Modularized belt transporting equipment

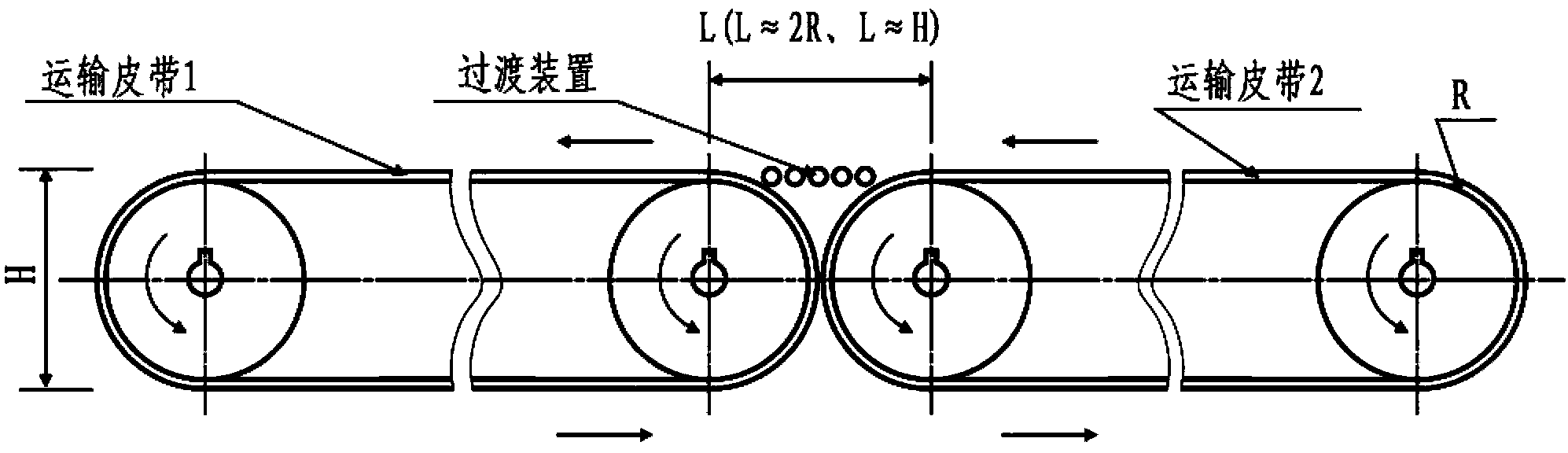

A belt transportation and modularization technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of large gaps at the joints of transportation belts, and achieve the effects of easy installation, transportation and debugging, cost reduction, and flexible assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

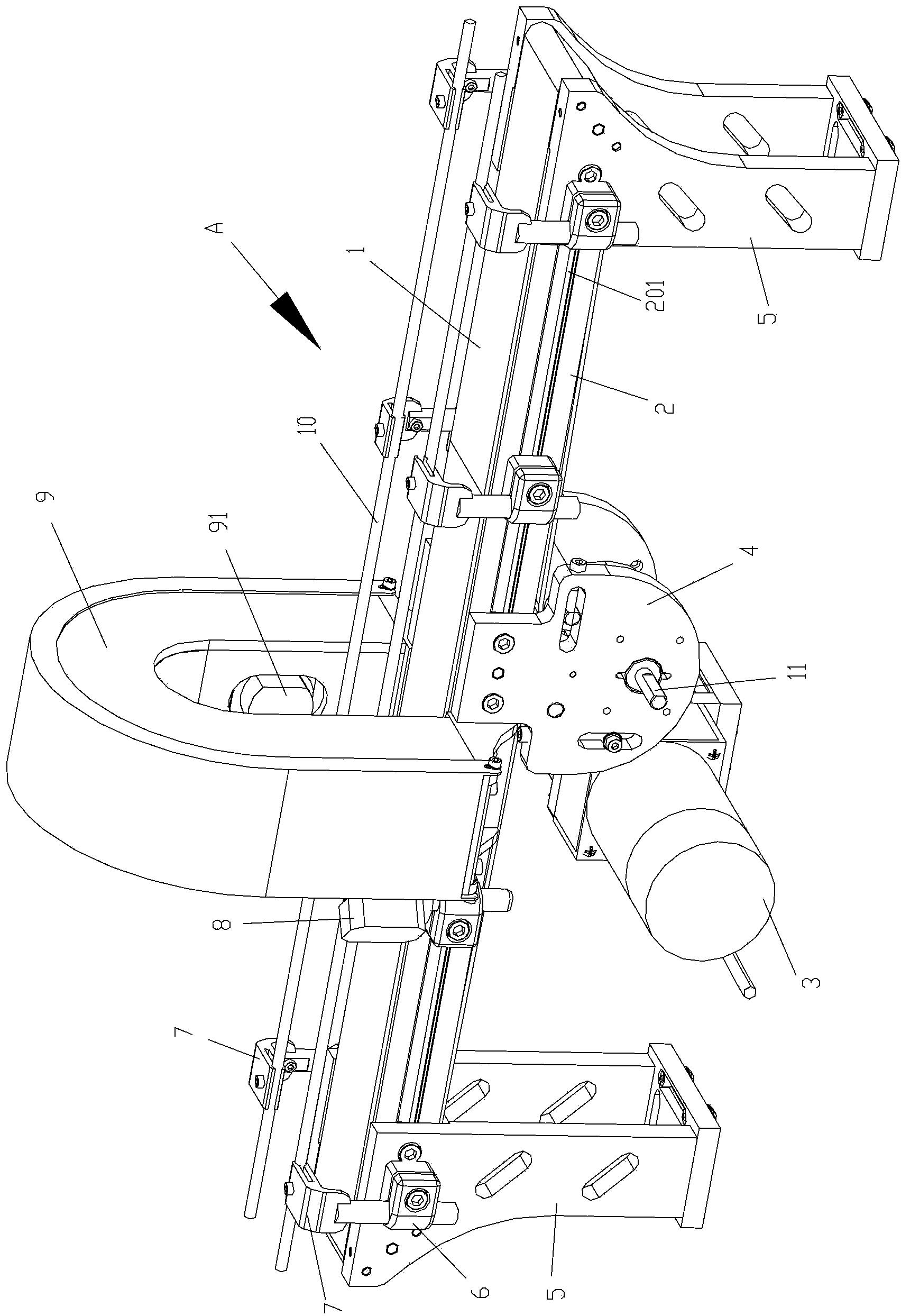

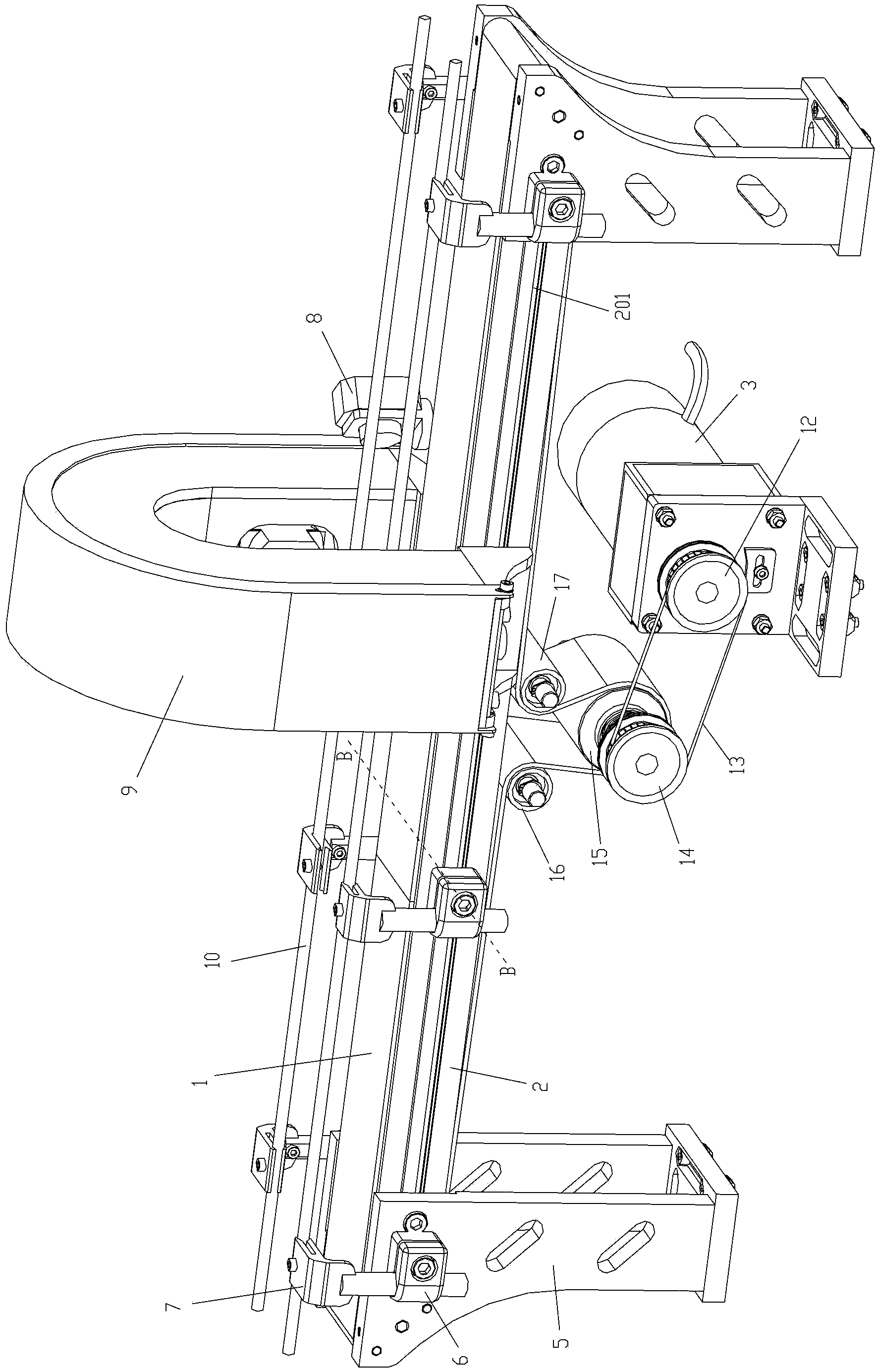

[0042] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical idea claimed in the present invention more clearly.

[0043] Such as Figure 1 to Figure 8As shown, the modular belt transport equipment includes an endless transmission belt 1, a driving pulley 12, a first transmission pulley 14, a second transmission pulley 15, a first tension pulley 16, and a second tension pulley 17. A first driven wheel 18, a second driven wheel 19, a third driven wheel 20, a fourth driven wheel 21, an endless transmission belt 13, a drive motor 3, an accessory mounting plate 2, several universal mounting seats 6. Two support frames 5, a roller mounting plate 4 and a U-shaped detection gantry 9.

[0044] The output end of drive motor 3 is connected with driving wheel 12 mechanical transmission; Driving wheel 12 is connected with first transmission wheel 14 mechanical transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com