Novel tunnel ventilation system for subway station

A tunnel ventilation and subway station technology, applied in the field of ventilation systems, can solve the problems of large occupied ground area, difficulties in land acquisition and demolition, large investment in power distribution, etc., to reduce civil construction costs, reliable start and operation, and small machine room footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

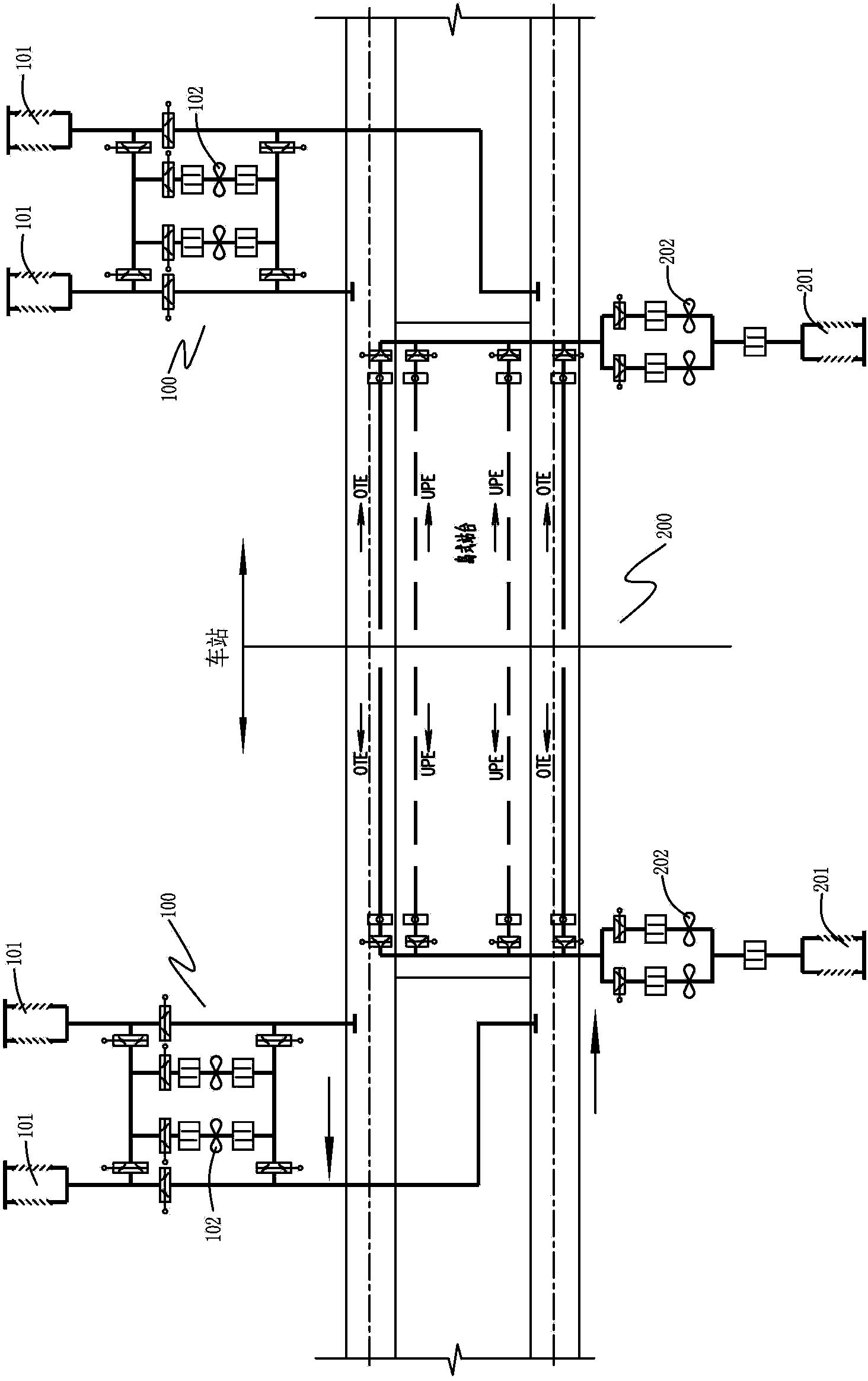

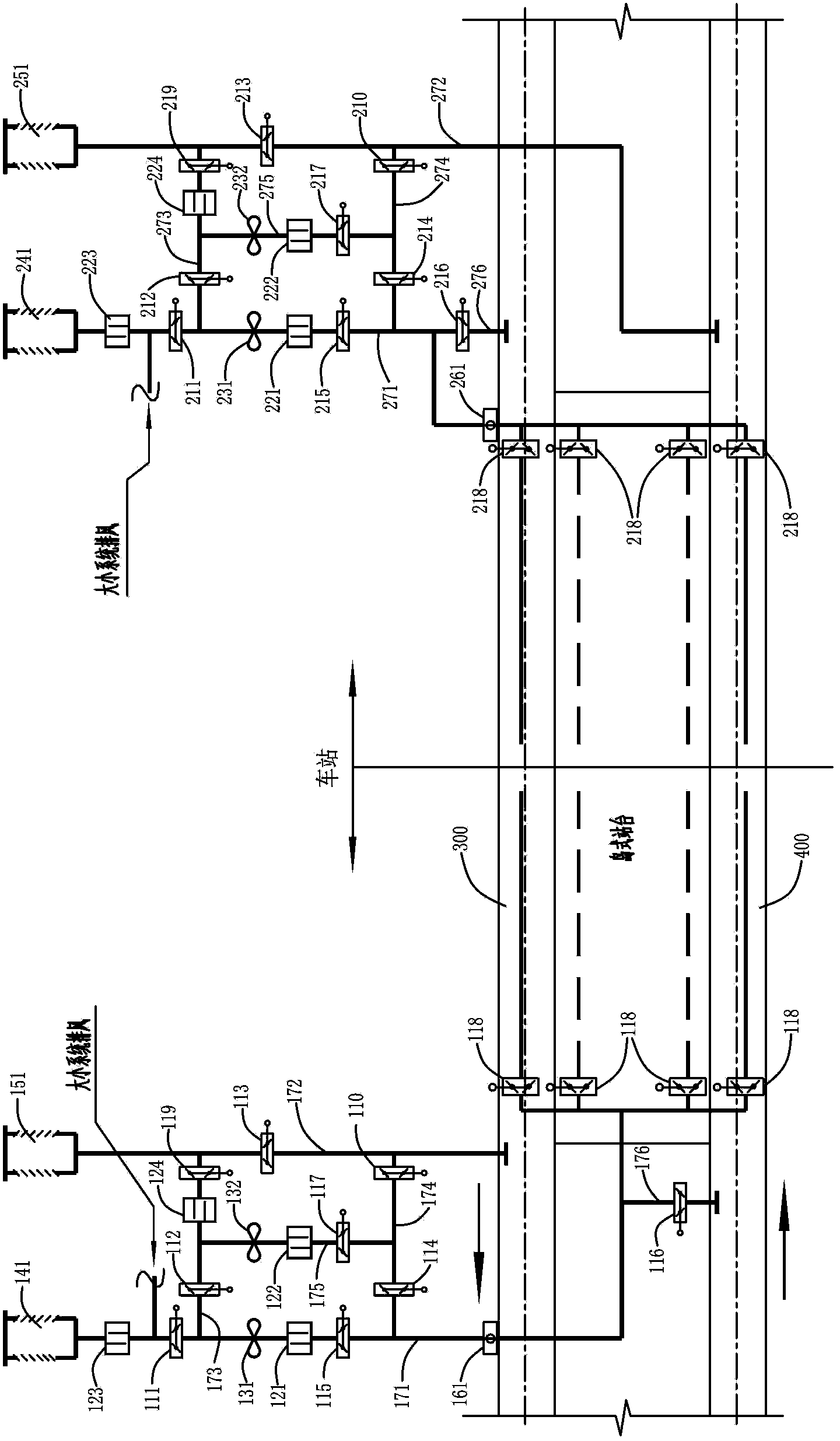

[0027] Such as figure 2 As shown, a new tunnel ventilation system of a subway station is used to ventilate the section tunnel and the station tunnel. By combining the station tunnel and the section tunnel ventilation system 100, the tunnel ventilation system greatly reduces the number of piston air shafts and The number of tunnel fans reduces the area occupied by the station and the construction cost, and reduces the operating cost and energy consumption of the ventilation system.

[0028]This tunnel ventilation system comprises the first air shaft 141 and the second air shaft 241 respectively arranged at the two ends of the station, the first piston air shaft 151 and the second piston air shaft 251, which communicate with the first air shaft 141, the station tunnel and The first row of air ducts 171 in the platform hall, the first connecting air duct 176 connecting the first row of air ducts 171 and the downlink tunnel 400, the first piston air duct 172 connecting the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com