Oil cooler assembly

A technology of oil coolers and coolers, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems that the heat transfer efficiency of cooler parts is difficult to further improve, and the heat transfer efficiency of cooler parts is reduced, so as to achieve oil Reasonable and stable temperature, good cooling effect and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

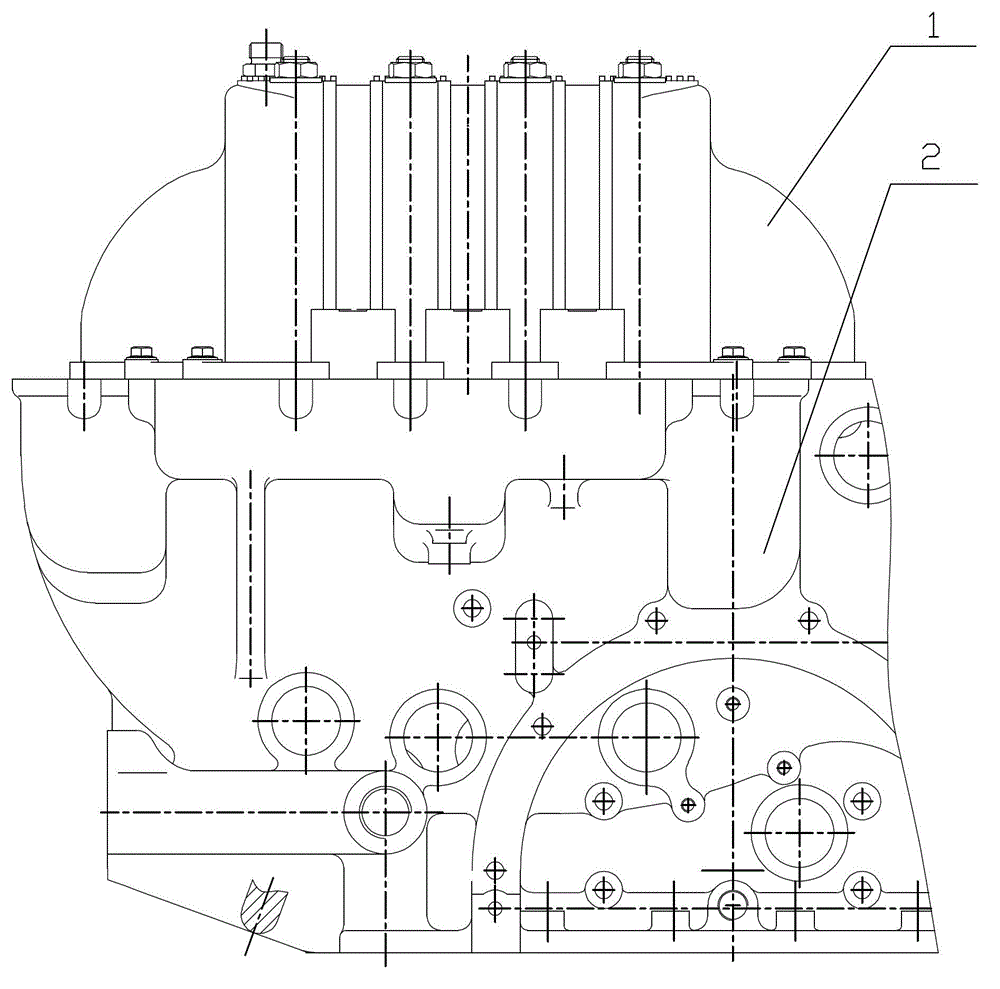

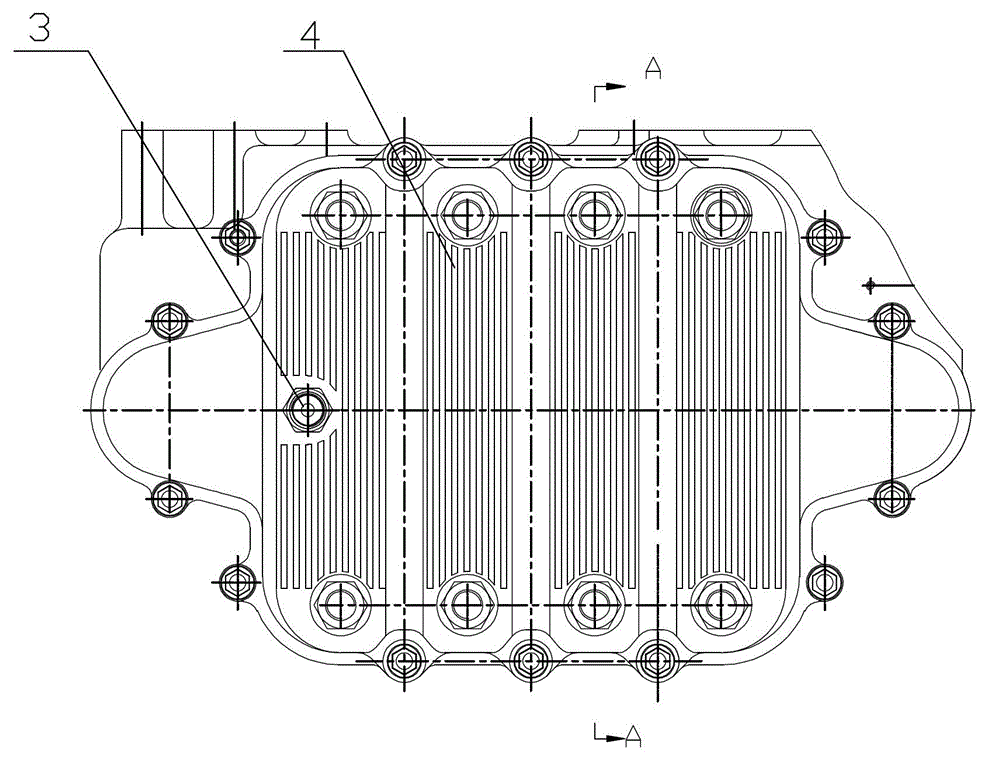

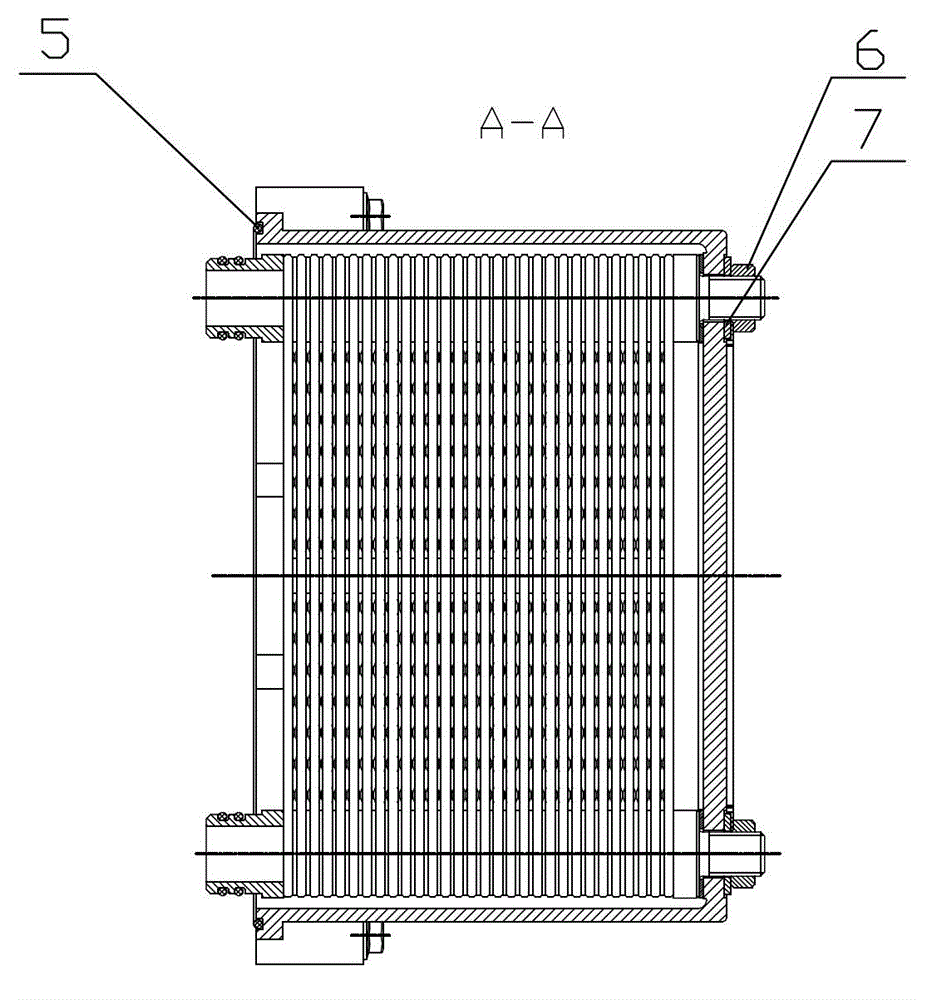

[0014] Such as Figure 1 to Figure 5 As shown, it includes cooler parts 1, gear chamber 2, air release joint 3, cooling ribs 4, cooler sealing ring 5, nut 6, gasket 7, cooler shell 8, plate-fin cooler core 9, Oil inlet 10, water inlet 11, oil outlet 12, water outlet 13, gear chamber oil outlet 14, gear chamber water outlet 15, gear chamber oil return port 16 and gear chamber return water port 17.

[0015] In the present invention, the plate-fin cooler core 9 is located in the cooling water chamber formed by the cooler housing 8 and the gear chamber 2 , and is connected with the cooler housing 8 through nuts 6 and gaskets 7 . There are four plate-fin cooler cores 9, which can be interchanged. The plate-fin cooler core 9 specifically refers to the cooler core part for filtering engine oil. There is no other structure, but there are various sizes and spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com