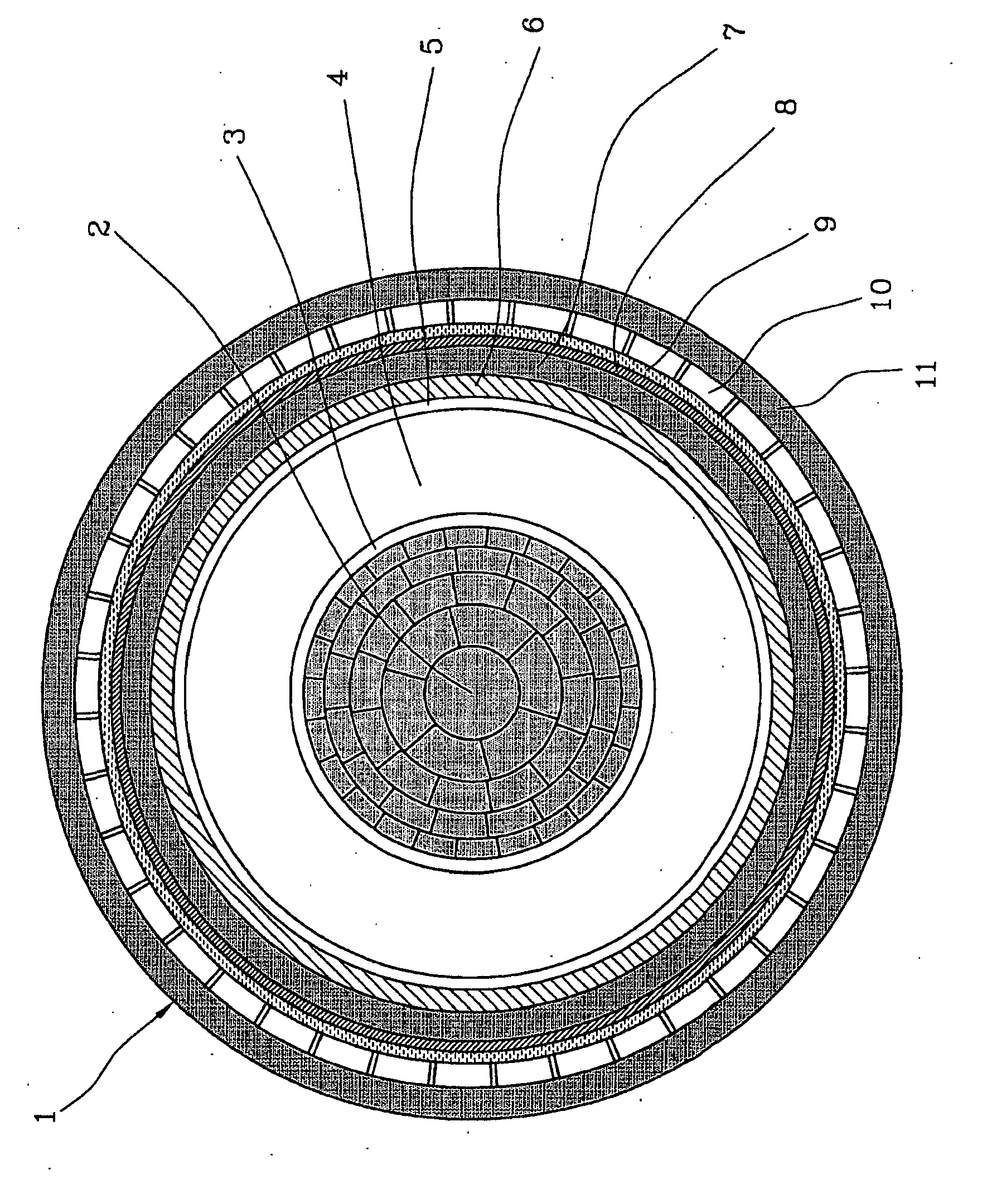

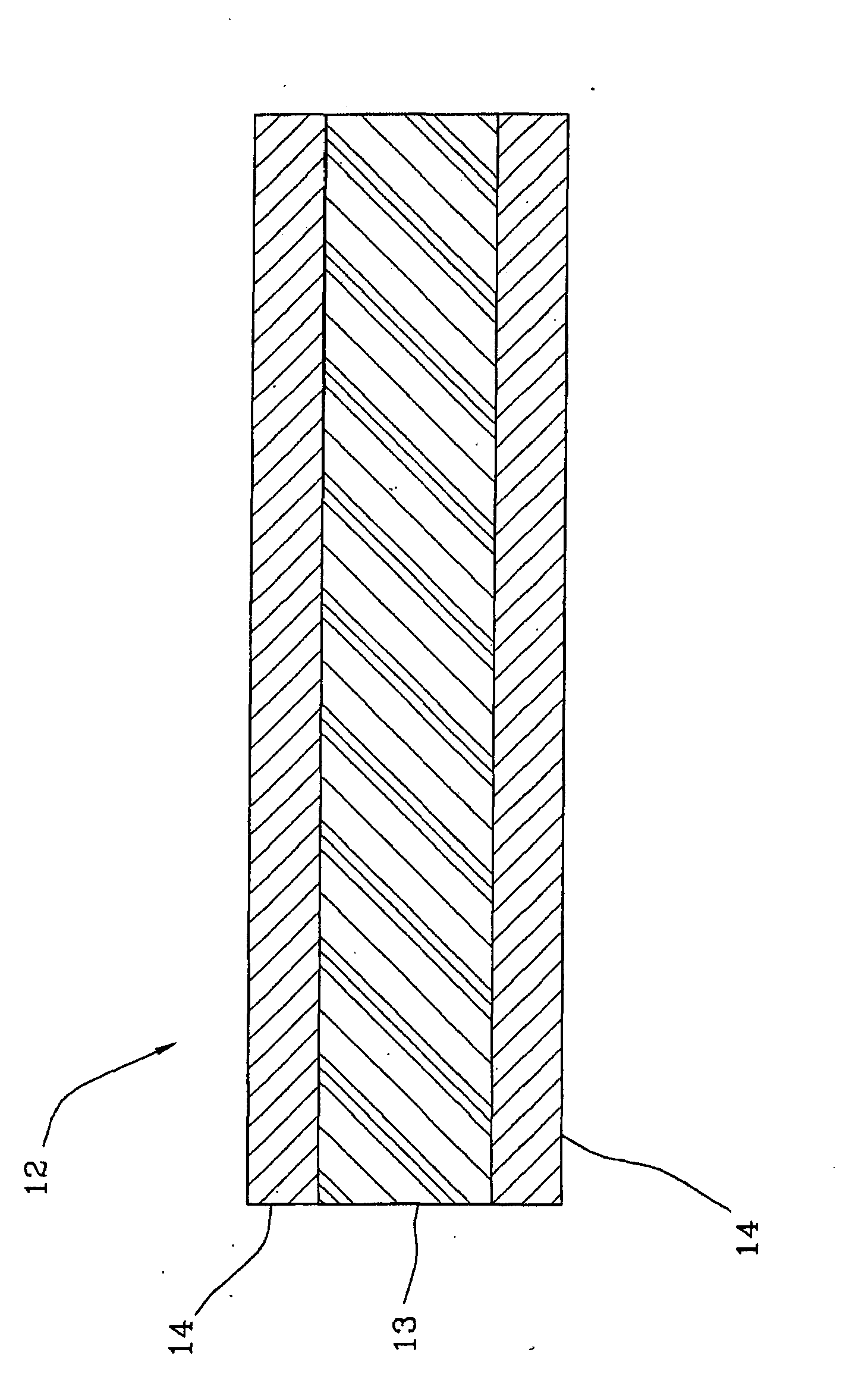

Method used

Image

Examples

example 1

[0055] 0.025 mm thick, 0.93 g / ml density and 100,000 Gurley seconds air impermeability -1 Two layers of kraft paper (pure conifer cellulose) and one layer of Pro-fax TM Combined with PF611 (Basell), this layer of Pro-fax TM PF611 (Basell) is a propylene homopolymer (PP) with a density of 0.902 g / ml (ASTM D 792) and an MFI of 30.0 g / 10 min (ASTM D 1258) at 230°C / 2.16 kg. The resulting paper / PP / paper laminate had a thickness of 0.100 mm, a PP percentage of 60% by weight and a weight of 100 g / m2. In the dry laminate, the peel strength between PP and paper was measured according to standard ASTM D1876-08 and the result was 13 g / 15 mm.

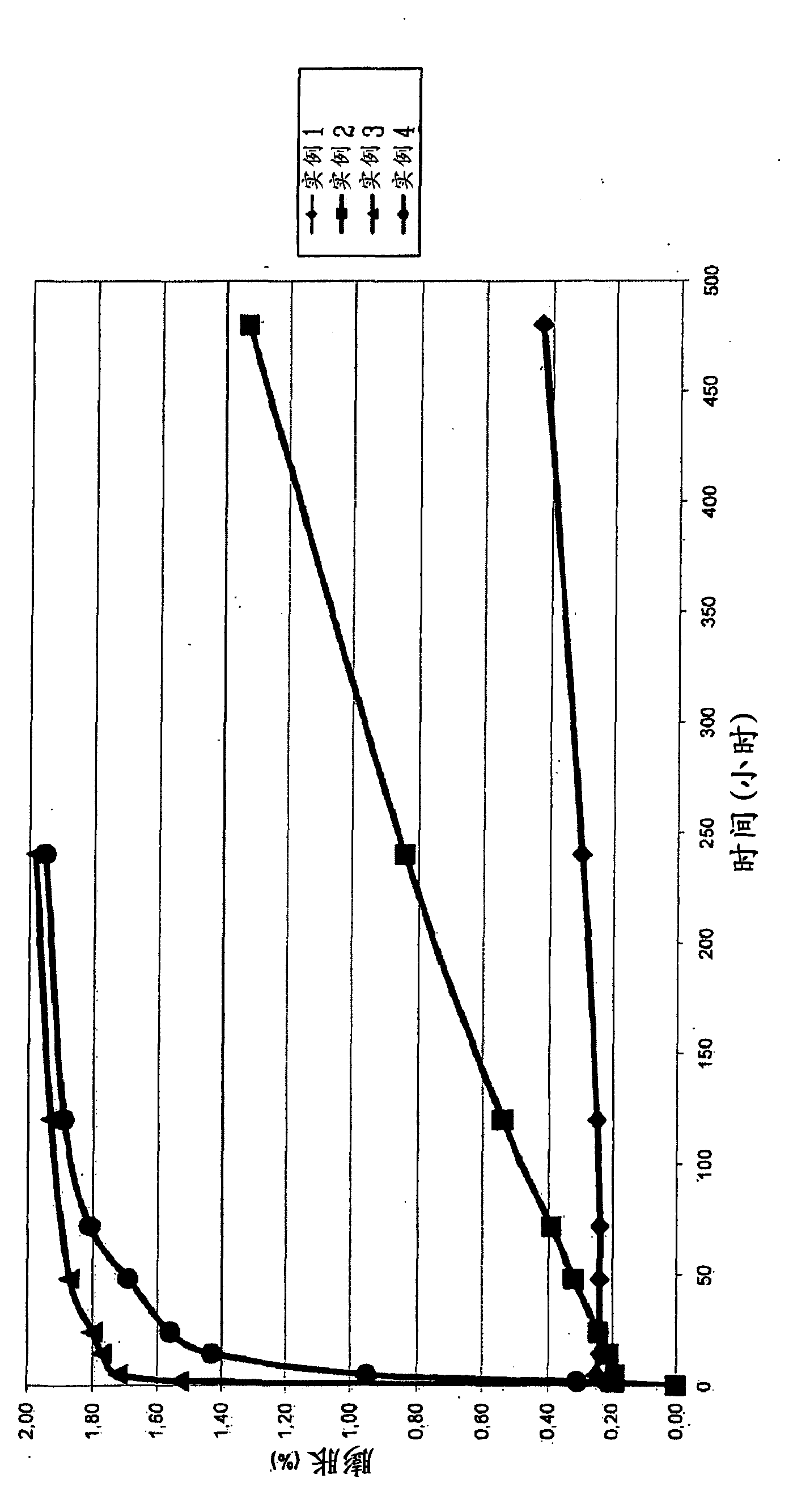

[0056] The laminate thus obtained was dried under vacuum in a thermostat at 135°C for 8 hours, followed by impregnation at 125°C with an insulating fluid having a viscosity of 1200 cSt at 100°C (commercial product T2015 of H&R ChemPharm (UK) Ltd.) . During the impregnation, the thickness change (swelling) was measured at regular intervals: the...

example 2

[0059] 0.025 mm thick, 0.93 g / ml density and 100,000 Gurley seconds air impermeability -1 Two layers of kraft paper (pure coniferous cellulose) combined with one layer of HD601CF (Borealis) which has a density of 0.90 g / ml (ISO 1183) and an MFI of 8 g / 10 at 230°C / 2.16 kg minutes (ISO 1133) of propylene homopolymer (PP). The resulting paper / PP / paper laminate had a thickness of 0.100 mm, a PP percentage of 60% by weight and a weight of 100 g / m2. In dry laminates, the peel strength between PP and paper was measured according to standard ASTM D 1876-08 and the result was 100 g / 15 mm.

[0060] The laminate thus obtained was dried under vacuum in a thermostat at 135°C for 8 hours, followed by impregnation at 125°C with an insulating fluid having a viscosity of 1200 cSt at 100°C (commercial product T2015 of H&R ChemPharm (UK) Ltd.) . During the impregnation, the thickness change (swelling) was measured at regular intervals: the results are reported in the graph of FIG. 4 . The to...

example 3

[0061] Example 3 (comparison)

[0062] 0.025 mm thick, 1.01 g / ml density and 40,000 Gurley seconds air impermeability -1 Two layers of kraft paper (mixed pine / hardwood pure cellulose) and one layer of Pro-fax TM Combined with PF611 (Basell), this layer of Pro-fax TM PF611 (Basell) is a propylene homopolymer (PP) with a density of 0.902 g / ml (ASTM D 792) and an MFI of 30.0 g / 10 min (ASTM D 1258) at 230°C / 2.16 kg. The resulting paper / PP / paper laminate had a thickness of 0.100 mm, a PP percentage of 60% by weight and a weight of 100 g / m2. In the dry laminate, the peel strength between PP and paper was measured according to standard ASTM D1876-08 and the result was 50 g / 15 mm.

[0063] The laminate thus obtained was dried under vacuum in a thermostat at 135°C for 8 hours, followed by impregnation at 125°C with an insulating fluid having a viscosity of 1200 cSt at 100°C (commercial product T2015 of H&R ChemPharm (UK) Ltd.) . During the impregnation, the thickness change (swel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com