Tire tread pattern structure for all-terrain vehicle

A tire tread and pattern structure technology, applied in tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problem of reducing the smoothness of turning slip, weakening the rigidity of pattern blocks, and affecting tire slip performance, etc. problems, to achieve the effect of improving turning control performance, improving slip performance, and increasing the ability to get out of trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

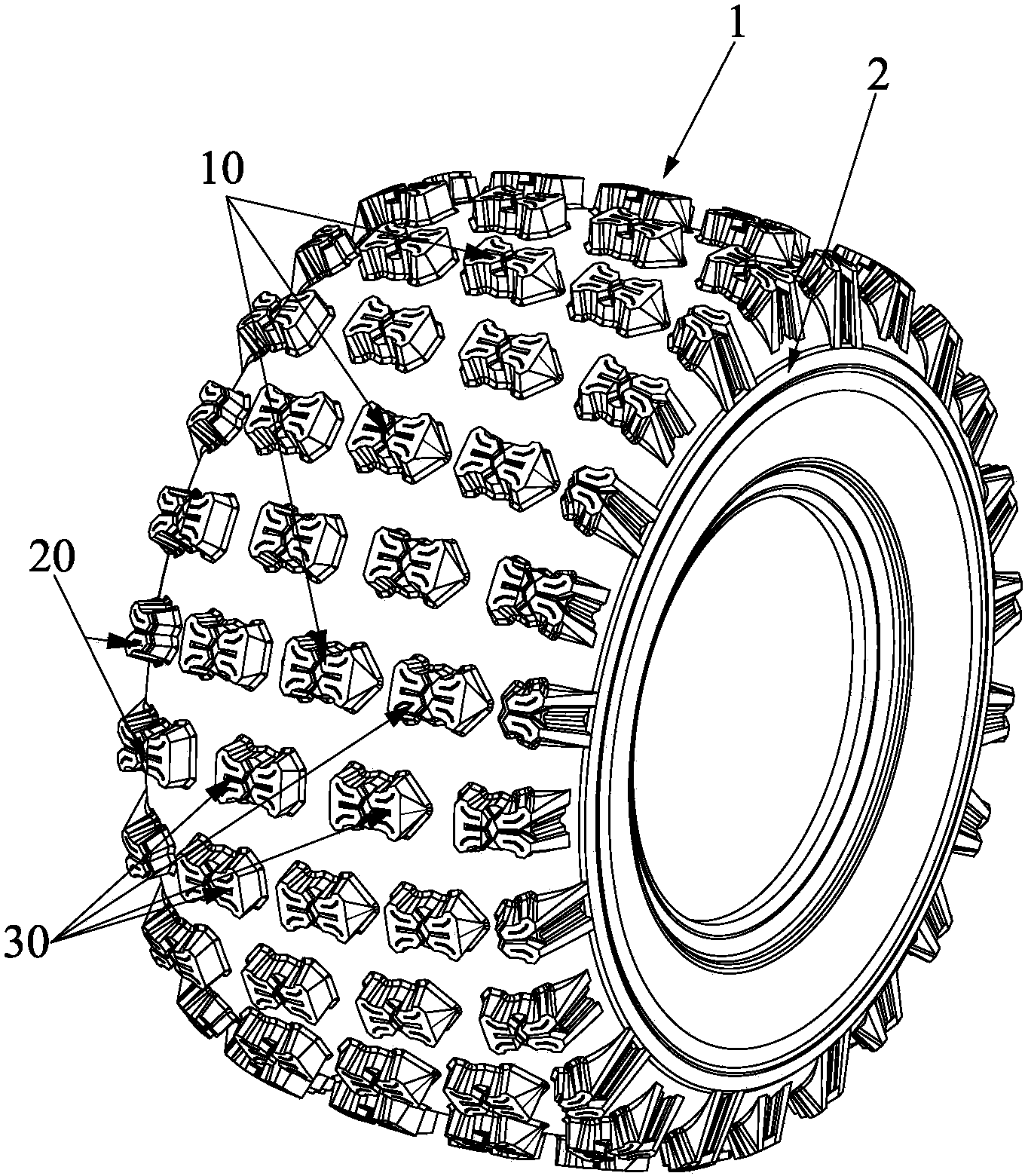

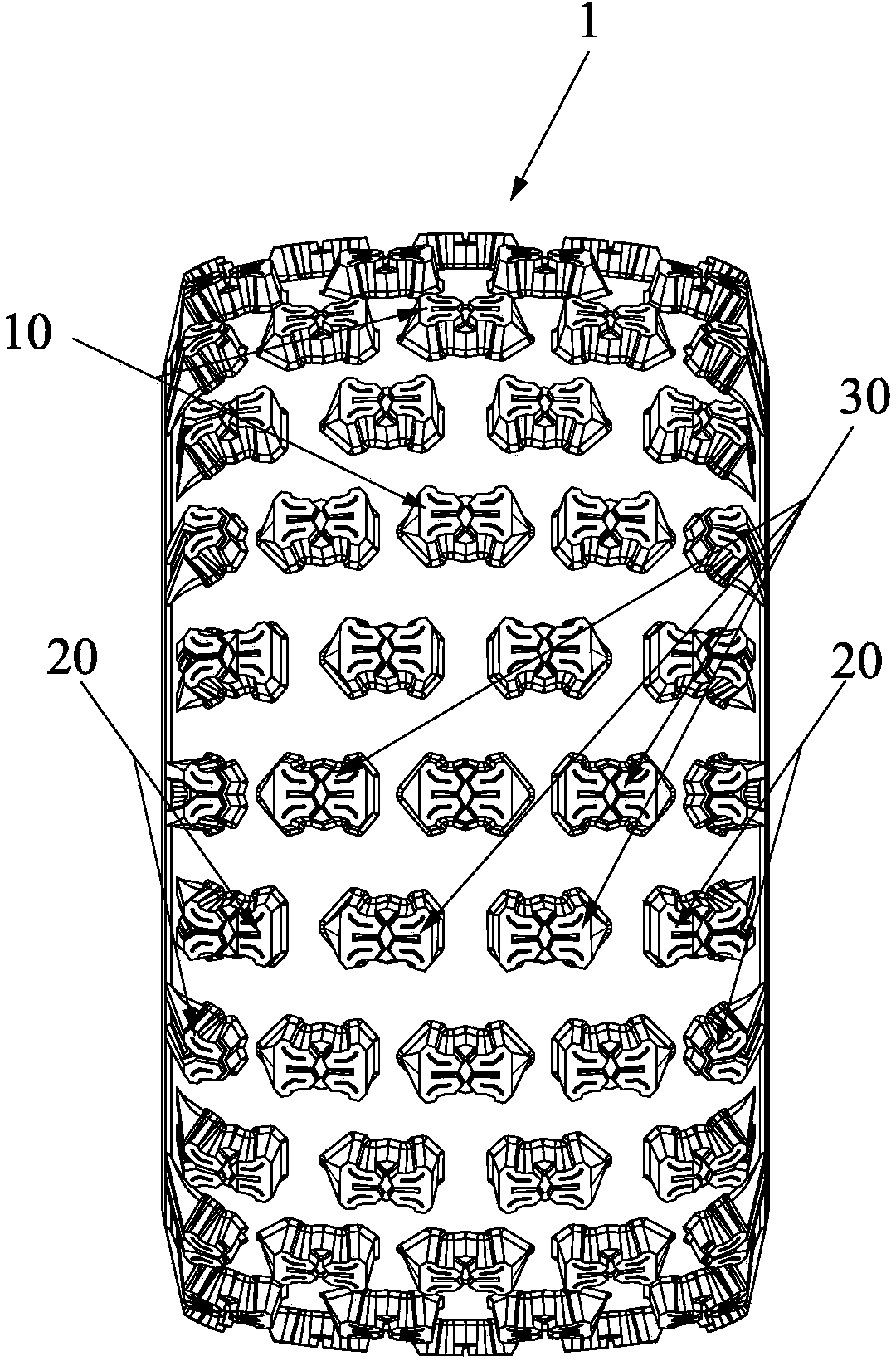

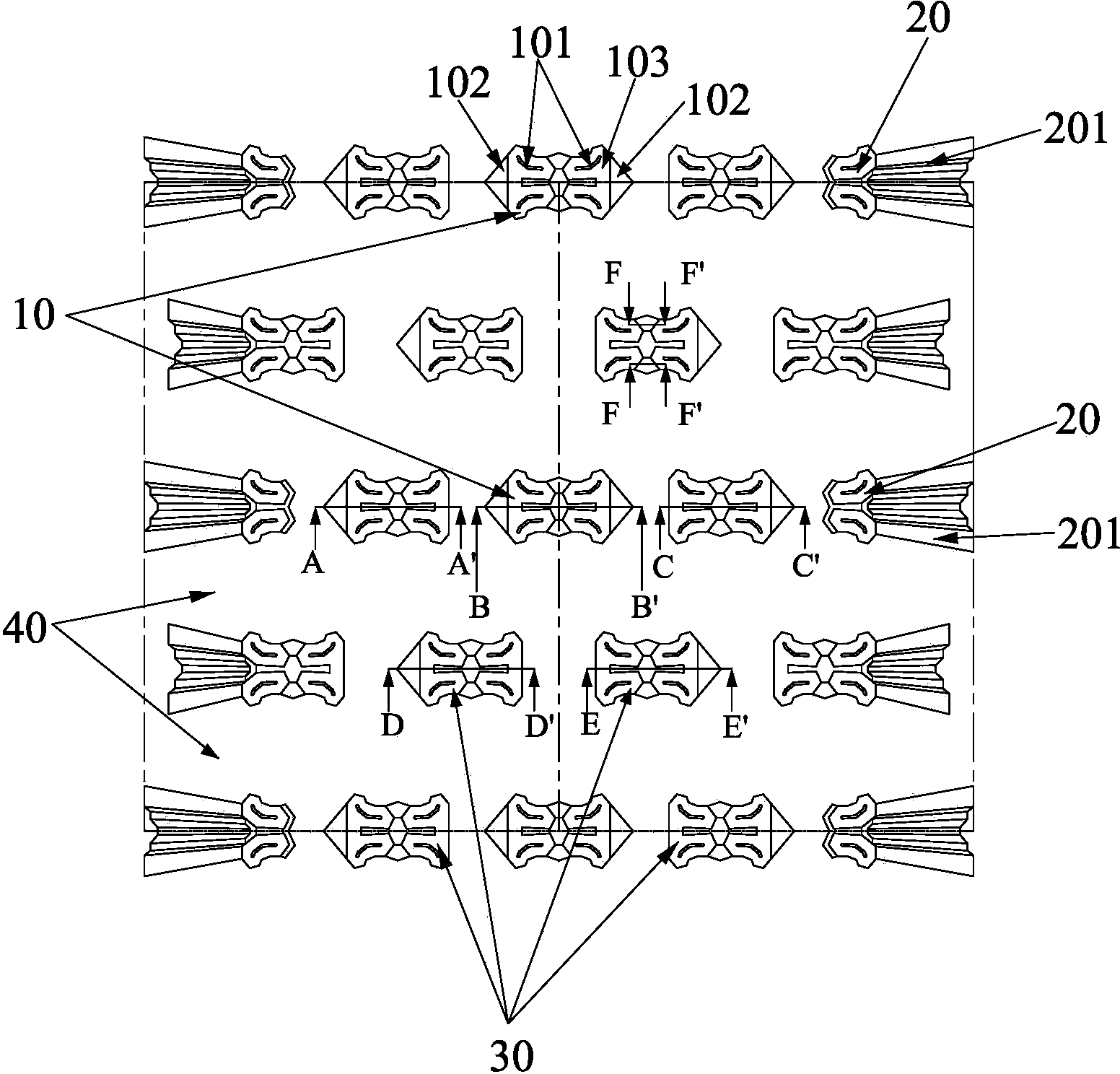

[0032] like Figure 1 to Figure 10 As shown, the present invention discloses an all-terrain vehicle tire tread pattern structure, which is mainly distributed with independently raised pattern blocks on the tread 1 of the tire, wherein each pattern block is distributed on the tread in the form of a horizontal arrangement 1, and the pattern blocks of each row are arranged in a staggered manner, that is, the pattern blocks of the second row are just aligned with the gap between two adjacent pattern blocks of the first row, thus forming pattern blocks arranged in odd rows On the tire circumferential line at the same position, the pattern blocks in the even rows are on the same position of the tire circumferential line, and the outer extending slopes of the pattern blocks located on both sides of the tread 1 are connected with the bead 2 .

[0033] The above-mentioned pattern blocks are divided into a central pattern block 10 located at the center of the tread, a shoulder pattern b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com