Biaxially oriented film binding-type horizontal stretching method and device

A biaxially stretched film and transverse stretching technology, applied in the field of biaxially stretched film bundled transverse stretching and devices, can solve problems such as increased energy consumption, increased manufacturing costs, and difficult control, and achieves a reduction in floor space and equipment Cost reduction, easy to achieve the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

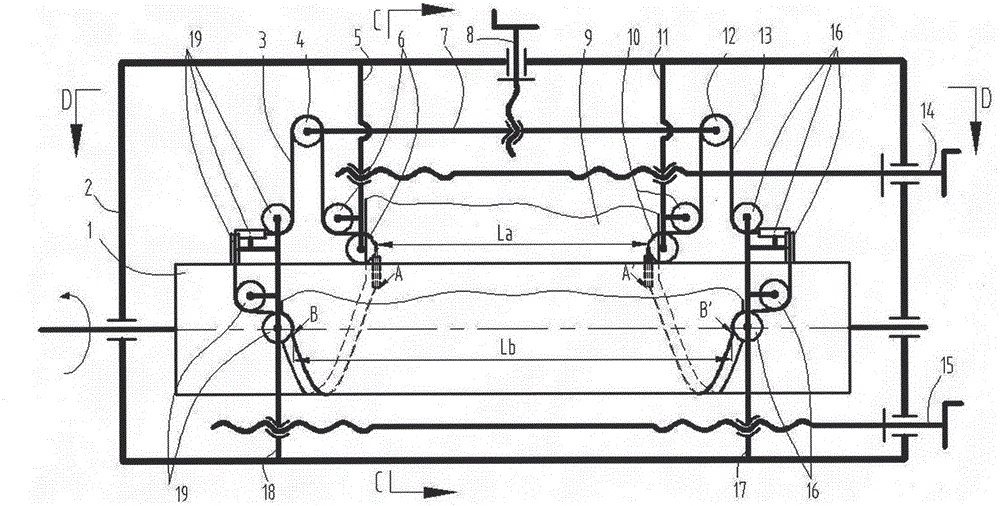

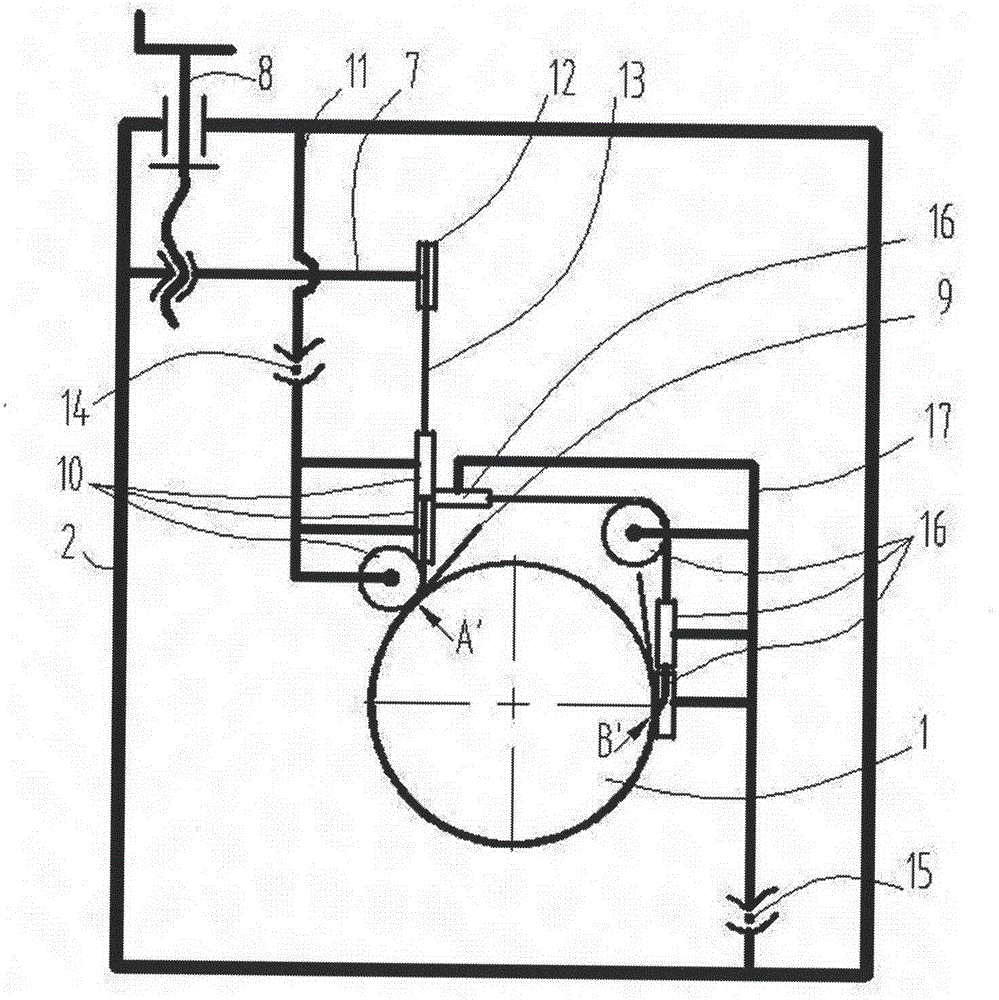

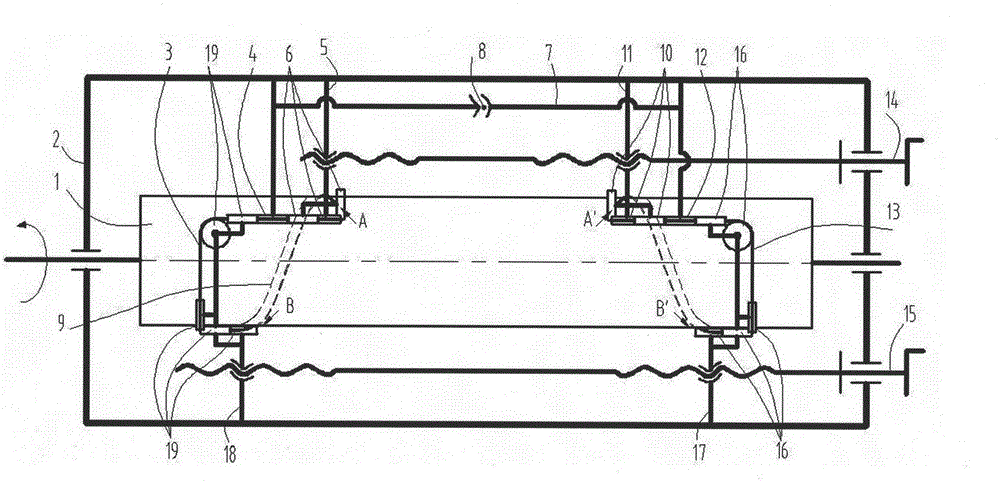

[0021] see figure 1 , figure 2 and image 3 , the device of the present invention consists of a longitudinal tension roller 1, a first flexible binding rope 3 and a second flexible binding rope 13, a first deflection pulley 6, and a second deflection pulley 10 that are symmetrically wound outward on both sides of the longitudinal tension roller 1 for less than one week. , the third steering pulley 16, the fourth steering pulley 19, the first tensioning pulley 4, the second tensioning pulley 12, the first screw mandrel 8, the second screw mandrel 14, the third screw mandrel 15, the first reference arm 5 , the second reference arm 11, the first stretching arm 17, the second stretching arm 18, the tensioning pulley fixing seat 7 and the basic support frame 2, wherein the first deflection pulley 6, the fourth deflection pulley 19 and the first The tight pulley 4 supports the first flexible binding rope 3, the second diverting pulley 10, the third diverting pulley 16 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com