Automobile wheel hub fan

A technology for automobile hubs and fans, which is applied to wheels, vehicle parts, brakes, etc., can solve the problems of small surrounding space and difficulty in installing heat dissipation mechanisms, and achieve the effects of improving reliability, reducing temperature, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

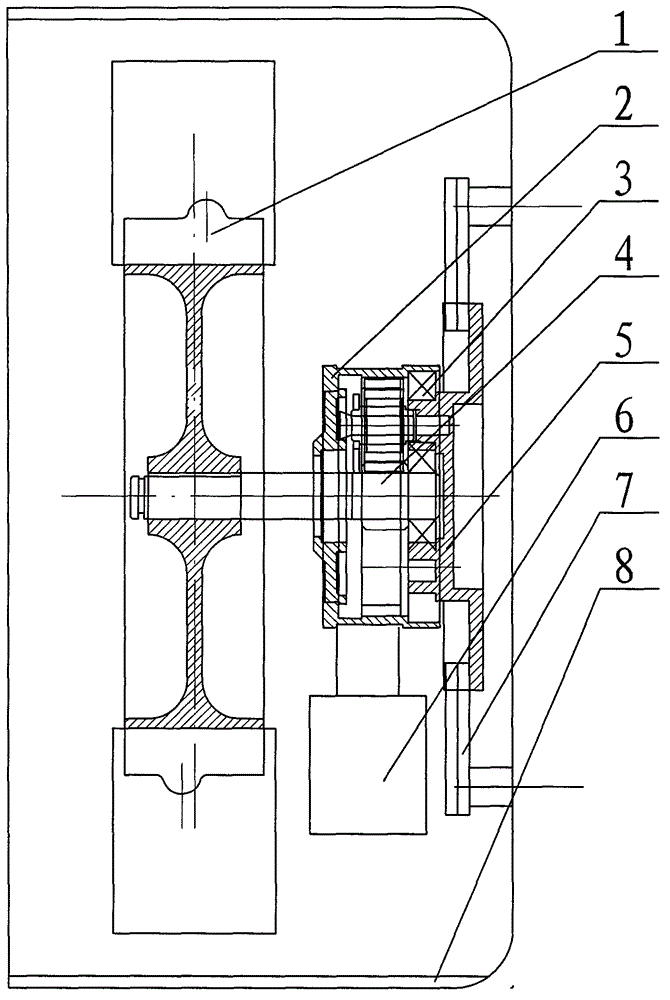

[0013] The automobile hub fan of the present invention, as shown in the accompanying drawings, it comprises fan blade base (1), ring gear (2), bearing (3), sun gear shaft (4), rear end cover (5), counterweight (6), mounting strip (7) and wheel hub (8), the hub (8) is equipped with fan blade seat (1), inner ring gear (2), bearing (3), sun gear shaft (4) and rear end The automobile hub fan formed by the cover (5) is connected with a counterweight (6) on the outer circumference of the ring gear (2). When the hub (8) rotates, the inner ring gear (2) cannot rotate more than half a turn under the gravity of the counterweight (6), so the sun gear shaft (4) accelerates to rotate relative to the hub (8), and drives the fan blade seat ( 1) Accelerate the rotation, generate air volume, blow to the wheel hub (8) and the brake, and reduce the temperature of the car wheel hub and the brake.

[0014] The fan blade seat (1) includes left and right fan blade seats at the same time, and the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com