Multi-roll Xingyu type multi-variable combined rolling mill and its principle

A combined, roll technology, applied in the direction of metal rolling stands, metal rolling mill stands, driving devices for metal rolling mills, etc., can solve the problems of complex four rolls and complex structures, and achieve simple structure and diverse uses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

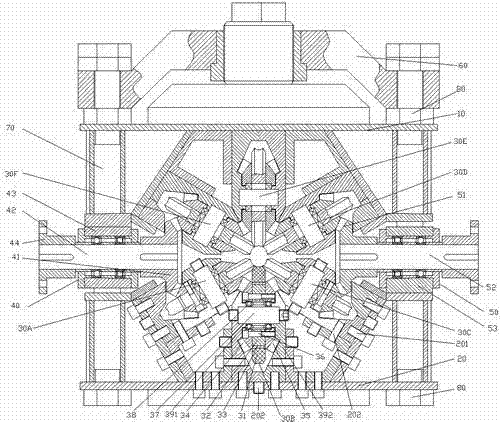

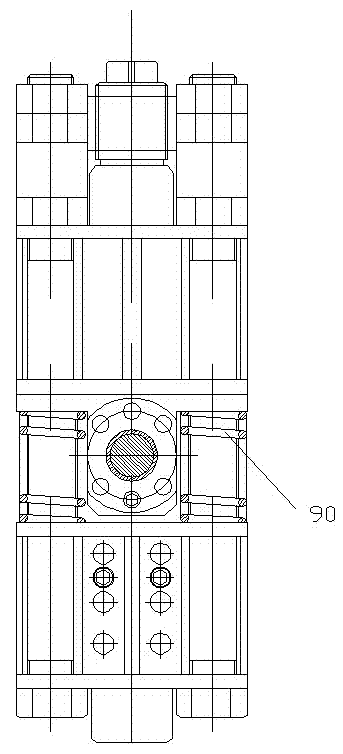

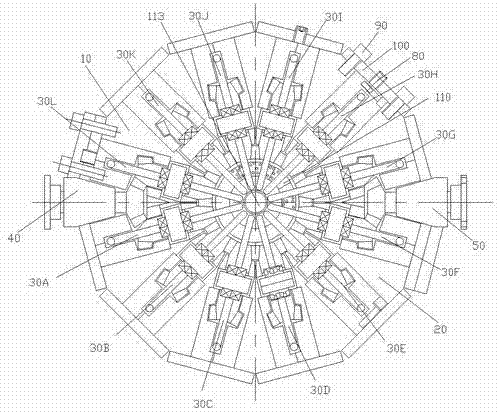

[0029] refer to figure 1 with figure 2 , Embodiment 1 has preferably selected a six-roller star-shaped multi-variable combined rolling mill with n=6, including a roll combination 30, an upper frame 10, a lower frame 20, a left transmission device 40, a right transmission device 50 and a press Device 60, the roll combination and the transmission device are installed in the upper frame and the lower frame, and the pressing device is installed on the top of the upper frame to drive the upper frame to move down as a whole, of which 6 The roll complexes are 30A, 30B, 30C, 30D, 30E, 30F, respectively.

[0030]In order to realize the purpose of the invention, one of the problems first solved by the present invention is the structure of the roll, that is, the working part of rolling: the part that the roll contacts with the rolled piece is the outer roll ring, and the roll combination is composed of the outer roll ring 31, the inner roll ring 32 , the left bevel gear 34, the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com