Triangular rhombus bag packaging machine

A diamond-shaped, bag-packing technology, applied in packaging, transportation packaging, multiple packages, etc., can solve the problems of complex horizontal sealing mechanism, inability to adjust the packaging line, and inability to pack fragile items, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

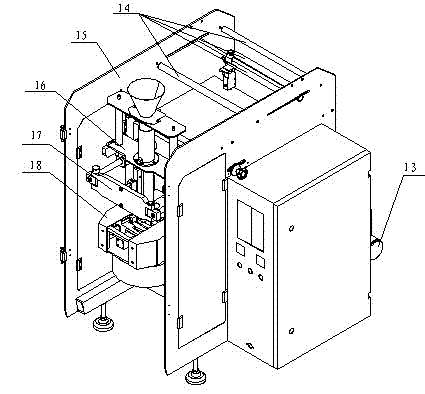

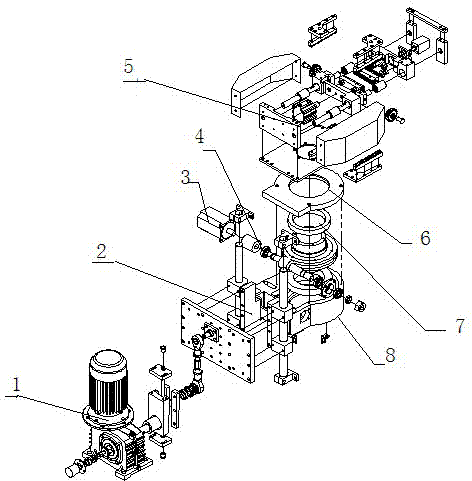

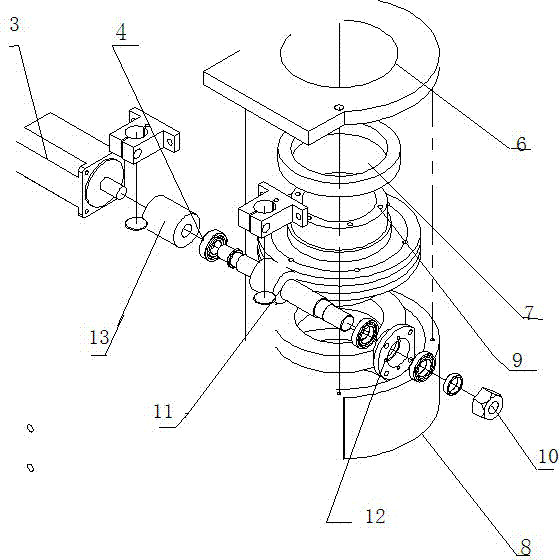

[0028] Such as figure 1 , figure 2 with image 3 As shown, a triangular diamond-shaped bag packaging machine includes a frame part 15, a film holding part 13, a film moving part 14, a bag forming part 16, a longitudinal sealing part 17 and a horizontal sealing part 18, and is characterized in that: The direction of the film supporting part 13, the film moving part 14, the bag forming part 16, the longitudinal sealing part 17 and the horizontal sealing part 18 are installed on the frame part 15 in sequence, and the longitudinal sealing part 17 is installed on the bag forming part 16, the horizontal sealing component 18 is installed below the vertical sealing component 17, and the horizontal sealing component 18 includes the horizontal sealing device 5 and the rotating device connected with the horizontal sealing device 5, and the rotating device includes the worm pair 11 and the decelerating The deceleration device includes a deceleration case 8, a worm gear 9 which is insta...

Embodiment 2

[0030] Such as Figure 4 As shown, the preferred horizontal sealing device 5 of this embodiment on the basis of Embodiment 1 includes a front knife seat 56, a rear knife seat 57, a front knife seat fixing seat 55 for fixing the front knife seat 56, and a front knife seat fixing seat 55 for fixing the front knife seat 56. The rear knife seat fixing seat 511 of the rear knife seat 57, the heat insulation pad 58 located between the front and rear knife seats and the front and rear knife seat fixing seats, the front and rear knife seats and the front and rear knife seat fixing seats are connected by a horizontal seal guide shaft, the front and rear A rack fixing plate 53 and a rack 54 installed on the rack fixing plate 53 are respectively installed in the front, rear and left and right sides of the tool holder fixing seat, and a gear seat and a sliding line bearing seat 23 are installed between the front and rear tool holder fixing seats. , the gear 59 meshed with the rack 54 is i...

Embodiment 3

[0032] Such as Figure 5 As shown, on the basis of embodiment 1 or embodiment 2, the present embodiment adds a lifting mechanism 2, which is connected to the reduction box 8. The lifting mechanism 2 includes upper and lower horizontal sealing connecting plates 24, fixed on the upper and lower horizontal Seal the guide shaft 22 on the connecting plate 24 and the seat plate 21 fixed on the guide shaft 22. The guide shaft 22 is sleeved with a sliding line bearing seat 23, and the seat plate 21 is connected to the bottom of the reduction box 8. When performing two heat seals, the packaging machine first heat-seals the bottom of the packaging bag with a set of heat-sealing blocks, then moves the packaging bag down a certain distance, and then uses the same set of heat-sealing blocks to rotate a certain angle to complete the sealing of the packaging bag. The bottom is sealed, so that a triangular diamond-shaped bag can be formed, but when the material falls, a certain large accelera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com