Adjusting-free bearing gap axle

A technology for adjusting bearings and gaps, applied to axles, wheels, vehicle parts, etc., can solve problems such as difficult assembly, cumbersome operation steps, and operational errors, and achieve the effect of avoiding errors and improving gap accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

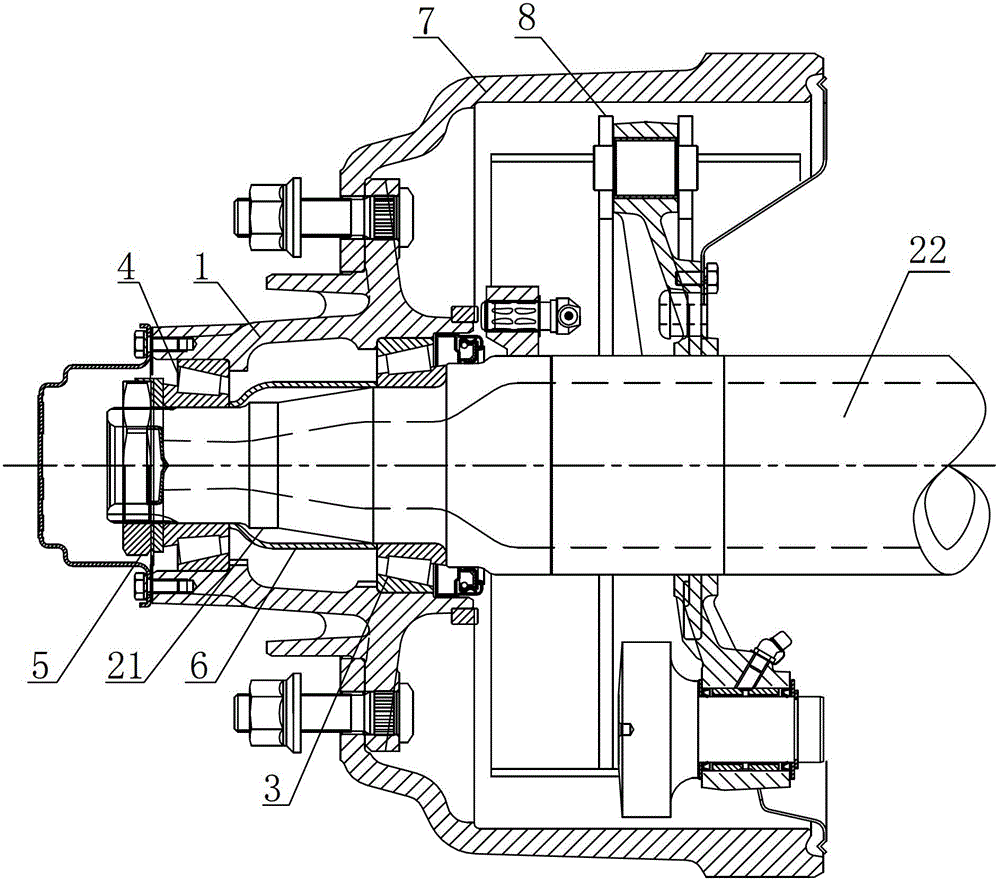

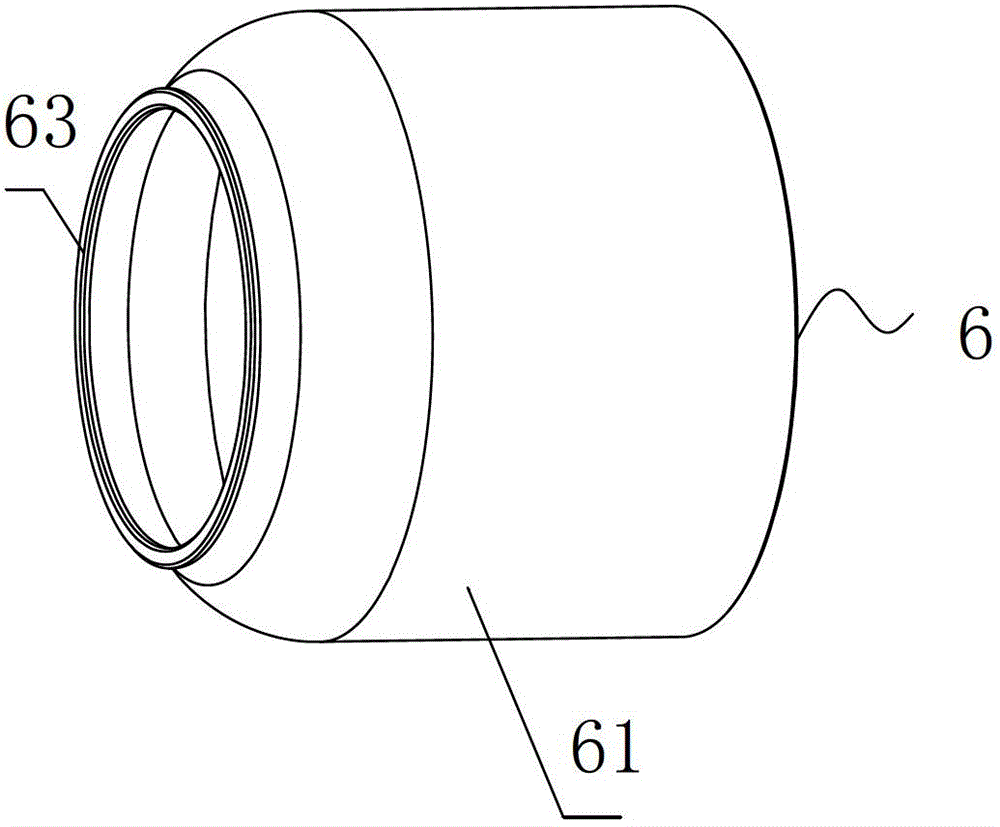

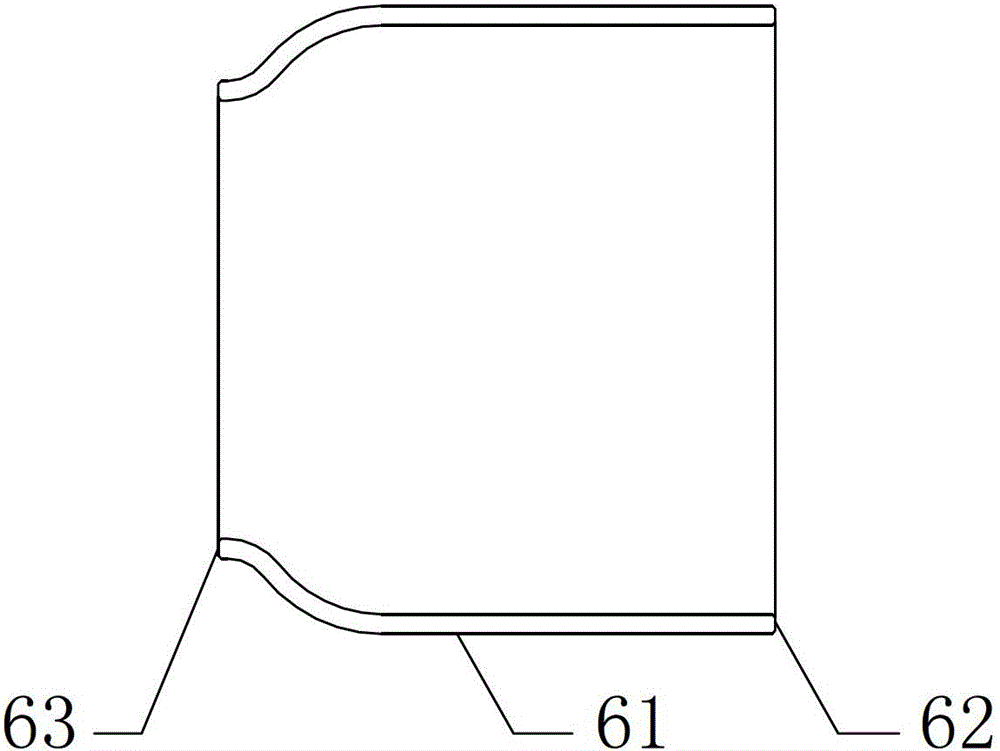

[0016] Such as figure 1 , 2 , 3, the present invention discloses an adjustment-free bearing clearance axle. The trailer axle is a follower axle, which bears the weight of the vehicle and the cargo load, and is used to support the rotation of the tire. It mainly includes the axle body, the wheel hub 1, the brake drum 7, the brake shoe assembly, and the camshaft assembly (not shown in the figure) out), the shaft body is divided into two parts: the shaft tube 22 and the shaft head 21 at both ends. The hub 1 and the brake drum 7 assembly are assembled on the shaft head 21 at both ends of the shaft body to perform wheel rotation and braking. The hoof assembly 8 is installed in the brake drum 7, and its brake pads are made of non-asbestos frictional environmental protection material. The shaft head 21 runs through the hub 1, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com