Guide wire horn nozzle of filter stick forming machine

A filter rod forming machine and trumpet nozzle technology, which is applied to e-liquid filter elements, transporting filamentous materials, thin material processing, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

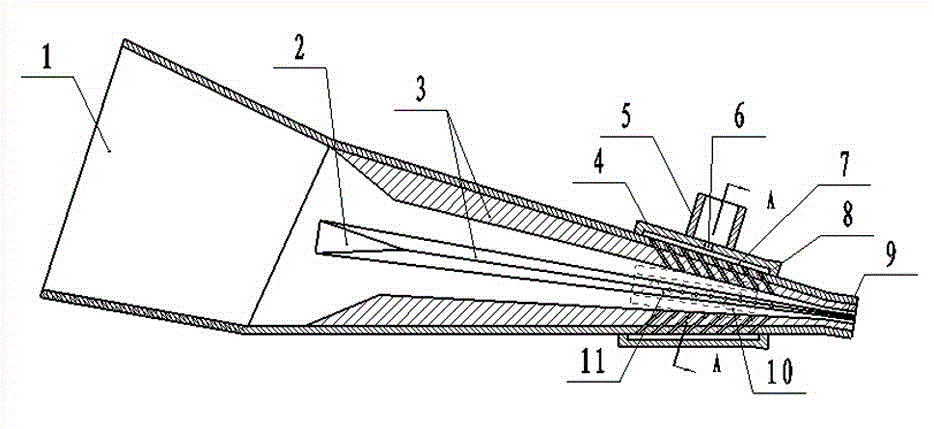

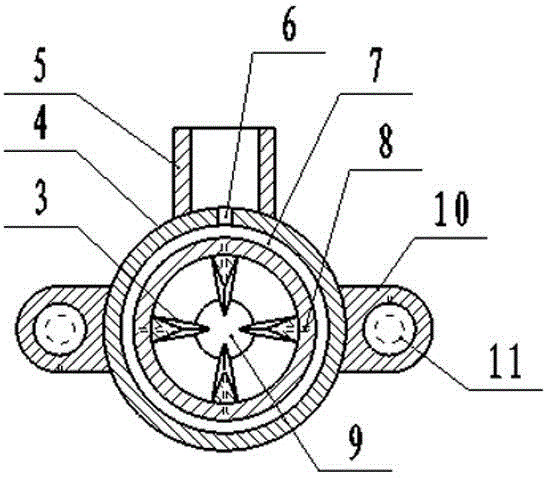

[0013] Example: such as figure 1 with figure 2 As shown, a filter rod forming machine guide wire trumpet nozzle is in the shape of a trumpet, and the opening at the end of the wire inlet 1 is relatively large, and the opening at the end of the wire outlet 9 is small, and the diameter of the wire outlet 9 is consistent with the diameter of the filter rod , the inwardly protruding rib 3 is installed on the inner wall of the horn mouth, and its front end is processed with an oblique contact surface 2, and the height of the rib 3 shrinks evenly from the middle of the horn mouth to the 9 ends of the silk outlet; on the horn mouth, Air inlet 8 is arranged on the side wall near the end of the silk outlet 9, and an overcoat 4 is fixed outside the air inlet 8, an air groove 7 is formed between the overcoat 4 and the side wall of the trumpet mouth, and an inlet is fixedly installed on the overcoat 4. The tuyere 5, the jacket 4 in the air inlet 5 has an air hole 6 communicating with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com